When you delve into the world of high-resolution 3D printing, the sleek finish and miraculous degree of detail immediately catch your eye. Before long, however, you'll be overwhelmed with a jungle of acronyms: SLA, LCD, and DLP. They all use photo sensitive resins, but they work in a fundamentally different way. What is this "DLP resin," anyhow? How does it differ from regular resins?

This guide will shed some of the mystery on DLP technology, outline the properties of DLP resin, and acquaint you with why it is so popular in commercial production.

To save time, here is a quick summary of the key conclusions.

Quick Reference: Choose Your Tap at a Glance

|

Features |

DLP (Digital Light Processing) |

LCD (Liquid Crystal Display) |

SLA (Stereolithography) |

|

Light Source |

Industrial-grade UV projector |

UV-LED array + LCD mask screen |

Precision UV laser |

|

Working Principle |

Project the entire layer at once, just like playing a movie. Use LCD pixels as a "mask" to selectively transmit light. Use a laser dot to depict the layer outline point by point. |

||

|

Print Speed |

Very fast, especially suitable for printing small parts in full panels Faster, comparable to DLP Slower, speed depends on layer complexity |

||

|

Core Consumables |

Projector lamp (extremely long life) |

LCD screen (limited lifespan, approximately 2000 hours) |

Laser (longer life) |

|

Resolution |

Determined by projector pixels and projection area |

Determined by the pixel density of the LCD screen (4K, 8K) |

Determined by the laser spot size |

|

Key Benefits |

Fast speed, long equipment life, high reliability, extremely cost-effective, and low entry threshold |

Extremely high precision and excellent surface quality |

|

|

Resin Types |

Resins optimized for DLP projector wavelength and light intensity General purpose resins optimized for 405nm LEDs |

Resins optimized for laser wavelengths |

|

|

Core Equipment |

A digital light processor (DLP) chip, which is made up of millions of tiny mirrors. |

||

|

Workflow |

The light emitted by the UV light source shines onto the DLP chip, and the micromirrors on the chip accurately reflect the light of that layer of image to the bottom of the resin tank according to the digital model. |

||

|

Key Advantages |

No matter if you are printing one part or one plate with ten parts, as long as the height is the same, print time is precisely the same. It is because it is cured layer-by-layer, not point-by-point. |

||

Here in this guidebook, we are going to examine DLP resins very closely and take a step further than definitions. By the time you have read this, you will be more informed about DLP resins and better equipped to make the best choice when selecting a product.

What is DLP 3D Printing Technology?

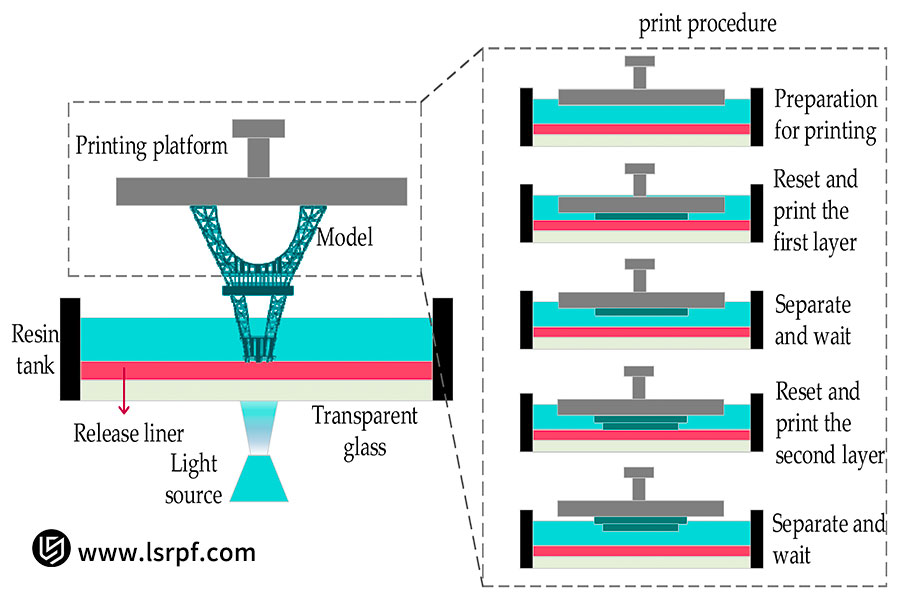

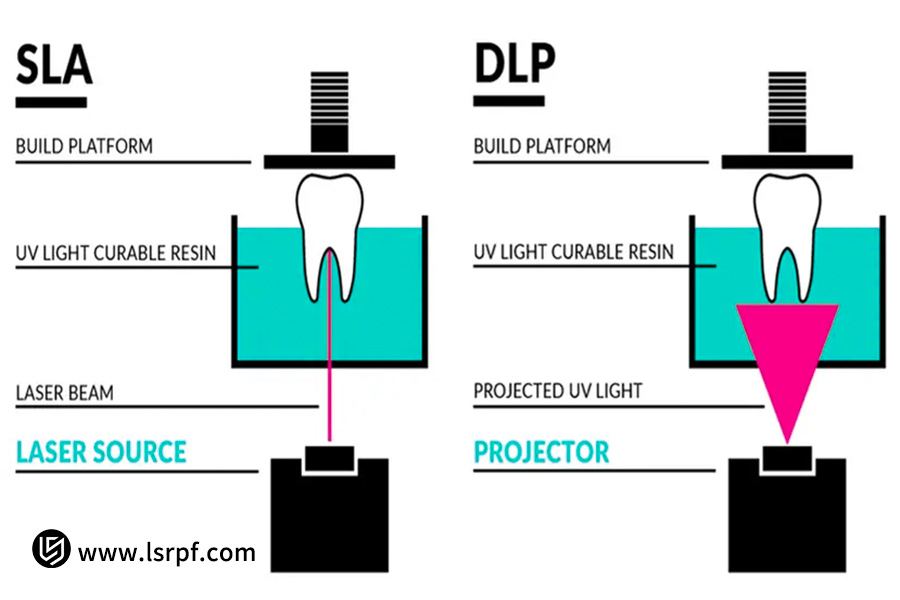

DLP (Digital Light Processing) 3D printing is a liquid resin additive manufacturing process where in a digital light projector cures in a layer-by-layer manner a liquid photopolymer resin to develop three-dimensional parts.

One such resin 3D printing technique involving the use of a light projector rather than a laser to cure the liquid resin layer by layer is quicker than some other resin printing techniques.

DLP printers use a matrix of micromirrors on a semiconductor chip to project light. Micromirrors cast light onto a digital micromirror device (DMD) and expose areas of the resin selectively to cure.

What Exactly is “DLP Resin”?

Now, let us answer the main question: What exactly is "DLP resin"?

DLP resin is a radiation-sensitive resin, specifically designed for the Digital Light Processing technology in 3D printing. It is cured by exposure to radiation of a specific wavelength (most commonly UV light), and it enables layer-by-layer curing reaction and the creation of three-dimensional objects.

So what are its advantages?

Optimization Point 1: Reaction Rate. Light emitted by a DLP projector is usually greater than light from an LCD backlight. Thus, DLP resin should have a faster curing reaction to sustain the effectiveness of DLP technology and avoid overcuring.

Optimization Point 2: Wavelength Matching. Different DLP printers write with different wavelengths of UV. Special DLP resins ensure their photo initiators are perfectly matched to the specific wavelength, so most efficient and precise curing.

Short version: "DLP resin" delivers the best from your DLP printer.

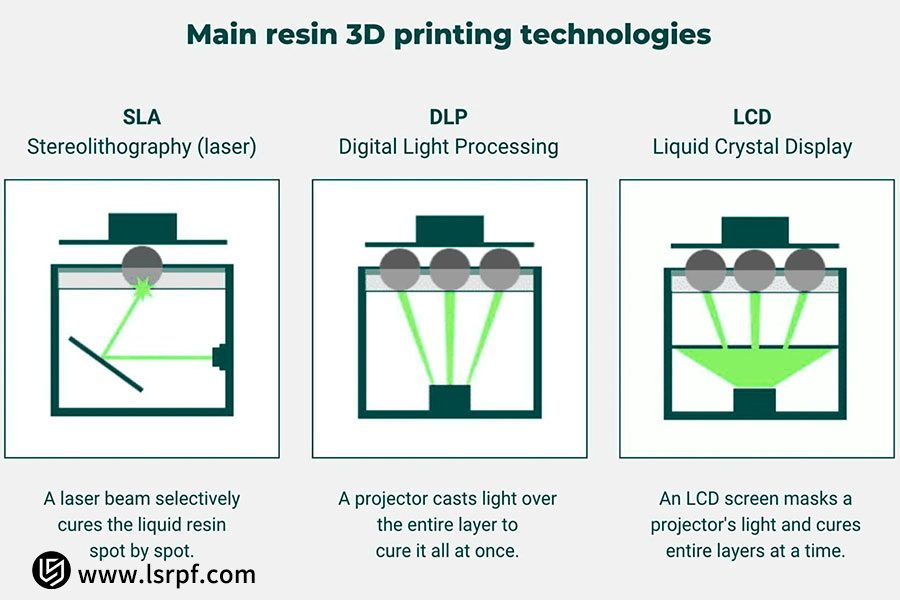

The Grand Showdown: DLP vs. LCD vs. SLA

Three mainstream technologies are available for stereolithography: DLP, LCD and SLA. These technologies are very different from each other. So, what are their advantages individually? This is an important question for everyone using stereolithography. Below, we will make use of a good analogy to give a better idea about the nature of these three technologies.

DLP (Professional Race Car Driver): Highly fast and particularly well-adapted for mass production. Although initial hardware investment is high, the projector is highly durable, so fewer operating expenses over the long term (especially maintenance).

LCD (Family Car): Greatest value for money. It offers better print quality at the relatively low price. But its all-important element—the LCD screen—is a consumable (resin printer LCD lifespan) and must be replaced every now and then, which translates to more long-term costs and lost time.

SLA(Artist): After the most detail and smooth surface finish. As a patient sculptor, it carves carefully with laser dots, offering the slowest production rate but sometimes the most beautiful output.

So what are DLP, LCD, and SLA, exactly? The following introduction will be able to provide a detailed explanation and comparison between them. Hope it will be helpful to you.

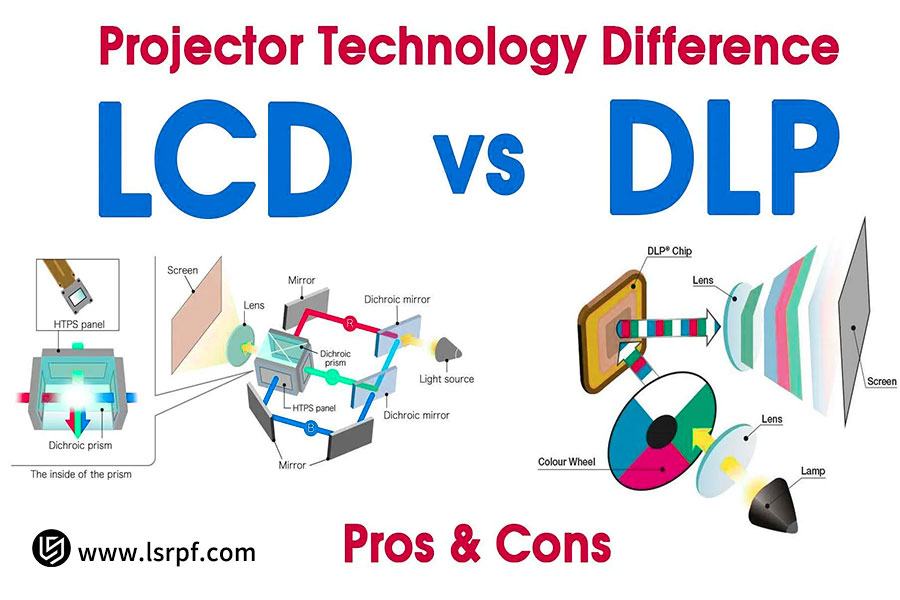

DLP, or digital light processing technology, is essentially just like LCD. The only difference is in the forming light source. DLP utilizes a digital projector to project the light for each layer. DLP digital projectors are cutting-edge and are dominated by the American company Texas Instruments, which makes them too costly to domestically utilize. LCD is utilized in 3D printers with a substitution of a typical LCD screen.

LCD technology, or Selective Area Deposition (SLA), is the most sophisticated and widely used photocuring technology available today. Its mechanism of creation is that a UV lamp emits light, which is subsequently "cut" by an LCD screen to create each layer's shape. This light is then projected onto a release film, where it cures the entire layer at once, layer after layer until the finished product is created.

DLP, or digital light processing technology, is practically similar to LCD. The difference lies only in the forming light source. DLP uses a digital projector to show the light for each layer. DLP digital projectors are very technologically advanced and are governed by US-based Texas Instruments, resulting in astronomically high prices for use locally. LCD is used in 3D printers by replacing a standard LCD screen.

SLA is the most sophisticated and oldest photocuring technology in stereolithography. Thanks to the development of laser technologies over the last century, 3D printing researchers were the pioneers who thought of using lasers with 3D printing. Unlike other technologies, it utilizes laser generator and galvanometer to perform point light source scanning molding, i.e., line molding instead of surface molding, and the direction of printing is upward, thereby being capable of printing very large or many large models.

Common Types of DLP Resins and Their Applications

Similar to other resins, DLP has a wide family of materials suitable for a wide range of engineering applications. In what follows, we'll present typical types of DLP resin and their uses in multiple types of 3D priting and elsewhere.

Standard resins: These are used for appearance prototypes and general purpose models, in a range of colours.

Tough/Durable resins: These behave like engineering plastics like ABS or PC and are used on functional prototypes and snap-fit parts.

Flexible resins: These behave like rubber or TPU and are used on seals, gaskets, or parts that must be flexible.

High-Temperature resins: These can withstand high heat and are used on test cores for injection moldings or fluid-conducting components.

Medical-Grade resins: They are biocompatibility certified and used in medical large-scale applications such as surgical and dental guides.

Why Choose DLP for Professional Manufacturing?

For professional applications and companies, the choice of DLP is not only for accuracy; it's also about efficiency and dependability.

High-volume production efficiency: The speed benefit of DLP really gets substantially amplified when producing huge volumes of tiny parts.

Long-term dependability: No LCD display to swap out on a regular basis equals less downtime for maintenance and more stable production output.

Accurate repeatability: The industrial-grade optical engine yields consistent quality from the middle of the platform to the perimeter.

DLP technology is the best choice for large and small screens. DLP chips drive digital displays. It is award-winning,long-lasting color accuracy, and independent of light source. All DLP chips are the same design as the award-winning DLP Cinema.

Case Study: From Slow Prototyping to Rapid Production

At LS, our team of experts combines real-world experience and real-world application to provide the best possible solutions and rapid prototyping. Below is a successful case study on how we used DLP technology to transform slow prototyping into rapid production:

Challenge: A medical device company needed to create 50 precise housing prototypes for its new product to test within the company. The housings contained intricate snap-fits and high-level textures.

Problem: With their own LCD printer, they could print only two at a time, which would take them eight hours. The LCD display failed during the 30th house when it had a pixel failure and other prints would not function and were behind schedule.

LS Solution:They sent their design files to our online 3D printing service platform. We offered DLP technology right away. On our industrial-grade DLP printer, we printed the entire print bed full of 12 housings and completed a batch in six hours.

Result: The customer got all 50 perfect, consistent samples within two days, allowing for seamless testing. Weighed down by DLP's speed and consistency, they've selected us as their go-to custom 3D printing partner.

FAQs

1. Can DLP resins and LCD/SLA resins be mixed?

Not advisable. Though they might cure, the outcome will be less than ideal. The wrong resin will result in incomplete curing, loss of features, or overcuring, leading to print failure. While DLP and LCD/SLA photosensitive resins share the same key ingredients, and the majority of printers nowadays utilize 405nm UV curing, they should not be mixed for a number of reasons: First, different manufacturers might have different formulations that will lead to non-uniform curing, decreased interlayer adhesion, and even denaturation of the resin. Second, some industrial-strength DLP printers employ special wavelengths, such as 365nm, and improper combination of 405nm resins will result in curing failure. That being said, if two resins are clearly labeled with compatible wavelength (i.e., both 405nm) and from the same reputed manufacturer, a small, conservative test mix might be acceptable—but new users should still use a single resin to protect print quality and machine stability. To ensure safety, always best to adhere to the printer manufacturer-recommended resin type.

2. Does the pixelation of a DLP printer affect print quality?

Yes, the pixelation of a DLP (Digital Light Processing) printer certainly has a very significant effect on print quality, affecting reproduction of fine details and surface smoothness.

A detailed discussion of its effects, including its inherent "voxelization" and how present advances mitigate these issues.

Pixelation inherently sets the "maximum obtainable detail" in DLP printing, but modern techniques like anti-aliasing and grayscale light modulation effectively "cover up" voxelization artifacts. The printed product is one that appears smoother than the uncompromised pixel grid would have one expect—bridging the difference between digital resolution and physical perfection.

3. Which is better for beginners, DLP or LCD?

If you have limited finances to invest and want to try resin printing on a budget, LCD is the way to proceed. If you require stable production over a long period, faster speeds, and do not want to replace consumables frequently, DLP is the wiser investment. As a beginner's starting point, LCD-based light-curing 3D printers(like MSLA technology) are typically an easier and more convenient starting point. They are relatively cheap, easy to use, and need minimal upkeep. Even though their LCD panels will need to be replaced in a year or so, they are tremendous value for money and therefore make an excellent entry-level option. They yield excellent print resolution, and there is a good selection of models to choose from, such as the Anycubic Photon Mono 4K or Elegoo Mars 3, both excellent beginner options. On the other hand, DLP printers, with a bit higher accuracy and longer light source lifespan through optical projection technology, are more expensive, more complex, and require high calibration requirements. They're suited for serious users who require severe detail or large quantities of small precision parts. If the user wants an easy introduction and a light investment, LCDs are a suitable starting point. For those who need industrial-level accuracy at an affordable price, there is DLP technology as an alternative.

4. What are the main advantages of DLP technology?

Speed and reliability. The unmatched speed of curing one entire layer with one pass, along with the very long lifespan of industrial-quality projectors, are the essential competitive advantages of DLP in the pro market.DLP 3D printing technology has engineering-grade qualities of performance, with the "speed and fury" of digital production.

DLP's speed benefit is the result of break-through surface projection technology that cures a full cross-section simultaneously, akin to the snap of a camera shutter. In dental applications, printing an entire panel of 28 crowns only took 11 minutes, 3.5 times quicker than LCD technology. That speed is maintained even when printing clusters of highly textured jewelry. Even more remarkably, the new DLP machines carry an intelligent light intensity control system, reducing the exposure time per layer to 0.8 seconds without sacrificing accuracy. With it, the printing of a regular-sized hearing aid housing takes only 6 minutes.

The biggest strength of DLP lies in its reliability. Its optical core engine is based on an aerospace-grade sealed configuration, and after running continuously within the dirty environment of an automobile production facility for 12 months, its accuracy drift was still less than 25 microns. Its dynamic optical calibration system is a special feature that addresses focus movement due to thermal variation in real-time to provide 99.7% dimensional uniformity to every batch of 2,000 electronic connectors. Confirmed statistics show the mean time between failures of DLP equipment is more than 8,000 hours, more than four times the industrial-grade LCD equipment.

This. ultimate blend of speed and dependability makes DLP the go-to option for mass production environments. Following the implementation of a DLP production line, an aviation components supplier cut its turbine blade prototype production cycle to 18 hours from 72 hours, cutting scrap rates in half from 5% to 0.3%. This. superior blend of speed and stability creates new standards of production efficiency that modern manufacturing is expected to deliver.

Summary

Stop worrying about choosing 3D printing technology. We've got it covered. Send us your design files on our secure and reliable online platform. We'll analyze your design, recommend the optimal 3D printing solution, and provide you with an immediate 3D printing quote! Let our expertise drive your innovation. DLP resin is not magic, but the fuel that is specifically designed for fast, dependable, and professional-level 3D printing. With DLP projectors, it enables engineers and designers to quickly create high-accuracy parts. If your work is more than just a hobby and requires speed, dependability, and large-scale production, DLP technology and its dedicated resin are the ideal solution.

In the face of these higher challenges, LS'sCNC turning serviceis your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized.Choosing LSis to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instantCNC turning quote(cnc turning price), let LS be your strong backing in pursuit of ultimate woodworking precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com