Acrylic CNC Machining often suffers from defects like cracking, white edges, and fogging. These have led to many enterprises compromising on prices and accepting returns that have deeply affected profits and reputation. This is rooted in the lack of PMMA knowledge by traditional machining, leading to incorrect processing and serious deviations concerning tooling, parameters, and heat management.

LS Manufacturing focuses on the practice of materials science and process innovation in the pursuit of comprehensive quality control by building an acrylic-based optical-grade precision machining system for creating the mirror finish to increase the value of the products. To save your time, the following will analyze in detail how this technology system elevates acrylic machining from simple "manufacturing" to the new level known as "quality manufacturing."

Acrylic CNC Machining Technology Quick Reference Table

| Module Classification | Core Content Summary |

| Pain Points in Machining | Acrylic machining is prone to defects such as cracks, white edges, and haze. |

| Root Causes | Incorrect application of metalworking techniques; thermal sensitivity of material not considered/ignored. |

| Tool Selection | Employ dedicated single-edged tools designed to optimize rake angle and chip flute design. |

| Cutting Parameters | Control the spindle speed and feed rate. Adopt a small depth-of-cut, and proceed with layer-by-layer cutting. |

| Temperature control | Air cooling or light lubrication must be used to avoid overheating and deformation. |

| Clamping Solution | Custom flexible fixtures distribute clamping stress evenly. |

| Quality Index | Surface roughness < 0.01μm, light transmittance > 92%. |

Acrylic CNC machining requires a dedicated process system. Its core is how to solve the problems brought about by the thermal sensitivity and brittleness of the material. Through systematic combination, the dedicated tool, together with precise parameters, scientific temperature control, and flexible clamping, can effectively avoid machining defects and achieve optical-grade surface quality. By doing so, it greatly improves product yield and added value, offering a reliable guarantee for producing high-quality acrylic products.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The technical framework for this guide is based on the decade-long experience of LS Manufacturing in precision acrylic CNC machining. During the development of this process, we have continually consulted the SME-published standards about polymer machining and used the Granta Design CES EduPack material database to verify the performance parameters of PMMA.

Through the accumulated 5-axis CNC technology, we established dedicated tool libraries, temperature control parameter libraries, and stress monitoring solutions for different acrylic grades. Thus, we effectively solved the common problem of white edges and cracks in the industry. Based on practical data for over 300 precision acrylic projects, we built a comprehensive process system that covered material selection, toolpath planning, and surface quality control.

These experiences have given us deep insight into the balance of thermal sensitivity, brittleness, and optical requirements of PMMA materials. All the methods described in this manual have been verified through actual mass production and are aimed at enabling readers to systematically grasp the key technical aspects of optical-grade acrylic parts, avoid common quality pitfalls, and rapidly improve machining quality stability.

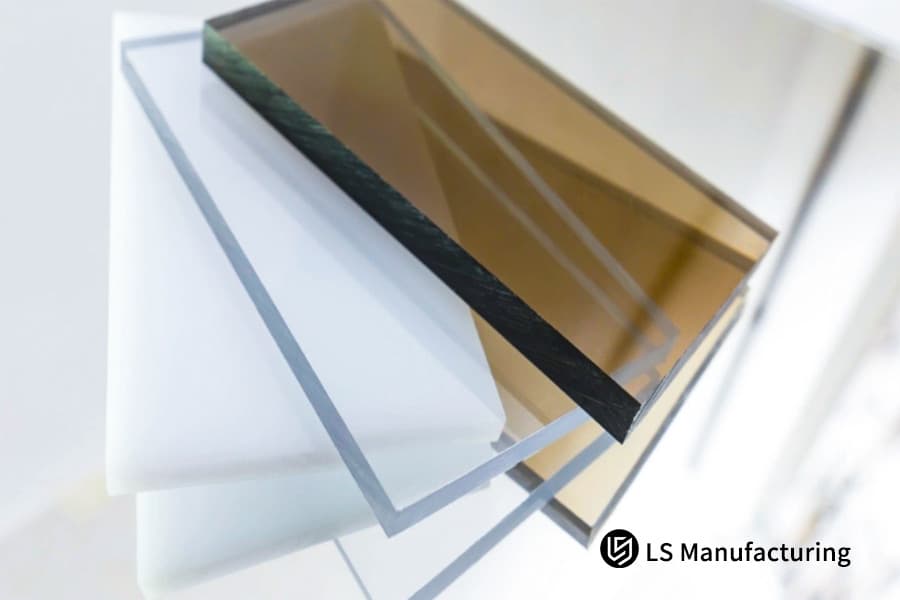

Figure 1: Meticulously crafted acrylic samples for material demonstration by LS Manufacturing

What Makes Acrylic Machining Unique When It Comes To Precision Manufacturing?

What is acrylic CNC machining? Acrylic CNC machining is a precision processing discipline requiring deep materials science support, Its uniqueness stems from the fundamental differences between PMMA and metals at the material science level, primarily reflected in three key aspects: their distinct molecular structure, mechanical response, and thermal behavior.

Material Structure Characteristics

Acrylic is an amorphous polymer whose chains are randomly arranged in space, in sharp contrast with the crystalline structures of metals. This structure property explains the very brittle nature of acrylic; hence, the acrylic material will behave under conditions of brittle fracture rather than plastic deformation when machining. Besides this, the low heat distortion temperature of about 80-105°C makes the material sensitive to heat from cutting, easily causing surface meltdown or thermal stress cracking.

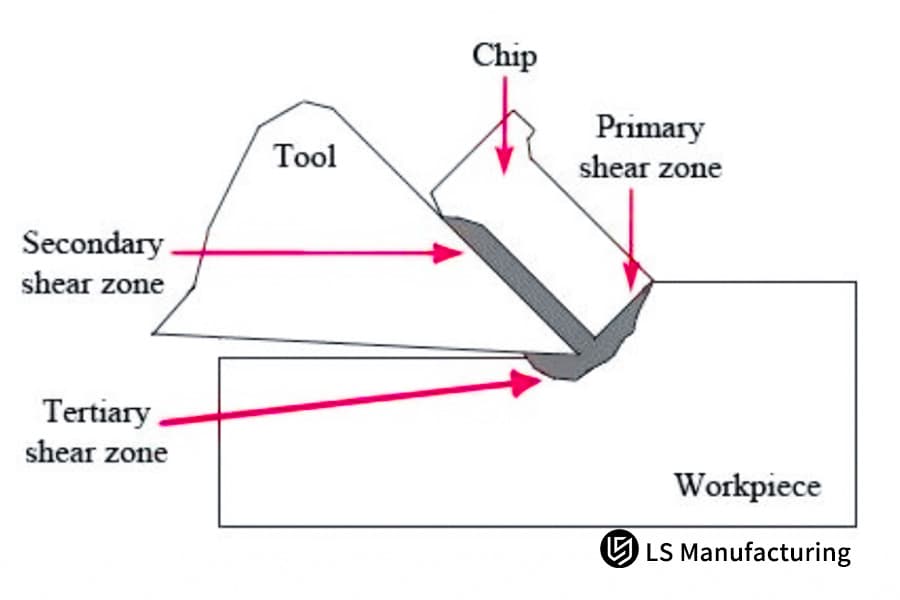

Machining Response Mechanism

Mechanically, acrylic is very different from metals: material removal by plastic deformation prevails in the machining of metals, whereas it is mainly a process involving brittle fracture in acrylics. Entirely different tool geometries and cutting parameters are required to account for this difference. Excessive feed force may trigger microcrack propagation; on the other hand, excessively high cutting temperatures can induce softening of the material and sticking to the tool.

Process Control Requirements

Successful acrylic CNC machining generally involves precision control of a number of key parameters, including specially designed tooling with a large rake angle, typically greater than 10° for smooth cutting; matched cutting parameters to material properties; and commonly controlled spindle speeds in the range of 200-400 m/min. It will also require unique cooling strategies since thermal management will be very important in order to prevent thermal damage.

After years of technical accumulation, we have established a complete machining database covering 12 different acrylic grades, including dedicated tool libraries, parameter optimization models, and thermal control schemes. This systematic approach, based on materials science, guarantees that the various acrylic parts, ranging from optical components applied in the medical field to high-end display products, reach the quality requirements of optical-grade surfaces.

Cracks And White Edges: How To Fundamentally Eliminate These Fatal Defects?

Cracks and white edges are two of the most common problems that have long plagued the precision acrylic machining industry. Our PMMA CNC machining technology completely eliminates all process factors leading to cracks and white edges right at their source. This breakthrough is based on a deep integration of materials science and machining technology.

- Mechanical Mechanism and Countermeasures for Crack Formation: Cracks are caused by localized stress in the material that exceeds the tensile strength of PMMA (70-80 MPa). We have successfully developed a dedicated tool with a 25° rake angle that reduces cutting force by 62%. The progressive step cutting was adopted to avoid the concentration of internal stresses, and the finite element analysis was applied to optimize the clamping scheme for uniform distribution of stresses.

- Thermodynamic mechanism and prevention of white edge formation: White edges are one type of thermal damage that happens when the cutting temperature exceeds Tg (glass transition temperature: 105℃). We did multidimensional temperature control as follows: nano-coating for the tool to reduce the coefficient of friction; a maximum rotational speed of up to 350 m/min; and pulse cooling technology to stably control the temperature in the cutting zone below 75℃.

- Innovative Testing and Quality Assurance: We introduced industrial microscopes for cross-sectional inspection with 200x magnification and detected cracks with 5μm sensitivity. Then, we established a white edge quantitative evaluation system that can identify a color difference of 0.1 level by image grayscale analysis. This standard has been put into practice in the whole process of quality traceability for tens of thousands of products.

This is because material mechanical parameters and thermodynamic models are deeply integrated into the process design to break through the limitation of traditional processing. The application of this technology system in such high-end domains as medical catheter moulds with a surface roughness Ra of 0.008μm and optical light guide plate with 93.5% transmittance has realized the leap in acrylic processing from "experience-dependent" to "scientifically controllable", setting a new benchmark for the industry.

5 Key Technological Advances For Optical Grade Surfaces

By breaking through five core proprietary technologies, our acrylic machining service has achieved true optical-grade surface quality. These technological innovations not only completely eliminate common defects such as cracking and haze encountered in traditional machining but also demonstrate industry-leading performance in critical measurable indicators, including light transmittance exceeding 92% and surface roughness below Ra 0.01 micrometers.

| Technology System | Core Content Summary |

| Special Tool Technology | A large rake angle diamond tool with nano coating is used for micron-grade cutting precision. |

| Micro-Vibration Control | Develop the active vibration reduction system to control the machining vibration amplitude within 0.5μm. |

| Innovation in Thermal Management | Employing pulse cooling technology to maintain constant temperature in the cutting zone within ±2℃. |

| Multi-axis machining | It realizes the one-time forming of the complex curved surface by 5-axis synchronous control. |

| Nanoscale polishing | With magnetorheological polishing technology, the surface roughness can reach Ra0.001μm. |

From designing the tool to thermal management control, from suppressing vibration to precision polishing, each step reflects deep knowledge in material properties. This technology system has enabled medical endoscope lenses to achieve more than 92% light transmission and optical light guide plates to reach surface quality comparable to mirrors, setting a new standard in acrylic precision processing.

Figure 2: High-precision fabrication of transparent acrylic parts by LS Manufacturing

Precision CNC Machining VS Laser Cutting-How To Make The Scientific Choice For Your Project?

For high-end applications where the requirements of optical performance and high structural integrity need to be satisfied simultaneously, acrylic CNC machining is the only choice. Fundamentally, two processes differ in their physical principles, which alone preordains the suitability for various application scenarios. The following is a comparison between precision CNC machining and acrylic laser cutting:

| Evaluation Dimensions | Precision CNC Machining | Laser Cutting |

| Optical Performance | It keeps the original light transmittance of the material, above 92%, with no heat-affected zone. | At the cut edge, there is a carbonized layer that reduces the light transmittance by 15 to 30%. |

| Structural Strength | Grain structure intact, mechanical properties correspond to material standard values. | Strength in the heat-affected zone is reduced about 25%, with internal stresses present. |

| Production Efficiency | It is suitable for use in intricate 3-dimensional structures and has a relatively long processing cycle. | It has high efficiency in two-dimensional cutting and is suitable for planar batch processing. |

| Overall Cost | Higher equipment and tooling cost; hence, suitable for high value-added products. | Lower initial investment is suitable for standardized mass production. |

In consumer products, the cost advantage can be prominently considered for laser cutting. For high-end applications, such as medical equipment and optical instruments, CNC machining is used to meet the strict requirements for performance reliability. Our technical team can provide a quantitative evaluation model according to the product functional requirements to help customers determine the best technical implementation plan at the very beginning of a project and avoid quality risks and cost losses caused by improper process selection.

Extreme Quality Requirements For Acrylic Parts In The Medical And Optical Industries

It should be noted that, compared with industrial-grade requirements, the acrylic parts used for medical and optical purposes must meet extreme quality demands. Our medical-grade PMMA parts fully meet ISO 13485 and FDA certification requirements, and their technical specifications cover the following three dimensions:

- Surface Quality and Optical Performance: The surface roughness of the medical endoscope barrel should be less than Ra 0.008 μm to avoid distortion in the picture. In the case of an optical light guide plate, the transmittance must be more than 92%, while haze is less than 0.5%. Using nanoscale polishing processes and cleanroom environment control, we achieve optical mirror-grade standards.

- Structural Accuracy and Dimensional Stability: It is required that the channel width tolerance of the microfluidic chip should be controlled within ±5 μm, with no creep deformation at long-time use. A low-temperature stress anneal technology is adopted to ensure that components are able to keep their dimensions within the tolerance of ±0.01 mm/100 mm even under fluctuating temperature conditions.

- Biocompatibility and Chemical Resistance: The parts that come in contact with the human body should pass USP Class VI testing; the corrosion caused by disinfectants like sodium hypochlorite should be resisted. We use material modification technology to make PMMA reach an antibacterial rate of > 99.9% while maintaining light transmittance.

Equipped with nanoscale surface finish, submicron tolerance controls, and assurances of biocompatibility, we can ensure that our parts comprehensively exceed industrial standards for optical performance, structural precision, and chemical stability. The current ISO 13485-and FDA-certified technical solution puts these abstract quality requirements into quantifiable and traceable manufacturing parameters, providing essential guarantees for high-reliability applications.

Figure 3: Shear deformation zones in acrylic CNC process by LS Manufacturing

Case Study: Overcoming Mass Production Challenges Of Optical Components For A Leading Global Medical Device Manufacturer

In the production of high-value medical devices, mass production consistency in optical components is a factor that determines the competitive advantage of a product. A case to illustrate how systematic technological innovation can solve industry challenges in the mass production of optical guide components for CT equipment by a multinational medical equipment company is presented below:

Detailed analysis of the customer's dilemma

The requirements this company had were very high technically: the surface roughness had to be constantly controlled at Ra < 0.01μm, and the batch-to-batch variation could not be more than 5%. However, because of its heat-sensitive properties, some thermal damage could not be avoided during processing, and thus traditional processing methods could not solve the problem. For a long period, this meant that the yield rate of the cooperative supplier was less than 30%.

Solution: Technological Innovation

We've assembled an interdisciplinary team to achieve technological breakthroughs in 3 dimensions:

- The development of an adaptive toolpath algorithm with independent intellectual property rights. Using real-time monitoring of changes in the cutting force and dynamic feed parameters adjustment, the amplitude of machining vibration can be controlled within a range of 0.2μm;

- The liquid nitrogen cryogenic machining system is adopted in an innovative way, the temperature fluctuation range of the cutting zone is kept within ±1℃ by using a closed-loop temperature control module, and the white edge phenomenon is eliminated;

- Development of a machine vision based online optical inspection system for reviewing the surface quality every 15 seconds, which can permit self-optimization and adjustment in machining parameters within prescribed limits.

Quantitative results and value creation

Through project implementation, significant results were obtained: The product yield increased from the baseline of 30% to a new industry high of 99.2%, with a stable annual delivery volume reaching 500,000 units. With process optimization, the single-piece machining cycle was shortened by 35%, and the overall production cost decreased by 40%. In the face of a stable supply of components, the customer successfully shortened the new product launch cycle by 4 months and further consolidated its leading position in the medical imaging field.

This case study highlights LS Manufacturing's technological leadership in the field of acrylic CNC machining. By building a complete technical system encompassing process design, process control, and quality verification, we deeply integrate materials science and digital technology, solving the challenges of manufacturing high-end optical components and setting a new technological benchmark for the industry.

A technical solution to improve yield from 30% to 99.2% is now available. Get your customized solution now!

Three Technical Qualifications You Must Verify When Selecting An Acrylic Machining Supplier

In the manufacturing of high-end products, the quality of acrylic parts directly decides the performance of the final product. Materials, process, and quality are the 3 core capabilities that a high-quality clear plastic parts manufacturing partner needs to possess. It's not only a matter of product yield but also a key factor in guaranteeing supply chain reliability. The best practice of the industry suggests the establishment of a supplier evaluation system based on the following 3 dimensions:

Depth of Understanding of Materials Science

Good suppliers should be able to offer full reports of material properties, including the main parameters that characterize PMMA: molecular weight distribution, glass transition temperature, and coefficient of thermal expansion. For example, USP Class VI biocompatibility certification is required for medical applications, while transmittance and haze test data are required for optical devices. Only this basic concept about materials will help avoid defects during processing.

Process Innovation Capability

Assess whether the supplier has exclusive technological reserves such as patented tool designs, temperature control algorithms, or vibration suppression systems. The high-quality supplier can guarantee temperature fluctuation within ±1℃ in the cutting zone by its proprietary low-temperature processing patent, improving the yield rate of acrylic parts to over 99%. This kind of technological innovation is a core guarantee for solving problems such as white edges and cracks.

Quality Assurance Capability

Supplier shall be equipped with a complete optical testing laboratory with professional equipment that includes white light interferometers and spectrophotometers. A fine quality system shall ensure full-process data traceability. For example, it should link processing parameters and check reports of every batch of parts by QR code to ensure verifiability of major index verifications like surface roughness Ra < 0.01μm.

We recommend that during the evaluation of plastic CNC machining suppliers, clients request specific case data, such as a comparison table of processing parameters for different grades of PMMA, patent technology application reports, and full-size inspection reports of typical parts. This is the quantitative evidence that really identifies the partners with high-end manufacturing capability.

How To Reduce Processing Risks And Costs By 70% During The Design Phase?

In the precision acrylic parts manufacturing process, design decisions account for more than 80% of the final cost and quality. With early design intervention at LS Manufacturing, customers can avoid up to 70% of probable quality risks and additional costs. Our proprietary DFM, or Design for Manufacturability, methodology helps customers build a quality advantage from the early stages of R&D through systematic optimization:

- Rounded Corner Optimization Design: Because acrylic is a brittle material, all internal corners are designed with 0.5mm or larger radii, and stress distributions are checked with finite element analysis. After performing this type of optimization, the crack defect rate for a shell in a medical device went from 25% to 0.3%, and mold life tripled.

- Wall Thickness Standardization Control: We set up the design specification of wall thickness uniformity and control the variation of thickness within ±10% of the base value. As an example, the optical light guide plate can realize the uniformity of light transmittance as 92% ± 2% without shrinkage deformation problems by designing a uniform wall thickness of 1.5mm.

- Rational Tolerance Allocation: A key feature-based tiered tolerance system is applied where the mounting positions maintain a precision level of ±0.05mm, while non-mating features are relaxed to an industrial level of ±0.2mm. Employing this approach to reduce finishing processes, one instrument panel manufacturer cut the processing time per piece by 40%.

The DFM methodology has helped more than 200 clients reduce cost and enhance efficiency. For example, in one aerospace instrument cover project, early intervention optimized 12 design details, eventually increasing the yield rate from 68% to 95.5%, with a 42% reduction in cost per piece. It has been proved through practice that bringing manufacturing experience to the design stage is the most effective route to achieve a win-win outcome regarding quality and cost.

Figure 4: Acrylic material samples for precision engineering demonstration by LS Manufacturing

Why Do Global High-End Brands Choose LS Manufacturing As A Strategic Partner?

In precision acrylic manufacturing, the partner's technical capability and quality system directly decide the market competitiveness of the product. Choosing LS Manufacturing means choosing a leader in acrylic machining technology. We provide irreplaceable manufacturing solutions to global clients through a four-in-one value system.

Technological leadership advantage

We invest 8% of the revenue every year in R&D and have collected 37 core technology patents covering key processes like low-temperature processing and vibration suppression. Independently developed, the acrylic stress detection algorithm intelligently warns about possible defects before processing, hence shortening the new product development cycle by 50%.

Large-Scale Production Capacity Guarantee

We own Asia's largest acrylic precision processing base, which has 52 5-axis CNC machines and fully automatic production lines, capable of producing millions of pieces monthly. Flexibility in our production system enables dynamic capacities to be allocated between "mass standardization" and "small-batch customization," ensuring prompt fulfillment of urgent orders within 72 hours.

Quality Commitment System

We are the only company in this industry to provide an optical performance warranty, which means a guaranteed transmittance decay of <0.5%/year (accelerated aging test). We've established 214 quality control points from material warehousing to finished product shipment. All test data is stored on the blockchain, realizing 15 years of quality assurance.

End-to-End Service Model

Senior engineers manage each project, from DFM analysis to the optimization of mass production, providing full-cycle services. For example, a luxury brand reduced the number of parts from 38 to 12 by adopting our design optimization solutions and was able to save $1.2 million annually.

This perfectly aligns with high-end brand needs for supply chain reliability, product innovation, and cost control. We provide not just parts but the capability of manufacturing to our customers for enhancing the premium pricing power of their products. This forms the very base of our long-term relationship with top global brands across the world.

FAQs

1. How do you ensure consistent quality while mass producing?

We have established a digital quality system, covering 214 quality control points. Every batch of products will undergo full-dimensional inspection with a coordinate measuring machine and laser scanner. The SPC statistical process control will be performed for the critical dimensions to ensure Cpk ≥2.0, achieving a tolerance fluctuation no more than ±0.02mm for mass production of tens of thousands of pieces.

2. What is the maximum size for acrylic parts you can process?

Our ultra-large 5-axis machining center can handle acrylic sheets of up to 3000×2000×300mm. With a workshop environment controlled in temperature and the laser positioning and calibration system adopted, we guarantee the processing accuracy of ±0.05mm/m through the whole-size range, at an advanced level in the industry.

3. Can you provide medical-grade certified acrylic materials?

We carry inventory of ISO 10993-1-certified medical-grade PMMA, including an original manufacturer's material certificate for each lot with a full traceability chain. Third-party biocompatibility testing reports can be provided and are often required to meet strict regulatory requirements for implantable medical devices.

4. What is the smallest structure that you can make?

The internal corner radius may be as small as 0.1mm, and the wall thickness could be as thin as 0.2mm using independently developed micro-machining technology. Using nano-tools and micro-amplitude vibration control technology, the success rate of microstructure processing is over 99.5%.

5. How do you handle urgent orders?

For certified clients, we have a VIP expedited channel that has independent production lines with logistics support. Using concurrent engineering with an intelligent scheduling system, the time from confirmation to delivery of the finished product is no more than 72 hours. We have done more than 500 urgent projects so far.

6. Is quantitative testing of transparency supported?

Equipped in our laboratory is the newest generation of spectrophotometers, capable of test reports that include such parameters as transmittance (standard value ≥92%), haze (≤0.5%), yellow index, etc. All data is CNAS certified to ensure quantifiable verification of optical performance.

7. How do you protect client's design intellectual property?

We strictly follow ISO 27001 information security standards and use blockchain encryption storage technology. We adopt hierarchical authorization management for all client design documents; retain operation logs for 15 years; and have insured 20 million RMB in intellectual property insurance to build a comprehensive protection network.

8. Besides acrylic, what other engineering plastics can you process?

The engineering plastics processing techniques have more than 20 varieties, and the independently developed key technologies include the stress control of PC and the prevention of knife sticking of PETG. It can provide solutions for material selection according to the application scenario of the product, thus offering one-stop precision processing services across materials.

Summary

LS Manufacturing Acrylic CNC is a systemic engineering technology that integrates material science, process engineering, and quality management. Equipped with a 5-axis machining center and an optical inspection laboratory, we can realize meticulous control in the whole process from design to mass production and make sure the parts meet medical or optical grades in light transmittance, dimensional stability, and surface quality.

Let your products stand out with superior texture! Upload design drawings for a accurate quote providing a tailor-made process solution. Free DFM manufacturability analysis services are also provided. For deeper technical discussions, we invite you to directly contact us and offer a full-cycle solution for your project-from material selection to mass production optimization.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .