CNC lathe technology stands as a cornerstone of modern manufacturing, directly addressing industry pain points.The traditional approach fitting and apt for carrying out operations on a lathe involves inaccuracies and irregularities as regards production standards. It implies that there are production standards with very high costs of production, which are unscaleable as regards the current toughest challenges.

The solution will begin with digital transformation. CNC lathe bring about a machining revolution with control authority, which changes from humans to precision programming. The solution offered by the aforementioned technology will be examined with regards to assured and precise production. It will be introduced with regards to an LS Manufacturing solution offer and CNC turning as a solution for production issues.

CNC Lathe Cheat Sheet

| Section | Core Theme | Key Points |

| Introduction | From Pain Points to Solution |

Problems: Lack of consistent precision, low repeatability, operator dependence; Root Cause: Lack of automation and digital control; Solution: CNC programming represents an absolute revolution in precision machining. |

| How It Works | The Digital Command Chain |

Process: CAD Design → CAM Programming → CNC Controller → Servo Drive → Machining; Core: It interprets commands given from a design software and moves materials based on these interpretations. |

| Key Advantages | Beyond Conventional Machining | Precision & Consistency: Micron-level accuracy, identical parts in batches; Complex Parts: Handles intricate geometries, threads, and contours with ease; Efficiency & Automation: High speeds, enables lights-out manufacturing with automation. |

| Application | Industry Solution for Client | Technological Capability: More than two axes CNC turning centers, mill; Quality System: Full-process control from material to final inspection; Value Offered: Delivers stable, high-quality, customized part solutions. |

| Industries Served | Broad Applicability | Automotive, Aerospace, Medical, Energy, and General Precision Engineering. |

CNC lathes will be an integral component within the modern sector because CNC lathes will effectively solve problems, inconsistencies, and subsequent costs created by machining. By combining modern capabilities and functionality present within digital programming with precision control functions, CNC lathes will allow an advanced manufacturer to offer excellent custom machining services and empower a customer to develop better scalability. CNC lathes will allow an advanced manufacturer to offer excellent custom machining services and will empower a customer to develop better scalability.

Figure 1: Running a metal gear shaft on a CNC lathe by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

As precision manufacturers, there should be an area where trustworthiness should be attained at a shop floor and not on some theories. We appreciate our trustworthiness and expertise on more than a decade of doing and acquiring expertise on highly demanding domains like aerospace, medical, and automotive. We don’t just know specifications; we live and breathe specifications because we believe and subscribe to guidelines offered by some authoritative bodies, like Society of Manufacturing Engineers (SME), so that every recommendation we offer should be tried and should be proven efficient.

Our credibility should be measured on account of our success as we have been successful enough to develop more than 50,000 custom CNC machined components. The projects that we have completed, ranging from high strength alloys to very intricate medical implants, have given us an unparalleled amount of knowledge and experience on optimizing. Finally, we have completely adhered to guidelines that will be pointed out below on subjects pertaining to quality and inspections from sources like US Environmental Protection Agency (US EPA), among others.

Whether it be aerospace or medical devices, as a reference guide, it encapsulates an immediate compendium on these insights. We share these insights gleaned from experience—to get perfect functionality on a critical aerospace thread or medical device tolerance. To cut it short, with our reference guide, you would have insights into not only better ways but ways that have passed our strict standards.

How Exactly Does A CNC Lathe Work? What Is Its Core Principle?

The operation of a CNC lathe is fundamentally driven by translating digital instructions into precise physical movements: from a conceptual design to the finished part. The workflow provides a clear answer to what is a CNC lathe—a computer-controlled machine tool that automates the turning process. The core explanation of how does a CNC lathe work lies in the seamless execution of digital commands that direct every action on the machine tool.

- Creating Digital Blueprints: It begins with Computer Aided Designing. Computer Aided Designing A process wherein an intricate representation of a 3-D part will be generated. All geometry and specifications are conceptualized here. It is the source wherein all operations originate.

- Programming the Machine: The CAD file would then be transmitted into Computer Aided Manufacturing. The procedures would include tooling, speed, and removal of materials. All procedures would then be compiled by CAM. The CAM would then generate G-code. The G-code would control the CNC turning machine. It would provide it with procedures.

- Control and Execution: The generated G-code program will then be processed by the CNC controller. It functions as the brain because it translates all commands issued from the program. Consequently, there will be a flow of signals that will then be sent to the servo motors. The result will then be controlling the movement of the cutter on the X and Z axes and on the spindle.

- Material Precision Removal: From the programme, there will be an interaction with the cutting tool and the rotational workpiece. Consequently, due to the fact that there will be an interaction with the workpiece at the same time as precision movement on the linear axes and spindle movement, there will be a controlled removal of materials. Consequently, raw materials will be converted into a product.

The working principle of a CNC lathe will be said to be an automatic control process with interactions including tools and works. It will be said to be an implementation of “digit command controlling physical machining” because all cuts will be made with the help of a programme. Based on its working principle, it will be conceived that a CNC turning machine will have a capability of generating intricate components with higher speed and accuracy compared to a CNC lathe.

What Machining Scenarios Are Different Types Of CNC Lathes Suitable For?

It becomes an imperative task that you educate yourself on different models of CNC lathes. It would enable you to make a judgment on which CNC lathe would be most apt for your project. Different CNC lates have capabilities and facilities that differ from one CNC lathe to another, as per the requirements for various projects. This section outlines the key differences and typical CNC lathe applications, helping you match the machine type to your parts.

| Type | Structural Feature | Typical Part Application | Primary Benefit / Common Use |

| Vertical CNC Lathe (VTL) | Has a vertical spindle with a horizontal working area. | Has large diameter and weight with short size (discs, rings, and gears). | Processing heavy components with stability, loading and unloading facility, and easy removal of chips. |

| Horizontal CNC Lathe | Horizontal spindle and traditional layout. | Those with shaft-like features and large size, for example, shafts, screws, and bushings. | Common, versatile; good chip evacuation; suitable for long, rotating parts. |

| Turning-Milling Center | Turning and rotary tool on one spindle. | Machining operations involving milling, drilling, and tapping. | Single machining operation with high accuracy. |

In summary, selecting among the various types of CNC lathes depends on part geometry, size, and complexity. A Vertical CNC lathe will be appropriate for large discs. A horizontal CNC will be appropriate for conventional shafting. But for more complex products and multiple machining operations, a turning milling center will be necessary. A Turning Milling Center will be an entire precision CNC lathe. Evaluating your part portfolio against these strengths ensures the most effective CNC lathe applications.

What Are The Key Advantages Of CNC Turning Compared To Traditional Lathes?

A departure from conventional CNC turning machines marks a paradigm shift in machining capabilities. The key advantages of a CNC lathe depends primarily on its programmable and digital control functions. It may be seen that these alone have been significant factors in making a CNC lathe better than conventional ones.

| Advantage | Quantitative/Key Benefit | Impact |

| Superior Precision | Accuracy as high as ±0.005mm. | Enables the production of high-tolerance parts, defining a true precision CNC lathe. |

| Batch Consistency | Enables statistical process control. | Guarantees every part in a batch is identical, eliminating variation. |

| Complex Geometry |

The capabilities include intricate curves, profiles, and unique threads. |

Boosts creativity and functionality with geometry on a single fixture. |

| High Productivity |

Reduces set-up times and cycle times. Enables automation and unattended operation. |

Maximizes spindle operations. Reduces cost per piece and productivity. |

It would also be possible to identify that it would be feasible to assume that the significant advantages of CNC turning have some association with benefits associated with competitive advantage within the region of operation for the manufacturing sector. It would be possible to achieve predictability and cost-effectiveness with the help and assistance of precision ensured due to the advanced CNC turning machine.

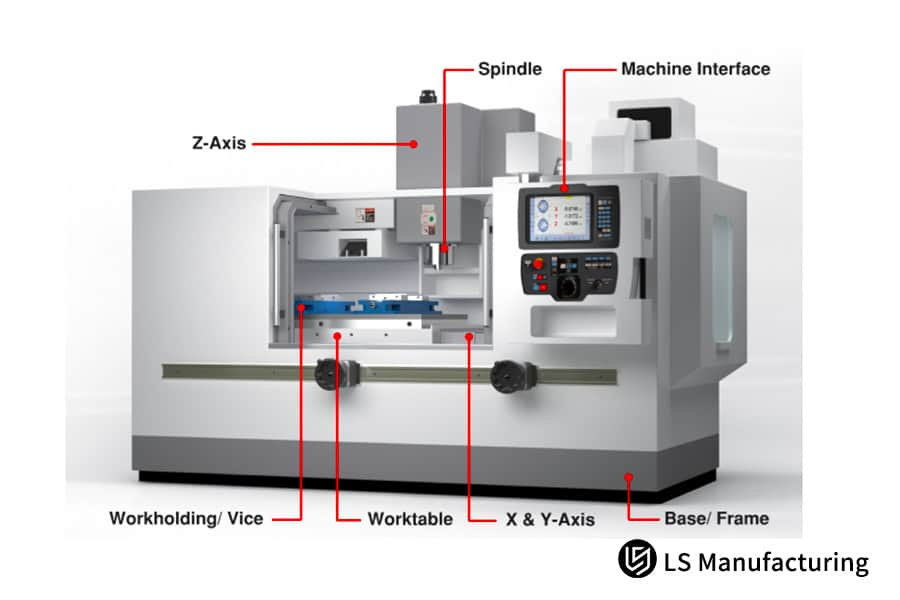

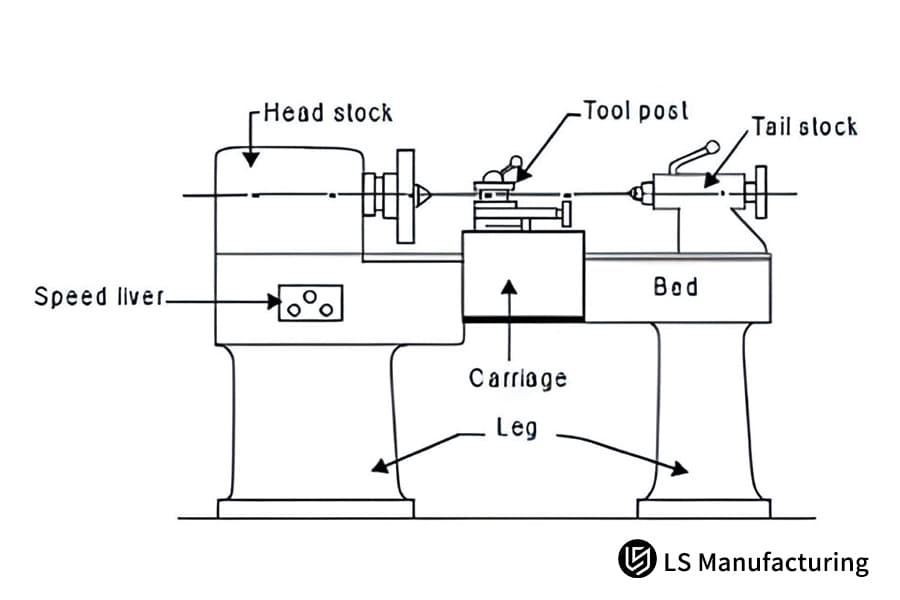

Figure 2: Instructional schematic identifying precision machining parts by LS Manufacturing

How To Select The Appropriate CNC Lathe Configuration Based On Your Part Requirements?

As regards efficient equipment selection, there should be an efficient process for your needs analysis compared with that of your equipment capabilities because it is significantly outlined within your problem. Successfully navigating how to choose a CNC lathe involves analyzing key part characteristics to determine the necessary technical specifications.

- Part Size and Material: Size and type of your materials will govern your machine. Maximum size and diameter of your part will govern your spindle bore size, chuck size, and your bed size. Material hardness will govern your spindle horsepower and rigidity.

- Geometric Complexity and Tolerance: It should be necessary for you to check your components' specifications. Whether your components have simple turned shapes or more complex ones with holes and flats centered or offset, you would then have a requirement for a 22-axis turner, M/C with live tools and Y/C and C-axes, or better accuracy and resolution with high-end LS Manufacturing CNC lathes.

- Production Volume and Automation: Production volumes will be drivers for your configuration regarding automation. Lower volumes and high mix will have highly valued quick-change tool turrets. Higher volumes will focus on or concentrate on machines with abilities involving bar feeders, gantry loaders, and robotics.

- Future Proofing and Support: It needs to be analyzed not only with the focus on the demands at present but should be considered with the focus on what it can be done with it in the future. To be more flexible, it would be more worth choosing a versatile type of CNC lathe with more axes or with an enlarged working area. The reliability and service should be given equal importance.

That is, some process will be at work regarding your understanding of “how to choose a CNC lathe.” By taking into consideration your piece size, complexity, accuracy, and production volumes, you will be able to select a configuration ranging from simple 2-axis CNC lathes through more complex multi-tasking. It will be possible for your project to have a custom CNC lathe solution offered to it with the help of someone with expertise, such as LS Manufacturing.

Case Study On Turning Stainless Steel Precision Shafts For Medical Devices: How LS Manufacturing Achieves Micron-Level Precision

It relates directly to our next case study as it shows our commitment and professionalism with hard-to-transfer challenges with high stakes and product made. It directly shows exactly how LS Manufacturing CNC lathes and professionalism with customer needs and goals relate with challenges and solve beyond what they would normally solve within standards within respective industries.

Client Challenge

A medical device OEM customer had a bottleneck on its hands. Their needs were precision shafts made from medical-grade implant stainless steel with tight specifications of ±0.008mm with an Ra value of 0.4. Several suppliers have failed delivering consistent quality with a low percentage of 70% at best.

LS Manufacturing Solution

We solve problems with the solution implementation of medical-grade precision machining on a precision CNC lathe engineered and designed specifically for machining. Also included, taking a holistic approach at optimizing cuts and paths associated with materials sold with a specialty fixture with an emphasis on preventing distortion due to heating and clamping, as well as included with an in-process measurement system.

Results and Delivering Value

The percentage at which qualified product emerged dramatically increased to 99.2%, meeting all applicable medical needs. Furthermore, we have partnered and achieved precision specifications accuracy with precision, but we have also partnered with our customer and made sure they achieved a savings on total procurement cost expenses of 15%.

To bring it all into perspective, it is imperative to acknowledge that it took micron precision accuracy and consistency beyond superior machining skills, which took expertise. At LS Manufacturing, our expertise and knowledge pertaining to CNC turning machine relate to optimization, specialty fixtures, and control. To put it very clearly, hard-to-transfer problems with tight accuracy specifications are solved and made more consistent, or as we would refer to it as ‘manufacturing certainty’ with regards to our customer.

Do your precision turning components have accuracy problems? Let LS Manufacturing help you today and get your solution and price from our experts.

What Core Capabilities Should Be Considered When Evaluating A CNC Turning Service Provider?

This makes the selection of a CNC turning service provider one of the most important decisions you will make that involves your product, your timing, and your budget directly. Such a question-like how to select a CNC lathe service-may sound simpler than it actually is and may require much more detail and expertise than comparing prices. Testing competencies with regard to machining services rests on how to select a CNC lathe service.

Capabilities of Technology and Equipment

No shop is complete without machine tools. Again, its capability would have to be compared with brand and age factors, as well as specifications regarding precision. Furthermore, analyze configuration options such as the availability of live tooling and multi-axis operation. Lastly, the number of machines would yield information on production capacity and redundancy.

Precision Quality Control and Process Reliability

With precision production, it is in control. Check their system of quality control, mostly through certification under ISO 9001. Also, inquire about their dimensional control tools that would offer first article inspection and production inspection by coordinate measuring machines and profilometers. A sound control system should work toward assurance that even a batch of production protos, like those made on an LS Manufacturing CNC lathe, will be made to tight specifications.

Engineering for Manufacturing Support

A good partner should be proactive about providing you with insights into your product designs. You need to know their capability for DFM analysis and get to know how you can optimize your design based on cost improvement, manufacturability, and improvements over and above. That will enable you to identify issues before production, and as a result, it will be very helpful for your project.

Industry Experience and Success Record

Ensure they have some kind of track record with proven expertise. It would rather be great to request case studies or references concerning the medical, aerospace, and automotive industry. The best reference they can afford to ensure the delivery of your parts is to look at samples within their portfolio with the same or similar part complexity, tolerance, and using the same material your product uses.

In finding a proper CNC lathe service provider, the talk is about a relationship based on partnership. It is of great importance to look at seeking a CNC lathe service provider with a mix that would be able to meet your needs for the technological equipment, advances in quality, added value regarding engineering support service, and established record. It then becomes important for you to have focused on these basic essentials as brought out by the leaders within the sector.

Figure 3: Comparing different types of CNC lathe machines by LS Manufacturing

What Are The Main Factors Affecting The Cost Of CNC Turning? How Can They Be Optimized?

Understanding cost drivers in machining is part of budgeting and optimal design. From raw materials to the inspections done, there are many interlocking variables that determined the CNC turning cost and, subsequently,CNC lathe processing quote. Dealing clearly with these variables, with openness, would certainly ensure value for money in addition to cost-effectiveness.

Material Selection and Utilization:

The choice of material (e.g., stainless steel vs. aluminum) significantly impacts raw cost and machining time. Optimization involves selecting a grade that meets but does not exceed functional requirements. Furthermore, designing parts to maximize yield from standard bar stock sizes and minimizing material waste directly reduces this substantial cost component.

Part Design and Manufacturing Complexity:

The complexity of the designs in parts is what triggers the prime cost. Heavy internal grooves, tight tolerances, and shapes are costly to program, rely on special tools, and drive up the cycle times. Simplicity, scaling down the design, establishment of practical limits for tolerances, and standardization of design wherever possible will help a lot in bringing down costs without compromising functionality.

Production Volume and Setup Strategy

Cost per part highly depends upon the quantity ordered. In any given situation involving prototyping or low volumes, there would be some amount of setup and programming cycles divided among only a few parts. Large batches will have the opportunity to optimize by using dedicated tooling and optimizing processes. Strategically, excellent planning in respect of ordering quantity and studying family-of-parts machining will provide quite a big deal of advantage relating to cost.

Process Efficiency and Technical Expertise

This is where the expertise of a business partner becomes useful. A technical person, for example, at LS Manufacturing uses multi-axis CNC lathes with process knowledge that no match can find to maximize parameters related to a cut process. The result shows shortened cycle times, which is extension of tool life, and fewer materials get scrappage; thus, direct reductions of CNC turning cost.

It goes without saying that CNC turning cost needs consideration based on an amalgamation of design, materials, volumes, and manufacturing efficiency. Needless to say, collaboration with a technical expert would optimize these factors right at this stage. To realize these objectives, once again it would be highly proactive on your behalf if these goals are ensured with a focus on providing you with the best CNC lathe processing quote with guaranteed value based on expertise related to CNC lathes at facilities using advanced LS Manufacturing CNC lathes.

Figure 4: Diagram showing the labeled components of a CNC lathe by LS Manufacturing

What Is The Process For CNC Turning Projects In Collaboration With LS Manufacturing?

Large precision machining at LS Manufacturing demands a highly detailed level of open collaboration on our part for our own success, from conception and on into fulfillment. Listed below is an extremely well-considered CNC turning collaboration process for maximum successful communication and least risk levels involved as surefire ways for us to fulfill as the very specific needed components on our highly advanced LS Manufacturing CNC lathes.

- Consultation and Data Analysis: It starts with an analysis of your requirements and demands pertaining to functionality, materials, tolerance, and quantity. You are required to provide your CAD models and diagrams. There would be an analysis of your models and diagrams with an objective intention to evaluate your scope of your project. We would begin with an interactive process for your CNC lathe machining service.

- Free DFM Analysis: We will conduct a completely free DFM Analysis. We will analyze your designs based on manufacturability opportunities that exist within your designs, either for reliability, cost savings, and/or performance.

- Formal Quotation and Plan Confirmation: As per our confirmed plan, we will be providing you with a formal quotation on crystal clear prices and production schedules. We will then finalize project schedules and will be initiating procurement as per your approval.

- Programming, Setup, and First Article Inspection: Next, we will optimize machining paths on our CNC lathes. We will then set up on our CNC lathe and first article build. We will then evaluate your part with metrology at that stage. It will be shown to you with a proposal before we continue on with production.

- Full Production and In-Process Quality Control: Once approved, we move on to production. Moreover, being an integral part and process within our fabrication processes, we check it for compliance with your specifications with every revolution of our production unit because at CNC lathe machining service, we have very high standards.

- Final Delivery and post-sales Service: Once we have finished our verification process as it relates to your quality, we would then be packaging your components and shipping these out. But at LS Manufacturing, we will be there with you at the distribution level as it relates to your components, at whatever stage you would have your questions, and at whatever document as it relates to the fulfillment of your production needs.

As a result, it could be suggested that with the pre-arranged CNC turning collaboration process, we have at our disposal, We start with certainty and add value with added value with our engineering know-how and with our state-of-the-art LS Manufacturing CNC lathes, we will turn your designs into superior reliable components.

FAQs

1. What is the minimum order quantity (MOQ) for CNC lathe machining?

We have flexible MOQs and capabilities and expertise appropriate for product life cycles at different stages. Whether it be verification production at an initial stage or at an advanced stage with considerable production quantity, we can assist you with our personalized production service.

2. What machining tolerances do you typically guarantee?

As regards general materials, we have been maintaining machining accuracy with an error rate no more than+/- 0.01mm. As regards more demanding products, we are also capable of maintaining machining accuracy with an error rate no more than+/- 0.005mm.

3. How soon after receiving some drawings can I get a quote?

We have an extremely fast turn-around on quotes. Even for somewhat simpler components, we would be offering detailed quotes within 2-4 hours. Also, irrespective of architectures and processing detailed within more complex components, we will make it a point to evaluate and revert within a business day so that you can proceed with your projects.

4. Do you provide material certification and quality reports on the processing done?

Yes, we undertake comprehensive material quality assurance certifications in form of material reports and traceable quality reports. As per your requirements, we will be offering reports on first article inspections, comprehensive dimensional reports, and so on. Hence, traceability and standards will be ensured on all proceedings from materials to end product.

5. Do I have special optimization needs for my CNC turned product?

Yes. It would be required with 3D modeling alone or with a drawing. A feasibility analysis as regards production would be done by our experts, and they would assist with special tips as regards optimization as per production process requirements, like tolerance, simplification on architectures, and easy machining. Thus, manufacturability and cost would be optimized.

6. What materials can CNC turning process?

As compared to machining centers, we have very strong capabilities pertaining to materials processing, and these include various metals ranging from stainless steel, aluminum alloys, titanium alloys, copper alloys, and engineering plastics. We would be capable enough to identify an optimal material and process match applicable for your region.

7. How can I ensure the security of my design drawings and intellectual property?

We highly appreciate your dedication towards our intellectual property rights, confidentiality agreements, and document security and control as it relates your designs and documents within our cooperation framework as contained within an encrypted file management system.

8. How can new clients start their first CNC turning project?

You can contact us with your designs and 3D models and project requirements either via contact form available on our website or contact us on phone numbers and emails. Our project engineers will revert back immediately and assist on project start.

Summary

CNC lathes are at the foundation of modern precision machining. With these revolutionizing modern precision machining, it becomes super imperative and necessary that CNC machining be done with precision and professionalism. At LS Manufacturing, we have state-of-the-art equipment, precision control, and expertise on precision high-quality and reliable component production.

Get your precision machining today! Just click on the button below on 'Get Your Free CNC Turning Quote & DFM Analysis'. Upload your machining needs and get your professional solution and accompanying competitive quotation as per your needs.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.