Vacuum casting and centrifugal casting are two significant specialty casting processes in precision metal part manufacturing, providing solutions for the production of high-performance complex parts. Vacuum casting effectively removes oxidation and porosity by casting under vacuum conditions and is particularly chosen for high-quality titanium alloy and heat-resistant alloys. Centrifugal casting, on the other hand, employs centrifugal force brought about by rapid rotation to form the part. It is notable for its close metallurgical structure and is ideal for casting sleeve-shaped components.

Being a technical leader in the industry, LS Precision has been intensively engaged in these two state-of-the-art casting techniques for decades. Based on our rich technical expertise and experience in project undertaking, we have been able to provide full-service solutions, from process R&D and small-batch trial manufacturing to mass production, for customers in aerospace, medical devices, and high-performance automobile applications. In order to save you time, we have summarized the key findings below.

Vacuum Casting vs. Centrifugal Casting: Core Quick Reference

| Characteristic Comparison | Vacuum Casting | Centrifugal Casting |

| Core Principle | Vacuum pouring and forming. | Forming takes place by centrifugal force created due to the rotation of the mold. |

| Process Precision | Good. It can produce complex, thin-walled parts with good detail. | Medium-to-low accuracy, suitable for plain, axisymmetric parts. |

| Microstructure Density | High but highly sensitive to process parameters. | Extremely high, centrifugal action creates a dense microstructure without pores. |

| Mechanical Properties | Good and stable. | Excellent, especially high radial mechanical properties. |

| Typical Applications | High accuracy aerospace parts, medical devices, golf head. | Protectors, bushings, cylinder liners, rollers. |

| Applicable materials | Wide variety, particularly for reactive metals such as titanium and cobalt. | Reasonably wide variety: steel, cast iron, copper alloys, aluminum alloys, etc. |

| Production Costs | High (complex equipment and controlled environment) | Reasonably low (simple equipment and operation) |

| Production Cycle | Long production time (with vacuum pumping) | Short, high efficiency. |

| Surface Quality | High surface finish, even surface, low oxidation flaws. | Inner bore is good quality, outer surface may be machined. |

Whether or not to employ vacuum casting or centrifugal casting depends vastly on product shape, performance specification, and material type:

- Where complex designs, high precision, and active parts (such as titanium alloy medical implants) are required, vacuum casting is a necessary option, with better overall performance and accurate replication, albeit more expensive.

- Where axisymmetric parts (such as engine cylinder liners) require extreme material density and mechanical strength, centrifugal casting offers a natural advantage, with unparalleled material density and hardness at less cost.

This is where LS Precision excels: Not only do we have a full spectrum of equipment for high-end processes, but we also possess great application experience.

LS Precision can adequately analyze your part requirements, recommend the ideal process, and even combine a number of different processes if necessary to ensure maximum cost-to-performance balance.

Why Trust This Guide? Practical Experience From LS Experts

The data presented here is not theoretical speculation but a reflection of our long practical experience in high-end casting at LS Precision. We have a complete vacuum melting and pouring system (VIM-IC) and a full automated centrifugal cast production line, and are successfully AS9100D aerospace and NADCAP specialty process certified.

That is, our processes, quality control, and material properties always follow the highest standards of the world. LS Precision always supply core high-temperature alloy blades to the world's top aircraft engine producers and precision cast biocompatible titanium alloy implants to the world's top medical device manufacturers. Such experience, together with stringent industry audits and large-scale production validation, provides a solid foundation to our good counsel.

A customer required, as an example, a high-strength stainless steel bushing with a zero-defect interior wall and far more strength than can be achieved using castings. While in theory vacuum casting could supply this, it was prohibitive cost-wise. Based on experience, LS Precision's engineers chose centrifugal casting. By integrating advanced mold preheating control, speed-pouring curves specially optimized for maximum results, and precise computation of centrifugal force and gravity impacts upon alloy solidification, they managed to eradicate normal segregation.

The final product not only achieved the performance requirements of vacuum casting at the cost of centrifugal casting, but also achieved Class A inner wall density after ultrasonic inspection.

Understanding Two Cutting-Edge Processes In One Minute: Vacuum Casting vs. Centrifugal Casting

Vacuum casting and centrifugal casting are both very highly regarded advanced technologies in precision manufacturing. These technologies differ in principle from one another, with each having its own advantages.

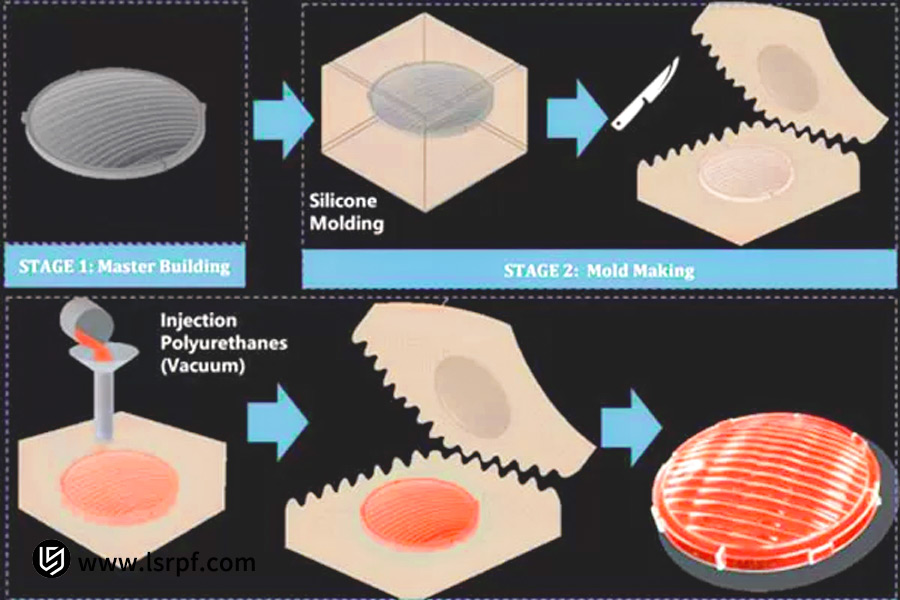

1. Vacuum Casting:

Vacuum casting merely involves pouring molten metal in a mold under vacuum condition. This "vacuum" effectively evacuates the air from the cavity of the mold, removing a large percentage of the bubbles and oxides inclusions in the casting, ultimately achieving extremely high dimensional accuracy and detail reproduction, hence it finds its best application to complex precision parts.

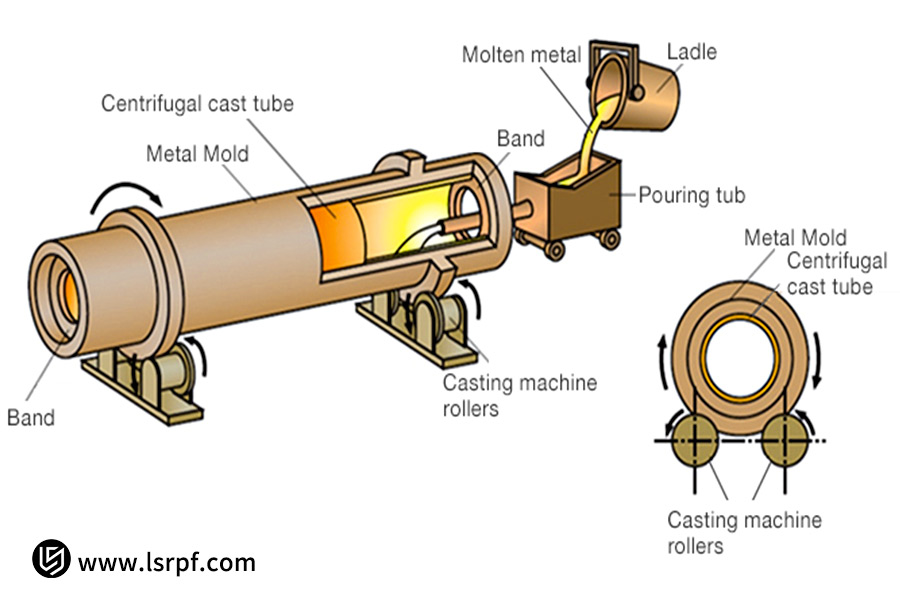

2. Centrifugal Casting:

Centrifugal casting utilizes the centrifugal force generated by high-speed rotation to cast the molten metal against the mold cavity walls and form the part. The strong centrifugal force serves to keep the casting density intact, and therefore it is particularly effective in producing symmetrical shapes such as rings and cylinders that create identical internal structures and better mechanical properties.

Vacuum casting is the option for maximum complexity and precision; centrifugal casting is best for strong and durable ring-type and cylindrical parts. Choosing the right process appropriate for your use is key to successful production.

Why Carefully Select A Casting Process For Your Project?

In precision manufacturing, choosing the most appropriate casting process for your high-stakes endeavor is a strategic decision of critical importance. It is more than simply setting up how production will be done; it really defines the DNA of your product—its final performance, quality level, competitiveness in the market, and even commercial viability.

The choice of the proper process is crucial. No matter if you are vacuum casting, attempting to copy superior detail, or centrifugal casting, attempting the best material properties, an exact replica can provide you with:

- Guarantee of quality and performance: Ensures that the components meet the mechanical properties, accuracy, and reliability specifications at design time and lower the risk of failure chances.

- Optimizes cost effectiveness: Provides best production process for budget, with minimal waste in material, labor, and post-processing from inefficient process.

- Maneuverable production cycle: Good process selection gives a guaranteed project schedule and avoids excessive delays.

The opposite selection can be a project's Achilles' heel. The consequences of the misalignment of process and requirements are fatal and costly:

- Using vacuum casting to produce simple, thick, cylindrical parts will result in unnecessary expensive equipment and high cycle times;

- Improperly using centrifugal casting to produce complex, thin-walled parts may result in failed parts due to inadequate mold filling and cold shuts.

Besides creating significant financial losses (scrap material, mold remakes, and project delays), this can also result in substandard product performance and even loss of market confidence.

Proper scrutiny of requirements and careful decision between vacuum casting and centrifugal casting at the initial stage of project ideation is the first and most important step to avoid extreme risks and gain extreme project value.

Vacuum Casting vs. Centrifugal Casting: The Ultimate Showdown Of Precision And Strength

When you compare vacuum casting and centrifugal casting, you are actually choosing different "genes" for your project. Differences in their fundamental principles inevitably lead to differences in the final product's precision, stability, and applications. The following table briefly outlines the major differences in this ultimate showdown.

| Feature Dimension | Vacuum Casting | Centrifugal Casting |

| Fundamental Principle | Vacuum or negative pressure casting relies on pressure differentials of air to feed the mold. | Centrifugal force resulting from high-speed rotation of the mold completes the filling and solidification of the metal. |

| Applicable Materials | Extremely broad, particularly well suited to reactive metals such as titanium alloys and high-temperature alloys; also suited to stainless steel and aluminum alloys. | Broader range, particularly suited to stainless steel, copper alloys, cast iron, and some aluminum alloys. |

| Product Accuracy | Extremely high, usually to CT4-CT6, able to precisely reproduce extremely thin details and thin-wall structures. | Medium, usually CT6-CT8, better for macro-size control, but not as well suited to reproduce fine details. |

| Surface Quality | Excellent. The vacuum environment effectively reduces oxidation and bubbles, resulting in a smooth and brittle surface and minimal post-processing. | Fair: Very dense and high-quality interior surfaces, but potentially having a coarser outer surface, usually requiring post-processing. |

| Structural Density | High. Vacuum conditions minimize porosity and slag inclusions, which result in a uniform microstructure. | Extremely. The centrifugal pressure applies uniform pressure to the melt, which results in an extremely dense microstructure with virtually no shrinkage cavities or porosity. |

| Typical Application | Shapes Extremely complex three-dimensional special-shaped pieces (e.g., impellers, chambers, and artwork). | Axisymmetrical bodies of revolution (e.g., sleeves, bushings, pipes, and rollers). |

| Maximum Size Limits | Limited by furnace vacuum size, normally suitable for small and medium-sized precision castings. | Large cylindrical parts (such as pipes of a few meters' length) are possible to cast. |

In this vacuum casting vs. centrifugal casting comparison, there is no universal winner; there is only the choice that best fits your needs.

- Vacuum casting is the "king of precision," born for material flexibility and complexity;

- Centrifugal casting is the "king of strength," constructed for extreme density and symmetrical forms.

Knowing the difference between vacuum casting and centrifugal casting is crucial to making the best choice.

Holistic Comparison: Advantages and Disadvantages of Vacuum Casting and Centrifugal Casting

To make a well-informed process choice, you must have a comprehensive understanding of the advantages and disadvantages of vacuum and centrifugal casting. The following table provides a wide-ranging objective analysis from various primary perspectives to allow you to see the overall picture.

| Comparison Points | Vacuum Casting | Centrifugal Casting |

| Surface Quality | Advantages: Excellent, smooth surface, low oxidation defects |

|

| Internal Porosity | Advantages: Vacuum environment greatly reduces porosity, enabling a dense internal structure. | Advantages: Very good, centrifugal force separates out the gas and impurities, leaving virtually no pores. |

| Dimensional Accuracy | Advantages: Extremely high, capable of producing complex thin-walled precision parts. | Disadvantages: Medium, very poor duplication of intricate details in complex structures. |

| Castable Materials | Advantages: Wide, specifically well-suited for reactive metals like titanium and cobalt. | Disadvantages: Short range, more appropriate for common alloy steels, stainless steel, copper alloys, etc. |

| Part Suitable Size | Disadvantages: Limited by machines, overall suitable for small-medium precision parts. | Advantages: Suitable to mold large cylindrical and tubular parts. |

| Production Cycle | Disadvantages: Long (includes vacuuming, cooling, etc.) | Advantages: Short, high molding speed, high efficiency of production |

| Cost Per Part | Disadvantages: High (high process cost equipment, energy consumption, and process costs) |

Advantages: Fairly low, especially for symmetrical parts, with very good cost-effectiveness. |

| Key Advantages | Excellent accuracy, good range of materials, very good quality. | Good efficiency, low cost, and high structure density. |

| Key Disadvantages | Expensive, long cycle time, size constraints. | Shape restrictions, poor surface finish, and limited material flexibility. |

This in-depth analysis of the pros and cons of vacuum casting and centrifugal casting results in a definitive conclusion:

- If your project calls for very high surface quality and internal quality, and the part is intricate, is of a special material (like titanium alloy), and is small or medium-sized, vacuum casting should be used.

- If your major concerns are cost and efficiency, and the part is a basic rotating mass of small or medium size, then centrifugal casting will be cheaper.

Cost Demystified: What Are The Key Factors Affecting Vacuum And Centrifugal Casting Costs?

When determining the cost of precision casting, individuals have a tendency to hold a stereotype: centrifugal casting is inherently low, vacuum casting is inherently high. The reality is, however, that the cost of a vacuum-cast component and the cost overall are far more complex than an exercise that involves numbers; they are a complex result based upon multiple dynamic elements.

1. Key factors in vacuum casting cost:

Some of the most important factors that drive vacuum casting costs include:

- Material cost: Reactive metals utilized (such as titanium and cobalt alloys) are extremely expensive and constitute the highest-cost driver.

- Equipment and energy consumption: Vacuum furnaces and other equipment are expensive to buy, and development of the vacuum environment is power-consuming, contributing to extremely high depreciation and operating costs per part.

- Mold technology: Mold precision and material requirements are extremely critical, contributing to extremely high mold production costs.

- Post-processing: Its major advantage lies in the extremely high quality of the casting blank, requiring fewer future machining, polishing, and other processing operations, which significantly reduces future costs and man-hours.

2. Key factors in centrifugal casting costs:

Primarily affecting centrifugal casting cost are:

- Production efficiency: Rapid cycle time, high efficiency, and high hourly output minimizes fixed costs per part.

- Material utilization: For symmetrical products, material utilization is high and scrap is lower.

- Post-processing: Although the casting's interior is dense, the exterior surface often requires turning to remove excess material and achieve a smooth finish, which incurs additional processing costs and material loss.

The unit prices of the two processes are not comparable:

- Vacuum casting may seem expensive per unit for extremely complicated parts, but it possesses very high total yield and near-net-shape characteristics that end up saving lots of money and time in post-processing, lowering the entire cost of the process perhaps.

- For simple rotating parts, centrifugal casting is definitely the most economical. An accurate precision casting cost estimate should be based upon an exhaustive analysis of the part's overall technical specifications.

What Are The Main Application Areas Of Vacuum Casting And Centrifugal Casting?

In high-end manufacturing, centrifugal casting and vacuum casting are two leading processes, meeting the specific needs of many industries through their high-performance features. Their usage in casting is largely concentrated in the following sectors:

1. Aerospace:

The industry demands extremely high material characteristics. Vacuum casting is used to produce titanium alloy and heat-resistant alloy engine blades and casings with oxidation-free and low-porosity components. Centrifugal casting is ideal for producing symmetrical rotary components such as engine rings.

2. Automotive:

The industry prioritizes reliability and durability. Industrial centrifugal casting suppliers tend to use the process for mass-producing wear-resistant cast iron components such as engine cylinder liners and brake discs. Vacuum casting is used for light-weight aluminum alloy components for high-performance vehicles.

3. Medical and Dental:

Maximum biocompatibility and precision. Vacuum casting operations play a crucial role in the production of cobalt-chromium and titanium alloy artificial prostheses, dental bridges, and crowns, ensuring clean accurate castings for meeting medical standards.

4. Energy Machinery:

Harsh working conditions require that materials are capable of withstanding high pressure and high temperature. Centrifugal casting is used to produce large alloy pipes and cylinder liners, and vacuum casting is used for critical components such as gas turbine blades.

5. Successful Experience and Customization Ability of LS Precision:

As a leading supplier of vacuum casting services and centrifugal casting plant, LS Precision's greatest selling point lies in extensive customizability. Leveraging an exhaustive understanding of all types of industry standards, we provide comprehensive solutions from material choice and process optimization to finishing, so that our customers receive high-performance and dependable castings.

Vacuum and centrifugal casting are high-end production processes that are integral to high-end manufacturing. Choosing a partner who has technical expertise and vast application experience such as LS Precision can enhance the quality and competitiveness of your products.

Vacuum And Centrifugal Casting Materials: Beyond Aluminum And Zinc

Most individuals typically expect material casting possibilities to be restricted to zinc and aluminum. The desire of modern industry for ultra-high part performance has created a greater range of applications for engineering materials. LS technical capabilities are much more expansive than this. We maintain a vast material library and process knowledge for working with a wide range of high-performance specialty alloys. Beyond the run-of-mill material possibilities:

1. Magnesium Alloy Casting:

Magnesium alloy casting is the optimal choice for achieving ultra-lightweighting. Its reduced density over aluminum and superior specific strength and stiffness make it specifically suited to weight-sensitive moving components in aerospace, consumer electronics, and luxury automotive markets.

2. Copper Alloy Casting:

Copper alloy casting is a technology of significance when the needs of applications require higher thermal and electrical conductivity or resistance to corrosion. Copper alloy casting finds extensive use in motor end rings, radiators, high-pressure valves, and marine products, offering unmatched performance.

3. Stainless Steel Casting:

Stainless steel casting provides the perfect solution for high-performance structural parts requiring high strength, hardness, and excellent corrosion resistance. Regardless of being used in medical devices, food machines, or chemical devices, it ensures steady and long-lasting reliability.

LS Precision has extensive experience in casting these unique materials. We are thoroughly familiar with the nature of each material and, through tightly controlling vacuum or centrifugal casting process, render magnesium alloy castings non-oxidizing and non-burning, copper alloy castings dense and defect-free, and stainless steel castings with stable performance.

With LS Precision, you are able to access an expanded base of engineering materials, including magnesium alloys, copper alloys, and stainless steel, to achieve new product design freedom and achieve full performance breakthroughs from lightweighting to function and durability.

LS Case Study: Vacuum Casting Solves The Challenge Of Lightweighting And Strength In High-End UAVs

Structural strength and lightweighting are a core dilemma of the luxury UAV manufacturing industry, and especially in the case of load-bearing parts, where traditional approaches fall short of achieving a harmony between the two. This is precisely what LS Precision Manufacturing, a leading vacuum casting producer, excels in resolving.

1. Difficult Challenge Faced by the Client:

A well-known premium UAV manufacturer was faced with a challenge in engineering its next-generation product: a critical wing connector. The component is of a multi-feature geometry and has extremely thin walls but must withstand enormous flight loads. The customer needed to realize extreme weight reduction with extremely high strength and stiffness.

Internal flaws such as pores and shrinkage must be eliminated completely to prevent them from becoming sites for initiation of fatigue cracks leading to catastrophic failure. Traditional casting and machining methods could not meet these strict demands at the same time.

2. LS Precision's Innovative Solution:

Faced with this challenge, the production team of LS Precision responded quickly and decided to apply sophisticated vacuum casting technology. The team used high-strength 7-series aluminum alloy because of its extremely high strength-to-weight ratio. Vacuum casting avoided melt oxidation and gas entrainment efficiently, ensuring purity of the molten metal and the ability to fill the mold.

Moreover, the team successfully modeled and designed the mold cooling system with the capability of directional solidification, completely avoiding the risk of internal shrinkage cavities and ensuring extremely high casting density.

3. Outstanding Results and Value:

Lastly, the LS team succeeded in producing a wing connector that fully met the specifications. After rigorous customer testing, the part was as much as 25% lighter than the original component, yet still equalled all of the mechanical performance requirements. Notably, after non-destructive testing, the internal quality of the component achieved a flawless "A" grade with no defects.

Not only did it benefit the customer's drone product in achieving a good upgrading performance and enhancing market competitiveness directly, but also fully display the excellent technical capability and professionalism value of LS Precision Manufacturing in solving complex engineering problems.

From Casting To Finished Product: LS Provides Precision Post-Processing And Machining Services

In precision manufacturing, a good-quality casting is only the beginning. Many customers have a defect-free finished product ready to be assembled as a requirement, and this is where the benefit of LS's single-source manufacturing services comes into play.

1. Precision machining:

As your reliable manufacturing partner, LS Precision recognize that precision machining is critical in ensuring the ultimate performance of components. Therefore, we own advanced CNC machining centers to precision mill, turn, and drill castings, strictly holding each critical dimension and tolerance up to drawing specifications, achieving a precise conversion from casting to end product.

2. Surface treatment services:

Apart from this, to meet product requirements for looks, durability, or special properties, LS Precison have comprehensive surface treatments. From minor deburring and sanding to high-precision polishing, electroplating, anodizing (for example, enhancing wear and corrosion resistance), and painting, we perform all these tasks with efficiency. These are made part of our production process, ensuring consistency in quality and timely delivery.

With LS Precision, you no longer have to schedule foundry with fabricator. We handle everything from material and casting to precision machining and surface treatment with our true one-stop manufacturing. This greatly reduces your management cost and time, and you receive a fully qualified end product.

FAQs

1. Can vacuum casting completely replace die casting?

No. Vacuum casting enjoys great cost and flexibility advantages in producing small-lot, very complex prototypes or end-use parts. However, for mass production of relatively simple structures, die casting still has overwhelming advantages with regard to cost and efficiency per unit. Therefore, it is an ideal complement to mass production die casting, but not a replacement.

2. Why are centrifugal castings more prone to shrinkage?

While centrifugal force may be useful for shrinkage feeding of molten metal, solidification is more complicated for alloys with a wide solidification temperature range. Inefficient control of the most crucial process parameters such as the rate of rotation and pouring temperature will prolong the movement of slag and impurities to the free surface, which leads to insufficient shrinkage and ultimately concentrates shrinkage defects in the inner diameter (axial) area. To avoid this, precise process control must be done.

3. What is the maximum size of vacuum-cast parts that LS Precision can produce?

LS Precision latest vacuum casting capability can accommodate up to 0.5 square meter maximum projected area parts. This is the size range that best meets the manufacturing needs of most small and medium-sized precision structure components applied in the aerospace, medical, and high-end consumer electronic industries, such as drone arms, medical device cases, and complex heat sinks.

4. What is the typical surface roughness of the castings you deliver?

Through the use of high-quality silicone molds and a vacuum pouring process under precision control, LS Precision typically deliver castings with a finish of Ra 3.2 or better. This degree of quality means that the casting surface is perfectly flat, reducing the amount of material and cost required for downstream finishing (e.g., CNC machining). Certain surfaces are even suitable for use as is.

Summary

Vacuum casting with high precision and density is best suited to the production of high-precision high-end components; centrifugal casting, on the other hand, is best geared towards wear-resistant and pressure-resistant components for symmetrical rotating masses. It is essential to understand the features, cost profile, and usage limitations of each process in order to accomplish product design and manufacturing successfully.

If you need a centrifugal casting supplier for your project or technical assistance from a established vacuum casting manufacturer, don't wait any longer! You can upload a part drawing or elaborate on your needs in detail. LS Precision assure you of delivering a professional process analysis, feasibility suggestion, and clear-cut initial quote within 24 hours.

Upload your design drawings now and get an instant metal casting quote ( metal casting price), let LS be your strong backing in pursuit of ultimate metal casting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com