Online CNC machining services could be a risk for procurement managers and engineers because of certain factors such as a long quotation response time, no quotation response at all, and quality-related concerns. The reasons for such risks could be the low digitization and a lack of transparency with respect to competence for online services. The engineers should analyze online services and online communication systems used by the online services provider.

In this article, you will understand the selection process for a good online CNC machining service. In all the examples shown in this discussion, the instances illustrated take into consideration companies like LS Manufacturing, in which all the analysis and monitoring in their operations are handled in real-time in order to be accurate and precise.

Quick Reference Table For Full Text Of Online CNC Machining Services

| Section | Key Points |

| Introduction |

Barriers: Slow quotes, delay, quality/conivery issue. Problem: Low digitization, unclear capability. Solution: Prepare a guide on the best practices. |

| Core Capabilities |

Critical to include would be instant quoting, DFM, material/process choice, pricing, and quality certifications. |

| Quoting & Feasibility | Process: Upload file, AI/expert review, instant DFM & quote, design optimization facilitation. |

| Transparency | Offers: Provides real time tracking of orders and production and maintains transparency in documentation and communication. |

| Quality Assurance | Systems: In-process inspection, final quality control, cert.ISO 9001), metrology laboratories. |

| Supply Chain | Strong: logistics, inventory management expertise, and capacity for mitigation of risks. |

| Selection Criteria | Assess: technology platform, manufacturing needs, quality management, communication, reviews. |

The online CNC machining services have somewhat leveled the playing field because companies have been buying their needs for a while now. The technology relies on digital intelligence integrated with manufacturing. The ideal company would therefore incorporate intelligent solutions for their online platform with features such as immediate quoting, automatically generated Design for Manufacturing tools, and live monitoring. There is a smooth experience from design all the way through to delivery.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Experience from LS Manufacturing experts It is in this ocean of CNC machining options that are available on the Internet that trust needs to be established on the shop floor. Our advice and expertise that we have developed are in response to the tough properties of materials, as well as the tolerance, in the aerospace and biotech sectors. We do so by strictly adhering to guidelines provided by institutions such as the Society of Manufacturing Engineers (SME), known by the acronym SME, among others.

We are able to provide tens of thousands of custom-made machined components by CNC. Every challenging project we undertook-involving the most critical engine components all the way to those most critical for life-support implants-has given us incalculable experience. It is this experience that drives our expertise on how you can avoid costly errors.

We respect sustainable production. In this respect, we ensure we use the most efficient methods and which do not lead to the wastage of either the final product or the material used to achieve the final product. This is in consistency with the stipulations provided by the Environmental Protection Agency (EPA) but more so as it relates to the sustainable production methods. Throughout the process of your dealing with us through services we provide via the online use of the CNC machining process for your project activities, you will be able to garner the best possible knowledge as opposed to theories.

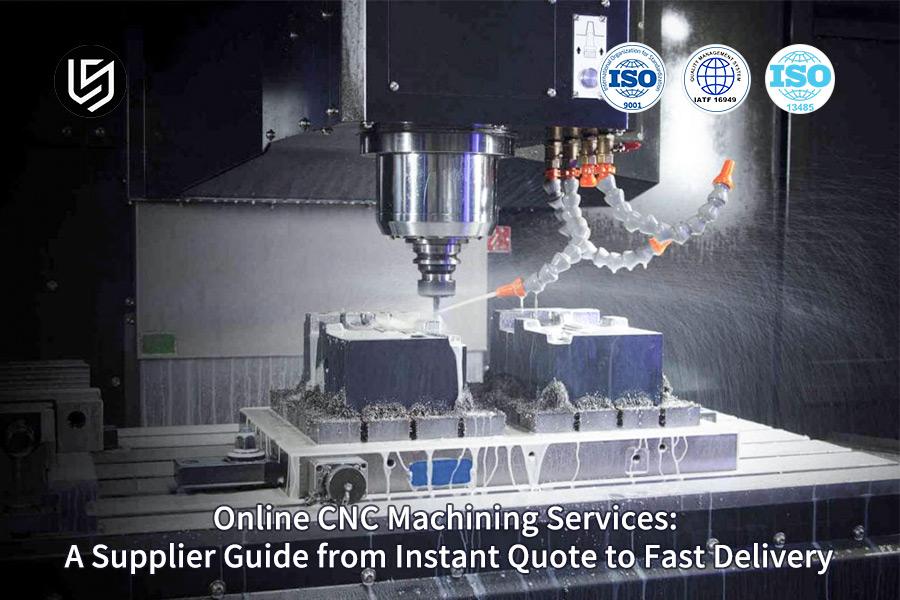

Figure 1: Custom CNC machining parts with active blue coolant by LS Manufacturing

How To Identify Truly Efficient Online CNC Machining Services?

In the present ever-changing scenario, being efficient online CNC machining service is much more complex than just having an online presence. The reliable CNC machining online provider is the one that will be able to harmonize the innovative online platforms and the knowledge base within the engineering / production domain. Efficiency within the domain will depend on three operational key pillars:

Precision within the Process Planning

Precision is the starting point for the trusted CNC machining supplier. Speed within the response time for the ‘instant’ quote will be rendered useless if the precision is lacking. Efficiency will always prove to be unreachable if the precision has to be established on the basis of an infinite and ever-growing library of processes on the benefit of years of machining knowledge.

Automation in Engineering Collaboration

The most effective engineering services are always collaboration tools first and foremost. This implies that from the time you upload, it automatically triggers the execution of the DFM check. Then the key areas are assessed for improvements to be made. This would therefore be the foundation in avoiding the aspect of having to make adjustments in production.

Digital-Physical Synchronization

The challenge in this lies in the fact that it requires real-timevisibility. It requires an optimum level of efficiency, which has to be achieved only through one-time synchronization between the online portal and ERP/MES in the shop floor. It also helps in tracking status in terms of production, materials, as well as machine schedules in a real-time manner. It ensures correct timings for delivery.

It will take more for a person to find a quality online CNC machining service. Real efficiency will be achieved with a reliable CNC machining online platform which has much manufacturing experience, where online flexibility and physical implementation are in perfect harmony and will make truly capable of being a CNC machining supplier.

How Does An Online Real-Time Quotation System Reflect A Supplier's Processing Capabilities?

The instant quote CNC machining is definitely far from being just a cost calculator. In point of fact, it offers first technological proof of capability in the form of a very complex digital imitation of an entire manufacturing process. There is, therefore, a definite level of accuracy on the part of the CNC machining price that is directly related to levels of knowledge.

| Quote System Feature | What It Reflects About Capability |

| Material & Finish Library | It is empowered by automotive DFM analysis on ontap engineering skill set. |

| Automated DFM Analysis | Engineering proficiency in optimizing designs for manufacturability. |

| Detailed Cost Breakdown | Transparent understanding of cost drivers (machine time, setup, materials). |

| Lead Time Accuracy | Mature production planning and shop floor efficiency. |

In final analysis, while the instant quote CNC machining can make available only the window of perfection in the operational activities of a supplier’s side, the exact CNC machining cost online would make available the transparency of perfection in the activities of the supplier’s side and would be designed based on actual knowledge of the process regarding the final cost of approximations rather than possibilities.

In Order To Achieve Rapid Delivery, In Which Process Steps Should Suppliers Optimize?

A really fast CNC machining service is a much more intricate matter than one would consider in attempts to optimize on the speed factor alone. In fact, the really fast CNC machining service is actually a paradigm shift in the entire flow process from design preparation to the inspections and still fulfills all the requirements of a precision CNC machining.

| Process Optimization Area | Method for Acceleration |

| Engineering & Preparation | Concurrent engineering (DFM, quoting, tool path simulation to avoid delay). |

| Shop Floor & Machining | Multiple pallet changers, high Pressure coolant, optimization of cutting factors for shorter cycles. |

| Production Planning | Smart machine scheduling in the entire network via superior ERP/MES systems. |

| Post-Processing & Quality Control | Parallel processing operations such as non-critical processing or inspections done in parallel with other operations. |

In short, a good fast CNC machining service is like an orchestra where all kinds of optimizations are in perfect harmony. It is a method through which a custom CNC machining online gets converted into a smooth process where the processing power of digital technologies meets to generate fast and precision CNC machining parts.

How To Ensure The Quality Control Of Precision Parts In An Online Collaboration Mode?

The hardest part of precision online CNC machining is the concern for the quality. The quality must be assured while carrying out the process unsupervised. The reliable CNC machining manufacturer will solve this issue by setting up an environment concerning quality based on a system that involves the client for the process through the data system.

- Full Digital Documentation: The key to online quality verification is having traceable data. A good CNC machining partner will have digital copies of the first article inspection report, process inspection report, process report, or the final CMM report. These refer to the critical dimensions concerning your features. This forms a chain.

- Comprehensive Digital Documentation: The foundation of remote quality assurance is traceable data. A credible CNC machining manufacturer provides digital First Article Inspection (FAI) reports, in-process inspection logs, and final CMM reports. Each document details critical dimensions against your GD&T callouts, creating an unbroken chain of custody and verification.

- Real-Time Production Monitoring: While reporting was one thing, the reality of transparency has much to do with real-time monitoring. The cutting-edge supplier has an internet-enabled shop floor where the monitoring of job status, machine status, and even cameras for the critical jobs is possible. This ensures that long distance monitoring is set to become more of a two-way street.

- Collaborative Engineering: Quality is design-in, it is not inspected-in. The precision online CNC machining arrangements are those wherein there is potential for commenting on manufacture-ability. A good engineer to engineer communication process, when machining, ensures that any change in direction is corrected right away.

This means that, for quality to be realized in the online model, there has to be a reliable CNC machining manufacturer involved in the process so that the internal control can be converted to the external flow of evidence. The best possible way this can be realized is if the best CNC machining manufacturer has the utmost confidence that distance is not an issue in the production of quality in the precision online CNC machining.

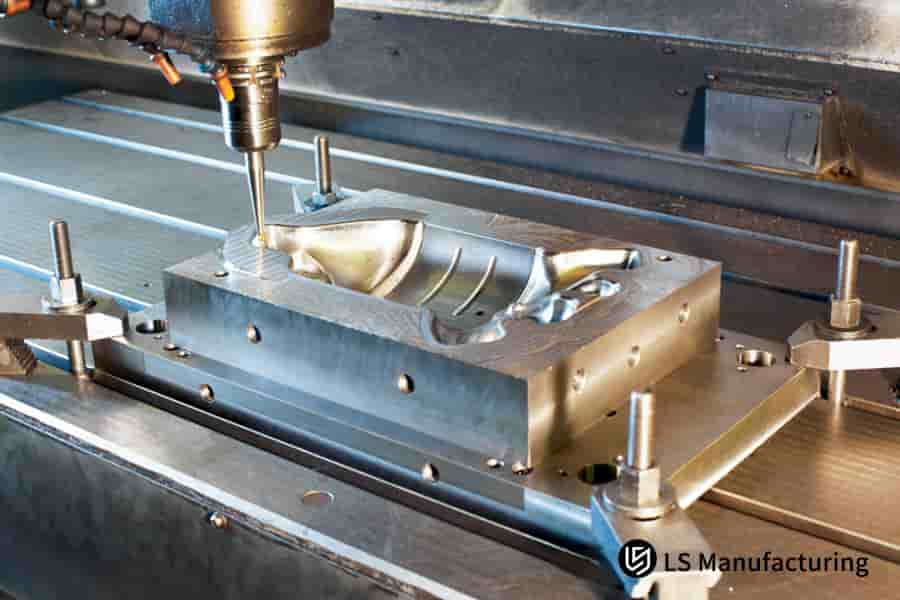

Figure 2: Trustworthy online CNC machining and vendor evaluation platform by LS Manufacturing

How Does LS Manufacturing Customize High-Precision Titanium Alloy Brackets For Aerospace Customers?

This is a comprehensive case study of exactly how the integrated digital manufacturing solution offered by the terms of this competition transforms some of the most daunting obstacles in aerospace industries into lasting market differentiators. This case analysis illustrates in exact detail exactly how an intriguing digital inquiry could become a physical product with premier levels of performance and reliability from the time the first file is uploaded until finished product manufacturing partnerships.

Client Challenge

The aerospace start-up was struggling with the most critical challenge for their satellite development. They needed a short supply of light, strong, and lighter-weight titanium L-brackets featuring complex thin wall sections in a short term. The existing suppliers currently had an 8-weekturnaround cycle to deliver their product and a high cost associated with their geometric complexity. They also took a long time to respond to their strenuous AS9100 certification. They required an online CNC prototyping service their digital designs into certified ready-to-fly parts.

LS Manufacturing Solution

Engagement commenced with an instant quote CNC machining that provided immediate DFM analysis, suggesting a smart design modification to a split configuration for enhanced manufacturability. With the implementation of multiple axes for machining, customized fixtures, and heavy pressure cooling, the compliance with the fast CNC machining service strategy was realized. This strategy minimized setups and rigorously controlled thermal stress, ensuring the precision online CNC machining required for the mission-critical application.

Results and Value

The produced brackets have met the specifications as detailed in the AS9100. The integrated process optimization in the digital era with the processing occurring at the higher level provided a 25% reduction in total cost within a 3-week lead time against the 8-week previous lead time. The fortuitous outcome in the reduction in the lead time has proved invaluable in allowing the optimization in the cycle time in the digital era.

Ultimately, this is the recognition of what is possible within the integrated digital/physical flow. Being able to move from the instant quote CNC machining request to being an exemplary example of the online CNC prototyping service is exactly what enabled LS Manufacturing to complete the fast CNC machining service. This served both to fill the existing need as it also presented the beginnings of future innovation.

Are you ready to produce your precision aerospace components? Get your instant CNC machining price quote now!

What Key Points Should Be Considered When Comparing The Core Capabilities Of Online CNC Machining Service Providers?

When conducting a thorough CNC machining supplier comparison, moving beyond basic quotes is essential. A meaningful evaluation requires a structured look at the underlying capabilities that guarantee project success. This is crucial in determining how to choose a CNC supplier that aligns with your technical and business requirements for a true partnership.

- Technical Skills/Infrastructure: The basis for searching for quality a CNC machining service provider has been its technical skill. It is necessary to check out its skill set for two axis and multi-axis solutions, as well as Coordinate Measuring Machines. Much more important is its respective ISO 9001 and AS 9100 certifications. This reveals an established quality control system.

- Operation Process Transparency: To test them on transparency in operation processes, the world-class supplier can describe the transparency in its operation process through transparency indicators/or facilitators such as the report on DFM, job tracking systems, and pro-active engineering support. The flow of communications from the supplier to your company might include responses to your technical queries that reflect cooperation or distance management.

- Expertise and Business Viability: The level of expertise provided through the application interface by the service supplier has to be judged. Expertise they have demonstrated in the form of case studies related to problem-solving skills, especially in your niche, is always welcome. The other thing one needs to assess is the stability the supplier has, including things like profit levels, supply chain, and data security terms.

In carrying out a CNC machining supplier comparison, a certain harmony must be reached regarding the tangible and non-tangible process. In fact, a prime CNC machining service provider is an exemplary harmony of the most advanced technology and high-quality assurance systems and open cooperation. Being experts in understanding a comparison of a CNC supplier in carrying out such an approach, you shall hold the power in choosing the best one that could not only supply you with the parts but also supply you with the deal.

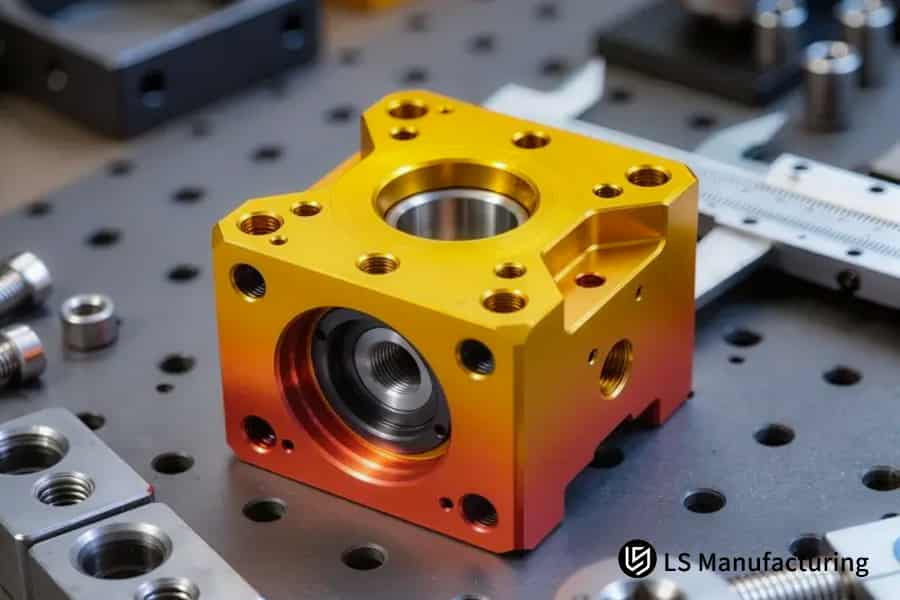

Figure 3: Accurate online CNC machining for intricate metal turbine components by LS Manufacturing

What Are The Different Considerations Between Online CNC Prototyping And Mass Production?

In the situation of custom CNC machining services, the needs pertaining to prototypes as well as manufacturing are very different. In regard to prototypes, the requirement is to be fast and flexible with the aid of online CNC prototyping service. In the aspect of manufacturing, the requirements are to be cost-effective and the ability to produce repeated results much like the requirement pertaining to services related to small batch CNC machining.

Speed and Optimization of Costs

Although speed is the most important relevance of online CNC prototyping service, it is cost optimization for small batch CNC machining. The engineer needs to analyze form, fit, and function as quickly as possible and is prepared to pay a higher cost for it. In the case of small batch CNC machining, the most important relevance is cost optimization.

Flexibilities should rather be exercised during prototyping

This is mainly because, as a prototyping partner, there is a need to exercise flexibility when there is high intensity of design changeovers and when creating individual parts with distinct features. Once there is completion of design, there will be a requirement for a custom CNC machining service having a high level of repeatability. This will mean that all parts will be similar to each other in terms of the product.

Material Strategy & Finishing

In situations where prototype developments are required, material concerns could need to take into consideration existing standards. This is quite handy if evaluation concerning design intentions takes a relatively short time. Surface finish could need to settle on basic necessity pertaining to surface finish. However, if mass production is a concern, specifically small batch CNC machining services, material concerns pertaining to traceability and surface finish ought to be.

In summary, there should be distinction in terms of the development of concepts and the development of products, as far as prototyping and production are concerned. Online CNC prototyping service will therefore help with the process of verification, while small batch CNC machining refers to getting assistance from the right partner, in terms of affordability, with respect to the partner for the small batch production. Even the best custom CNC machining firms will therefore synchronize their process in terms of the life cycle of your product.

Figure 4: Custom CNC machining featuring live blue coolant application by LS Manufacturing

FAQs

1. Will the Internet-quoted price affect the final price?

As you provided accurate 3D drawings, this enabled our pricing engine driven by AI to make a believable price determination. But it is only when areas of optimization are identified by our engineers through analysis related to DFM that the final determination on price will be discussed.

2. What is the minimum order quantity?

We offer a seamless transition from single-piece prototypes to mass production, with no hard minimum order quantity. Whether it's proof of concept or small-batch pilot production, we treat everything with the same care, providing you with truly flexible and efficient manufacturing services.

3. How can I safeguard my design intellectual property rights?

Legal contracts of strict NDA, as well as bank-grade encrypted transmission and storage systems, ensure security. Design data, once complete, can be completely erased based on your need. This creates an all-round information security system so you innovate without worry.

4. What are the key materials that are machined in CNC machining, and how do I need to choose them?

We have hundreds of qualified materials such as aluminum alloys, stainless steel, titanium alloys, and engineering plastics in stock. Our expert engineers can provide scientific material selection analysis along with solutions based on your requirements for mechanical performance, environmental resistance, weight reduction, and cost considerations.

5. What are surface treatment options?

We have very advanced surface treatment processes, including anodizing, sand blasting, passivation, electroplating, and spraying. These processes not only give it a better aesthetic appeal but improve the wear resistance, corrosion resistance, or conductivity of the component. It achieves this by balancing functionality and aesthetics.

6. What are common tolerance standards?

It can be achieved with stability in ±0.025mm regarding the standard machining tolerance. We perform ultra-precision machining through five-axis simultaneous machining and temperature measurement because of the requirement for precision work in the precision of ±0.005mm.

7. Would you have an assembly service?

Our company also offering integrated manufacturing services in a one-stop process ranging from precision machining, surface treatment, and component assembly to assembling and quality-checking. In fact, with an expert workshop in assembling and quality-checking procedure, it is ensured that it is reliable so that the supply chain management for valued clients is greatly reduced.

8. Problems regarding the acceptance of the parts?

We practice 100% quality responsibility. As soon as we notice any issue, we start an traceable process and present solutions through rework, replication, and rapid replacement in 24 hours. This is for ensuring your rights in the project development phase are guaranteed.

Summary

Again, we emphasize through this document that the identification of CNC machining service providers is a technical task. Based on the immense knowledge we possess in the technical world, attained by us at LS Manufacturing, along with the transparent way through which we conduct operations in cyberspace, we at LS Manufacturing recognize the first contradiction in the posed problem.

Reasons why your project qualifies for optimal support: Upload your 3D files now and get a free and quick quote and a Design for Manufacturability study in a matter of hours. Otherwise, simply contact our technical experts and participate in a consultation to help engineer and find the most optimal and affordable solution for your custom prototyping and production requirements.

Delivery delayed? We offer online CNC precision machining to ensure your project stays on time with flexible and efficient productivity. Contact us now for a quick response.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.