Did you ever have to balance metal casting vs. CNC machining? Faced with the process of creating products, do you find yourself often irritated by the difficulty of achieving precision in castings, or by the high material wastage and high cost of having fully CNC machined parts, thereby impacting the final project cost and delivery timeline?

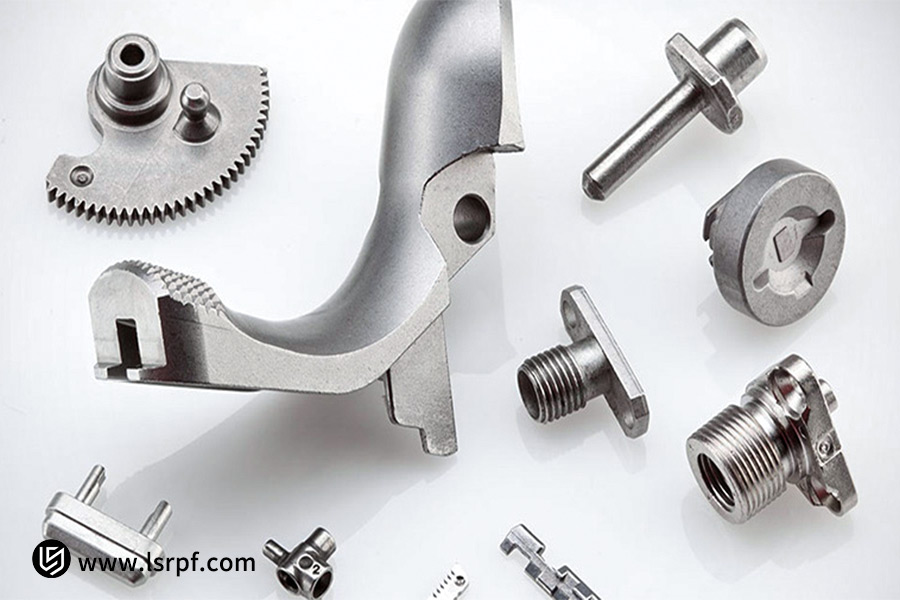

In fact, metal casting and CNC machining are not competing technologies; rather, they are a perfect synergy. Combining profoundly the virtues of both, creating a "casting + machining" joint process, is the optimal solution for low-cost and effective production. LS Manufacturing is not just a standalone provider of metal casting and CNC precision machining, but an uncommon industry partner that provides highly integrated manufacturing solutions.

We are experts at leveraging collaborative processes to drastically lower total costs and truncate manufacturing cycles for our customers, sidestepping the production issues of intricate parts. If you have a specific part drawing, please upload it now and receive a free, customized "casting + machining" combined solution and precise quote from LS Manufacturing engineers. To save you time, here’s a quick overview of the core conclusions.

Metal Casting vs. CNC Machining Main Comparison Quick Reference

| Dimensions | Metal Casting | CNC Machining |

| Process Principle | Liquid metal is poured into a mold cavity, cooled, and shaped. | A computer-numerically controlled tool cuts away material from the solid blank. |

| Key Advantages | Very good at producing intricate internal cavities and geometries; well-suited for mass production with low unit costs. | High precision, good surface quality, and good control of tolerances; well suited for a wide range of batch sizes, but especially small batches and prototypes. |

| Major Disadvantages | Relatively poor dimensional accuracy and poor surface finishes; often require follow-on machining. | High scrap factor (subtractive process); difficult and costly machining of complex internal cavities. |

| Economic Scenario | Highly cost-effective per-part cost in high-volume production; able to cast intricate parts in one piece to reduce assembly. | More economical to produce low-volume runs of high-precision parts; minimal or no tooling expense, and instant start. |

Metal casting and CNC machining are not duplicative, but complementary. Ideal manufacturing approach most frequently is a "cast first, then mill" cooperative model:

- Metal casting: By applying casting to quickly prototype intricate part blanks, we realize material and structure layouts that are efficient in nature;

- CNC machining: CNC machining subsequently does high-precision milling of vital mating surfaces and holes to a perfect blend of cost-effectiveness and precision. This is the final route to cost minimization and the improvement of efficiency.

4. Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The principles found here are not theoretical; they are working rules honed by LS Manufacturing on hundreds of advanced projects. We're aware that classroom process boundaries will get fuzzy in actual production; the real challenge is to use them creatively in combination. LS Manufacturing helped a customer maximize a large aluminum alloy housing part, for example. This portion of the part was complex in its internal structure, and using just CNC machining would have resulted in a material usage rate of less than 30% and a process that was lengthy.

LS Manufacturing solution: Using precision sand casting to create the main blank with a machining tolerance of 2-3mm and then using a five-axis CNC center to precisely machine all the mounting interfaces and precision holes within one pass. This cooperative strategy ultimately saved the customer over 40% of the unit cost and halved delivery cycles.

LS Manufacturing's experience in resolving countless special problems, such as thin-walled castings deformation control and clamping and positioning for structural special-shaped parts, allows it to provide manufacturing solutions that not only are accurate but are also truly economical and feasible.

Why Is "Casting + CNC Machining" The Golden Combination For Complex Part Manufacturing?

In the case of complex-structured components, inner cavities, curved surfaces, or thin walls, a single process cannot solve them. The "casting + CNC machining" cooperative method conquers such challenges and has been widely adopted as the recognized golden rule in complex part manufacturing. Its inherent advantage is to keep optimal synergy between the two processes and yield an overall benefit of "1 + 1 > 2."

1. Limitations of a Single Process:

- Metal casting: While it can cast complex shapes to "near net shape" at low casting costs, its surface accuracy, tolerance, and mechanical properties in sensitive regions cannot be met directly to the high-requirement assembly requirements.

- CNC machining: While it can create very high accuracy and finish, it is machining from solid material. For complex parts, this means enormous waste of material and too much machining time, leading to a gigantic rise in cost.

2. Synergistic Advantages of "Casting + CNC Machining":

- Metal casting (such as sand casting or precision casting) is used to rapidly produce sophisticated part blanks with perfect closeness to final product shape (near-net shape), forming a cost advantage.

- CNC machining processes precisely complete assembly interfaces, keyholes, and high-precision tolerance surfaces, guaranteeing completely the final size and performance of the finished product.

Such synergy between CNC machining and metal casting provides maximum cost effectiveness and accuracy.

3. Achieving Overall Cost Optimization:

The combined approach of casting + CNC machining significantly reduces the original raw material investment and amount for CNC machining cutting required, significantly lowering the cost of material and machining time. It actually removes the two main disadvantages of the imprecision of pure casting and the material wastage of pure machining, providing the overall cost optimum solution for making complex parts for the whole life cycle.

With such strong synergy, LS Manufacturing can make complex metal parts which are "impossible" or "uneconomical" to make more economically and efficiently.

How Can Collaborative Design Reduce Total Production Costs From The Outset?

The majority of cost issues actually are resolved in the design phase. The key to cost-effective manufacturing is to integrate thinking about manufacture into the design, the leading philosophy of co-design and DFM advocated by us. As your strategy partner, LS Manufacturing's engineers will intervene early and work with you to maximize your plan, initiating the next "casting + machining" co-design cycle. Co-design benefits you by:

1. Accurately reserve machining allowances for maximum efficiency:

With final performance requirements of the part, LS Manufacturing can help you develop precise and consistent machining allowances for subsequent CNC machining. This avoids casting surface defects that cannot be removed by insufficient allowances, or unnecessary machining time and tooling costs by over allowance, making way for cost-efficient production to begin with.

2. Structural Optimization and Integration to Reduce Processes and Assembly:

Drawing on a background of extensive experience in integrated manufacturing solutions, LS Manufacturing engineers look into the potential for casting multiple individual parts simultaneously, eliminating necessary assembly phases and connector costs.

As an additional suggestion, we recommend eliminating complex features difficult to machine or cast, for instance, replacing deep holes with drilling afterward or reinforcing thin forms in an effort to prevent deformation when casting, thereby significantly increasing yield. By performing all this detailed, upfront work, LS Manufacturing is able to anticipate potential manufacturing risks and cost savings before they even arise.

It's this integrated manufacturing solution that LS Manufacturing delivers which gives it an edge over stand-alone machining services, eventually enabling you to bring high-quality products to market earlier and at a lower overall cost.

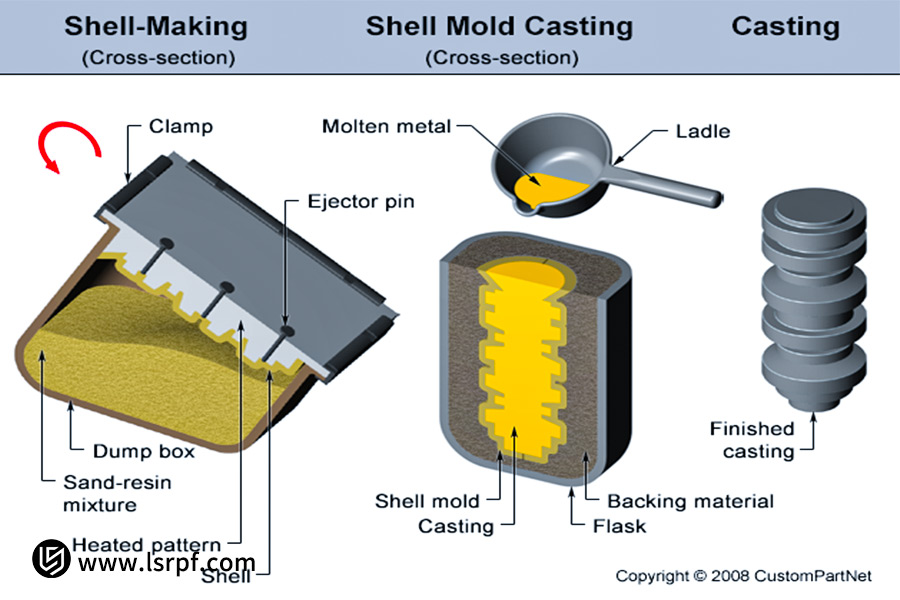

How Should Common Metal Casting Processes Be Paired With CNC Machining?

Accuracy, surface finish, and blank machining allowance from different metal casting processes vary greatly, directly affecting subsequent CNC high-precision machining strategy and cost. To make an optimal process plan, these interactions must be understood.

1. Sand Casting + CNC Machining:

- Casting Features: Well-suited for making very large and complicated blanks at a relatively low cost but also produces rugged surfaces, enormous tolerances, and typically requires big machining allowances.

- CNC Machining Considerations: After CNC precision machining assumes the important task of "reshaping" the part. The art is to first correctly position the datum, and then perform "rough machining + finish machining" on all the functional surfaces in a way as to remove excess stock and achieve the dimensional accuracy and surface finish called for in the drawing. This method is employed in order to counteract the inherently imprecise precision of sand castings.

2. Investment Casting + CNC Machining:

- Casting Features: It can produce small, near-net-shape components with extremely complicated shapes, with higher surface quality and tolerance control than sand castings.

- CNC Machining Considerations: Given that the casting itself is already very near its ultimate shape, CNC precision machining requires only a few critical areas of precise fit requirements (such as threaded holes and high-precision mating surfaces). This radically reduces the level of machining effort required, weighing efficiency and cost to the finest precision.

3. Die Casting + CNC Machining:

- Casting Features: Best suited for the mass production of thin-walled parts, it is energy-efficient and has a good finish. The castings are prone to internal porosity, though the hard, brittle surface top layer is not suitable for cutters.

- CNC Machining Considerations: The focus is to remove the hard, brittle surface layer and produce a dense inner metal layer. Controlled parameters and sharp carbide tools have to be employed to prevent chipping and increased wear. Minimal finishing is performed on critical points such as mounting surfaces and hinges.

By precisely coordinating processes, we maximize the value of each step, which translates into an effective and affordable overall manufacturing solution whilst meeting technical requirements.

LS Manufacturing Helps Reduce Lead Time For Key Articulated Arms In Industrial Robots By 35%

In high-end equipment production, production of complex core pieces is usually the last cost and efficiency test. One of our LS Manufacturing examples vividly shows the way combination between CNC machining and casting can overcome this obstacle.

1. Customer Pain Point:

An established industrial robot firm had a major challenge with its design of a core articulated arm piece for its next model. This component was enormous and contained complex, irregularly shaped cooling channels. CNC machining alone would result in more than 60% material waste, and the machining cycle time would be weeks, which would be extremely expensive. Conventional casting would lack the accuracy and roughness specification of the critical bearing mounting surfaces for high-precision long-term use.

2. LS Manufacturing Integrated Solution:

In order to address this challenge, LS Manufacturing provided a synergistic solution that combined precision sand casting with a five-axis CNC machining center:

- Rapid Prototyping and Near-Net Shape: We first utilized the precision sand casting technology to cast a part blank in a single pass economically with complete internal cooling channels. This process allowed for structural complexity and intense material usage, which was the beginning of rapid prototyping of the main body.

- Precise Control and Performance Assurance: The blank casting was then transferred to our five-axis CNC machine center. CNC precision machining of all the difficult bearing mounting surfaces, sealing surfaces, and threaded holes was done with precision in one single clamping operation. This not only precisely assures millimeter-level tolerances and high surface finish, but assures hassle-free coordination between casting and CNC.

3. Result and Value:

This solution blended smoothly theory-promises and quantifiable business value:

- Material expense was reduced significantly: Raw material savings compared to a fully machined solution were over 40%.

- Overall costs were significantly reduced: Overall production expense was reduced by nearly 30%.

- Efficiency of delivery was significantly enhanced: Because of the simplified process path, overall delivery cycle duration was reduced by an astonishing 35%.

The success of this case of LS Manufacturing production not only met the short-term needs of the customer but also earned their long-term trust, which developed a good strategic alliance between the two.

How Can These Two Technologies Be Flexibly Utilized In Rapid Prototyping?

In the harsh world of product development, rapid prototyping is not just creating a prototype but also quickly testing out designs and gaining market response. LS Manufacturing understands this and can seamlessly combine metal casting and CNC machining to provide the most suitable rapid prototyping method based on your prototyping objectives.

1. Prototypes for Functional Testing:

If your prototypes must undergo comprehensive mechanical and thermal test stress, the authenticity of the material itself is very significant. Under normal circumstances, we would employ a "3D printing sand mold/investment mold + metal casting + CNC machining" method.

This approach effectively develops metal prototypes of the same material as the end mass-produced product. Targeted CNC precision machining is subsequently applied to ensure the accuracy of critical zones. This makes the functional test results of the prototypes very valuable, providing valuable data support for subsequent small-batch and even mass production.

2. Prototypes for Design Verification and Display:

If your primary goal is to quickly inspect structure assembly, inspect appearance, and inspect ergonomics, we recommend an alternative that is more efficient. For complex structures, "3D printing with high-performance resins/melts" can be used for direct construction of the entire model; for simple structures, "direct CNC milling of soft metals (such as aluminum)" can be used.

These strategies emphasize economy and speed so that you can test several design iterations in the shortest amount of time, significantly cutting R&D time and paving the way for finalization and trouble-free production launch of small runs.

With this goal-oriented and flexible blend, LS Manufacturing ensures every prototype investment reaps rewards, efficiently advancing the product from idea to market.

Is "Casting + Machining" Still Economical For Small-Batch Production?

Previously, metal casting was conceived to be feasible only for mass-volume orders with a high cost of tooling. Modern manufacturing technology has paid out this general perception entirely. For short-run production on high-value machines, aerospace, and special equipment, synergistic metal casting and machining solutions optimized to their maximum potential are not just an option but can even deliver superior economics compared to machining. Cost benefits for small-order requests are realized by LS Manufacturing through:

1. Revolution in Mold Technology:

LS Manufacturing applies 3D-printed sand molds and investment mold technology, enabling "moldless" molding. Complex casting blank production no longer uses expensive traditional steel molds, halving initial cost and lead time on small batch orders. Complex structural blanks casting becomes affordable for the first time on small batch production.

2. Maximizing the Value of Flexible Manufacturing and Collaborative Processes:

In small production runs, LS Manufacturing's elastic manufacturing system enables rapid response. By quickly casting blanks and subsequently CNC precision machining key features, we reduce the enormous material and labor investment tied up in cutting finished complex parts from solid stock. This hybrid of metal casting techniques inherently beats single subtractive manufacturing on the basis of material use and overall cost.

No matter how small your order of just a few dozen parts or more, there is no compromise on price and performance. LS Manufacturing's combined solutions allow you to realize the savings in cost and efficiency associated with collaborative processes even with small runs, and you can more easily make complex metal components at reduced cost.

What Are The Advantages Of Choosing A One-Stop Integrated Supplier Over Outsourcing?

When one is given the traditional model of outsourcing of "first finding a foundry, then a machining shop," project management is significantly increased in complexity and risk. Choosing a partner like LS Manufacturing, which offers highly integrated manufacturing capabilities, yields advantages far beyond process cooperation extending as far as the whole process of implementing the project. The basic advantages of LS Manufacturing's one-stop integrated capabilities include:

1. Unified Responsibility, Fully Controlled Quality:

From blank casting to CNC finishing, the whole process in LS Manufacturing is under one system of quality management. We coordinate the processes internally so that you don't incur the cost of coordination and arbitration in having the quality issues go around between the foundries and machine shops. You are guaranteed consistent and reliable quality in the finished product.

2. Efficient communication and shortened overall cycle time:

Seperate outsourcing requires you to act as an "intermediary project manager," communicating information and tracking progress between two or even multiple suppliers. Our integrated manufacturing solution provides one point of contact, with easy communication between internal process groups. This reduces information errors and wait times dramatically, reducing the total lead time from drawing to qualified parts significantly.

3. Optimized processes for true peace of mind:

LS Manufacturing can design the entire manufacturing chain from design time, e.g., design machining standards to be appropriate for the structure of the casting. This holistic method avoids issues with inadequate process integration and heterogeneous benchmarks that can result from employing independent outsourcing.

LS Manufacturing can provide an end-to-end manufacturing solution with properly defined tasks, open processes, and controllable results so that you can actually focus on your core business and save effort.

What Capabilities Should You Focus On When Evaluating An Integrated Manufacturing Partner?

In selecting a partner capable of achieving the "casting + machining" integrated process, in-house machining ability alone cannot serve to resolve intricate part production issues. A comprehensive assessment checklist can help you find authentic experts and ensure that your project is completed as you expect in terms of cost, quality, and cycle time.

| Evaluation Dimensions | Key Points | LS Manufacturing Practices |

| Deep Process Understanding | Are you experienced in collaborative design for manufacturing (DFM) and able to optimize part structure and allocate machining allowances from origin? | The engineering team engages early on to provide design reviews and optimization suggestions to achieve maximum manufacturability. |

| Equipment and Technical Capability | Do you have casting technologies (such as precision sand casting and investment casting) and advanced CNC precision machine tooling (such as five-axis CNC) for high-precision part manufacturing? | You have diversified casting lines and a number of five-axis CNC centers in order to maintain internal control of the entire process, from molding to finishing. |

| Quality Assurance System | Do you have a standardized system of quality inspection and documentation throughout the entire process (from raw materials, casting, to machining)? | You conduct full-process IPQC inspections from material receiving to final shipment with data traceability in order to ensure consistent quality for every single product. |

| Project Management and Experience | Do you have successful case histories of complex part production? Is the project communication process clear and transparent? | We have numerous successful examples of LS manufacturing, such as robot articulated arms, and provide a specific project manager to each customer for easy communication. |

A good integrated manufacturing partner is a lot more valuable than just piling up equipment. It must be able to deeply integrate process knowledge, engineering knowledge, and quality control in order to provide you actual reliable and effective combined CNC precision machining and molding services, and become your one-stop manufacturing extension.

Why Choose LS Manufacturing As Your Partner?

With so many suppliers to choose from, you need more than a simple implementer; you need a strategic partner who completely understands your needs and provides real value to you. LS Manufacturing is committed to being this partner, and our integrated manufacturing solutions are based upon the following four main benefits.

1. Experienced Team of Process Experts:

LS Manufacturing has a group of multidisciplinary engineers who are not only knowledgeable in casting characteristics but also highly qualified in machining operations. They can scrutinize your design at the beginning of the product life cycle to ensure that your design achieves the optimal balance between cost, manufacturability, and performance. This is the technical aspect of our combined manufacturing solutions.

2. Seamlessly Integrated Production Line:

LS Manufacturing possesses its own foundry plant and advanced CNC machining plants. This in-plant concentration, along with an integrated production management system, offers data sharing and seamless process flow from rough cut to finished product, removing completely communication failures and time wasted with outsourcing as well as ensuring highly manageable delivery cycles.

3. Full-Process Quality Control System:

We are strongly convinced that excellent quality is a result of design and management. From receipt of the raw material to shipment of the finished product, we adhere to standardized quality inspection and traceability of data throughout the whole casting and machining process, where every product we supply to you is highly consistent and dependable.

4. Customer Success-Driven Partnership:

We feel like an extension of your manufacturing and R&D staff. LS Manufacturing's goal is not to merely fill orders, but to help you reduce overall cost and enhance market competitiveness by trading experience and co-optimizing products, and through it all, enjoy shared success and sustainable growth.

FAQs

1. Will collaborative production lead times be longer than pure machining?

For products with complex structures or internal cavities, joint production tends to have quicker lead times than single-source machining. This is because preparing the rough casting cuts can be done simultaneously with CNC programming and tool setup. Much more important, near-net-shape blanks reduce allowances to be machined and significantly shorten processing time. LS Manufacturing's vertically integrated production systems and seasoned project management ensure that all processes are smoothly integrated together, eliminating the attendant waiting times of traditional outsourcing and reducing total cycle time.

2. What materials can you cast and process?

LS Manufacturing boasts enormous material processing facilities, handling an enormous range of metals including aluminum alloys, zinc alloys, stainless steel, ductile iron, and carbon steel. Not only do we finish off the casting of these materials, but also perform subsequent precision machining. For specialized requirements, we also offer high-temperature alloy solutions and material certification to industry standards, coping with high-end manufacturing's stringent material traceability specifications.

3. How do you ensure consistent quality from casting blanks to machining?

LS Manufacturing has consistent quality through an integrated full-process quality assurance system. All steps, from raw materials to finished goods, are performed in-house. Every batch of blanks is exhaustively subjected to preliminary dimensional, surface, and non-destructive testing before processing, so that only qualified products are processed through to the next stages of processing. Such a "prevention-first" quality management system, along with full traceability of data, guarantees high yield and consistency in the final product.

4. Can I entrust you with only CNC machining, while I provide the casting blanks?

Yes, LS Manufacturing can provide clean CNC machining of customer-provided blanks. For ultimate end quality assurance, we strongly suggest professional incoming material quality inspection. Shrink cavities and pinholes in blanks, which do not become apparent later on, can lead to scrap parts and significant loss. Choosing our single-source service allows you to ensure quality at the source, with single-source responsibility and lowest cost.

Summary

A joint manufacturing process closely coupling metal casting with CNC machining is the sole viable method of economically and efficiently manufacturing intricate metal pieces. It ideally leverages the strengths of each process, giving the best combination of "low-cost molding" and "high-precision control" and simultaneously un-paralleled cost, efficiency, and quality benefits to firms.

Choosing LS Manufacturing is not choosing a supplier; it's choosing a strategic partner dedicated to making your supply chain and product as competitive as possible. With our deep process expertise, vertically integrated supply chain platforms, and quality control procedures, every component of every project is designed to optimize the trade-off among efficiency, cost, and quality.

Forward your part drawings or specifications today and our expert team will get back to you within 4 hours with a complete process analysis, cost estimate, and production cycle report! Contact LS Manufacturing and upload your design drawings now and get an instant metal casting quote ( metal casting price), let LS Manufacturing be your strong backing in pursuit of ultimate metal casting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.