When a screw ruins a perfect panel

Imagine:You receive a batch of valuable, perfectly finishedanodized aluminumpanels. During assembly, a standard flat-head screw cannot fit neatly into the countersunk hole - either the edge is lifted up to leave a gap, or the bottom is suspended to form a "seesaw". A batch of expensive parts is instantly at risk of being scrapped.

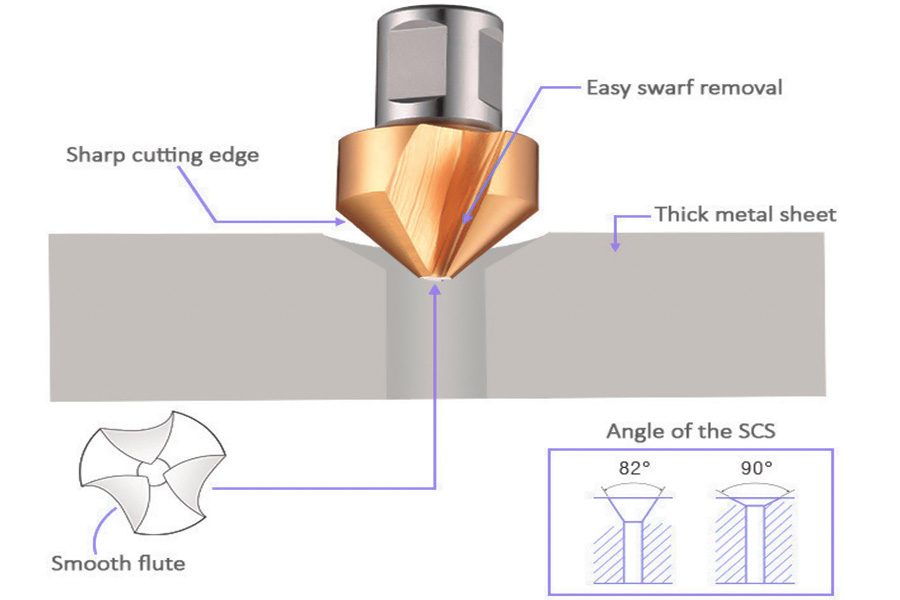

The root of the problem is likely the 8-degree difference between the countersunk hole (82°) and the countersunk hole (90°). This tiny angle difference is difficult to detect on the drawing, but it is ruthlessly magnified in the precise world of metal contact, resulting in a serious mismatch between the screw and the hole shape.

You may wonder: Aren't all countersunk holes 90 degrees? What is 82 degrees?This is not nitpicking. In the field ofprecision manufacturing, choosing an82° or 90° countersunk holeis a key decision involving the standard system, tool matching, ultimate reliability and aesthetics. The wrong angle can lead to assembly failure, stress concentration, loose connections, and even direct destruction of the workpiece.

So, what is the mystery of this fatal 8-degree angle?

82° countersunk holesoriginate from specific high-strength standards in aerospace and other fields (such as ANSI/ASME), requiring special screws and tools.

90° countersunk holesare more common metric/universal standards.

Confusing the two is costly.

This article aims to clearly explain the origin, standards, application scenarios and selection points of 82° and 90° countersunk holes for you, helping you to accurately avoid this "destructive 8 degrees", ensure that every assembly is perfect, and protect your design results and precious budget.

An 8-degree difference is the beginning of destruction. Choose the right angle and tighten easily.

Clear Comparison Table Of Countersunk Hole Angles And Screw Standards

| Standard system | Countersunk hole angle | Typical applicable screws | Main application areas/industries |

|---|---|---|---|

| Unified/Imperial | 82° | #4-40, 1/4"-20 and other American screws | United States, Canada and industries that follow ASME/ANSI standards (such as aerospace, traditional manufacturing) |

| Metric | 90° | M3, M5, M8 and other ISO metric screws | Globally used (Europe, Asia, Australia, etc.), ISO standard fields (such as automobiles, electronics, machinery manufacturing) |

This guide will thoroughly explain why there are two standards, 82° and 90°, show the disastrous consequences of mismatching, and through a real case analysis, teach you how to correctly mark on the drawing, ultimately ensuring that yourCNC machined partsare foolproof. "

Here’s What You’ll Learn:

- 30-second decision rule:A simple framework to immediately determine whether your project should use 82° or 90° countersinks.

- The truth behind the angle dispute:Analyzing the design logic, strength differences and historical roots of 82° (American Standard) and 90° (ISO).

- Warning of catastrophic mismatch:Illustrated explanation of how an 8° angle difference can cause screws to "float", loosen or even scrap the workpiece.

- High-end audio panel rework case:A real lesson from a $15,000 loss, see how vague drawing markings can cause manufacturing disasters.

- Engineers' Quick Reference Manual:Countersinkmarking specifications, size comparison tables and professional tool selection guides for steel processing.

- Ultimate FAQ:Answers to key controversial questions such as "Can angles be mixed?" and "How to measure existing countersinks?"

Now, let's uncover the engineering truth behind the standard dispute and put an end to assembly errors caused bycountersink angles!

Why Should You Trust This Guide? Experience From LS Quality Inspection Station

I’m Gloria, a manufacturing engineer at LS. This guide to countersink design is based on real lessons learned by our QC team behind microscopes and measuring instruments, not just theoretical advice.

Countersink angle: small differences, huge costs

Rejection due to incorrect countersink angles is a frequent problem at theLS QC station. In-depth analysis reveals that theroot cause is often in the design source, not the workshop. “Standards” are very regional: American engineers default to 82° or 90°, while German counterparts often use 90° or 120°. If the drawings do notclearly mark the angle, the workshop will process it according to the “conventional” method, which will cause the screws to not fit, the function to fail, and cause returns and cost waste. We know that clear marking is crucial - this is one of the core points of the guide.

Metric/Imperial Confusion: The Value of DFM Review

When conducting a DFM review for a multinational customer, we found that the imperial parts designed by their US team had countersink specifications in key locations that incorrectly matched the planned metric screws (such as an M6 threaded hole with imperial countersink parameters).This problem before CNC startup saved the customer from scrapped parts, production line downtime, and tens of thousands of dollars in losses. This demonstrates the extreme importance of rigorous cross-validation of unit systems and standard parts matching during the Identify design phase.

Guide: From practical experience, aimed at prevention

This guide condenses the essence of our internal knowledge base for dealing with such problems. It understands the subtle differences between standards such as ASME and DIN, covers key parameters of metric/imperial screws, and makes it clearer about the production consequences of ambiguous markings on drawings. Clear goal: Provide clear specifications to help engineers avoid pitfalls when drawing, andimprove the manufacturability and quality of designs from the source.

Trust comes from practical experience and problem-solving ability. This guide carries the professional vision of LS Quality Inspection and is willing to be your trusted reference.

The Root Of The Angle Debate: Imperial vs. Metric Standards

“The answer to this question is not which angle is ‘better’, but which measurement system you use for the screw.”

Overview of countersunk screw angle standards

| Features | 82° camp (US) | 90° camp (metric/ISO) | Other angles (special cases) |

|---|---|---|---|

| Standard system | Imperial (US unified standard) | Metric (international standard) | Standards for specific application areas |

| Typical angles | 82° | 90° | Common 100°, occasionally others |

| Applicable standards | ASME/ANSI (US) | ISO (international) | Industry-specific standards (such as aerospace) |

| Application range | US standard machine screws, bolts (#2, #4, #10, 1/4", 3/8", etc.) | Global standard metric screws (M3, M4, M6, etc.) | Specific scenarios (such as thin-skin connections in aviation) |

| Main reasons | Historical engineering balance: strength and load-bearing area | Easy to measure and process, global uniformity and convenience | Meet special needs: larger load-bearing area, stress reduction |

82° Camp: American Unified Standard (ASME/ANSI)

- Core explanation:In American engineering practice, all standard flat head/countersunk head screws that follow the American Unified Standard (developed by ASME/ANSI) have a unified angle of 82°. This covers a wide range of sizes from small machine screws (such as #2, #4, #10) to common bolts (such as 1/4", 3/8").

- "Why 82°?":This specific angle is not randomly selected, but the result of along history of engineering optimization. It is designed to achieve the best balance between the strength of the screw head (avoiding the head being too thin and fragile due to too small an angle) and the effective bearing area of thecountersunk hole(ensuring that there is enough contact area between the conical surface of the screw head and the conical surface of the hole to disperse the tightening force). 82° is considered to be the most effective way to disperse the huge pressure generated during tightening to the conical bearing surface of the hole, providing a reliable connection.

90° Camp: International Organization for Standardization (ISO)

- Core Explanation:In most countries and regions around the world that adopt the metric system, ISO standards are the cornerstone of engineering practice. According to ISO regulations, the head angle of all standard metric flat head/countersunk head screws (such as M3, M4, M6) is clearly defined as 90°.

- "Why 90°?":The underlying basis for choosing 90° ispracticality and normalization. 90° is an integer angle, which isfar simpler, more precise and less expensive in manufacturing (tool manufacturing, tool machine adjustment), measurement (angle gauge, projector test) and quality inspection. ISO adopted it as the global unified standard for the metric system, which considerably improved engineering cooperation, part interchangeability and international trade among various countries and manufacturers, and eliminated the compatibility barriers created by non-standard angles.

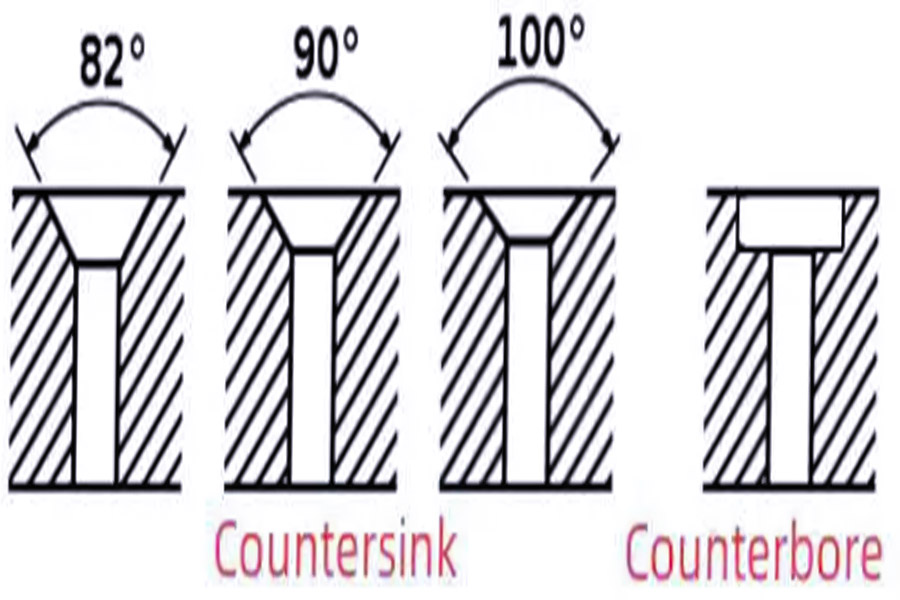

Less familiar exceptions: 100° and other angles

- Breadth of coverage:While82° and 90° are the absolute norm, to recognize the special cases will demonstrate the real depth of expertise.

- Fundamental explanation:Most familiar special case is the100° countersink hole,which is common in theaerospace sector. It is used mainly to fit thin metal skin panels. The main reasons for using 100° (versus 82° or 90°) are:

Increased bearing surface:The softer angle (100° is softer than 90° and very much softer than 82°) produces the impression that the contact area between the screw head and thin sheet material is larger for a given head size. This is especially useful in thin sheet structures where supporting the load is a required condition.

Reduced stress concentration:The slow variation of the angle also helps in a more uniform distribution of the load, and this leads to significantly reduced stress concentration at the hole edge, and therefore much reduced danger of fatigue crack or thin sheet material deformation at the fastening location. These unique angles must be specified or chosen by engineers for a specific application (material thickness, type of load).

The difference in countersink head angle of the screw (82° vs. 90°) is between the two historical parallel system standards of the global engineering community: the British (American) and the metric (ISO).The ASME/ANSI United States-controlled standard chose 82° based on historic engineering optimization in order to achieve a compromise between strength and load efficiency. The ISO metric standard used in most of the world chose90°based on ease of manufacture measurements and uniformity. Moreover, to address special difficulties like thin plate connections, some industries (like aerospace) will employ non-conventional angles like100°to achieve a bigger load-carrying surface and minimize stress concentration.

Therefore, the answer to the issue is not in what angle is "better" (they are both best solutions in their own systems), but in eliminating the specific standard system (English/American or Metric/ISO) employed by the existing project or component, or special requirements for special usage conditions (i.e., thin plates for aviation).Understanding of the standard origins to this "angle controversy" is essential to correct selection, application anddesign of countersunkscrew joints.

Catastrophic mismatch: An 82° screw meeting an 90° hole

"An 8-degree difference may appear to be nothing, yet in mechanical assembly it is the difference between 'perfect' and 'scrap'." The secret of a sure union is in the precise matching of the cone angle of the screw head (usually 82° for imperial and 90° for metric) with the cone angle of the countersunk hole. Small variation of angle can lead to a colossal change in the conditions of force and generate huge effects. The following table provides two typical mismatch situations:

| Characteristics | Case 1: 90° metric screw placed in 82° imperial hole | Case 2: 82° imperial screw placed in 90° metric hole |

|---|---|---|

| Contact point | The bottom of the screw cone first contacts the hole opening | The upper edge of the screw cone first contacts the hole wall |

| Contact type | Line contact at the hole opening | Line contact at the outer edge of the screw head |

| Gap position | There is a gap between the upper edge of the screw cone and the hole wall | There is a gap between the bottom of the screw cone and the bottom of the hole |

| Screw status | Unable to be properly centered, partially sunk into the hole | "Floating" on the hole, unable to sit completely flat |

| Main risks | The edge of the hole opening or screw head is crushed | The outer edge of the screw head is deformed or the hole wall is damaged |

| Common consequences | Insufficient tightening force, easy loosening, connection failure | Insufficient tightening force, easy loosening, connection failure |

Case 1: 90° Metric Screw Placed in 82° Imperial Hole

- Contact Mechanism:Since thecountersink taper angle(82°) is smaller than the screw headtaper angle(90°), the bottom of the screw taper (close to the threaded shank) will first contact the sharp mouth of the countersink edge. The upper part of the screw taper cannot contact the wall, forming a significant annular gap between the two.

- Consequences:

- Extremely small contact area - line contact:Contact only occurs on a narrow circumferential line at the edge of the countersink mouth. This results in extremely high pressure (force per unit area) in the contact area.

- Stress Concentration and Damage:The huge tightening force is concentrated on this thin line at the edge of the countersink, which can easily cause the hole mouth material to collapse (deform or break). Similarly, the edge of the screw head contact area may also be squeezed, deformed or broken.

- Cannot be centered:The screw cannot sink to the bottom of the hole and center itself, and its position is unstable.

- Very easy to loosen:The extremely small contact area and stress concentration make the connection extremely sensitive to vibration, the preload will decay rapidly, the screw will easily loosen and fall off, and completely lose the tightening function.

Case 2: 82° imperial screw placed in a 90° metric hole

- Contact mechanism:Since the countersink taper angle (90°) is larger than the screw head taper angle (82°), the upper edge of the screw head taper surface (close to the top of the screw head) will first contact the side wall of the countersink. The bottom of the screw taper surface cannot contact the bottom of the hole, forming a gap between the two.

- Consequences:

- Extremely small contact area - line contact:The contact occurs on a circumferential line on the outermost edge of the screw head taper surface. The contact area is also extremely small and the pressure is extremely high.

- "Floating" state and damage:The screw looks like it is "floating" on the countersink and cannot completely fit into the bottom and sit flat. High stress concentration acts on the outer edge of the screw head, which may cause it to curl, deform or crack, and may also damage the hole wall.

- Unable to provide effective support:The screw head does not get effective support from the bottom of the hole, and the rigidity and stability of the entire connection are poor.

- Very easy to loosen:Same as situation 1, line contact leads to extremely poor vibration resistance, preload is difficult to maintain, the screw is very easy to loosen under load and vibration, and the connection reliability is extremely low.

Small angle difference, huge performance disaster

Whether a 90° screw is mistakenly installed in an 82° hole, or an 82° screw is mistakenly installed in a 90° hole, this mismatch of only 8 degrees of cone angle will lead to catastrophic consequences.The core problem is that the design requires a large area of cone surface to fit to transfer load and achieve self-locking, but it is forced to become a high-stress line contact. This mismatch:

- Completely destroys the contact mechanics:Downgrades the surface contact to a line contact with extremely high stress, far exceeding the material's bearing limit.

- Inevitably leads to local damage:Whether it is the hole mouth, hole wall or the edge of the screw head, it is very easy to collapse, deform or crack.

- Make the connection lose its core function:unable to effectively transfer load, unable to provide reliable preload, and unable to achieve self-locking center. The loosening and failure of the screw under vibration and load is almost an inevitable result.

- There are also severe safety dangers:Such incompatibility can cause the equipment to disintegrate, parts breaking off, and cause safety accidents.

Therefore, "82° is a little awkward to meet 90°" is not "a bit awkward", it is a basic and catastrophic incompatibility. In mechanical assembly religious adherence of the cone angle congruence requirement of screws and countersinks (82° for British and 90° for Metric) is an absolute sine qua non condition to provide the strength, reliability and safety of connection. Any lapse of the same can be expensive. This small 8 degrees is in fact the gap between "perfection" and "scrap".

A costly lesson in countersink angles: How we saved a high-end audio panel project

I would like to share with you a very teaching example that we had first-hand experience of. It does very beautifully convey the truth of detail making or breaking achievement or failure of precision manufacturing, and represents ourLS' prime value- not just processing, but also engineering guarantee.

1. Customer Challenge: Strict Requirements for the Pursuit of Ultimate Aesthetics

- We do work for an industry-leading American audio equipment maker. The front panel of its mainline amplifier is made from heavy-duty 6061 aluminum alloy andCNC machined/black anodized to achieve a "mirror-like" finish.

- Core Difficulty:All M4 countersunk screws for fixing should be absolutely flush with the surface of the panel and no projections are allowed. This requires very high precision in countersunk hole machining.

2. Root cause of the issue: a disaster caused by a "standard"

- Negligence in design:The design drawing of the customer's American engineer simply indicated "M4 countersunk hole" without clearly defining the countersunk hole angle. The engineer unconsciously adopted the most commonly used 82° standard in the United States.

- Mismatch of parts:What was bought was a 90° head German M4stainless steelhigh-quality screw (according to ISO standards).

- Manufacturing error:The first batch of processing factory was greenhorn and used only 82° tools to machine all the countersunk holes according to the tag "M4 countersunk hole" on the drawing without realizing it by checking the angle.

- Dramatic fallout:500 gorgeous anodized panels were all "killed" on the production line - the 90° screws would not go into the 82° holes and all "floated", completely destroying the seamless look that the product was famous for. The cost overrun was momentarily in excess of $15,000 and the product was delayed by six weeks.

3. LS's timely rescue and correct cure

- Acute vision - DFM check:Our engineers immediately saw the fatal ambiguity of the drawing during thedesign for manufacturability(DFM) check - the missing countersink angle after receiving the customer's emergency request for help.

- Major confirmation:We immediately inquired and confirmed the screw standard (ISO 90°) to be utilized by the customer, which was the major clue to solving the problem.

- Precise implementation:CNC programmingclearly defines the 90° countersink processing path.

- Strict first-article inspection:Use 90° angle gauges and physical M4 screws for match tests to obtain "perfect fit and absolute flushness."

- Efficient delivery:With precise craftsmanship and strict quality control, we successfully delivered a panel that fully satisfied the requirements within 5 days.

4. Achievements and core values

- Saving the crisis:We not only saved the valuable panel, but more importantly, saved the customer valuable time to market.

- Establishing trust:This successful rescue mission put the customer keenly focused on thevalue of LS, and we established a solid long-term relationship.

- Key Takeaway:This case aptly illustrates that:

Uncertainty in drawings is an expensive trap. Apparently small standard deviations (82° vs 90°) can prove catastrophic.

Professional processingis far more than "construction to drawings." A partner with extensive engineering know-how and rigorous processes (e.g., DFM checking) can proactively identify and eliminate these "standard traps" before production.

Quality springs from control of detail. From clear standards, precise programming to first physical check, the discipline of each step is the assurance of the final quality.

AsLS professionals, we are fully committed to our responsibility: your dream design requires us to bring professional know-how, keen judgment and diligent follow-up to protect it and avoid costly "rework storms". We are not just your producer, but your trustworthy engineering partner.

Machinist's Quick Reference: Tools, Diagrams, and Drawing Notations

Theory is the basis, practice is the master. This convenient reference manual hopes to help you mark countersinks correctly onengineering drawingsand select the appropriate processing methods to ensure proper manufacture.

1. Countersink annotation definitions on drawings (clarity and precision are basics)

- Simple symbols: On engineering drawings, countersinks are referenced by the standard "V-shape" symbol (↧).

- Correct annotation format (to ISO/ASME):

Metric example: M5 X 0.8 ↧ ⌀9.8 X 90°

- M5 X 0.8: Thread designation (M5 screw, pitch 0.8mm).

- ↧: Symbol for countersink.

- ⌀9.8: The required large diameter of the countersink head (9.8mm).

- 90°: Countersink taper angle (ought to be clearly marked!).

Imperial example: 1/4-20 UNC ↧ ⌀.478 X 82°

- 1/4-20 UNC: Thread designation (1/4 inch diameter, 20 threads/inch, unified coarse pitch).

- ↧: Symbol for countersink.

- ⌀.478: The required large diameter of the countersink head (0.478 inches).

- 82°: Taper angle of countersink (it must be properly marked!).

Key Hint:Countersink angle (90°, 82°, 100°, etc.) is a measure that should properly be marked! Don't omit it or leave the processor to guess, this is the trick in avoiding machining errors and rework.

2. Quick reference table of standard screw countersink sizes (metric & imperial)

To make your life easier, here is a list of the maincountersink sizesand suggested tools for frequently used screws (this table is the essence of utility):

| Screw Size | Head Diameter | Standard Countersink Angle | Recommended Countersink Tool |

|---|---|---|---|

| Metric | |||

| M3 | ⌀6.0 mm | 90° | HSS 90° Countersink |

| M4 | ⌀8.0 mm | 90° | HSS 90° Countersink |

| M5 | ⌀9.8 mm | 90° | HSS 90° Countersink |

| M6 | ⌀11.8 mm | 90° | HSS 90° Countersink |

| M8 | ⌀15.8 mm | 90° | HSS 90° Countersink |

| Imperial | |||

| #6-32 UNC | ⌀0.270 in | 82° | HSS 82° Countersink |

| #8-32 UNC | ⌀0.332 in | 82° | HSS 82° Countersunk drill |

| #10-24 UNC | ⌀0.386 in | 82° | HSS 82° Countersunk drill |

| 1/4"-20 UNC | ⌀0.478 in | 82° | HSS 82° Countersunk drill |

| 5/16"-18 UNC | ⌀0.572 in | 82° | HSS 82° Countersunk drill |

(Note: The values in the table are standard approximate values. Please refer to the latest relevant standards or screw manufacturer specifications for specific applications.)

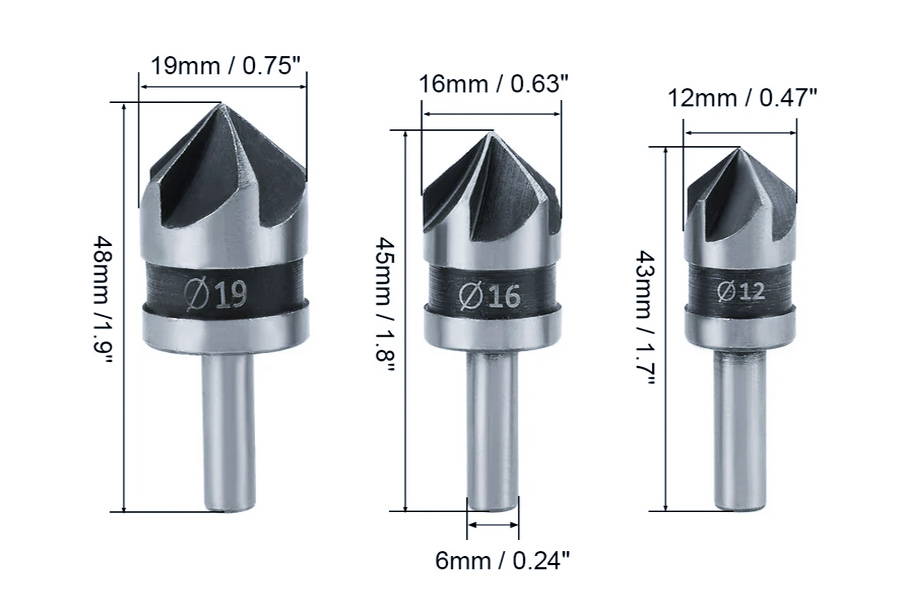

3. Countersink tool selection recommendations (optimized for materials)

Hard materials (such as steel):

- Tool material: High-quality high-speed steel (HSS-E) or cobalt alloy (Cobalt) countersink drills are highly recommended.

- Coating: TiN (titanium nitride) or TiAlN (titanium aluminum nitride) coated tools are preferred. These coatings can significantly improve the wear resistance and heat resistance of the tool, thereby extending the tool life and improving the cutting finish of the hole.Processing parameters: Always use appropriate cutting fluid for cooling and lubrication. Using a lower speed (RPM) helps reduce vibration, avoid irregular chatter marks at the hole mouth, and ensure a clear and flat countersink edge.

Accurate drawing markings (especially angles!) are the starting point for good communication. Combined with the quick lookup table to select the appropriate countersink size, and then select matching tools and processing parameters (coating, cooling, speed) according to the material characteristics of the workpiece. These three steps are the key to ensuring a successful countersinking process and avoiding rework. LS can provide high-qualitycountersink tools(HSS-E, Cobalt, TiN/TiAlN coating) that meet the above requirements and technical consultation. If you have specific application questions, please feel free to contact me.

FAQ - Get your last doubts answered

1. So, which is better, an 82° or 90° countersink?

Expert answer: This is not a question of "which is better", but a question of "which is right". The only criterion for choosing the countersink angle depends on the screw standard you are using: metric (ISO) screws must match the 90° countersink, and imperial (ANSI) screws must use 82° countersink. The wrong angle will cause the screw head to not properly sink or not be flush with the surface, affecting the strength and appearance of the structure. Therefore, it is important to choose the angle according to the screw standard, not subjective preference.

2. What is the standard countersink angle?

Authoritative answer: There are two major mainstream standards in the world: 82° (imperial screw standard) is commonly used in the United States and North America, while the international standard (metric ISO standard) is 90°. The basis for selection depends on the location of your project, the source of the supply chain, or the customer specifications. For example, machinery exported to Europe requires a 90° countersink, while domestic projects in North America often use 82°. Be sure to clarify the standards of the target market before designing, or directly follow the specifications of the screw supplier.

3. Can I measure the countersink angle without a screw?

Clear explanation: Absolutely. The most accurate method is to use a counterbore angle gauge (directly inserted into the hole to read) or an optical comparator (projected profile comparison). If you need to quickly detect, you can choose a tapered gauge (different angle numbers) to observe the fit and light transmittance of its cone surface and hole. In daily quality inspection, angle gauges are most commonly used because of their portability and economy; for micron-level accuracy requirements (such as aerospace parts), optical equipment is preferred.

Summary

Countersunk hole 82° or 90°? This seemingly simple choice is far from a debate over technical details. It deeply reveals thecore challenge of standard unificationin the context of global manufacturing and is a silent manifestation of professional barriers in the engineering field. Choosing the wrong standard means expensive adaptation costs, long delivery delays, and even complete failure of product functions. Behind this tiny angle, it reflects a deep understanding of international standards, material properties and functional requirements - it ruthlessly separates the insights ofprofessional manufacturing from the "taken for granted" of amateur attempts. In the field ofprecision CNC machining, the cost of "taking it for granted" is the highest. It consumes not only money, but also the chances of project success and market trust.

Don’t let a simple angle problem become a stumbling block on the road to success for your project!

At LS, we know that these details determine success or failure.Our onlineCNC machining servicenot only provides machining capabilities, but also has a rigorous DFM (Design for Manufacturing) review process built in.Before the tool touches your material, our team of experienced engineers will carefully examine your design drawings (including every countersunk hole angle!) like an eagle eye, proactively discovering and assisting in correcting such potential design pitfalls and manufacturing risks.

Take action now to avoid risks for your project!

Upload your CAD file now, and in just a few minutes, you can:

- Get an instant, transparentCNC machining quote.

- Experience our professional DFM review service to clear manufacturing obstacles in advance.

- Get high-precision, zero-riskprecision machined partsguaranteed by professional engineers.

Choose professionalism and start by avoiding "assumptions".Click here to uploadyour design and start a smooth and worry-free manufacturing journey!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com