Are you not sure how to choose a laser for your aluminum cutting application? Concerned about low cutting speeds, uneven surfaces, or equipment damage due to high reflections? Choosing the right laser technology is the first step towards ensuring efficiency, quality, and cost savings. This paper will methodically compare the difference in performance between CO2 lasers and fiber lasers in aluminum cutting from key dimensions such as cutting mechanisms, efficiency, quality, and applicable cases, providing an objective and practical reference.

As a commercial metal laser cutting company, LS Manufacturing not only has state-of-the-art fiber aluminum cutting machinery but also has years of experience in the application of aluminum laser cutting. We provide one-stop-shop solutions from materials and processes to post-processing.

For your specific aluminum cutting requirements, please get in touch with us today. Give us your material specifications and have a free trial cut by LS Manufacturing to experience the superior cutting result firsthand! To save you time, here’s a quick overview of the core conclusions.

Fiber Laser vs. CO2 Laser Key Comparison For Cutting Aluminum

| Comparison Dimensions | Fiber Laser | CO2 Laser |

| Cutting Principle | Solid-state laser, wavelength 1.06μm, high metal absorption | Gas laser, wavelength 10.6μm, low metal absorption |

| Cutting Speed | Highly fast (typically 3-5 times CO2) | Comparatively slow |

| Cutting Quality | Lighter cross-section, improved precision, significant advantage for thin and medium plates. | Comparatively coarse cross-section, more stable cutting for heavy plates. |

| Reflection Risk | High risk of reflection, requiring specialized equipment and procedures. | Relatively low reflection risk. |

| Energy Efficiency | Very high (photoelectric conversion efficiency >30%), energy conservation. | Lower (photoelectric conversion efficiency ~10%), high power usage. |

| Maintenance Cost | Maintenance-free lenses, no gas usage, low operating cost. | Requires periodic lens and gas replacement, high operating cost. |

| Applications | High-quality and efficient machining of thin and medium aluminum plates (<12mm). | Suitable for thick aluminum plates, but the overall advantages no longer apply. |

Although the risk of back reflection does need consideration, the modern technology can handle it easily. CO2 lasers still retain application in thick plates but generally become much less competitive. When it comes to investment in the future, a better option is to prefer fiber lasers.

In aluminum cutting (especially below 12mm), fiber lasers have huge advantages in terms of efficiency, quality, and cost of operation, and are hence the best method in the modern era.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

What is here found is not a result of theoretical deduction but the observation of practical experience validated in daily production at LS Manufacturing. Being a metal laser cutting service specialist, LS Manufacturing cuts tons of aluminum every day, ranging from thin-walled parts less than 1mm to heavy plate structural pieces greater than 15mm. This broad sample of processing provides us with a clear understanding of laser cutting characteristics of aluminum.

LS Manufacturing is quite familiar with the issue of aluminum's high reflectivity to lasers. Not only are we equipped with expert anti-reflection fiber laser cutting machines, but also, by extensive process testing, have created a database of exclusive cutting parameters specific to various grades and thicknesses of aluminum. This enables LS Manufacturing to effectively avoid possible reflection risks that could damage equipment as well as optimize assist gas pressure and cutting rate to deliver clean, burr-free cuts.

This experience, acquired on an immense number of orders, enables us to provide you with expert advice tailored to your requirements. LS Manufacturing provides not just machines but also stable, efficient, and reliable aluminum cutting process solutions.

Why Does Aluminum Cutting Place Special Demands On Laser Technology?

Among the many applications of laser cutting of sheet metal, aluminum laser cutting probably occupies one of the most technologically challenging positions. This is owing mainly to the unique physical characteristics of aluminum, which place extremely stringent demands on the laser cutting process.

1. Risks and energy challenges posed by high reflectivity:

Aluminum surfaces exhibit very high reflectivity to lasers, particularly near-infrared lasers. Not only does this waste a great deal of laser energy, but worse, the reflected light can be fed back into the laser and cause irreparable damage to the optical components or even to the laser source, a hazard referred to as "burnback."

2. Cutting energy loss due to high thermal conductivity:

Aluminum is an excellent thermal conductor, and the resulting heat from laser irradiation conducts away very quickly from the cutting area. This has a tendency to keep one from maintaining a stable melt in the cut, easily leading to decreased cutting speeds, incomplete cuts, or rough streaks on the surface of the cut due to uneven distribution of heat.

3. Interference between the oxide layer and the sticky slag:

The aluminum oxide (Al₂O₃) layer formed naturally on the surface of aluminum has an impossibly high melting point (over 2000°C), several times higher than that of aluminum itself (approximately 660°C). This "hard shell" does not allow absorption of laser energy but instead engages in a reaction with the molten aluminum while cutting, forming sticky slag that is impossible to remove, and has a severe effect on cut surface quality and dimensional tolerance.

Conventional laser cutting techniques are not on par for high-quality aluminum laser cutting. Specialized techniques and equipment must be utilized in order to eradicate these inherent challenges.

What Are The Core Advantages Of Fiber Lasers For Cutting Aluminum?

Being the trendy choice for sophisticated metal processing, fiber lasers offer several paradigm-altering advantages when cutting this challenging material, becoming the focal point of high-quality, high-efficiency aluminum laser cutting equipment.

1. Extreme Efficiency and Energy Saving:

Fiber lasers possess an electro-optic conversion efficiency in excess of 30%, significantly greater than traditional laser technology. It enables increased capability to cut with a lower energy draw, as well as transferring the load from the auxiliary cooling system, substantially lowering long-term operating costs for manufacturers.

2. Excellent Beam Quality and Cutting Precision:

The fiber laser beam is highly quality and highly focused into an extremely minute spot. This allows for narrower kerfs and a smaller heat-affected zone in precision laser cutting, easily leading to high-quality processing with sharp edge and smooth cross-sections. Fiber lasers are particularly best for doing fine work on delicate shapes and thin aluminum alloys.

3. Ultra-High Speed and Stable Anti-Reflection Capability:

Because of the higher absorption rate of the 1μm wavelength lasers by aluminum, fiber lasers are capable of operating at extremely high cutting speeds, several times faster than those available on conventional machinery, and ideal for thin to medium-thin sheet metal. Furthermore, modern high-end fiber lasers (such as IPG lasers) incorporate proprietary anti-reflection technology that effectively monitors and regulates reflected light, essentially optimizing the safety and stability of the aluminum laser cutting process and avoiding damage to the machinery.

With its perfect combination of efficiency, precision, and safety, fiber lasers are the most competitive technology solution for laser cutting aluminum today.

Is CO2 Laser Still Valuable For Aluminum Cutting?

While fiber technology has gone mainstream, we have to objectively consider the place of CO2 lasers still. Even though their market share is decreasing, they are still worth using in some applications of metal laser cutting.

1. Specific Advantages in Cutting Extremely Thick Aluminum Sheets:

For extremely thick aluminium plates (typically 15mm and above), the greater CO2 laser wavelength allows for an increased likelihood of improved coupling with the metal plasma, which allows for an improved stable cutting process. In some cases, the cut surface achieved is quite smooth, especially in older manufacturing plants that never had high-performance fiber-based metal laser cutting equipment to begin with. This continues to be one of the reasons why it remains in use.

2. Unavoidable Efficiency and Cost Disadvantages:

Its drawbacks are significant, however. Its electro-optical conversion efficiency is at best around 10%, with extremely high power consumption. Its cutting speed, especially for thin plate, is much lower than the fiber laser's. Moreover, the constant replacement of consumables such as laser gas and reflectors results in higher long-term maintenance and operation expenses.

3. Its Overall Competitiveness Has Significantly Declined:

Overall, the competitiveness of CO2 lasers in the aluminum cutting market has decreased significantly. With advancements in technology, fiber lasers have always competed with them in thick plate quality cutting and outshined them in overall efficiency. Except where they aim at targeting specifically thick plate orders for existing machines, CO2 lasers are no longer an economical and efficient option for new equipment procurement and technology purchasing.

CO2 lasers are more of a "fall-back option for specific applications" rather than a "popular recommendation" for future manufacturing. For companies looking to be efficient and profitable, the purchase of modern fiber-based technology is very much a wiser option.

Direct Comparison Of Cutting Quality, Speed, And Cost

To best make a decision, the two technologies must be quantitatively compared on the same terms. The table below offers a visual estimate of their performance in aluminum laser cutting in a number of the most important dimensions, which directly affect the quality and economic value of your laser cutting business.

| Comparison Dimensions | Fiber Laser | CO2 Laser |

| Cutting Speed | Extremely Fast | Slow |

| Surface Smoothness | Bright and delicate | Relatively rough, may show streaks |

| Cutting Perpendicularity | Good, small taper | More characteristic taper in cutting thick plates |

| Energy Consumption | Extremely Low (electro-optical efficiency >30%) | High (electro-optical efficiency ~10%) |

| Maintenance Cost | Extremely Low (lenses none, gas none) | High (periodic replacement of lenses and gas) |

| Equipment Investment | Mainstream option, high cost-effectiveness | Traditional technology, low cost-effectiveness |

The above direct comparison makes it very clear that fiber lasers possess a overwhelming advantage over almost all of the key performance and cost measures for laser cutting aluminum. Not only does it offer faster and improved cutting quality, but it also reduces the total lifecycle cost of manufacture by a significant amount through having extremely low energy usage and maintenance expenses.

For the vast majority of aluminum laser cutting operations, choosing a fiber laser is choosing higher production efficiency, enhanced processing quality, and higher market competitiveness. This is why leading laser cutting service companies such as LS Manufacturing have established fiber technology as a core processing capability.

LS Manufacturing Case: Powered By 10,000-Watt Lasers, New Energy Aluminum Parts Cutting Efficiency Increases By 50%

In the production of new energy vehicle components, efficiency and quality both decide market competitiveness. The following LS Manufacturing laser cutting case study powerfully illustrates how advanced fiber technology is transforming aluminum laser cutting applications.

1. Customer Pain Points:

A battery tray manufacturer used a common CO2 laser to machine 6-15mm aluminum alloy. Cutting speed of the equipment was not high, power consumption was costly, and hard dross often stuck to the cross-section. Secondary polishing in every batch of products was time-consuming and labor-intensive, which had substantial impact on the whole production capacity and delivery cycle.

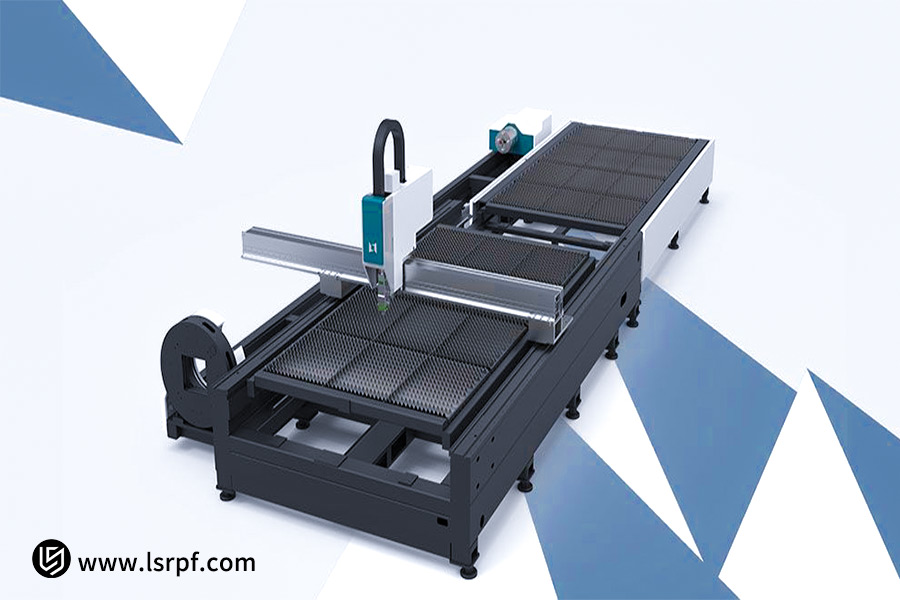

2. LS Manufacturing Solution:

To resolve the customer's issues, LS Manufacturing provided a professional, customized metal laser cutting solution. We brought in a high-power, 10,000-watt fiber laser cutting machine. Based on our extensive database of aluminum material processing experience, we coordinated important parameters such as assist gas type, pressure, and focal position to battery tray sheet materials of various thicknesses to attain an optimal cutting process.

3. Results and Value:

Once the new solution was introduced, LS Manufacturing saw instantaneous results:

- Efficiency Leap: Average cutting speeds rose more than 50%, eradicating production bottlenecks entirely.

- Quality Improvement: Surfaces of cuts are even and shiny, dross is eliminated nearly entirely, and secondary processing operations are reduced to zero.

- Cost Optimization: Due to the high energy efficiency of fiber lasers, energy consumption for production decreased by more than 60%, saving considerable unit costs.

This successful application of laser cutting aluminum proves LS Manufacturing's dedication to delivering core value to customers in terms of advanced technology and professional workmanship.

How Do Aluminum Thickness And Alloy Composition Influence Laser Selection?

During the planning of an aluminum laser cutting, material inherent properties play a very important role in determining which laser should be used. Thickness and alloy composition directly affect the selection of laser technology and the ultimate processing result.

1. Thickness is the primary dividing line in technology selection:

- Thin medium plate (<12mm): This is the advantageous thickness range for fiber lasers. Their extremely high energy density and cutting speed enable efficient, high-quality processing, yielding brilliant, dross-free cross-sections.

- Medium and thick plate (12-20mm): High-power fiber lasers remain the first choice. 10,000-watt lasers can effectively match aluminum's high thermal conductivity, yielding high-quality and perpendicular cut surfaces.

- Ultra-thick plate (>20mm): Simple thick aluminum plate cutting represents a significant challenge to laser technology. Very high-power (for example, higher than 20,000 watts) highly specialized fiber machinery is required, or else other methods such as water jets and plasma will have to be investigated. CO2 lasers are no longer of pivotal benefit here.

2. Alloy composition determines subtle adjustments to the cutting process:

Different series of aluminum alloys have varied cutting properties due to their varied element composition:

- 1-series pure aluminum: It has the highest reflectivity, and extra caution has to be exercised in controlling reflection risk in cutting.

- 5-series aluminum-magnesium alloys: These are high-strength but high-melting-point elements, which may cause increased slag in cutting and require gas parameter adjustment.

- 6-series Al-Mg-Si alloys: These are the most widely used structural alloys and possess good machinability as well as, with optimized process parameters, can yield good-quality cross-sections.

A successful laser cutting of aluminum depends on tailoring it to your material. LS Manufacturing, being well-equipped with a large material processing database, can offer accurate thick aluminum plate cutting and precision thin plate cutting solutions for any aluminum specification.

Besides Laser Type, What Other Factors Determine The Final Cutting Results For Aluminum?

Selecting a state-of-the-art laser is just the first step towards making high-quality, accurate laser cuts. To be capable of cutting through aluminum flawlessly again and again, the following process details generally are determining factors and signify a laser cutting services provider's expertise.

1. Selection and Purity of Assist Gas:

Nitrogen of purity ≥99.999% is most commonly utilized as the assist gas for cutting aluminum. Pressure and purity are essential: High-purity nitrogen can effectively prevent cut edge oxidation, resulting in a silvery-white, shiny cross-section; controlled air pressure accurately strips away the melt and keeps dross from forming on the reverse side. Any slight purity deficiency or pressure variation will immediately have an impact on cut quality.

2. Nozzle Technology and Process Parameters:

Nozzle geometry, nozzle size, and nozzle height have direct influences upon airflow structures and energy concentration. The proper nozzle structure design and precise height control system achieve a stable high-power air curtain, the physical foundation of dross-free cutting. Further, there are thousands of parameters, such as cutting speed and focal position, which must be well optimized according to material thickness and alloy composition.

3. Machine Tool Stability and Intelligent Programming:

A well-effective, robust, and highly dynamic machine tool is the prerequisite for precision cutting. It must be vibration-free and stable even at high-speed cutting. Furthermore, wise CNC programming reduces cutting path and piercing technique, prevents overheating, maximizes effectiveness, and protects the nozzle—all essentials in effective, reliable, and precise laser cutting.

At LS Manufacturing, not only do we invest in the finest equipment, but also strive for excellence in gas management systems, process databases, and machine care, so that all the laser cutting services that we provide are maintained at the highest levels.

When Selecting A Laser Cutting Service Provider, What Else Should You Consider Besides The Equipment?

State-of-the-art equipment is just the beginning; the real difference lies in the intangible soft skills. In finding a metal laser cutting service partner, especially for custom laser cutting, the following are often the reasons why your project succeeds or fails.

1. Deep Material and Process Experience:

Does the supplier have complete knowledge of aluminum properties? With this kind of extensive experience, they have a huge parameter library for different alloys and thicknesses to forecast and avoid common problems such as dross and thermal deformation, which leaves a first-pass finish.

2. Comprehensive Quality Control and Design for Manufacturability Recommendations:

A reliable service provider maintains a complete quality control process from initial inspection to final inspection. Above all, they should actively provide design for manufacturability recommendations, optimizing your drawing specifications to improve workability, reduce costs, and lower lead times.

3. Reliable Delivery Guarantee and Continuous Service Support:

Timely delivery and stable production capacity are essential to keeping your production timeline on track. Also, look at their after-sales service responsiveness and technical support functions to ensure quick and professional resolution of any problems, guaranteeing trouble-free partnership.

Choosing a partner like LS Manufacturing means you're not getting an instrument, you're getting a complete, customized metal laser cutting solution that includes technology, expertise, and service, and serves as a solid foundation for the success of your project.

Why Is LS Manufacturing A Reliable Partner For Your Aluminum Laser Cutting Projects?

Choosing LS Manufacturing is choosing not only a supplier but a deeply enabling technical partner. We are committed to becoming your most trusted metal laser cutting service expert. The following are our core commitments:

1. Leading Equipment Matrix for Efficiency:

LS Manufacturing boasts an outstanding matrix of expert aluminum processing tools with several high-power fiber laser cutting machines designed for efficient and high-quality reflective material cutting like aluminum. This ensures optimal production efficiency and quality cuts for your orders, large or small, regardless of complexity.

2. An Experienced Process Team Ensures Quality:

LS Manufacturing's strengths lie in the company's team of process specialists. Equipped with profound materials science expertise and rich hands-on experience, they are able to accurately solve all types of laser cutting problems, from thin plates to thick plates, offering professional opinions on all aspects ranging from material selection to process optimization.

3. One-Stop Service, Responsible for Results:

At LS Manufacturing, we give you a complete metal laser cutting service from design and manufacturing (DFM) review, precise process development, and rigorous quality checking. Our comprehensive process guarantees a high level of consistency from the design intent through to finished product, saving your time and cost of management.

LS Manufacturing is always customer-centered and committed to reducing your total costs and creating long-term value above your expectations through continuous technology and process improvement.

FAQs

1. What is the minimum kerf width and accuracy achieved when cutting aluminum with fiber lasers?

LS Manufacturing precision fiber laser machines utilize an ultra-high beam quality laser source and a patented optimized focus control technology in a bid to achieve stable kerf width control of 0.08-0.1mm as well as positioning accuracy of ±0.03mm. This precision machining is particularly suitable for very tightly dimensioned aluminum components, such as medical equipment and electronic heat sinks, enabling precise reproduction of complex contours.

2. Will the aluminum edges oxidize and turn black after cutting? How can this be avoided?

With high-purity nitrogen and patented nozzle technology, an ideal protective air curtain is created in the zone of cutting and fully isolates it from oxygen. LS Manufacturing's "bright surface cutting" process produces a consistent silvery-white metallic sheen on the cut edge, basically eliminating oxidation concerns and fulfilling the direct assembly requirements of high-end exterior components.

3. Can you process coated aluminum sheets (such as powder-coated aluminum)?

We have a vast database of processes for coating materials. By precisely monitoring the waveform of laser power and cutting speed, we can control the heat-affected zone to an incredibly narrow range. LS Manufacturing offers clean, chip-free cut edges on aluminum sheets with powder coats, anodizing, and other coatings, maximizing the protective qualities and aesthetic appeal of the coating.

4. Can you provide small batches or trial cutting services?

We strongly recommend trying our trial cutting service, which has no minimum order requirement. All clients must provide drawings and material specifications, and LS Manufacturing will employ professional technicians to pursue the case at every step. Through trial cutting, they will validate results and fine-tune parameters, providing uniform quality assurance and cost estimates for future mass production.

Summary

In cutting aluminum, fiber laser technology has been found to be a wise choice for industrial manufacturing today due to its higher cutting efficiency, better cross-sectional quality, and lower overall operating cost. When it comes to executing precision machining of thin plates or medium- and heavy-plates structural parts, fiber lasers have solutions much superior to traditional CO2 lasers.

Send your aluminum specifications and drawings today. And the LS Manufacturing team will provide a free trial cut, a rigorous cut quality analysis report, and a very competitive quote! Choosing LS Manufacturing is choosing a commitment to quality and tangible improvements in efficiency.

Upload your design drawings now and get an instant laser cutting quote ( laser cutting price), let LS Manufacturing be your strong backing in pursuit of ultimate laser cutting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.