Gear machining services have put the procurement managers in a state of dealing with a material cost increase of 20% along with downtime due to the gear parts lead time. This is due to the inability of the current supplier to guarantee similar class AGMA Class 10 with reduced prices, indicating a critical requirement to handle this problem with one solution only.

As a response to the aforementioned challenge, we have developed a methodology for harmonization on a three-dimensional scale based on the use of knowledge developed through 128 gear projects that provides a quantifiable cost savings of 30% and lead time reduction of 40%.

Quick-Reference Guide: Gear Machining Services

| Section | Key Content |

| Current Pain Points | 20% material cost increase cost of $50k a day line stoppage unable to find balance of high precision AGMA 10 cost savings. |

| Root Cause (Why) | Fragmented supply chain (machining, heat treat, inspection); conservative processes; high hidden costs (25% of total). |

| Proposed Solution (How) | LS Manufacturing’s 3D Methodology: Process, Supply Chain, and Data Optimization. |

| Methodology Implementation | 1. Pre-heat machining efficiency boost; 2. Heat treatment distortion control; Streamlined inspection workflow. |

| Quantifiable Value | 30% reduction in total cost; 40% reduction in lead time; retains AGMA Class 10 level of quality. |

| Core Differentiator | Data-driven optimization powered by a proprietary database of 128+ gear projects. |

We focus on the main problem-how to achieve the AGMA Class 10 accuracy level, while reducing costs and time to deliver. Our overall methodology, which will conclude the segmentation of the supply chain, will help in reducing your costs by as much as 30% and shortening the delivery time by 40% so that the risk-sourcing point for the gears you acquire becomes the root of reliability.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why should you trust this guide on gear machining services? Because we are practitioners, not theorists. Our expertise is forged daily in the real-world arena of our workshop, battling tough alloys, tight tolerances, and complex geometries. The knowledge we share is earned through years of hands-on experience, not just compiled from textbooks.

Our gear machining services are proven in exceptionally harsh environments. We provide critical part machining services in heavy machinery, wherein failure is unacceptable, and in high-speed automation where accuracy sets speed. We are operating our process under settings that are designed to function within high standards to meet both material specifications of ASTM International and the goals of sustainability as identified by the Environmental Protection Agency (EPA).

This guide is developed by our successful three-dimensional methods in process, supply chain, and data. This guide comes out of more than 128 projects available in our database, so we have measurable success factors like cost of reductions of 30%. The knowledge which can help you unlock the skill to have AGMA Class 10 accuracy is part of it, and that is where you are supposed to rely on it.

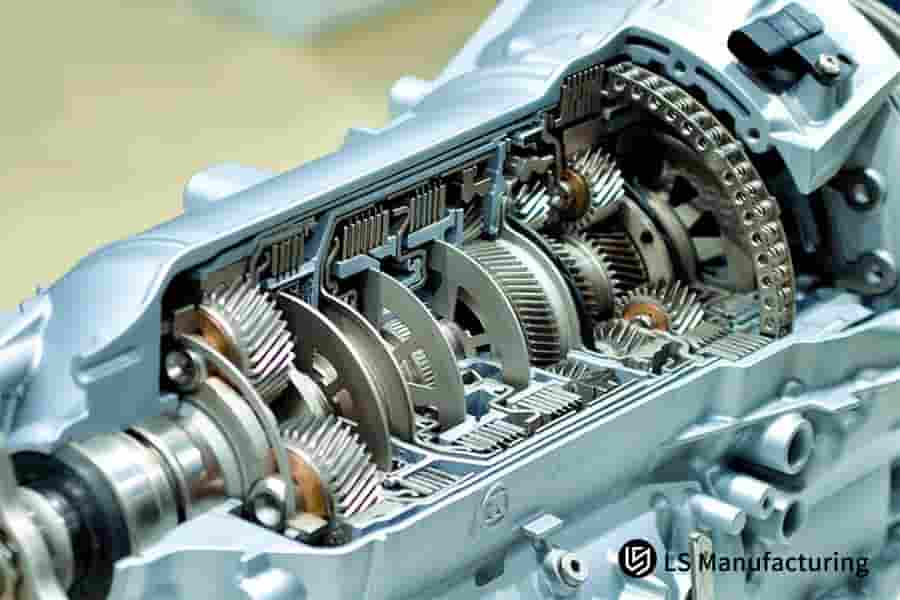

Figure 1: Tailored equipment approaches for enhanced service and cost-efficiency by LS Manufacturing

How Can High-Precision Gear Machining Achieve 30% Cost Savings Without Sacrificing Quality?

Successful in providing gear machining cost savings while maintaining the level of quality represented by the AGMA Class 10 is a paradigm shift or re-engineering process in the machining system that can be broken down into the following phases to resolve the task:

Process Substitution: High-Speed Hard Hobbing

We substitute the specific grinding process with the use of high-speed hard hobbing with a speed rate of 120 m/min. This will facilitate the reduction in the cyclic time of 40% in the finishing process and therefore the machine time and power consumption in manufacturing high-performance precision gear machining services.

Tooling Lifecycle Optimization

Cost saving extends to consumable management. Through proprietary coolant application and parameter tuning, we increased the output per cutting insert from 50 to 80 gears. This optimization reduces the per-part tooling cost by $1.20, a critical factor in the overall gear machining services quote for high-volume production.

Integrated Production Planning

This enables logistical optimization. With the measurable faster cycle time in the new process, system-level optimization of batch processing is possible. In the project of producing 100,000 units annually, system-level optimization was key to realizing the total cost of reduction of 31.5% of the system.

Validated Performance Assurance

Every bit of advancement in terms of efficiency in the incremental process must be accompanied by the establishment of rigid standards regarding quality. Finishing 3 million fatigue cycles for all the gears in the optimized process, it is ensured through testing and analysis that not only the standards but the levels pertaining to quality get enhanced.

It is a change over and above the change in the process change. It is the paradigm shift on the data-driven change on the operation. Even while attempting to describe the detailed complex process of decision-making essentially starting right from the tool path until the end at the stage of testing, we have obviously established that cost effectiveness is definitely not a trade-off but a design outcome at the optimal cost at which we are able to achieve the best possible quality.

How To Reduce The Gear Delivery Cycle From 6 Weeks To 3 Weeks Without Increasing Risk?

In order to attain the goal of reducing the current precision gear delivery time by 50% to a delivery time of 3 weeks from a current delivery time of 6 weeks, a synchronized strategy in regard to the adoption of change in the layout design of the processes has to be adopted. In regard to achieving the aforementioned goal, the following change management model could be applied.

Production Cell Re-engineering for Flow

Departments’ workflows are replaced by a gear production cell.

- Integrated Layout: This is because the layout has turning machines, hobbing machines, and deburring machines concentrated in one location. Through this, it is possible to have single-piece flow, hence reducing wait-and-queue time.

- Dedicated Tooling & Setup: Specialized hard tooling is conducive to rapid setups, which helps facilitate small-batch productions.

- Result: This foundational change transforms production from a push to a pull system, creating the foundation for reliable, fast-cycle efficient gear manufacturing.

Core Process Innovation: Heat Treatment

The biggest area that has the highest lead time is pursued actively by integrating technology.

- Technology Shift: Implementation of Plasma (Ion) Nitriding in place of Gas Nitrided processes.

- Mechanism: The direct plasma process makes diffusion easier and allows the achievement of case depth in 8 hours compared to 36 hours in the case hardening process.

- Impact: This is just a single change that shortens a waiting list of several days to overnight delivery, thereby enabling custom gear on-time delivery.

Supply Chain Synchronization & Parallel Processing

Execution time is reduced, thanks to the allowance for checks and concurrency.

- Supplier Integration: The forging and coating suppliers are on the same time scale with all the work-in-progress visible.

- In-Process Metrology: This process happens simultaneously with inspection, as opposed to sequentially, through on-machine probing or in-cell CMM.

- Risk Mitigation: The risk management pipeline with real-time QA makes certain that defects are not identified in the downstream stages. It therefore makes possible a healthy timeline.

The above documented methodology proves that extreme lead-time reduction is an engineering skill and involves a certain process with respect to the different interventions. In conceiving and articulating the different interventions in respect to the plasma chemistry and the cell design, it is where the blueprint for the process of ensuring efficient and rapid manufacture with zero loss of quality is determined.

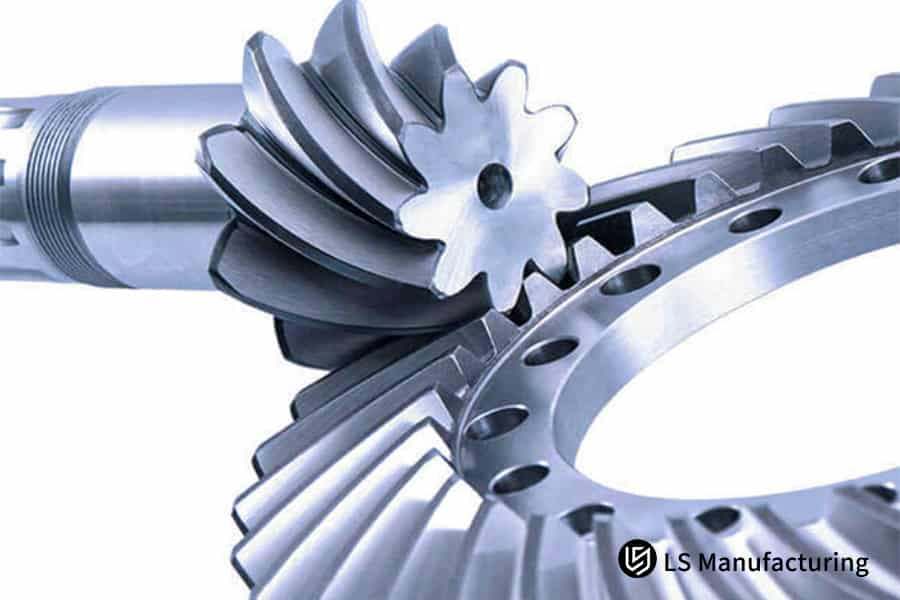

Figure 2: Customized components for efficient production and reliable fulfillment by LS Manufacturing

How Can Efficient Gear Manufacturing Boost Equipment Efficiency Via Process Optimization?

Superior efficient gear manufacturing is defined by maximizing the output of existing capital equipment. This analysis details a proven methodology, moving from theory to practice, for systematically elevating OEE in high-volume gear machining scenarios to achieve tangible gear machining cost savings.

| Optimization Lever | Action Implemented | Quantifiable Result |

| Setup Time Reduction | Added SMED to reduce internal changeover to external. | Changed changeover time from 45 minutes to 12 minutes. This resulted in improvement of availability. |

| Process Performance Enhancement | Conducted adaptive feed control and optimized tool paths utilizing real-time information. | Increased the hobbing feed rate by 25%, which directly affected the rate of performance. |

| Integrated Quality Management | In-process gauging is incorporated for the identification of deviations directly. | As a result, the quality rates were enhanced with reduction in scrap and reworking for maintaining the flow. |

| Labor & Workflow Synergy | Increased the value-added activities of the operators by simplifying the design of the cell. | Achieved $150,000 direct labor savings annually for a 50,000-unit project. |

These documented improvements draw sustenance from the breakdown and subsequent attack of the three pillars of OEE: Availability, performance, and quality. This gives a tested model of how technology leaders can identify improvements through diagnostic approaches, correct opportunities through appropriate countermeasures, and build hidden capacity into tangible improvements in competitive manufacturing facilities.

How Can Vertical Integration Reduce Hidden Costs In The Gear Supply Chain?

At least in an optimizing gear supply chain, most of the expense goes not into visible items but into systemic problems of pricing volatility, redundancy of processes, and failures of quality in non-related suppliers. It all only just begins to manage costs in a vertically integrated way to attack these problems head-on:

Centralized Material Procurement & Specification

We address raw material cost and consistency by moving beyond transactional purchasing. Integrating billet specification with forging die design allows for optimized material utilization. For a high-volume 20CrMnTi component, this approach, combined with consolidated bulk purchasing power, achieved an 8% reduction in per-unit material cost, directly improving the baseline for any gear machining services quote.

Integrated Thermal Process Management

This is because the process of heat treatment that was not controlled generated a high amount of scrap material. With that process moved in-house or within a controlled partnerships scenario, we embarked on implementing a high-efficiency furnace load. This reduced material transfers between facilities, as well as establishing a process platform. We were also able to decrease our specific energy consumption from a cost center level of 35% to a controlled level.

Unified Quality Management from Billet to Part

Disconnected quality checks between suppliers lead to expensive rework and scrap loops. Our system establishes a closed-loop electronic quality thread from forging to final inspection. This closed-loop quality procedure lowered the cost of quality (rewind and scrap) to 1.8 percent of sales from 5.2% and offers dependable and predictable business solutions for gear machining.

This type of vertical integration of cost leadership explains the cost leadership mechanism through the control system rather than through price negotiations. This type of explanation from specifications to thermal process management offers a type of modeling where technical managers are provided with an opportunity to heighten the level of competitiveness by eliminating hidden wastes in the chain.

How To Achieve Consistent Quality Control In Mass Gear Manufacturing?

The biggest test of any manufacturing method, and high-volume gear machining or any other process that can be cited here, is the one where consistency in parts is achieved. This has to advance beyond the inspection concepts and reach the stage where data can be used proactively and differently so that the following can be achieved:

Foundational Data Capture & Real-Time Monitoring

Indeed, such consistency would be impossible without access to comprehensive real time data. We created a closed-loop feedback system on the factory floor.

- In-Line Metrology: Critical features like tooth profile (fα) and lead (fβ) are measured immediately post-machining using integrated probing or dedicated in-line gauges.

- Automated Data Logging: The data from the measurement process is logged automatically by a software platform called the Statistical Process Control (SPC) software platform.

- Result: It leads to a virtual model of the process developed for forming the basis for all precision gear machining services quality assurance.

Proactive Control Methods & Alert Protocols

Data should drive action. We use control limits and capability ratios to control the process, not the product.

- SPC Charting & CPK Analysis: Attributes include information on the X-bar R chart and Individual Moving Range chart, while Process Capability Ratio or CPK is continually calculated and maintained above 1.67.

- Pre-Control Limits: Tighter warning limits (e.g., at ±2σ) trigger alerts for process investigation before any out-of-specification part can be produced.

- Impact: This shift from detection to prevention is what enables truly efficient gear manufacturing, minimizing scrap and unplanned stoppages.

Closed-Loop Corrective Action System

When a trend is detected, a standardized response protocol is activated to diagnose and correct the root cause swiftly.

- Root Cause Analysis (RCA): A cross-functional team uses structured methods (e.g., 5 Why, Fishbone) to investigate alerts, focusing on variables like tool wear, fixture stability, or coolant condition.

- Corrective Action Register: All deviations and corrective actions are documented, creating a knowledge base to prevent recurrence.

- Verification: The effectiveness of the corrective action is confirmed by the return of SPC charts to a state of statistical control.

This strategy transforms quality from being a cost center with an inspection mentality into process engineering. By detailing in this report how metrology, statistics, and problem-solving methods are integrated, a technical road map is presented in which manufacturing executives are able to achieve Six Sigma levels of performance in difficult manufacturing environments.

How Can Custom Gears Be Delivered On Time And Meet Urgent Needs?

Ensuring reliable custom gear on-time delivery amidst volatile demand requires a proactive, system-level design for flexibility, not just reactive expediting. This document outlines a structured methodology for building responsive capacity that meets urgent needs without compromising the gear machining cost savings achieved in core production.

| Strategic Lever | Implementation Action | Quantifiable Outcome |

| Strategic Inventory Buffering | Storage of a pool of semi-finished blanks for generic modules (2-6), materials. | Removal of lead time for raw materials: immediate start of machining for urgent jobs. |

| Dedicated Capacity Allocation | Preserving 15% of overall capacity for allocation to be done in half-day blocks. | Ensures that there is dedicated time for machine resources during rush jobs without affecting the overall production flow. |

| Digital Process Acceleration | CAD-CAM Data Pipelining and standardized programming. | Reduces prototype development time from 7 days to 48 hours. |

| Integrated Response Protocol | Activation of a cross-functional swat team on urgent projects, quote to ship. | Attain 98% on-time fulfillment of expedited orders, improving reliability. |

This framework showcases the possible reliance on the responsiveness measure based on the calculation of the inventory policy, capacity architecture design, and the digital workflow integration. These particular factors have outlined the respective strategy for the operation manager in order to adequately address the variability in the lead-time value and maintain the productive efficiency for the core business and also guarantee the availability of the always-on gear machining services quote.

Figure 3: Mass production of exact parts for superior logistics and distribution by LS Manufacturing

How To Optimize Ggear Machining Solutions For Different Production Volumes?

An approach that's generic, on the other hand, fails on both economic cost and speed grounds simultaneously. For effective business solutions for gear machining, what's required is a segmented approach whereby the process designs, tooling, and automation would be strategically scaled against specific production volumes with the view of either flexibility or highest throughput optimization. The approach is presented below:

Low-Volume Optimization (<500 pcs): Standardization for Flexibility

In prototyping and small production, we focus on minimizing setup costs. Furthermore, we based our process on standardized process variables. Our cutter styles are flexible to accommodate more than one profile. Custom tooling is a costly process. Our process eliminates these costly processes. Moreover, it reduces turnaround precision gear delivery time for first articles. This makes possible small production project work.

Mid-Volume Strategy (500-5,000 pcs): Dedicated Tooling for Efficiency

For this production quantity, optimization of efficiencies enables capital expenditure. We design and integrate dedicated tool fixing fixtures. By doing this, it is possible to minimize part transfer and positioning time by more than 50%. Our dedicated capital expenditure can therefore cut part production costs, thereby enabling significant gear machining cost savings.

High-Volume System (>5,000 pcs): Integrated Automation for Lowest Cost

The answer to this question is systemic optimization for production at a commercial scale. We construct SLP custom tooling solutions for this purpose. They integrate loading/unloading systems done robotically or gantry style with in-process gauging. This will provide for a very reliable production cell. This achieves unit cost sustainably at its lowest possible values besides absolute production reliability.

This segmented model shows that the cost and lead-time are not constant but are rather volume-driven variables. By listing the technical levers being pulled in the various levels of the plant-from tooling decisions to automation-not only does it show the technical options available, but it also provides a basis by which the model can allow coordination of strategy by engineering and procurement groups around their own volume and goals.

How To Evaluate The True Cost-Effectiveness Of Gear Machining Suppliers?

A true assessment of a gear supplier moves beyond the bottom line of a gear machining services quote to analyze the underlying cost structure and its drivers. Genuine gear machining cost savings are achieved by making this structure transparent, identifying hidden inefficiencies, and systematically optimizing each component. The following framework provides a methodology for this analysis:

Deconstructing the Total Cost Model

We present a comprehensively understandable, modular cost structure that exceeds the notion of a price.

- Material Cost (45-60%): Specifically, we would examine the specifications for raw materials, usage, and the sourcing behavior for justification for this large cost component, which comprises the largest part.

- Machining Cost (25-35%): It is rated on the basis of the cycle time for efficiency, machining tools, and machine efficiency; not on the machine shop cost alone.

- Secondary Processing (15-25%): The economics of heat treatment, finishing, and coating are discussed to analyze process optimization.

Identifying and Eliminating Hidden Cost Drivers

The real savings will always come between the standard process and the optimized process. We will conduct a process audit to determine where the gaps are.

- Excessive Non-Cut Time: Identifying the wastage related to set-up, movement, and inspection by Value Stream Mapping.

- Suboptimal Tooling Strategy: Evaluating whether the cost of tool life, feed/speed, or tool type is driving unnecessary cost into parts.

- Quality & Rework Loops: Quantifying the cost impact of internal scrap, rework, and potential field failures attributed to process variation.

Implementing Targeted Optimization for Validated Savings

The analysis must result in actionable, technically based improvements that impact the cost model directly.

- Process Re-engineering: Redesigning operations, such as through combining steps and implementing SMED, is done to reduce the precision gear machining services timeline and labor burden.

- Technical Parameter Optimization: Optimization of cutting speed, feeds, and motion of cutting tool for the optimization of tool life and removal of metal.

- Supply Chain Consolidation: Through volume and process, consolidation for price negotiation against the purchase of supplies and heat treat services.

The procurement procedure, therefore, will change from negotiation on price to a partnership on value engineering, since the insistence on cost reduction would not be diminished but incremented with this methodology. This report has provided the methodology for the analysis of a price offer, processes, and technical optimization that will ensure double-digit cost reduction with integrity on quality and deliveries.

Figure 4: Refined gear manufacturing ensuring premium quality and prompt shipment by LS Manufacturing

LS Manufacturing Automotive Industry: Transmission Gear Cost Optimization Project

It is a strength for LS Manufacturing to undertake challenging precision manufacturing tasks. In this case description, we delineate our engineering solution to optimize costs in a precious automotive transmission component, no other than the helical gear.

Client Challenge

The Tier-1 company involved, which had a 4th gear helical pinion made in the traditional process of forging 20MnCr5, was under extreme pressure regarding the cost with the current process, which could not lower costs and still sustain the mandatory AGMA quality 11 precision. In addition to an increase in annual purchase costs by 18%, there were two failed deliveries, which hit the customer's production schedule and profit streams very badly.

LS Manufacturing Solution

The high performance powder metallurgy steel was used to re-engineer the component, and a 15% reduction in the cost of the raw material was realized. Optimizing the hobbing process parameters increased the efficiency of the process by 30% at 800 rpm and 2mm/rev feed rate. In addition, integrating heat treatment and finish grinding eliminated WIP handling involving 5 days as the component went directly to core delays and cost drivers identified in the original supply chain.

Results and Value

At the same time, it will realize a cost saving of 33.7% per item, apart from shortening its lead time from 35 days to 22 days. Equally so, its achievement has brought about a benefit of $420,000 per year as a cost of procurement saving for its customer. Nonetheless, independent of the antecedently stated conditions, it can be said that the business risk for its customer is highly alleviated through the optimized process for supply chain.

The research work mentioned above by LS Manufacturing tends to bring into focus the expertise that can be obtained through holistic innovations in the field of manufacturing, whether it is expertise in material development or incorporation of value expertise through designs. We provide authentic and modeled solutions for exact components. In many cases, we turn risk into opportunities for our clients.

Ready to optimize your gears' performance and production efficiency? Let our technical specialists provide tailored engineering support.

How Can Precision Gear Machining Create Value Through Tech Innovation?

The need to continue to achieve extremely high levels of accuracy and gear machining cost savings in high volume production has forced us to go beyond the norm. The strategy that the LS Manufacturing has adopted is to incorporate these improvements into the gear machining process so that a measurable benefit is realized by our clients:

Cryogenic Machining for Superior Dimensional Stability

Thermal distortion is a primary cause of post-machining geometric error. We implement controlled cryogenic cooling at the cutting interface, which virtually eliminates heat-induced part growth. This allows us to consistently hold tight tolerances, such as maintaining gear profile deviations under 0.02mm, ensuring right-first-time quality and reducing costly scrap and rework, directly contributing to significant gear machining cost savings.

Intelligent Tool Monitoring for Uninterrupted Production

The tool may malfunction, resulting in downtime and bugs. The solution developed, a patented system using the data from the sensors (vibration, power, and so on), generates a map of the regular cycle of operation of the tool. This informs the user about the predictive replacement of the tool, hence the maximum uptime and quality, the foundation of efficient gear manufacturing.

Digital Twin-Driven Process Optimization

We create digital twins for machining. Noting machine dynamics, machining trajectories, and processes down to material, we combine them. From our digital twin simulation, we simulate cuts to evaluate possible errors that may be embedded. With optimization on a wide range of factors such as machine speed and force bound to clamping in our simulation digital twin, we eliminate trial and error in traditional procedures.

Holistic Value Integration Beyond the Single Part

We are driven in our collaboration by the comprehensive value chain for manufacturing. The benefits related to the innovations in processes, which drive improvements onto the boundaries of stability, predictability, and speed, provide a cumulative effect that leads to a reduction in costs of ownership. Our customers can rely on a stable source for high-precision components, reducing risks of supply chain management.

This charter empowers us to declare our intentions of unlocking those basic challenges that have always bugged gear manufacturing through engineering intervention. This knowledge and skill come not only from general statements about what we could do but also by the identification of the means through which we are able to do efficient gear manufacturing at low cost and with competitive advantage for our clients.

FAQs

1. What accounts for the largest portion of gear machining costs? How can it be optimized?

Material prices typically contribute to overall prices between 45-60%. Possible ways to cut down on prices by 8-15% would be the optimization of material choice and careful control of allowances. LS Manufacturing's VA/VE analysis helps customers save more than $150,000 yearly in material prices.

2. What is the fastest lead time for urgent gear orders?

Merging traditional gear library and effective response mechanisms, the company can provide samples in 3 days and small batches within 7 days, an advantage of an average 60% over the competition.

3. How is the quality stability of batch gear machining guaranteed?

SPC process control, auto inspection, and first-article inspection are performed to maintain batch CPK at higher than 1.67 and to keep the defect rate below 200 PPM.

4. How are gear machining prices priced for different production volumes?

LS Manufacturing offers a multi-tier pricing system for gear production: small production runs (< 500 units) which aim at cost optimization in processing, medium production runs (500 to 5000 units) with tooling allocation in balance, and large production runs (>5000 units) cost-effective using a specialized tool.

5. How does gear manufacturing cope with raw material price fluctuations?

The strategy LS Manufacturing applies to control the volatile prices of raw materials is futures procurement, alternative material certification, and inventory. It keeps the range within ±3% so that in any case, the costs become controllable by the customers.

6. How to assess the actual delivery capability of a gear manufacturing supplier?

We focus on equipment capacity saturation, supply chain integration, and production planning systems. The 99.2% on-time delivery rate depends upon integrated ERP-MES scheduling.

7. Will gear cost optimization affect service life?

While ensuring performance, the cost optimization is scientific. All cost reduction projects achieved by LS Manufacturing through process optimization have been verified through bench testing and their service life indicators meet or even exceed the standard requirements.

8. What information is needed to obtain an accurate gear manufacturing quote?

Please provide gear drawings-module, numbers of teeth, precision grade. Materials and heat treatment requirements, annual demand. Our firm LS manufacturing will offer detailed quotation and optimization suggestions within 2 hours.

Summary

Gear processing can realize significant cost savings and efficiency improvement through process optimization, supply chain integration, and effective management. The systematic approach developed by LS Manufacturing has enabled several customers to realize over 30% in cost savings and 40% reductions in lead times, which testifies to the possibility of technology-based quality development.

Please do not hesitate to contact LS Manufacturing for gear processing cost optimization solutions specific to the customers' needs and get a quote in accordance with the requirements for the gear and yearly demand.

Get a customized solution and quote, save 30% on costs, and shorten the delivery cycle by 40%!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.