Selecting a local laser cutting supplier is a key responsibility in project development that affects the final product quality, cost of production, and lead time. But most of the customers would make typical errors in looking for "local laser cutting services": they might be lured by cheap prices and neglect equipment precision and process capability; or they might not examine communication efficiency and post-sales service of the supplier. It then leads to hidden costs such as project delay and low quality, which once again increases the overall cost.

To avoid such mistakes, you need a reliable partner with technical expertise in addition to a good service culture. LS Precision Manufacturing, a high-quality local laser cutting services provider, incorporates advanced technology and skilled technical professionals to deliver customers high-precision and efficient cutting solutions. Here at LS Precision, we don't merely provide cutting services; we provide you with safe, risk-minimizing solutions so that you may get maximum return on investment. In order to save time, the following is a brief summary of our points of importance.

Core Quick Reference: Laser Cutting Supplier Selection Guide

| Assessment Dimensions | Key Points and Action Guide |

| Strategic Importance | Selection of the laser cutting supplier directly affects prototype accuracy, mass production uniformity, and project cost, and thus is a strategic consideration. |

| Pricing and Equipment Traps | Watch out for price pitfalls, which may be the result of old equipment with low laser power and compromised precision. Evaluate the laser equipment brand, positioning accuracy, and stability. |

| Material and Process Compatibility | Verify the vendor's familiarity with laser cutting your materials (e.g., stainless steel, carbon steel, aluminum alloy, or acrylic), their skill at handling thickness limits, and cutting quality. |

| Delivery Guarantee | Examine their production schedule and CNC programming effectiveness to determine whether they can produce rush orders. Insist that specific delivery milestones for laser cutting processing be clearly stated in the contract. |

| Real-World Capability Verification | The simplest approach is to provide your CAD drawings as hard copies to directly verify their actual process capabilities, e.g., laser cutting accuracy, surface finish, and minimum hole distance. |

| Supplier Added Value | Good suppliers can provide added value services such as laser cutting route optimization and lead point setting suggestion, which maximize efficiency and save material, and therefore are a good collaborator for your project. |

When selecting a laser cutting supplier, it is crucial to investigate their experience in detail. The secret is to peer beyond the quote and establish their laser processing experience, quality consistency, and service responsiveness for your particular needs by on-machine inspection on site, test cutting of materials, and physical proofing and thereby establishing a reliable partnership.

Why Trust This Guide? Practical Experience From LS Experts

All of these suggestions are based on LS Precision Manufacturing's decades of actual metal laser cutting experience. We know it's a matter of detail to take a drawing and turn it into a finished part: from methodically adjusting laser power and speed for varied metal thicknesses, to optimizing cutting geometries for detailed designs to save material and time.

LS Preicision have successfully fulfilled customers' urgent demands across different industries, including industrial and smart home automation. For example, through the best cutting parameters, we successfully recovered a smart lock panel project on the verge of postponement due to processing deformation from another supplier and completed the delivery smoothly.

All these experiences have given us a keen insight into the real pain areas of our clients. So not only do we have common processes, but also we give forecast and solution to any potential risk in this niche process.

LS Precision Manufacturing realize that real expertise lies in integrating your design requirement without effort with production processes, so the output is foolproof.

Why Is Choosing The Right Laser Cutting Supplier So Crucial?

Laser cutting services are a fundamental element of product design and production in current production, directly affecting the precision of component models and overall quality of the end product. This is a critical choice that affects the entire project. Choosing the wrong supplier jeopardizes your project to some risks:

| Risks | Key Points |

| Risk of Quality Loss | Irresponsible manufacturers will face obsolescence of equipment or poor workmanship, which results in inferior cut edges, excess dross, and even catastrophic defects like overheating and warpage of the material, reducing the product value significantly. |

| Risk of Delivery Delay | Improper control of manufacturing or lack of equipment capacity can quite possibly result in scheduling conflicts in manufacturing, delaying your project and ultimately losing market opportunities. |

| Risk of Over Cost | Low initial cost may conceal high hidden costs in the form of rework, scrap, and delay, and overall costs far in excess of budget. |

It is crucial to have a professional business partner such as LS Precision Manufacturing. Not only do we provide metal laser cutting services that are advanced, but we provide an overall solution that includes high precision, high speed, and complete services.

From design consultation to the last sheet metal processing, LS Precision ensures dependability and efficiency in every process, lowering risks and building a stable project success basis well.

Mistake 1: Focusing Solely On Price While Ignoring Equipment Accuracy And Stability?

When ordering metal laser cutting services, the majority of purchasing decision-makers tend to fall into the trap of concentrating only on the price. The low bid quote, though, oftentimes is a red flag of an indicator of old equipment and subprofessional workmanship that might cause a chain of unrecoverable concealed costs and threats to your project.

1. Loss of precision leading to scrapped parts:

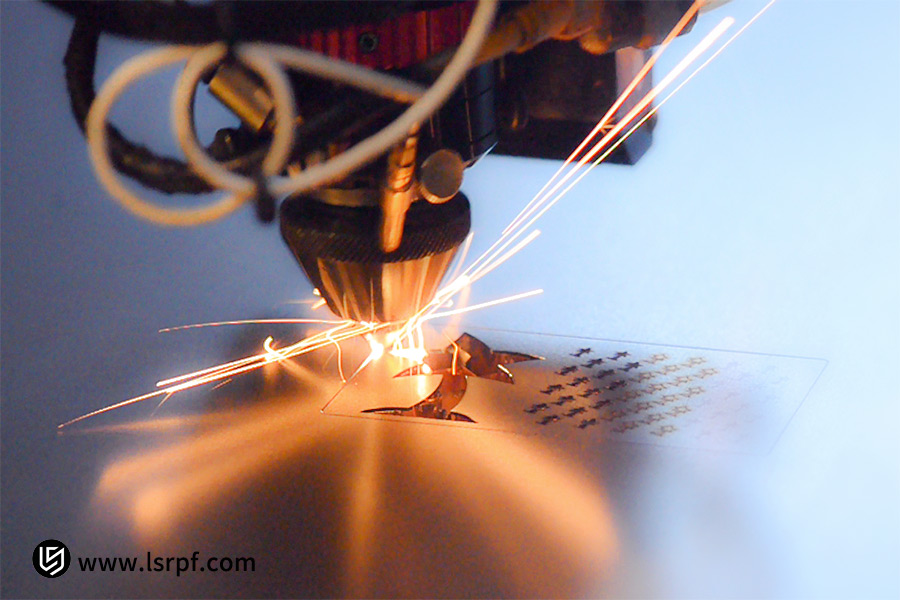

The low-end or aging laser machine has poor dynamic performance, and the cutting head oscillates at high cutting speeds, leading to extremely large errors in the cut shape and design pattern. If you require accurate custom metal laser cutting, this inaccuracy will cause direct un-assemblable parts that need to be scrapped as a complete block of material.

2. Rough cutting quality and increased post-processing:

Over-attenuation of the laser power or defocusing will cause too much dross, burrs, and burnt layers. That will subject your parts to extra grinding and cleaning at delivery, costing time and labor dollars and even damaging the workpiece surface aesthetically and functionally.

3. Poor equipment stability delays overall delivery:

Older equipment has a great likelihood of breaking down, and routine maintenance downtime is the rule. Your project can be delayed indefinitely by a poorly timed equipment breakdown, pushing your entire project schedule off track and costing many times more than the initial processing fee savings.

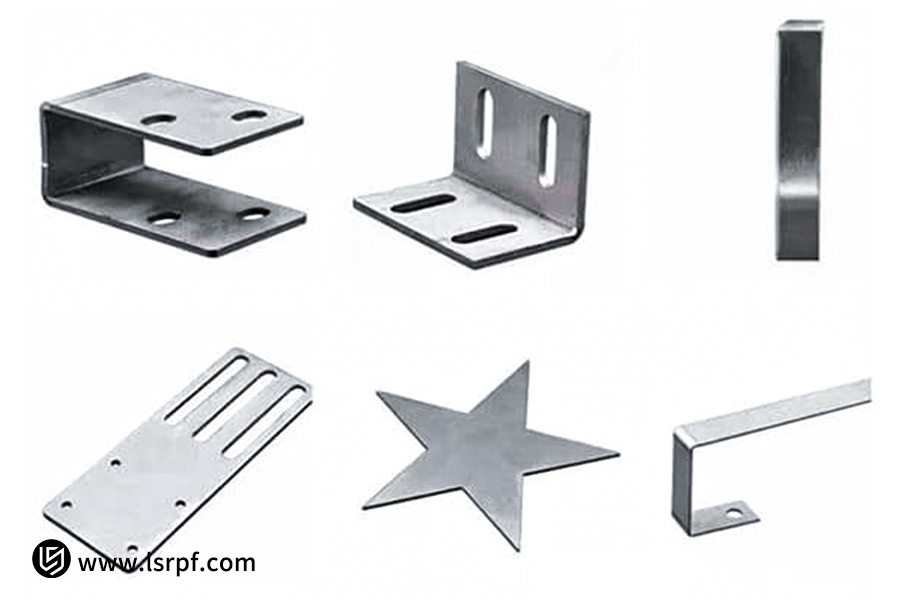

LS Precision Manufacturing keeps investing in the new fiber laser cutting machines and top-grade CNC machine tools to ensure consistent and stable cutting from day one.

LS Precision machines have machining tolerances of ±0.1mm and leave smooth cut surfaces without dross. This ensures that every metal laser-cutting component you receive maintains enhanced quality consistency and assemblability, delivering true value for money.

Mistake 2: Failing To Confirm Material Compatibility And Process Range

When ordering sheet metal processing or cutting of other materials or cutting non-metal materials, some customers simply provide just the material name without ensuring that the supplier has a good procedure for that particular material. Various materials differ considerably in laser absorption, melting point, and thermal response. Incorrectly matched cutting parameters affect efficiency at best and actually cause workpieces to be scrapped at worst.

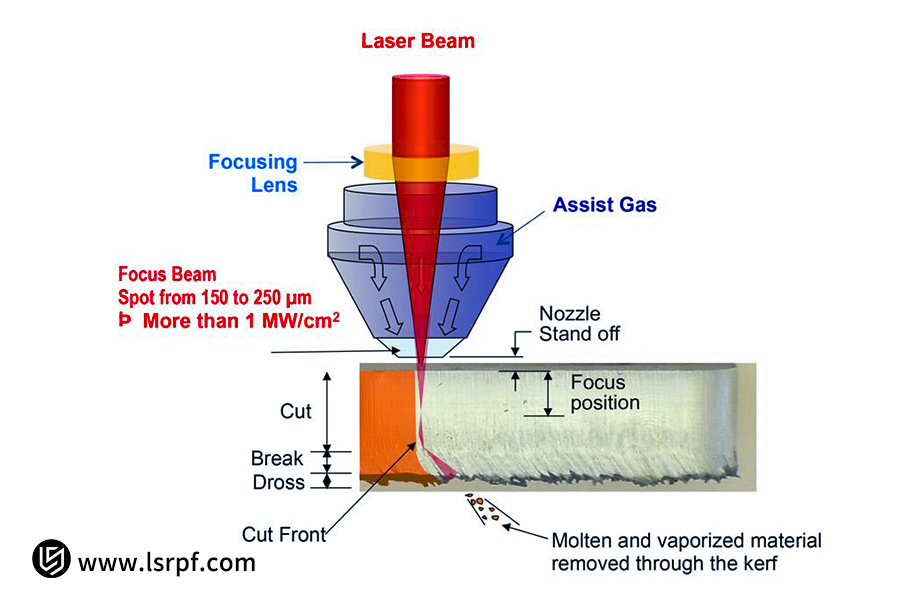

1. Metal Materials: Parameter Mismatch Leads to Quality Defects

During cutting of different metals such as stainless steel, aluminum, and copper, strict control of laser power, speed, and assist gas is required. For instance, cutting of aluminum is prone to reflection hazard, and cutting carbon steel requires oxygen-assisted burning. Unprofessional manufacturers, by the absence of equipment or experience, can create the cut surface of stainless steel with serious oxidation and discoloration, or hard, difficult-to-clean slag on the cut edge of aluminum, leading to inconvenience in subsequent processes.

2. Acrylic: Poor process impacts the aesthetics of the finished product

The key to acrylic laser cutting services is achieving a crystal clear, flame-smoothed edge. One can easily end up with over-melting, white edges, or foggy metal with improper processing, severely impacting product quality. Skilled cutting can create a near-polished finish, minimizing secondary processing needs.

3. Wood and Composite Materials: Controlling Burns to Maintain Clean Edges

LS Precision's wood laser cutting trick is in controlling the thermal effect of the laser to avoid over-carbonization and burning of cut edges. This is needed for lovely models, crafts, and furniture components. Experienced operators can modulate power and speed to successfully cut and preserve the original texture and loveliness of the wood.

The major plus point of LS Precision Manufacturing is our extensive material and process repository and sufficient hands-on experience. Not only do we provide sheet metal processing services of various metals to perfection, but we also target perfection in wood and acrylic laser cutting.

Mistake 3: Unfulfilled Delivery Dates: How To Avoid This?

Among the other risks of utilizing a local laser cutting service is trusting suppliers' unrealistic delivery timelines. Suppliers often rashly shorten production cycles to secure orders, then are beset with serial delays in manufacture due to capacity overload, machine breakdown, or poor management, and ruin your entire project schedule.

- Risk 1: Production Plans Are Ineffective. Suppliers who lack scientific scheduling facilities will most likely be in "firefighting" mode. Your order will be inserted whenever, but unplanned downtime due to built-up backlog of prior orders or unplanned equipment maintenance renders the planned delivery date impossible.

- Risk 2: Lack of Emergency Response Capabilities. When mission-critical urgency is required, amateurish supply chain systems become inflexible. They will not redirect resources to expedite your order, and the so-called "expedited" shipping is an empty guarantee.

- Risk 3: Lack of Transparent Communication and Passive Waiting. When there are delayed orders, these suppliers will not discuss openly and actively, and you are left passively waiting and complaining, unable to get proper information on the progress of production and make wise decisions.

In order to bypass this problem, the key is to select a partner like LS Precision Manufacturing, a partner that values "delivering on promises." We are aware that timely laser cutting service is the lifeblood of our customers' production. So we ensure clean delivery dates in the following ways:

- Scientific capacity planning: LS Precision schedule production against available equipment load and order status, never over-schedule orders, and maintain sufficient capacity to meet each commitment.

- Effective scheduling: LS Precision utilize a computerized management system to maximize cutting routes and sequences of production for maximum production efficiency and ability to respond rapidly to your urgent requirements.

- Open process communication: You will never know where your order stands with respect to production status, and we will actively synchronize information at critical points, so you are always in the loop and can have peace of mind.

Because you are working with your local laser cutting service expert, LS Precision's intention is not only to cut it, but to be your rock-solid and reliable "back-end factory" for your projects' safe delivery.

How Can You Verify A Supplier's True Processing Capabilities?

You can't rely on word of mouth or brochures to make the decision regarding the authenticity of a laser cutting service provider. Real strength requires hard, tangible evidence. The following are some practical ways of forming an idea regarding a supplier's real capacity:

1. Request an on-site or online factory inspection:

The simplest method is to visit their factory. Be it going to the Dongguan, Guangdong Province factory of the laser cutting service provider or seeing a real-time online video, one can personally observe the brand equipment, appearance, workshop management, and operation standards—a direct illustration of their capability.

2. Request diverse material samples:

Request that the supplier send actual samples of different materials they have handled (e.g., stainless steel, aluminum, and acrylic). Inspect the samples thoroughly for accuracy of cutting, quality of surface, minimum hole spacing, and scorch marks and distortion. These are standards for ascertaining their process suitability and consistency in processing.

3. Study their case studies:

Request the supplier to provide successful case studies that are comparable with your project (e.g., level of complexity and material) including drawings and photographs of the end product. Detailed case studies demonstrate their capability of processing real life issues, as opposed to core processing capability.

LS Precision Manufacturing is always with an open and honest cooperative spirit. We sincerely invite all potential customers to come to visit our Dongguan factory in person or check our factory online in real-time by video.

LS Precision is pleased to show you around our sophisticated machines, standardized process, and professional workers, guaranteeing you with reliable laser cutting services. Our cooperation begins with honesty and develops on the basis of professionalism.

High Communication Costs: How Can I Ensure My Requirements Are Accurately Understood?

For specialty sheet metal fabrication and metal laser cutting services involving complex work, clear communication of technical details is the success factor. Repeated communication with inexperienced customer service staff leading to miscommunication is a key culprit for returned parts. This "communication cost" is so fine-grained that it may not be felt until something goes wrong, yet it can already precipitate irreparable damage.

- Risk 1: Misunderstanding Drawing Details. Amateurs may not understand technical drawing notes of a high level (e.g., tolerances, datums, and special process specifications), and this causes parts to fail to meet critical dimensions or performance.

- Risk 2: Improper Process Selection. Differing design intent requires differing cutting process. Miscommunication leads to the inappropriate process being selected. For instance, stainless steel parts for cutting with nitrogen in order to gain a clean, oxide-free surface can be cut using oxygen, and this will result in a black, oxidized surface.

In order to better prevent such issues, LS Precision Manufacturing established a professional link system of project engineers:

- From the moment you submit an inquiry, there is a seasoned project engineer waiting to provide one-on-one service throughout the entire process. Not only can they quickly and accurately read through your technical specifications and drawings, but they can also proactively provide you with a Design for Manufacturability (DFM) analysis based on their extensive sheet metal fabrication expertise.

- For your own personal metal laser cutting project, the designs will be checked by an engineer and optimization suggestions will be provided for any potential design flaw that will impact cost or quality, e.g., sudden angles, excessively close hole spacing, or slot widths that are not suitable.

Preemptive and professional communication from LS Precision assures all of your specifications are faithfully and accurately translated into production instructions, achieving genuine "zero communication errors" and successful projects on the first attempt.

LS Case: How Did They Save A Smart Lock Project From Imminent Delay Due To Supplier Error?

Supply chain dependability sits atop hardware product development agendas. The second example is an actual description of how a committed local partner can be the crisis savior for a project.

1. Customer Dilemma:

The flagship smart lock project of a smart hardware firm had arrived at the final phase of mass production. But due to questionable equipment precision, the first supplier's batch-cut aluminum alloy lock housings contained out-of-spec tolerances on the assembly holes of the core module, in that the core module could not be installed. Not only did the original supplier fail to reprocess the parts in a timely manner, but they also backed out, threatening the customer with production line shutdown and huge contract breach, and threatening the whole team with panic.

2. LS Precision Solution:

The client called LS Precision in desperation. Our project engineers acted quickly, technically reviewing in two hours of viewing the drawings and acknowledging the potential shortcomings of the original process. Our programming team coded overnight that night to re-optimize the cutting path and parameters. To a high-power fiber laser cutter, we applied high-purity nitrogen as an assist gas, suitable to the property of the aluminum alloy material. Production began the next day, and all of the parts cut correctly the first time.

3. Results:

It took less than 24 hours from receiving the problem drawings at LS Precision to the delivery of the first batch of qualified parts to the customer. The batch of quality components perfectly solved the assembly problem and saved the entire project for the customer. Such rescue not only saved the customer from enormous losses, but also gained their firm trust by virtue of our sound technical competence and customer-centric philosophy. LS is now their long-term strategic sheet metal parts partner.

In case of emergency for your project, a sound local partner is your last guarantee. Make an appointment with an LS Precision engineering expert today for free one-on-one consultation!

Beyond Cutting, What Other Value-Added Services Should A Quality Supplier Provide?

The value of a good metal laser cutting service provider is much higher than receiving properly cut parts. Its true value lies in the fact that it can be integrated into your production process, a one-stop facility. LS Precision Manufacturing's sheet metal processing services are based on this principle, providing value-added services far greater than the cutting itself.

1. Post-Process Integration

LS Precision offers a complete set of post-processing capabilities, such as cutting, bending, welding, and deburring. This enables your parts to have most of the processing done here in our facility without sending parts from supplier to supplier. This drastically shortens the whole manufacturing cycle and eliminates the errors and cost of repeated communications.

2. One-Stop Surface Treatment

Besides shaping, LS Precision also possesses a large set of surface processes of powder coating, electroplating, and anodizing. This implies that from raw material to the finished product, appearance, texture, as well as function specs, are tightly controlled in one system, which ensures continuous product quality.

3. Design Optimization and Technical Support

The LS Precision engineers will proactively provide you with Design for Manufacturability (DFM) analysis of your blueprints, providing you with professional process cost-saving and feasibility recommendations. This early intervention works effectively to avert design flaw, improves production efficiency, and allows you to keep your overall costs in check right from the outset.

When you contact LS Precision, you receive more than a metal laser cutting service; you receive a very productive "outside production department." Our single-source sheet metal processing capabilities are dedicated to streamlining your supply chain management, minimizing product time to market, and actually achieving cost saving and efficiency gain.

FAQs

1. How many materials does LS Precision support laser cutting?

LS Precision has a complete material processing capability, from intricate cutting of most metals and non-metallic materials. They include stainless steel, carbon steel, and aluminum to copper, brass, and other metals to engineering plastics like acrylic, wood, and ABS. Most importantly, we have a large database process for various materials, and therefore we are able to recommend and apply the most appropriate laser cutting parameters based on your material brand, thickness, and end-use application to ensure optimum cutting quality and efficiency.

2. Is there a minimum order quantity (MOQ) requirement?

LS Precision fully understands the needs of product development, prototyping, and small-batch manufacturing requirements, and hence we provide you with convenient and flexible small-batch manufacturing services. We solemnly commit to accepting orders for a minimum order quantity (MOQ) of 1 piece. The aim of this policy is to allow you to test your designs at minimal cost risk, supporting you from prototype to small-batch test production, making it easy for you to make your ideas a reality.

3. What documents do I need to provide for an accurate quote?

For an instant and accurate quote, you just need to have a 2D vector drawing file of an industry standard format such as DXF or DWG. If you are placing an inquiry, please let us know the material type, exact thickness, surface treatment required, and approximate quantity. Upon receipt of this information, LS Precision quote engineers will thoroughly examine and forward to you a quote with itemized costs, process recommendations, and a mutually accepted delivery date, normally within the hour.

4. How can I ensure my design is suitable for laser cutting?

You don't need to take it upon yourself to concern yourself with making your drawings manufacturable. LS Precision offers a free Drawing Design for Manufacturability (DFM) service. The moment you deliver the initial sketches to us, our project engineers will carefully scan for aspects that can affect cutting quality or cost, e.g., sharp edges, very narrow slits, and minimum apertures, and provide optimization recommendations by experts. This value-added service actually avoids common production errors, which will save you money and time.

Summary

Choosing the right laser cutting supplier is not a question of price comparison but of strategic choice in entirety that can make or break your project. By avoiding pitfalls which this article has outlined, such as choosing on price alone with no consideration for accuracy of equipment, suitability of material, and delivery dependability, you can actually avoid hidden risks and cost pitfalls.

LS Precision Manufacturing, your local high-quality provider, is committed to being your reliable manufacturing partner. Relying on our cutting-edge equipment platforms, deep material and process database, deep project experience, and one-stop back-end services, we provide one-stop support from precision cutting to finished molding so that all concepts become reality efficiently in high quality.

Let professionalism be the passport to the success of your project! Upload your designs today and benefit from our free Design for Manufacturability (DFM) check and quote service, as a first step toward a fruitful partnership.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com