Have you ever submitted an RFQ electronically, only to wait hours or even days for a rough preliminary quote that must be repeatedly clarified? This industry norm is silently chewing up your precious project time and decision-making schedule. In the time-sensitive manufacturing industry, a wasteful request for quotation process is a cost in itself.

LS Manufacturing is dedicated to making this reality different. Our "speed" guarantee is not just speed: you have access to a detailed, open quote in 10 minutes using our intelligent system. It's also quality-focused—this quote is based on an accurate process analysis of drawings you've uploaded, including a transparent cost breakdown with no hidden surprises.

Upload your CAD files or design drawings today and experience LS Manufacturing's open and efficient quoting firsthand. In appreciation, you will also be provided a special "Design for Manufacturability Optimization Proposal" to allow you to achieve even greater cost and efficiency savings for your project. To save you time, here’s a quick overview of the core conclusions.

Quick Reference Table Of Core Elements Of Sheet Metal Quotation

| Dimensions | Key Parameter | Impact on Cost and Lead Time |

| Design for Manufacturing (DFM) | Bending complexity, number of holes, and tolerancing requirements. | The effect is essential. Best-practice design can directly reduce costs by 10%-20% and reduce production stages. |

| Material | Material type, sheet thickness, and optimization of sheet material usage. | These are major cost factors. They account for raw material cost; efficient nesting will minimize waste significantly. |

| Process | Cutting, bending, welding, and surface treatment. | These are the minimum cost drivers. The higher the number of operations and complexity, the higher the time and cost. |

| Order and Control | Order size, package, and shipping conditions. | These affect unit price. Batch runs are able to spread cost; special conditions will be additional. |

This concise summary describes the four fundamental elements of sheet metal quoting. Slowness in traditional quoting is due to inefficient manual calculation of these parameters.

LS Manufacturing's intelligent quoting engine, by integrating specialized manufacturability know-how into the system, provides real-time analysis and accurate pricing.

Why Trust This Guide? Real-World Experience From LS Manufacturing Experts

All the recommendations of this guide are based on LS Manufacturing's over ten years of experience and accumulated data in sheet metal work. We not only have the latest, highly automated equipment like laser cutting and CNC bending, but the core of our quoting and process engineering team also has over eight years of frontline experience and have processed tens of thousands of complex cases, from telecom enclosures to precision medical equipment.

Hence, LS Manufacturing understands that a "reasonable" estimate is more than material cost and labor hours. It is actually the true forecast of production problems. As an example, we helped a customer reduce steps to bend by three, from seven to four, by tweaking a design detail without reducing functionality. This reduced cost per part immediately by 18%.

This practical knowledge is deeply ingrained in the quoting process and Design for Manufacturing (DFM) analysis at LS Manufacturing. What you receive is more than a quote; it's the essence of our vast, realistic experience.

Why Is The Traditional Sheet Metal Quoting Process So Slow And Opaque?

Are you waiting hours and getting nebulous estimates when ordering sheet metal quotes? This isn't an isolated incident, but one manifestation of many entrenched pain points in the legacy model.

1. Manual review, an efficiency bottleneck:

The traditional process also relies heavily upon the experience of the quoter. Each new drawing must be searched for manually, translating all of the dimensions, bends, and tolerances. Engineers are inundated with the number of inquiries, and it takes a long time, resulting in the extremely slow process of obtaining sheet metal processing quotations.

2. Cross-departmental communication, a serious Internal flow:

Quoters are not omnipotent. Presented with complex processes or unorthodox materials, they have to continually coordinate with engineering, procurement, and other functions to check process routes and material costs. This in-efficient in-house loop also serves to prolong waits.

3. Empirical estimates, a vagueness:

It is at the final stage that quoters rely on past experience from performing similar assignments to make their "estimates." This results in very inaccurate quotes with one overall price figure, making it difficult for customers to clearly identify what are the accurate components of costs such as materials, processing, and surface finishing. It is this "black box" model that results in error and a lack of transparency in the final quote of sheet metal, sowing the seeds of controversy for future undertakings.

The traditional method is founded on manual labor, fragmented procedures, and inaccurate estimating, leading to the twin dilemmas of inefficiency and information lack of transparency.

How Does LS Manufacturing's "Smart Quotation Engine" Deliver Accurate Quotes In Just 10 Minutes?

Waiting for days has been a major pain area in the industry in the traditional sheet metal quotation system. LS Manufacturing's initial smart quotation system has made it all a thing of the past, and now genuine online sheet metal quotations can be made and obtained with accurate, detailed quotes in 10 minutes. Our intelligent quotation engine ensures fast sheet metal quoting by virtue of the following three fundamental processes:

1. Intelligent Drawing Analysis:

The system uses sophisticated image recognition technology to automatically extract key manufacturing details from your uploaded drawings. From complex geometric profiles to accurate aperture sizes, or even high tolerance specifications, the system recognizes and measures instantly features, ensuring a solid basis for subsequent quotes.

2. Real-time Data Matching:

According to analysis results, the system references immediately the included process parameter database and correctly identifies the corresponding:

- Material Cost: Automatically calculates material costs based on determined material type and thickness;

- Working Time Standard: Accurately calculates working time for every process depending on process complexity;

- Process Path: Smarts to design the ideal manufacturing process to minimize cost.

3. Structured Quote Generation:

The system intelligently integrates all the cost elements to create a readable and concise structured quotation. The accurate sheet metal quote not only displays the overall cost but also sub-items such as material cost, processing fee, and surface treatment fee, giving you an overall idea of the cost profile.

| Processing Steps | Core Functions | Value |

| Intelligent Drawing Recognition | It automatically identifies drawing. | It attributes without manual inspection and improves efficiency. |

| Data Matching | Automatically cross-references process parameters. | Ensure quote precision. |

| Quote Generation | It delivers formatted information. | Cost transparency |

This new system translates over a decade of sheet metal manufacturing experience into an exact algorithm. Not only does it enable rapid sheet metal quotation processing, but it ensures the professionalism and reliability of each quote, allowing you to get the best value cost analysis in real-time.

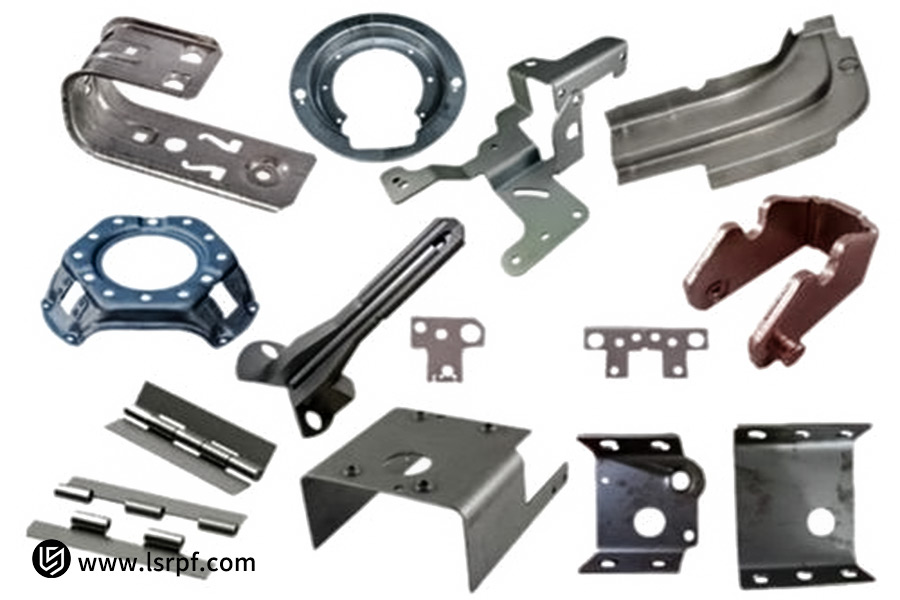

5 Core Factors Determining The Final Cost Of Your Sheet Metal Parts

An accurate sheet metal costing isn't just a price issue; it's actually a measure of manufacturing feasibility. Knowledge of the following five fundamental factors will further inform you regarding sheet metal cost factors and allow you to work with us to identify areas of improvement.

1. Material Selection and Utilization:

Material cost is the minimum cost. Significant cost difference exists in applying common cold-rolled steel (SPCC), stainless steel (SUS304), or aluminum alloys (such as Al6061). More significant is the usage of sheet metal: waste reduction through intelligent nesting is essential in controlling sheet metal costs.

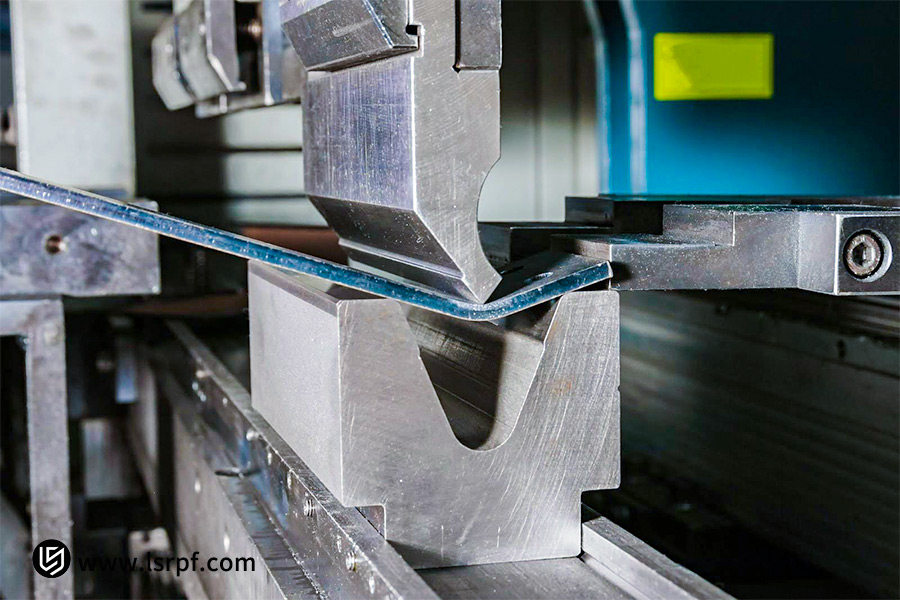

2. Processing Time and Processes:

Laser cutting is calculated on the basis of overall cutting time per meter. The more complex the holes, the more time is taken. Bending charges are directly proportional to the number of bends. Good process planning can save a lot of processing time for each process and therefore result in overall cost savings.

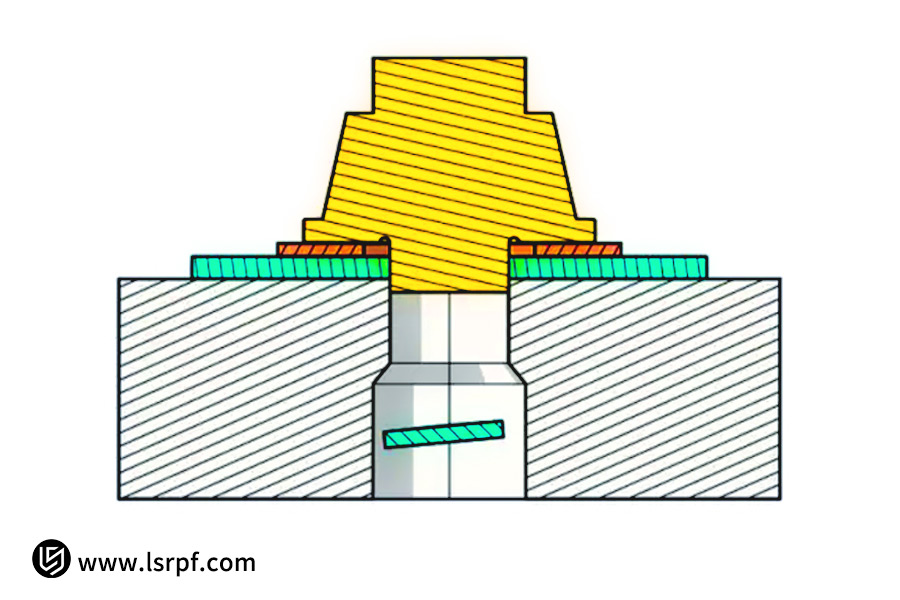

3. Process Complexity:

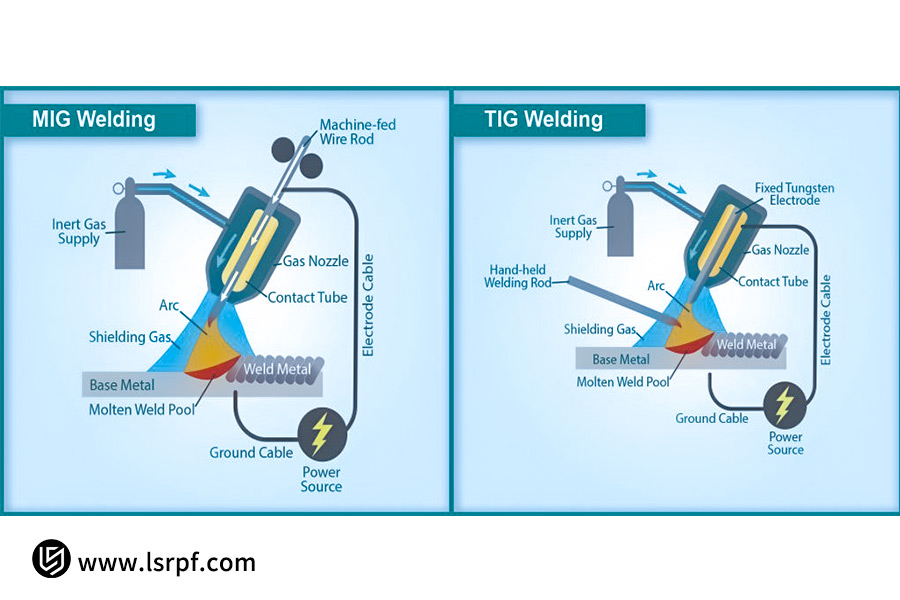

Besides the normal cutting and bending, processes such as countersinking, rivet nuts, or welding require specialty fixtures, tools, and man-hours and are thus essential variables factoring in sheet metal cost accuracy analysis.

4. Surface Treatment Requirements:

Prices of different treatments, such as powder coating, electroplating, and anodizing, are significantly different and their cost is a function of the area to be treated. Selecting a treatment process that is both functional compliance and cost-effective is essential in cost control.

5. Order Quantity and Packaging:

Batch production is able to spread fixed costs such as mold commissioning and equipment preparation, which realizes huge economies of scale. However, it also entails the need for packaging and logistics expertise, which incurs additional costs.

With a structured evaluation of these five key factors, we not only provide a quote but also a comprehensive sheet metal cost analysis report that helps you achieve cost optimization from design and procurement initiation itself.

How LS Manufacturing Saved Client A 15% In Sheet Metal Costs Through DFM Recommendations

This real LS Manufacturing case best illustrates how professional design for manufacturability analysis generates valuable value for customers. With precise sheet metal cost estimation and practical optimization alternatives, we effectively helped Client A save 15% on sheet metal costs without sacrificing quality.

1. Initial Client Requirements:

Client A provided line drawings for one side panel of communications chassis and requested it be fabricated from 2.0mm SUS304 stainless steel. The drawing contained an abundance of small mounting brackets for future welding and mounting, forming a complex arrangement.

2. LS Manufacturing Cost Analysis and DFM Recommendations:

When we reviewed the sketches, no quotation had been provided by our engineers. Instead, they provided a comprehensive Design for Manufacturability (DFM) analysis report with three key optimization recommendations:

- Structural Integration: We recommended substituting several independent brackets in non-critical load-bearing positions with one-bending structure integrated into the side panel. This eliminated welding, which saved processing time and cost significantly.

- Material Optimization: After strength verification, we had recommended replacing 2.0mm thickness SUS304 with 1.5mm thickness SPCC galvanized steel in non-load-carrying areas. This saved a lot of material cost and weight without reducing the functionality needed.

- Layout Optimization: We have redesigned the layout of the ventilation holes inside the panel so that their layout utilization within standard sheet metal was increased by nearly 20%, thus reducing material wastage at the source.

3. Results and Value:

Customer A finished every one of our professional recommendations. Finally, the sheet metal price for this order decreased by 15% and saved tens of thousands of yuan on the entire order in the entire cost altogether. The customer was extremely satisfied with the results and said that LS Manufacturing is not just a supplier but a cost-saving value partner who cannot be replaced.

This LS Manufacturing case better shows us that value of good design review is far higher than just low-price negotiation.

What Information Can I Provide When Submitting A Quote Online To Expedite The Process?

In receiving an instant sheet metal quote, and also a perfect refined quote system, precision of your original data is just as important. Properly defined inquiry package optimizes easy use of our system and avoids long backward-and-forward communication. Your waiting time will be minimized by using the "Perfect Inquiry Checklist" below:

1. Core Documents: Correct 2D/3D Drawings

Supply drawings in supported formats (i.e. DXF, DWG, STEP, IGES). Drawings should be fully dimensioned, including tolerances, technical details, and cross-section details as needed. This is used as the starting point for intelligent image recognition and process analysis of the system. The more detailed the data, the better the quote.

2. Material Specifications: Clear Material and Thickness Requirements

Please notify us politely of your material type preference (e.g., SPCC, SUS304, Al6061) and exact thickness. If you have any special material requirements (e.g., strength or corrosion-resistance), please also notify us of these. This will allow us to provide improved options.

3. Post-Processing Requirements: Surface Treatment Process

Specify the final surface finish, i.e., powder coat color and coat thickness, electroplating type (e.g., zinc plating, nickel plating), or anodizing color. This will have direct implications on outsourcing cost and production cycle planning.

4. Business Information: Order Quantity and Expected Delivery Time

Inform us of your estimated order size (e.g., pilot runs of 100 units, mass production of 5,000/month) and preferred delivery date. Unit price is directly influenced by quantity due to economies of scale, and delivery time will influence manufacturing scheduling priorities and is required in order to provide a competitive bid.

Including this complete information not only presents you as professional but also allows our smart system to exactly fulfill your needs, offering you an accurate, complete, and instant sheet metal quotation in a matter of minutes. Start creating your perfect inquiry package today!

Beyond Price, What Else Should A Professional Quote Include?

A professionally accurate sheet metal quote is well worth so much more than the final bottom-line price. It is a line-item breakdown of the expense, showing professionalism and a sense of cooperation on the part of the supplier. LS Manufacturing is extremely adamant that open pricing is the key to establishing long-term trust. A professionally constructed quote should plainly state the following breakdowns:

- Material Costs: Material type, specifications, piece price per unit, and consumables cost per unit are accurately detailed and enumerated, providing a clear understanding of all aspects of raw material costs.

- Processing Costs: Each processing step by step, like laser cutting, press bending, etc., are itemized so you understand the actual cost of each manufacturing process.

- Surface Treatment Costs: The cost of treatments such as powder coating, electroplating, and anodizing are individually listed to allow you to compare the cost feasibility of different process options.

- Outsourcing and Special Processing Costs: Special processes such as welding and riveting are individually listed and never grouped with other items.

- Overhead and Profit: We plainly display to you reasonable cost of doing business and a reasonable profit margin, a stark difference from open-ended quotations that have hidden costs elsewhere in the parts.

LS Manufacturing's transparent pricing approach not only ensures accurate sheet metal quotations but also enables you to make your decisions based on total cost data.

Can I Enjoy Competitive Pricing For Small Orders?

"Small batches inevitably cost more"—this may be an industry norm, but it's not a law that can't be broken. As a modern sheet metal fabrication factory, LS Manufacturing has built cost-effective solutions for small batches with innovative manufacturing models. We make the cost optimal for small batches with the following methods:

1. Flexible Production System:

We have also made investments in multi-purpose production lines that allow instant tool and program changing. This enables effortless switching between small batch orders with varied specifications, reducing production preparation time from hours to minutes, effectively reducing equipment commissioning costs from your unit price.

2. Intelligent Scheduling and Panelization:

Our intelligent scheduling system optimizes the loading of multiple small batch orders of various specifications from a set of customers onto a shared material palette. This "panelization" production process significantly increases the utilization rate of off-the-shelf sheet metal material, hence eliminating material costs per order, allowing you to enjoy material prices similar to large orders for small batches.

3. Standardized Process Modules:

As a professional sheet metal fabrication manufacturer, LS Manufacturing standardized and modularized standard processes (e.g., bending angles and cutting routes). When processing low-volume orders, the system automatically puts together these mature and efficient standard process modules, bypassing intricate, customized programming and increasing processing efficiency with assured consistent quality.

When you have LS Manufacturing as your sheet metal fabrication manufacturer, regardless of the size of your order, you enjoy the efficiency benefit of our optimization technology.

FAQs

1. Do my design drawings need to be kept confidential?

You are assured. LS Manufacturing understands your valuable intellectual property in the form of design drawings are your property. We have a legally binding, mandatory Non-Disclosure Agreement (NDA) with our clients prior to any project. Your technical documents and project information are deposited into a controlled confidentiality management system with access restricted to authorized project personnel. Your business confidentiality is safeguarded by us at the very highest level of professional ethics with no loss of information.

2. If there are minor design changes after a quote, do I need to re-quote?

For minor design changes, you don't need to worry about a time-consuming process. Our intelligent quotation system responds quickly, accurately marking out changes and re-pricing. Most often, simply upload new drawings online, and the system will automatically create a new quote for you within minutes so you can enjoy up-to-date cost information and efficient project decision-making.

3. How long are your quotes valid?

LS Manufacturing quotations typically have a 30-day validity period from the date of issuance. The time limit is in reference to the prevailing stable raw material market conditions. We also undertake that if significant price fluctuations are likely to take place within this time frame, our account managers will directly communicate with you in an open manner to ensure that both parties are equally agreed and can manage fluctuations in the market together.

4. Can you provide a lump sum price that includes shipping?

Yes. To present you with a completely turnkey quotation, we include shipping in the price. We just need you to provide us with your accurate shipping address during inquiry, and we will come up with the most economical logistics plan and fees based on shipment weight, volume, and destination. These will be clearly stated in the final quotation for your complete awareness of the overall amount.

Experience LS Manufacturing's Distinctive Quoting Service Now

Chosing LS Manufacturing for sheet metal quotes will give you so much more than just speed; it will also give you an open, value-added partnership model.

1. Ultra-Fast Response, Get Results in 10 Minutes:

Bye bye lengthy waiting times. Our patented smart system provides you with an actual online sheet metal quote experience, delivering accurate quotations to you in under 10 minutes, enabling you to accelerate project decisions.

2. Cost Transparency, Every Penny Counts:

LS Manufacturing commit to giving you itemized, organized quotes. You will clearly know the cost breakdown of each item, from material to processing and surface finish. All this full transparency sets a solid base of trust and gives you assurance.

3. Professional Value-Added, Complimentary DFM Optimization Recommendations:

This is more than just a quote. You'll also receive our expert engineers' Design for Manufacturability Optimization Report, highlighting potential areas of optimization from the source to allow you to successfully reduce sheet metal costs while enhancing product quality.

Upload your drawings now and experience for yourself how we blend efficient online sheet metal quotes with expert consulting services to deliver tangible value to your project.

Prepare Your Drawings, The First Step To Efficient Collaboration

Getting successful collaboration under way is as simple as one step. Publish your design drawings now and find out about LS Manufacturing's unique, fast sheet metal service. You can submit your order via any of the following simple steps: uploading your document in our online quote system; emailing it to a designated business email address; or direct submission via our official website.

This is not about receiving a proper sheet metal quotation; it's about beginning a professional manufacturing relationship. LS Manufacturing eagerly anticipate providing a comprehensive cost analysis and professional recommendation in ten minutes, in collaboration with accelerating your project to reality efficiently.

Upload your design drawings now and get an instant sheet metal fabrication quote ( sheet metal fabrication price), let LS be your strong backing in pursuit of ultimate sheet metal fabrication precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com