In the grand picture of the manufacturing industry,sheet metalprocessing is like a dexterous paintbrush, outlining works of various shapes and functions on thin metal sheets. From simple metal sheets to complex mechanical equipment casings, sheet metal fabrication uses its unique craftsmanship and technology to transform ordinary metal materials into practical and beautiful product parts. So,how does sheet metal fabrication work?This article will take you to explore the mysteries of this field in depth, revealing howsheet metalundergoes a series of delicate operations such as cutting, stamping, bending, and welding, and eventually becomes an indispensable part of our daily lives.

What is Sheet Metal Fabrication?

Sheet metal fabricationis simply a process of processing metal sheets. It covers a series of processes from simple shearing and cutting to complex stamping, bending, welding, etc, aiming to shape metal sheets into specific shapes and sizes that meet customer needs and design requirements.

What are the advantages of sheet metal fabrication?

Sheet metal fabrication includes a variety of techniques that offer many benefits. The final parts have uniform wall thickness with remarkable mechanical properties. The following are some of the majoradvantages of sheet metal fabrication

1.Accuracy and Efficiency

The accuracy and efficiency of sheet metal fabrication are top-notch. It is suitable for producing both prototypes and end-use parts. Furthermore, it is critical to understand that most sheet metal techniques are automated. The use of CAD software and CNC machining eliminates human errors. As a result, the final products usually have few or no deformations.

2.Versatility

The sheet metal fabrication process uses an array of techniques and tools. This makes it easy to choose the most suitable method for your project. Furthermore, metal parts fabrication does not limit the materials one can use. There are a thousand and more compatible metals. However, the application of the final part will influence the material you use.

3.High Capacity Production at Low Cost

With sheet metal fabrication, one can achieve a production capacity that is equal to the market demands. Though the initial cost may be high and the time of setting up may be long, it gets better when production begins. The more the parts produced, the more money one saves.

4.Manufacturing of Lightweight Components

Sheet metal fabrication produces lightweight yet durable parts. The excellent light-weight-to-strength ratio makes them useful in automotive and aerospace part manufacturing. Ultimately, it reduces manufacturing costs and improves fuel efficiency.

5.Custom-Built Designs

Sheet metal fabrication can be used to come up with innovative designs to build customized and unique parts. It is flexible and easily transforms metal sheets into personalized and aesthetically pleasing parts. The metal sheet fabricator can come up with innovative ideas and produce functional customized products.

What Materials are Used in Sheet Metal Fabrication?

1.Stainless Steel

Stainless steel material types for sheet metal fabrication and design are durable, cost-effective, and have excellent mechanical strength.

2.Copper

While copper is expensive, its excellent durability, thermal properties, and chemical resistance make it a popular type of material for fabricated sheet metal parts.

3.Aluminum

Aluminum is an excellent pick for sheet metal fabrication design when an effective strength-to-weight ratio is a priority.

4.Brass

Brass is an alloy of copper and zinc, which indicates its combined hardness and corrosion resistance properties.

5.Pre-Plated Steel

Pre-plated steel is similar to regular steel except that it has undergone coating with another metal, usually zinc. Hence, it has enhanced corrosion resistance and can withstand harsh weather.

What Types of Sheet Metal are Commonly Used?

Aluminum plate

aluminum sheet metalare widely used in the manufacturing industry due to their high strength-to-weight ratio and inherent corrosion resistance, catering to most applications. In aluminum plate manufacturing, usually Al1100 grade has strong corrosion resistance and easy formability. It has high thermal and electrical conductivity, making it suitable for use in transmission or grid lines. Grade 3003 is a medium strength alloy with good formability used in heat exchangers and cookware. Of the grades 5052 and 6061, the former is more common in sheet metal manufacturing due to its strength, formability, weldability and corrosion resistance. Grade 6061 is a structural alloy used in extrusion and high-strength applications such as truck and ship frames.

Galvanized sheet

The galvanized layer on the surface of thegalvanized sheet metalcan effectively prevent the steel sheet from rusting, extend its service life, retain the mechanical properties of the cold-rolled steel sheet, and have high strength. The surface is flat and smooth, suitable for occasions where appearance is required, the price is relatively moderate, and the price-performance ratio is high. Often used in the construction industry, automotive industry, household appliances, etc.

Copper/brass metal plate

Copper is an excellent conductor, and brass (copper-zinc alloy) also has good electrical and thermal conductivity, and is easy to cut, stamp and weld. Brass has better corrosion resistance than pure copper. Due to their different properties, copper and brass each have their own uses. Low zinc brass is easy to cold form, weld and braze. Copper sheet's high zinc content allows it to develop a layer of oxide or patina that will not continue to corrode and provide the desired appearance in applications such as construction and consumer products.

Titanium metal plate

Titanium metal sheets can be defined as thin, flat sheets of titanium, a metal known for its high strength-to-weight ratio and high corrosion resistance. These sheets are produced through processes such as hot rolling, cold rolling or powder metallurgy methods. Titanium metal sheets are widely used in the aerospace, automotive, medical and marine industries and their properties are highly appreciated. Due to its high strength, high temperature resistance and compatibility with the human body, it is used in the production of products such as aircraft frames, engine parts, human implants and marine products.

How does Sheet Metal Fabrication work?

1.Design

The design phase is where the foundation for the project is laid. Designers typically create an initial sketch or 2D/3D model of a product, which can be done using computer-aided design (CAD) software or by hand. Listing important factors such as the intended use of the product, required dimensions and tolerances, and any specific materials or finishes required before production begins.

2.Cutting

Laser cutting is often the first step in the manufacturing process. Laser cutting is one of the most precise methods of cutting sheet metal because of the laser's ability to follow the programmed design and cut the material accurately.

3.Bending

Use equipment such as a bending machine orCNC bending machineto bend the cut sheet metal parts. According to the design requirements, select the appropriate bending mold and bending angle to ensure that the bending area is smooth and crack-free. For parts that require local bending, such as corners or specially shaped areas, fine operations are required to ensure bending accuracy and appearance quality.

4.Forming

The forming process bends or deforms materials into the desired shape. Unlike cutting (reducing material), shaping actually reshapes material without reducing its mass.

5.Welding

There are a variety of welding techniques available for working with sheet metal, including MIG welding, TIG welding, robotic MIG welding, and spot welding.

Metal Inert Gas (MIG) Welding: This is a typically fast welding option that is better suited for thicker materials.

Tungsten Inert Gas (TIG) Welding: Provides better control and precision than MIG. Best for thinner materials. You may also see it referred to as gas tungsten arc welding (GTAW).

Robotic MIG Welding: This is an automated version of more traditional MIG welding.

Spot Welding: This is the follow-up process to the resistance welding process.

6.Finishing

Finishing is the final step in preparing a metal product and makes it more resistant to corrosion, adding another layer of durability. It also helps make the surface look more aesthetically pleasing. Common jobs include surface treatment, polishing and powder coating with optional colors, anodizing, passivation and more.

7.Test

Conduct comprehensive quality inspections on processed sheet metal products, including dimensional measurement, appearance inspection, performance testing and other aspects. Ensure products meet design requirements and quality standards.

8.Package

Products that have been processed and inspected must be properly packaged to prevent damage during transportation and storage. During the packaging process, attention should be paid to product fixation and protection measures to ensure that the product reaches the customer safely.

What are the Techniques Used in Bending Sheet Metal?

Commonsheet metal bending technologies mainly include:

1.Manual folding

If you don’t have a press brake, hand-bending sheet metal is also an option. First, you need to calculate the bending tolerance of the sheet based on the type of metal used. Next, mark the bend lines with a marker and cut the sheet to size. Place the board securely in the vise clamps, using the block of wood as a reference for the shape or angle into which to bend the board. Next, tap the sheet lightly with a wooden mallet until the metal deforms. This method is only recommended for sheets up to 2 mm thick, as thicker sheets may break. While manualbending sheet metalis a simple and quick method, it does not guarantee the level of quality and precision that a press brake can provide. For thicker sheets or more complex bends, it is recommended to use a bending machine to avoid sheet breakage.

2.Bending machine

Press brakes are essential for fabricating structures involving sheet metal fabrication. Itsheet metal bend by punching them into the correct shape on a mold. The machine can bend panels up to 20 mm thick. There are two types of bending machines: mechanical bending machines and hydraulic bending machines. Using a press brake, you can make V- or U-shaped bends. A V-bend (V-bend) is formed when metal is stamped into the shape of a die. This bending can only be done with sheets that are not thicker than 2 mm. Air bending can also be done using a press brake, where the punch only presses the sheet to the desired angle rather than completely into the die. The bending machine is a multifunctional tool that can perform various bends on sheets of different thicknesses.

3.Laser bending

Laser bending is a relatively new technology that relies on the precision of the laser beam to produce high-quality bends. The laser bending machine combines the advantages of laser cutting and bending machines. First, a laser is used to cut the metal sheet into the desired shape and size. Next, the laser is still used to heat the area of the metal sheet to be bent, making the metal more ductile, making it easier to bend the metal sheet. After the metal sheet is heated, a conventional press brake performs the bending. Thisbend sheet metaltechnology offers several advantages, including the ability to bend quickly and accurately and to bend very thick sheets. It can also bend at very large angles without the risk of deformation or cracking of the sheet.

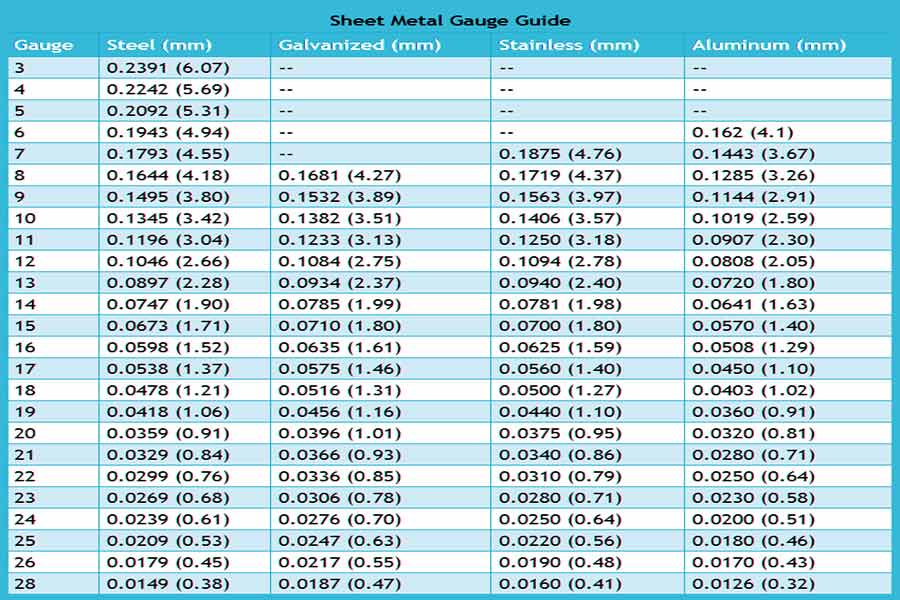

Key Takeaways on Choosing Sheet Metal Gauge Thickness

Understanding sheet metal gauge thickness is key for any project. It’s not just about picking a number. You need to consider several factors to make sure your parts fit and perform as expected.

| KeyTakeaways | illustration |

| Gauge System | Smaller numbers mean thicker metal. But gauges vary by material. Always check a gauge chart to know the exact thickness. |

| Project Needs | Think about strength, weight, and corrosion resistance. Thicker gauges offer more strength but can add weight. For outdoor projects, choose a gauge that complements the metal’s natural resistance. |

| Cost vs. Benefit | Thicker sheets often cost more. Balance material costs with your project requirements. Sometimes, a slight reduction in thickness can save money without compromising quality. |

| Material Availability | Always check what your manufacturer has in stock. Designing for unavailable gauges can cause delays and extra costs. Open communication with your manufacturer can help streamline your project. |

Choosing the right thickness requires making an informed decision. Consider strength, weight, corrosion resistance, cost and availability. Check with your manufacturer to make sure the material you are using is best suited for your needs. Some commonsheet metal gauge chart:

Estimate sheet metal fabrication costs

In today’s highly competitive market background, a comprehensive understanding of the cost structure of sheet metal manufacturing is the key basis to establish an appropriate pricing strategy. The sheet metal component production cycle covers all key stages, including cutting, bending, rolling molding, stamping and welding.

Estimate the raw material costs

We need to decompose the whole production cycle into several manageable units, and estimate these manageable units one by one to more accurately estimate the costs associated with each stage. On this premise, our focus should be on the calculation of raw material costs. Considering the product volume, material density and specific material cost, we can make an estimate of the raw material cost using the following formula:

Raw material cost = volumetric material density material cost (per kg)

As an illustrative example of the formula, assuming a density of 6.8 k g/dm3, a plate size of 700 x 300mm, a thickness of 1.5mm and a material cost of $0.8 per kilogram, we can calculate a value of unit raw material cost.

Mechanical processing cost

we can not ignore the processing cost, considering the hourly cost of the machine, the cycle working time and the processing efficiency of the system. The formula for calculating the machining cost is:

Efficiency / (cost per hour per unit of cycle time) = processing cost

For example, if the cycle time is 14 seconds, the efficiency is 84.5%, and the hourly cost is $78.8, we can calculate the processing cost per unit.

Total cost

the raw material cost and processing cost are summed up to get a total unit of direct production cost. By repeated calculation of this process in different production stages, we can fully grasp the cost structure of the whole production cycle, and provide a solid foundation for the development of effective cost and economic strategies. This detailed cost estimation plays an important role in the development of sustainable manufacturing plans and pricing strategies.

Factors affecting sheet metal fabrication costs

Several factors are particularly important in the estimation ofsheet metal fabricationcosts that will directly affect the economy and final cost of the project.

| material cost | The cost of materials used in sheet metal processing accounts for a large part of the total cost. The cost of different materials varies greatly, such as stainless steel, aluminum alloy, carbon steel and other materials at different prices. |

| Processing process | Differentsheet metal fabricationprocesses will affect the cost, such as the complexity and time-consuming of stamping, welding, cutting and other processes will affect the cost. |

| Equipment cost | The investment cost of the equipment, machinery and tools required forsheet metal fabricationis also an important factor affecting the cost. Advanced equipment and tools may increase productivity, but they will also increase costs. |

| Labor costs | Labor cost is an important part of thesheet metal fabrication cost,including the wages, training and welfare of operators, technicians and managers. |

| design requirements | The design requirements of products will directly affect the difficulty and cost of processing. Complex design requires more processing technology and precision, thus increasing the cost. |

| Purchase quantity | Mass production can usually reduce costs, because the cost of materials, labor and equipment can be saved through effects of scale. |

| quality requirements | High-quality products usually require stricter process requirements and inspection standards, which may increase costs. |

Longsheng: Your trustworthy sheet metal fabricators

At longsheng, we are not only proficient in various skills mentioned above, but we have a professional technical team that can provide leading sheet metal manufacturing services to manufacture high-quality parts for you at very competitive prices. As an ISO 9001:2015 certified company, we focus on the construction of quality management systems to provide customers with reliable services.

Our expert team has experience performing DfM (Design for Manufacturability) analysis to improve your design. We are not only a manufacturer but also a partner, committed to providing our customers with full support and expert advice to ensure designs reduce manufacturing costs while still meeting high quality standards.

If you have a design model that needs to be manufactured, please upload it to us immediately and we will provide you with a quote immediately.Choosing longsheng means choosing asheet metal fabricators with high quality, high technical level and high cost performance. Let us work together to create excellent parts for your project and achieve greater success.

FAQs

1.What is the process of sheet metal fabrication?

First, create an initial sketch or 2D/3D model of the product, use cutting technology to cut the metal plate, and then use equipment such as a bending machine, CNC bending machine, etc. to bend the cut sheet metal parts. Bend or deform the material into the required shape according to the drawings, then weld the metal plates, and finally sort, test and package the metal products.

2.How can we reduce cost of fabrication?

To reduce fabrication costs, focus on efficient material selection, streamline designs for simplicity, embrace automation for repetitive tasks, optimize energy usage, manage the supply chain effectively, invest in employee training, ensure rigorous quality control, explore reuse and recycling options, and foster a culture of continuous improvement. These strategies collectively contribute to cost savings without compromising on the quality of fabrication processes and end products.

3.What is the working principle of sheet metal?

The working principle ofsheet metalis mainly to produce the required shape and size by cutting, bending, punching and other processes on metal sheets. The combination and rational application of these process steps enable sheet metal products to be widely used in automobiles, aerospace, electronic equipment, construction and other fields.

4.How to reduce the production cost caused by the complex process flow?

Existing processes are reviewed and optimized to remove unnecessary steps. Introduce automation and robotics to reduce manual operations. Use of advanced processing equipment and tools to improve production efficiency.

Summary

Sheet metalis an important metal fabrication technologyand is widely used in many fields. High-quality sheet metal parts can be processed through precise engineering design and drawing production, strict material procurement and cutting, precise bending and assembly, and necessary surface treatment. During the fabrication process, safe operating procedures must be strictly followed to ensure personal safety and equipment safety. I hope this article can help readers better understand the process and key points of sheet metal fabrication.

Disclaimer

The content on this page is for reference only.LSdoes not make any express or implied representation or warranty as to the accuracy, completeness or validity of the information. No performance parameters, geometric tolerances, specific design features, material quality and type or workmanship should be inferred as to what a third party supplier or manufacturer will deliver through the Longsheng Network. It is the responsibility of the buyerseeking a quote for partsto determine the specific requirements for those parts.Pleasecontact usfor moreinformation.

LS Team

This article was written by multiple LS contributors. LS is a leading resource in the manufacturing sector, withCNC machining,sheet metal fabrication,3D printing,injection molding,metal stamping, and more.