Aluminium CNC turning faces both opportunities and challenges. The frequent surface scratches, precision fluctuation, even inefficiency leading to delayed delivery directly weakens your market competitiveness. Traditional machining usually faces insufficient material understanding and rigid processes that make the systematic control of machining quality difficult, especially for high-standard applications.

To that end, LS Manufacturing uses data-driven precision to define a new standard in aluminum turning and builds a closed-loop management system covering the whole chain from material science to cutting parameters. Combined with the advanced surface treatment technology, it changes aluminum turning from a manufacturing bottleneck into a quality barrier. The key for such a transformation lies in proper understanding of the synergy between the properties of aluminum and precision machining.

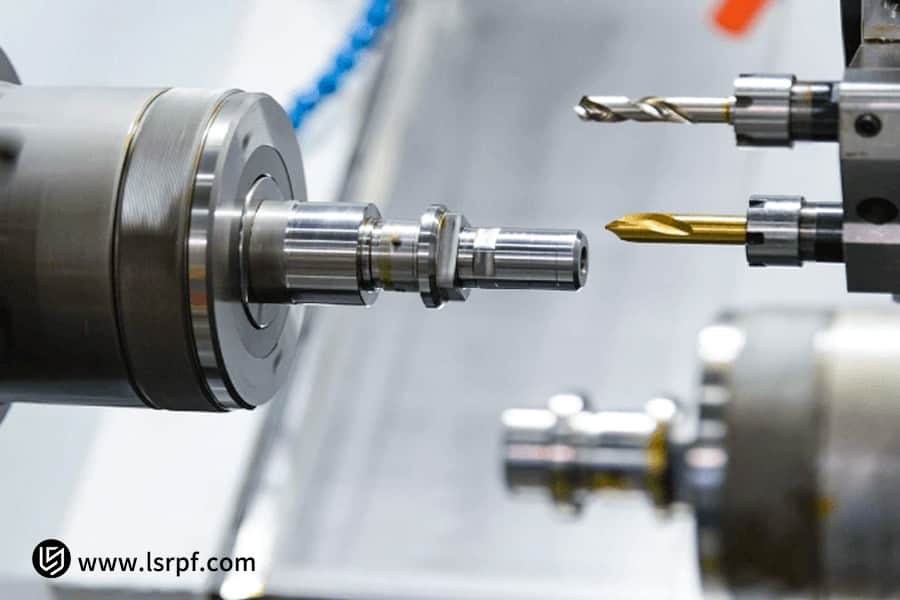

Figure 1: Precision aluminum part turning service by LS Manufacturing

Aluminum CNC Turning Full-Text Quick Reference Table

| Module | Core Points | Content Summary |

| Advantages of Aluminum Machining | Explains the inherent qualities of aluminum suitable for precision machining. | Aluminum has a lightweight and easy-to-machinate property with high specific strength, which is its inherent foundation for efficiently realizing precision turning. |

|

Core Technologies |

Specialized material processing, closed-loop quality control, advanced surface fininsh. |

LS Manufacturing's core technologies are comprised of three pillars: a materials database, real-time monitoring and adaptive compensation, and customized surface treatments. |

| Specialized Materials & Processes | For different grades of aluminum alloy, special cutting solutions are available. | According to the state and properties of an aluminum alloy, matching of the cutting tool, cutting fluid, and parameters will ensure quality right from the very start. |

| Closed-Loop Quality Control | Deviations are kept within tight limits through real-time monitoring and automatic correction in production. | Sensors and data analyses allow real-time feedback and fine-tuning of parameters for stable machining and dimensional consistency. |

| Application Cases | The following are some of the achievements in common industry and parts machining. | For instance, precision aluminum parts were delivered successfully in the fields of 3C, optics, and medicine to effectively enhance customers' product quality and competitiveness. |

| Choice Value | The key values that will be delivered to the customer are summarized. | Turning aluminum, which was a cost-related problem, is turned into a quality advantage. High reliability, fast delivery, and brand value are enhanced. |

This quick reference system gives an overview of how LS Manufacturing integrates the Data-Driven Precision philosophy into every aspect of its aluminum CNC turning process. The synergistic effect is such that, through its three core technologies, the most common pain point in production-aluminum machining-will be transformed into a core advantage of customer products, maintaining a proper balance in aesthetics, precision, and reliability.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Over the past fifteen years, critical components manufactured for industries such as aerospace, medical technology, precision optics, and semiconductor equipment have required our deep involvement in the entire manufacturing process. In practice, our team works on applying advanced technologies, including 5-axis CNC machining; within a decade, more than 50,000 complicated parts were delivered.

It is a process involving not only equipment but also stringent process specification and quality control. For example, in performing a machining process for the core structural components in semiconductor equipment, our dimensional tolerance control process strictly adheres to the traceability standards set out by the NIST to make sure that every precision micrometer can be reliably traced.

CNC Turning Of Aluminum: Why Is It The Ideal Choice?

With high specific strength and excellent thermal conductivity, aluminum has become a critical driver enabling product innovation across manufacturing today. Inherent properties that are translated into real-world marketplace advantages include lighter and more durable structures, improved thermal management for greater reliability, while enhancing both product performance and consumer appeal.

Superior dissipation of heat and structural stability

Excellent thermal conductivity makes the aluminum alloy a perfect fit for precision CNC machining of integrated heat dissipation components featuring complex fins and flow channels. This not only significantly raises the heat dissipation efficiency in both electronic devices and LED lighting to ensure stable performance and lifespan but also reduces the need to use extra heat-dissipation modules, which can simplify the structure.

Significant lightweighting and energy-saving benefits

Among all lightweighting solutions, aluminum is preferred for its high specific strength. Topology optimization of parts with aluminum CNC machining achieves extreme weight reduction while structural strength is maintained, meaning increased range for new energy vehicles and increased payload and fuel savings for aerospace vehicles.

These two most important properties of aluminum mean that not only is production cost reduced due to simplified design and reduction of components, but also the cycle from R&D to mass production can be greatly shortened due to its excellent machinability, and it has very profound strategic value for companies in responding quickly to the market and accelerating product iteration.

Figure 2: Production lot of precision aluminum turned components by LS Manufacturing

Core Process Steps In Precision Aluminum Turning?

High-standard precision aluminum machining is critically dependent on comprehensive control of every detail in the CNC turning process. At the core of our methodology stand three important pillars-rigorous raw material inspection, precision toolpath optimization, and stringent in-process quality monitoring-developed through extensive practical experience for the assurance of consistent, reliable, and high-quality results for each project.

Tool selection based on material science

It involves not only the appropriate tool selection but also the precise matching of tool geometry, edge treatment, and special coatings with those characteristics from various aluminum alloy grades, including silicon content and hardness. That effectively suppresses built-up edge formation from the source, which ensures a sharp and stable cutting process, thus laying the foundation for a smooth surface.

Application of the vibration-damping cutting parameter library

High-Pressure Cutting Fluid Precision Injection Technology

While cooling is an essential function, it is by no means the only role of high-pressure cutting fluid in precision machining. A strategically designed high-pressure fluid delivery system serves to effectively evacuate fine chips from the cutting zone. These chips can interfere with the tool-workpiece interface, causing micro-scratches or accelerated tool wear if not immediately removed. The precisely managed injection path and pressure ensure quick removal of these particles, hence avoiding secondary damage to the machined surface.

In brief, these three factors are all interrelated within this precision manufacturing loop: scientifically designed cutting tools ensure effective material separation, vibration-damping parameters ensure an accurate machining path, and high-pressure cutting fluid protects the perfect surface already achieved. They work together in a synergistic way to turn the machining potential of aluminum into stable, reliable microscopic dimensional accuracy and superior surface quality.

What Are The Primary Advantages Of CNC Machining Of Aluminum?

The greatest benefit of the aluminum CNC machining is that it can transform advanced manufacturing technology into quantifiable economic value that clients can easily understand. Its advantages of CNC machining are directly reflected in the significant improvement of aluminum parts cost-effectiveness, concretely reflected in the following key data:

| Core Benefits | Measurable Direct Value to the Customer |

| Ultra-high material utilization | By optimizing the tool path, aluminum utilization is above 95%, greatly reducing waste and raw-material cost at its source. |

| Extreme Precision and Stability | Keep stable dimensions within ±0.005mm for part interchangeability while reducing assembly losses and improving the yield and reliability of end products. |

| Extreme Response Speed |

Relying on drawing-free programming and an automatic tool changer system, the prototype delivery cycle can be shortened by up to 70%, further speeding up product launch and iteration speed. |

Aluminum CNC machining offers a strong strategic advantage owing to greatly reduced unit costs from minimized material waste. Besides that, the process boasts an extraordinary speed of response-much shorter lead times-and saves precious time and reduces opportunity costs for our customers. In sum, this amounts to a decisive dual lead regarding speed and cost that will let the customers move much faster toward product development and the acquisition of a better position within competitive markets.

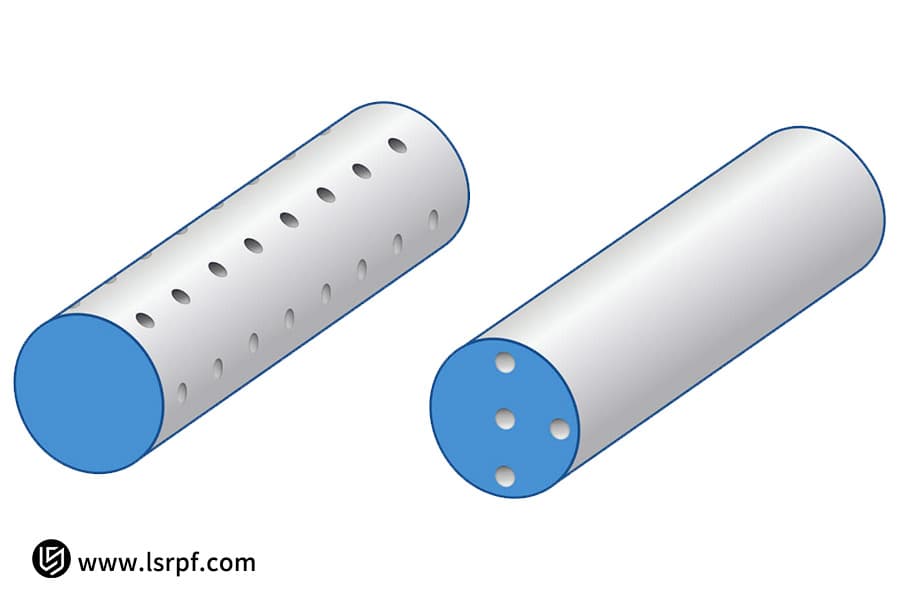

Figure 3: Aluminum turned parts with machined apertures by LS Manufacturing

How To Enhance The Value Of The Aluminum Parts With Surface Finishing?

In the manufacturing of today, professional surface finishing has changed from a simple "corrosion protection and decoration" process to an important step in increasing the core value of aluminum parts. In this sense, as surface finishing experts, we elevate the performance of aluminum with advanced engineering technologies that take it to new dimensions. Its value is achieved mainly through:

Hard Anodizing

The anodizing process, especially hard anodizing aluminum parts, provides an extremely dense, controllable-thickness ceramic coating to the surface. This greatly enhances surface hardness to HV500 or higher, guaranteeing wear resistance similar to that of high-quality tool steel, which can significantly extend moving parts' service life under conditions of high speed and friction.

Micro-arc Oxidation Technology

For extremely harsh environments, such as high temperatures, strong corrosion, and high insulation requirements, microarc oxidation technology can achieve a very thick alumina ceramic layer through high-voltage discharge. Such coatings possess excellent electrical insulation, corrosion resistance, and thermal shock resistance of over 1000°C, therefore being one of the indispensable value-added technologies in high-end fields like aerospace and the military for maximizing the performance of an aluminum part.

Besides protection, through processes like anodizing in aluminum, we fundamentally provide surface hardness, resistance to wear, and adaptation to the environment for the base material of aluminum parts beyond the capability of the base material itself, so as to ensure reliability under severe challenges and to enhance directly the competitiveness and added value of end products.

What Are The Major Uses Of Precision Aluminum Parts Within The Industry?

Precision aluminum parts applications have become indispensable in high-end manufacturing, offering a range of critical in fields such as aeronautics, medicine, and semiconductors. Their core value lies in offering highly customized and performance-driven solutions tailored to specific application scenarios. The following typical cases demonstrate how these components embody advanced engineering and sophisticated manufacturing capabilities:

|

Key Application Areas |

Core Components and Technical Requirements |

| LiDAR Heatsink housing | It requires extremely high dimensional stability along with excellent thermal conductivity to ensure the long-term accurate focusing of optical components under complex operating conditions. |

| Servo Mount for UAV | It is essential that it has an extremely high strength-to-weight ratio; excellent dynamic balance performance guarantees agile response and stable control of the aircraft. |

| Medical Device Handles | Achieve the highest standards of biocompatibility, grip comfort, and corrosion resistance for sterile use with perfect surface treatment. |

With deep understanding of the complex needs of the industries it serves, we has become a trusted technology partner serving high-end markets. We specialize in fully industry solutions, seamlessly covering expertise in advanced material science, high-precision machining, and specialized surface treatments to assure optimum performance, durability, and value for the most demanding applications.

Figure 4: Multi-stage CNC manufactured aluminum part by LS Manufacturing

How Does LS Manufacturing Solve The Challenge In Yield Of The Aluminum Parts For Drones?

The bottleneck in the production yield of drone aluminum parts continues with us. We deliver a superior engineering solution to address this, using a systematic scientific approach. This aluminum parts machining case study details a typical project, showcasing the proven LS Manufacturing solutions pathway—from initial challenge to final success.

Customer Challenge

LS Manufacturing Solution

Instead of simply adjusting the parameters, the CNC turning services team used finite element analysis in advance to simulate the process and find the accurate clamping deformation points, then made a contour-following vacuum fixture to ensure that the clamping force would be uniformly distributed. In the actual cutting, the team applied an innovative high-speed cutting strategy of "small depth of cut, high rotational speed, and large feed rate", effectively suppressing the occurrence of cutting force and thermal deformation.

Results and Value

The implemented solution reduced flatness errors to less than 0.015mm and increased the yield beyond 99.8%. Flight vibrations were eliminated, and the achieved reliability enabled the customer to secure strategic orders worth millions. More importantly, it transformed the customer's manufacturing operation from a cost center into a value creator, thereby giving them a decisive edge in the competitive market.

LS Manufacturing aluminum CNC integrates advanced tooling design with scientifically optimized process parameters, redefining aluminum processing from a basic manufacturing step into a decisive competitive advantage. This approach not only enhances end-product performance but also strengthens our clients' market position with measurable strategic value.

What Are The Most Important Selection Criteria For Suppliers Of Aluminum Processing?

Selecting a supplier for long-term aluminum processing requires a strategic approach that evaluates far more than the initial quoted price. A rigorous, multi-faceted selection criteria must be applied to thoroughly test a supplier's comprehensive capabilities. Moving beyond basic machining competencies, the evaluation should focus on three critical dimensions that are essential for ensuring sustainable quality, reliability, and partnership success over the entire product lifecycle. These key decision areas provide a framework for identifying a true technical partner capable of delivering consistent, long-term value.

- Quantitative evidence of process stability: The qualified supplier shall be responsible for reporting, on their own initiative, a Process Capability Index CPK ≥ 1.67 concerning key dimensions of the product. These data objectively prove that such a supplier is capable of maintaining process stability and producing qualified parts continuously in large-lot production, far beyond the limited validation afforded by sample-based inspections.

- Specific Process Solutions for Shaving Control in Aluminium: Since aluminum is easily scratched, the supplier should describe in detail the technical measures to control shavings in the machining process. This can include explanations of a high-pressure cutting fluid system, optimization in toolpath planning promoting chip evacuation, and dedicated cleaning stations. Solutions like these are necessary not only to preserve part surface integrity but also to avoid secondary damage and display precision in manufacturing.

- In-house integrated surface treatment capability: What's important here is whether major surface treatments, such as anodizing, are performed within the supplier's facility. Such an integrated post-processing capability will manage quality standards and negate delays and inconsistencies that may be created by outsourcing the process. Overall, this means uniform color and coating thickness for better performance of the parts, with the assurance of technical confidentiality.

Choosing an aluminum processing supplier means selecting a long-term technical partner. The best suppliers within the industry set benchmarks for process stability and integrated surface treatment by scientifically controlling chips. This creates strategic value extending far beyond basic part fabrication to encompass design optimization, risk mitigation, and supply chain reliability-all contributing to the sustained market success of your product.

How To Optimize Design To Control Costs?

- Avoid Complex Structures: The simultaneous existence of deep holes and thin walls is to be avoided. Such a design disproportionately increases machining difficulty, often requiring non-standard tools and multi-stage setups. This leads to a higher risk of scrap due to vibration or deformation, resulting in lower yield rates and significantly longer machining times, which directly raise production costs.

- Use Economic Tolerances: We consistently suggest applying economic tolerance zones, such as IT13 and above, for non-mating surfaces and non-critical dimensions. Specifying unnecessarily tight tolerances will demand more accurate equipment, specialized tooling, and extensive quality inspection, all of which are major sources of hidden costs without adding functional value.

- Standardize Corner Radius: Standardizing internal corner radii and chamfer dimensions across a design is highly recommended. This practice allows for the use of fewer tool types, which directly reduces the frequency of tool changes during machining, simplifies CNC programming, and minimizes the inventory and management overhead for tooling.

Great engineering designs need to balance functional requirements with manufacturing economics. We, therefore, provide a free DFM analysis report with every project to help our customers reach this important balance. The report will identify exact opportunities for design optimization and cost reductions that can be made to avoid any potential hidden costs right at the very beginning.

Figure 5: Ongoing aluminum CNC machining operation by LS Manufacturing

What Are The Key Skills Of LS Manufacturing In Aluminium Turning?

Dedicated Material Database

We cooperate with well-known university material laboratories and have set up a database of property-machining parameters covering multiple types of aluminum alloy materials. This allows us to match precisely the optimum tooling, cutting speed, and feed rate for your specific grade of material to ensure high efficiency in machining and superior surface quality from the first part.

End-to-End Digital Twin

Dual Technical Support System

For each customer's order, there is an allocated Project Manager and Process Engineer who cooperate very closely during the complete life cycle of the project. While the Process Engineer concentrates on optimizing technical solutions, the Project Manager ensures everything is performed and communicated perfectly.

LS Manufacturing advantages are rooted in our role as a technology-driven value partner, not merely a supplier. We integrate precise, data-driven insights, advanced process simulation, and dedicated expert support throughout the end-to-end project lifecycle. This holistic approach guarantees unmatched stability, efficiency, and cost-effectiveness for all your aluminum machining projects.

FAQs

1. How to avoid surface scratches and tool marks during aluminum part machining?

We adopt a comprehensive protection solution: non-contact robotic arm automation material handling with specialized flexible fixtures for fixation. In this regard, we plan the entry and exit path of the tool during CNC programming, keeping away from human-caused impacts and unnecessary tool marks that may appear on the part surface.

2. How to maintain price competitiveness for small-batch orders?

We standardize common processes in "process packages" for small-batch production, adopting modular combination fixtures to greatly shorten the time spent on changing over and debugging. This measure enables us to reduce the cost of setting up production per order by 60%, allowing price competitiveness for even small orders.

3. How to solve the color difference problems of the aluminum parts after anodizing?

We adopt the double approach of hardware and management to deal with the difference in color. Anodizing tank installations are equipped with a fully automatic temperature control and circulation filtration system; at the same time, the titration concentration is manually checked every hour to ensure the stability of tank parameters and guarantee thickness uniformity of oxide film and color consistency. Therefore, it enables the pass rate to be over 99.9%.

4. Can you provide quality data at the time of processing?

Of course, we can grant key customers partial access to the MES system, where they can view in real time the production progress of each of your orders and the quality inspection results of every process. SPC data for critical dimensions can be shown to ensure transparency and traceability of quality in the whole manufacturing process.

5. How do you handle urgent order requests?

A "rapid response channel" was established, production capacity was flexibly reserved every day, and a professional team was arranged to follow up through the whole process to guarantee urgent orders are finished in an effective and efficient manner without affecting normal production.

6. What is the minimum internal corner radius obtainable when turning in aluminum?

Most precision aluminum parts have very strict design requirements for minute internal corner radii, so we can clear internal corners down to a minimum radius of 0.2mm by employing custom-designed miniature high-rigidity tools together with a high-speed finishing strategy.

7. How do you protect my product design patents?

Information security is the basis of our collaboration. We've been certified with an ISO 27001 certification for information security management systems. We store every customer drawing and technical document in encrypted form. We implement strict internal access controls to eliminate all risks of technology leakage.

8. What is the process from inquiry to sample delivery?

All our processes are efficient and transparent. When you fill out your requirements online, we will quote-including DFM analysis-in 2 hours; confirm the order and assign a project team; process and deliver the first batch of samples in 5-7 working days.

Summary

CNC turning is an operation that requires very specialized skills. Here at LS Manufacturing, we take pride in three core advantages: data-driven processes, traceable quality, and professional surface treatment. With a dedicated material database, full-process quality transparency, and extremely controlled post-processing such as anodizing, it assures the best quality of parts from inside to outside. As such, it has won us a reputation as a reliable partner in the line of high-end manufacturing.

Now, contact us and let your brilliant designs be empowered by our engineering professionalism! We welcome you to upload your technical drawings and get a free "Aluminum Part Manufacturability Design and Cost Analysis Report," specially tailored by our expert team. With this comprehensive report, you'll get into the specifics of design optimization advice, risk alerts, and actual cost breakdowns that help you unlock exclusive cost-optimization solutions and thus secure a competitive advantage right from the very beginning of your manufacturing project!

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .