In high-end precision manufacturing, welding is not a simple metal join; it is the lifeblood that defines the life and value of a product. Whether turbine blades of aircraft flying across the skies, pressure vessels of submarines diving deep into the seas, or main pipelines in atomic power plants keeping millions of homes afloat, their remarkable service performance is dependent on the quality of welds measured in millimeters. So, weld quality is an unwavering supporting pillar of high-end manufacturing—it's the secret to unlocking the potential of frontier materials and a technological statement that ensures complex configurations stay rugged in harsh environments. We will discuss the specifics of welding technology and introduce you to more reliable metal welding solutions.

Quick Reference: Choose Your Tap at a Glance

| Evaluation Dimensions | Key Indicators/Requirements |

| Technical Capabilities |

|

| Certification Standards |

|

| Service Response |

|

Suppliers with ISO 3834 certification,ASME IX process assessment and full-process testing capabilities will receive preferential treatment, and their welder certificates and equipment calibration records will be verified on-site.

Why Use This Guide? Based On The Practical Experience Of LS Experts

At LS, we're not just experts in metal welding technology; we can accurately identify and optimize all welding issues, providing technical support and solutions. In high-end manufacturing, weld quality is the lifeblood of product performance. LS has been deeply involved in precision welding for two decades, building a technological barrier through practical experience.

- In aviation: LS provides micron-level precision electron beam welding for turbofan engine combustion chambers with a zero-failure history in hostile conditions at 1500°C.

- In energy equipment: LS completes tight-gap TIG welding of third-generation nuclear power main pipelines with 100% adherence to the rigid ASME Section III inspection specifications.

- In medical implants: LS engineers develop a laser welding process for a titanium alloy that achieves an orthopedic implant fatigue life of over 5 million cycles.

Every weld is a controlled test of the material's limit. Choosing LS means choosing an experienced, dependable technical consultant.

How To Determine The Overall Technical Competency Of A Welding Service Company?

To determine the completeness of the technical competence of a welding service provider, we must methodically examine three significant dimensions: equipment and processes, experience in materials, and quality assurance.

Start by assessing the range of process coverage and the advanced nature of their equipment

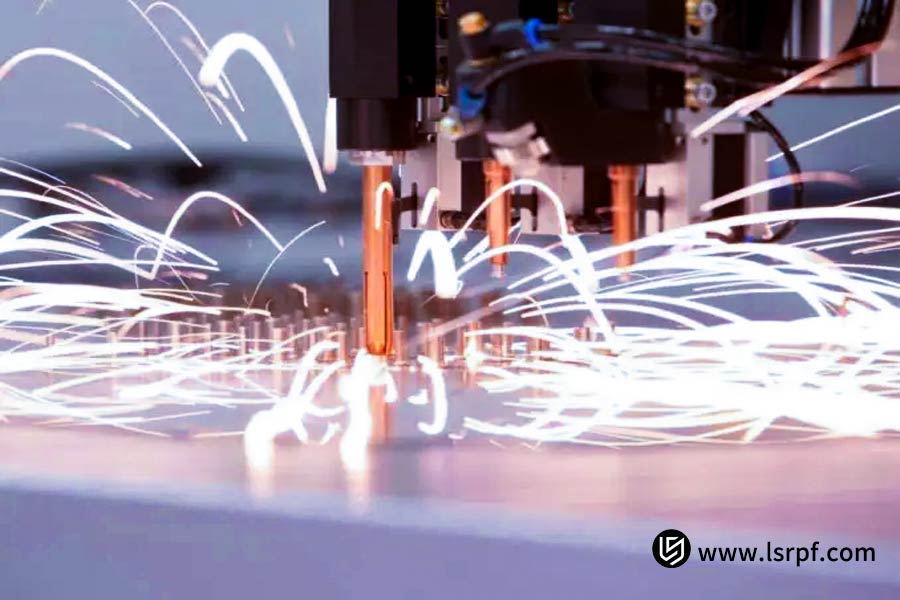

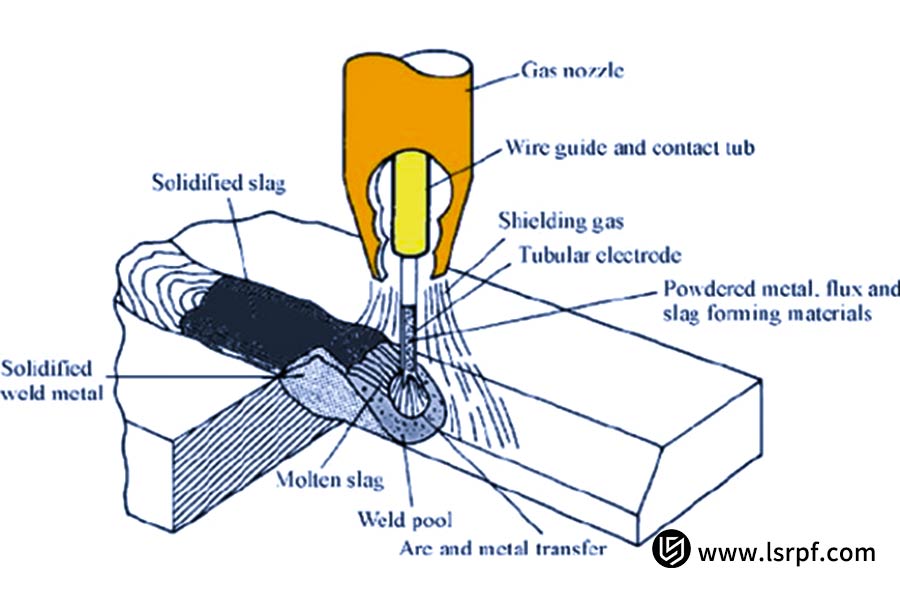

The best service provider should be an expert in mainstream and specialty welding processes (e.g., TIG/MIG precision welding and laser/plasma high-efficiency welding) and have automated equipment to meet volume demands. Top considerations are whether they can handle extreme specifications such as ultra-thin parts (<1mm) or ultra-thick plates (>50mm) and specialty technical capabilities such as vacuum welding and dissimilar metal joining. Maintenance history of equipment and calibration status also reflect the strictness of their technical management.

Material compatibility emphasis and experience on projects

Extensive technical expertise is expressed in their capability to handle extensive types of materials, including carbon steel, stainless steel, aluminum alloys, titanium alloys, and high-temperature alloys. Verify their case studies, especially for challenging projects that can meet your needs (e.g., pressure vessels, aerospace components, or equipment for corrosive applications). Welding specialty alloy certifications (e.g., duplex steel and nickel-based alloys) and accompanying process qualification reports (PQR/WPS) are more reliable.

Verify their end-to-end-process quality assurance system

An enclosed technical capacity in practice relies on rigid test procedures (e.g., X-ray and ultrasonic testing) and traceable documents (welding procedure (WPS) and inspection records). Check whether the specialized testing personnel and equipment exist and whether they are able to perform defect analyses based on international standards (e.g., ISO 5817 and AWS D1.1). An advanced technical service provider with complete technical strengths needs to have quality control span across all the welding steps, ranging from pre-weld preparation and process control to post-weld inspection.

In short, it is only an advanced process equipment-equipped service provider with substantial hands-on experience in working with materials and a closed-loop quality control system that can display truly complete and reliable technical strengths and meet the high-tech welding quality requirements of high-end production.

What Is The Effect Of Equipment Accuracy On Welding Quality?

Equipment accuracy is the foundation of welding quality. Minor inaccuracies can create systematic risks to material properties, structural integrity, and serviceability.

Positional accuracy has a direct impact on heat source-material interaction

For example, a positioning error of greater than ±0.05mm in laser welding results in greater than 10% variation in penetration depth, producing lack of fusion-type defects in thin-walled aerospace structures (such as a 0.8mm thick titanium alloy casing). High-precision servo drives (with ≤±0.02mm repeatability) ensure precise match of weld trajectory and heat input, improving weld pool stability to greater than 98%.

Metallurgical reaction processes require accuracy in parameter control

In pulse welding, more than 0.5ms deviation in the rise time of the current will alter the morphology of droplet transfer, resulting in a spatter increase (for example, spatter in stainless steel MIG welding from <3% to 15%). It also increases the risk of grain coarsening in the heat-affected zone. Electric power supplies (current fluctuation ≤ ±1%) precisely regulate thermal cycling curves to ensure a stable impact toughness of more than 180J of nuclear power main pipeline welds.

Accuracy within the motion system influences microstructural homogeneity

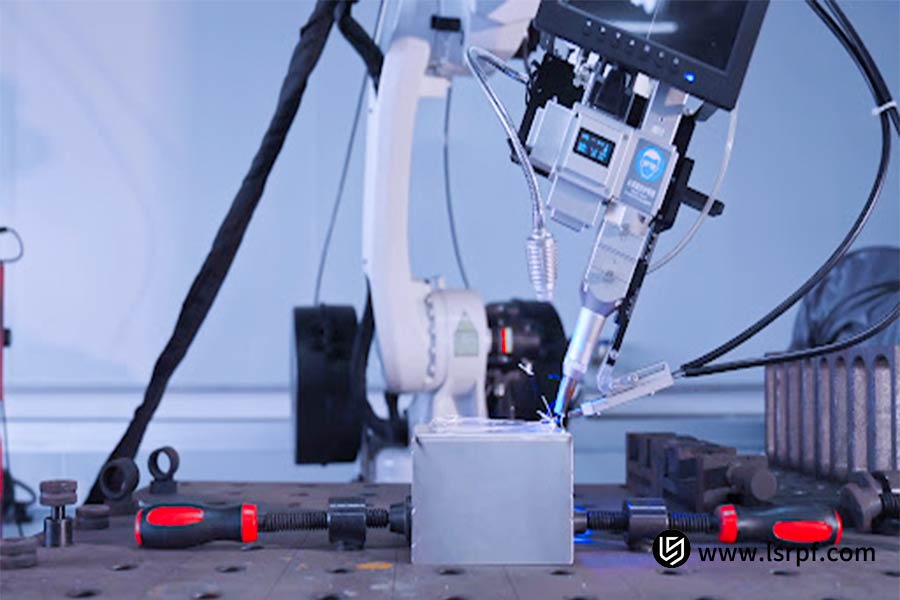

When the robot welding gun's posture angle deflection is greater than 1°, there will be offset melting of fillet welds on aluminum alloy, and strength will reduce by up to 20%. A six-axis robot equipped with a laser tracking system (path accuracy ±0.1mm) may, in real time, compensate for the heat source angle so that fatigue life in car battery tray welds will be greater than 500,000 cycles.

In a nutshell, from millimeter-sized optical path calibration to millisecond-sized power supply response, equipment precision is the foundation of high-end welding quality. It is only through submillimeter motion control, microsecond-sized parameter closure, and intelligent real-time compensation that the capability of materials can be transformed into reliable engineering miracles.

Case Study: How Did LS Achieve A 99.98% Welding Pass Rate For Medical Device Chassis?

In medical precision manufacturing, the weld quality directly influences the safety of equipment and the health of patients. LS applied systematic technological innovation to increase the welding pass rate of titanium alloy device frames to 99.98%. It is the innovation in three-dimensional space synergy of material science, process control, and smart quality control.

Material-Level Thermal Management Breakthrough

Regarding titanium alloys' heat sensitivity, LS has developed pulsed laser-argon gas synergistic protection technology. By tailoring the input waveform energy (peak/base switching in milliseconds), the HAZ width is reduced to ≤0.3mm, completely eliminating β-phase grain coarsening. The weld zone and parent material have ≤5HV hardness difference, which ensures long-term mechanical stability of the implant.

Micro-deformation Process Chain Design

A novel "pre-stress-step welding" technology is employed: deformation is first computed by finite element simulation, and a counter-compensation structure is incorporated into the tooling. Millimeter-level step welding relieves residual stress next. The flatness error of the end-chassis is controlled to ±0.05mm/m, half the industry standard, precisely meeting the assembly requirement of precision imaging instruments.

Holographic Quality Defense

Integrated machine vision monitors weld pool morphology in real time (2000 frames/second sampling rate), and AI programs adjust welding parameters dynamically. A 3D thermal cycle map is generated for each weld and automatically referenced against a metallographic database. In addition to the plasma cleaning process, the frequency of oxide inclusion falls to near zero, providing a zero-defect closed loop of "weld one weld, inspect one weld, complete one weld."

The secret of this quality leap is the shift from welding as an "experiential skill" to being a "computable science." LS rebuilds manufacturing reason through cross-disciplinary collaboration so that every weld arc is imbued with a respect for life.

What Expert Technologies Are Required To Weld Unusual Materials

Welding exotic materials like titanium alloys is to walk on a razor's blade—high reactivity, low thermal conductivity, and phase transformation sensitivity require a technological system that exists at the razor's edge of traditional techniques. LS utilizes a trinity of expert technologies: environmental control, heat source calibration, and metallurgical manipulation, to ideally leverage reactive metals.

An Absolutely Pure Welding Sanctuary

Titanium alloys quickly take up oxygen and nitrogen at temperatures greater than 300°C, so conventional welding methods such as "keeping a candle in a storm." LS utilizes a double defense strategy:

- Dynamic Air Tent System: Complete laminar argon flow envelops the process from preheating through cooling, lowering local oxygen concentrations to <50 ppm.

- Vacuum Tail Hood Tracking: A region of negative pressure is established at the rear of the welding torch, entirely suppressing air backflow.

This environmental control system has increased the silver-white color percentage of welds from the 75% industry norm to 99.2%, eliminating the "titanium cancer" hazard.

Millimeter-Level Energy Scalpel

Resolving the industry bottleneck of "welding overheating," innovative energy decoupling technology is utilized:

- Pulsed laser-cold wire synergy: High-peak pulses create an instantaneous molten pool, and low-temperature filler wire melts excess heat.

- Heat sink tooling system: copper mold with liquid nitrogen flow channels built into it correctly dissipates heat and controls temperature.

Constricting the heat-affected zone to 0.2mm prevents brittle fracture due to excessive growth of β-phase grains.

Restoring order in the microcosm

The key to surmounting the phase transformation problem is managing the solidification rhythm:

- Ultrasonic-assisted molten pool: 20,000Hz ultrasonic vibration breaks up dendrites, resulting in an equiaxed fine-grained structure.

- In-situ alloying wire: Coursing traces of yttrium and boron capture oxygen atoms to form stable compounds.

Special materials welding is, in a sense, the culmination of materials science. When an absolutely clean environment, submillimeter heat control, and atomic-scale metallurgical design form a feedback loop, titanium alloys transition from "unweldable" to "super-performance" materials—this is the technological key to LS's reinterpretation of the limits of materials.

How to Avoid Hidden Charge Traps?

Hidden charges in metal welding outsourcing could be like pores under welds—seemingly innocuous, but potent enough to sabotage project budgets. To methodically keep away from such dangers, there has to be a strong cost visibility system placed throughout the entire process.

The key is process transparency

Avoid general "adjustment on demand" terminology and require suppliers to state explicitly on their quotes groove prep specifications (e.g., V-groove angle tolerances), percentage of non-destructive examination (the price difference between spot X-ray inspections and full inspections can be three times), and special environment work fees (vacuum/low-temperature welding extra cost). There have been instances where a manufacturer added an additional polishing fee in the guise of "weld beautification" to bill for low surface finish quality.

The supply base requires even greater probing examination

Material cost is the largest gray area. Batch traceability of welding consumables should be required (providing warranty certificates and physical stamps), regulations for base metal substitution need to be delineated (e.g., written confirmation for 304 in place of 316L), and a discount recycling system needs to be employed for high-value scrap materials like titanium alloys. The critical control point is to negotiate a floating pricing formula—where greater than 5% monthly variation in materials like copper and nickel, price will be renegotiated immediately to eliminate material arbitrage at the source.

Warranty provisions should bring about a closed-loop protection

Deteriorated suppliers have a tendency to leave traps after sale. You need to clearly specify the defect liability period (recommended ≥12 months) and the details of how rework expenses will be divided (logistics, disassembly, secondary inspection expenses, etc.). In particular, avoid fragmented clauses like "partial warranty" (e.g., of only the primary weld but not the heat-affected zone). A tough lesson learned is as a reminder: one firm paid for an entire set of material in one cracked weld because rework consumable cost was not negotiated.

By process standardizing only in electronic form, material flow graphically mapped, and warranty clauses refined, welding expenses can be transformed from "fog and flowers" to "crystal clarity." The key to cost-effectiveness is always: open contract x manageable quality, and not an arithmetic game of paper unit prices.

What Is The Advantage Of Electronic Reporting For Subsequent Maintenance?

In welding metals, electronic reporting is electronic filing plus; it binds the strands of end-to-end lifecycle management together. It translates disconnected welding information into traceable, analyzable, and decision-making attributes that essentially redefine post-maintenance value creation.

Fault Tracing

When equipment cracks or leaks, paper files are a needle in a haystack. Structured digital reports (like welding parameter thermograms and non-destructive test 3D models) can instantly identify defective welds—dead-on to the welding gun number, operator ID, and even ambient temperature and humidity. In a nuclear power valve repair scenario, by retrieving past welding thermal cycle curves, hydrogen-induced over-interlayer temperature cracks were identified within 48 hours, reducing the troubleshooting cycle by 90%.

Risk Warning

Abandoning the "repair when it fails" culture, computerized reports are constantly passed into AI forecast models. Metallographic images are correlated with stress simulation data in real time by the system, alerting maintenance personnel to areas of high risk before microscopic intergranular corrosion can reach the surface. During a quarterly health checkup of a chemical plant's reactor tower, an algorithm spotted the risk of sulfide corrosion in the head girth three months in advance, saving unplanned downtime losses of over 2 million yuan.

Knowledge Reuse

Master welders' experience no longer is lost with retirement. Data such as welding process video streams and parameter optimization paths is accumulated continuously in a knowledge base, automatically producing an average defect treatment guide. New employees can scan a component's QR code and instantly bring up 17 repair techniques for similar structures. Far more profound is the fact that maintenance data drives design optimization. For example, analyzing a ten-year history of crack reports on an individual excavator boom led to the upgrade of a critical weld from a K-type to a double-J-type, tripling its lifespan.

The core of this maintenance revolution is transforming welding from a "black box process" to a "transparent ecosystem." Digital reporting is like imbedding a DNA identity into a metal part—each repair isn't just a repair at the time; it codes to ensure future operation for 30 years.

What Are The Primary Controls For Welding Residual Stress Management?

Welding residual stress is a "thermal ghost" latent in the metal. It causes at best distortion and deformation, and at worst stress corrosion cracking. To manage this silent killer, there is needed a three-pronged process of heat input control, mechanical interference, and prevention by design to keep stress within a limit that is safe.

Sophisticated heat source control is the fundamental solution

Moving away from brute energy accumulation, we are adopting intelligent heat control:

Using pulsed welding instead of continuous current, millisecond-order energy interruptions allow for periodic cooling of the molten pool, disrupting the cycle of heat accumulation. We are making a "stepped energy map" for multi-pass, multi-layer welding. Thin-layer welding with forced air cooling generates a stress-compensating zone in the heat-affected zone of every weld. Along with that, we are employing "heat sink tooling" for thick plate welding. Cooling channels are integrated in copper alloy dies, acting as directional heat sinks for the weld, minimizing stress generation space at the origin.

Mechanical decompression methods are bomb disposal emergency equipment

After stress has already developed, a multi-pronged strategy must be employed to minimize the crisis. Vibration stress aging subjects the material to mechanical waves of a specific frequency in order to generate microscopic plastic deformation that anneals residual stresses between crystal lattices like spring snow. Local thermal aging employs scanning flame with focal heating to selective areas, using the temperature differential expansion effect to reprofile the stress pattern. In ultra-high-strength steel, which is very sensitive, explosive shock waves are initiated on the weld surface, reprofiling the stress field in microseconds. These techniques are akin to "deep therapy" for parts, reorganizing the metal's internal structure.

Advanced structural design builds a firewall

True stress control begins at the drawing board: joint layout optimization, replacement of square corners with rounded gooseneck grooves, eliminates stress-concentrating crevices. When planning the sequence of welding, apply "center-radial" or "symmetrical jump welding" techniques to offset contraction forces. In precision frame welding, a thousandth-level anti-deformation compensation is reserved to predict the deformation path caused by stress. In a superconducting device support ring, a double-helix symmetrical weld bead profile was utilized for ovality deviation control to within the thickness of a human hair.

This struggle against forces one cannot see is, at its core, a subtle dance between thermodynamics and materials science. From the judicious control of energy in the welding flame to the anticipatory planning of the blue print, only by elevating stress control to the stature of a manufacturing philosophy can metal parts escape the slavery of internal friction and manifest their innate structural nobility in the fire of time.

How to Evaluate a Supplier's Continuous Improvement Capability?

For the metal welding business, it is the supplier's capability to advance continuously that directly correlates with the supply chain's long-term dependability. This calls for a tri-dimensional evaluation of technology iteration mechanisms, problem response systems, and talent development models.

Technology Iteration Mechanism Verification

Focus on examining the closed-loop process optimization by the supplier:

- Whether or not a welding parameters database is established and regularly reviewed (e.g., penetration fluctuation and spatter control trends);

- Whether introduction of new technology within the past two years (e.g., laser-arc hybrid welding replacing conventional methods);

- Patents/records of technological innovation review (e.g., examples of tooling optimisation, energy consumption lowering technology);

Core Evidence:

- Requires process upgrade reports in detail and proof of mass production implementation;

- Problem Response System review;

Focus on the in-depth solution capability by the supplier for quality issues:

- Review customer complaint handling reports for inclusion of root cause tracing (e.g., metallurgical analysis of weld cracks);

- Review Corrective and Preventive Actions (CAPA); Implementation closed-loop rate

- Review joint improvement projects with material providers (e.g., automobile manufacturer optimization of welding material composition tailored to specific application)

- Key metric: Three-year repeat quality problem reduction rate ≥ 40%

Talent development model audit

Ability for improvements ultimately rest with a talent pipeline:

- Welder's annual skill certification renewal rate (compulsory ≥ 90%)

- Frequency of engineer participation in revisions to international standards (e.g., AWS/ISO meetings)

Internal technical competition and knowledge-sharing mechanism coverage

- Substantial evidence: On-site verification of training and skills matrix records

- The solution to sustained improvement is systemic evolution: technology iteration must be data-driven, problem solutions must reach the core, and talent development must build an ecosystem. Only companies with these three elements are capable of taking welding quality from "meeting standards" to "sustained leadership."

Assessment and implementation recommendations

- Ask suppliers to provide a "Welding Procedure Change List" for the previous three years

- Inspection of closed-loop data for five representative cases in the CAPA system at site

- Randomly ask three welders about the content and quality of their annual training.

FAQs

1. Under an unexpected equipment breakdown, how long can welding services be provided?

If there is equipment failure, LS has a 24-hour emergency service hotline and technical team available within city limits within 4 hours for instant welding service. To top it off, for remote locations, the LS team can also provide remote technical consultation. Our response is prompt and professional.

2. Can stainless steel and aluminum alloys be welded together with high strength?

Variable polarity gas shielded welding is required for stainless steel and aluminum alloy high-strength welding, and LS has employed this with success in rail transit applications.

3. How do you guarantee the internal quality of welds?

You can request the supplier to submit an X-ray or ultrasonic inspection report to guarantee internal weld quality.

4. Do you have small-volume special orders?

We also do small batches of custom orders. LS has a minimum order quantity of one piece, with the minimum thickness being 0.8mm weld.

Summary

When selecting a metal welding service firm, consider three most critical aspects: technical capability in accordance with industry certification standards (ISO 3834/ASME IX), supply chain transparency for purposes of ruling out unseen costs, and improvement mechanisms in place to ensure long-term collaboration. Don't select based on a mere unit price; instead, verify welder certification rates and ensure a closed-loop management system for process documentation on-site, and incorporate emergency response timelines in provisions of the contract.

LS offers double protection. We provide welding quality diagnosis, complimentary weld CT scans, and stress distribution mapping to pinpoint the likely risk points accurately. LS's efficient service channel offers a 4-hour on-site response within city limits, an 8-hour provincial level service, and 24-hour standby for special conditions. We also make digital records of repaired parts and proactively provide preventive maintenance recommendations.

Upload your design drawings now and get an instant welding quote (welding price), let LS be your strong backing in pursuit of ultimate welding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com