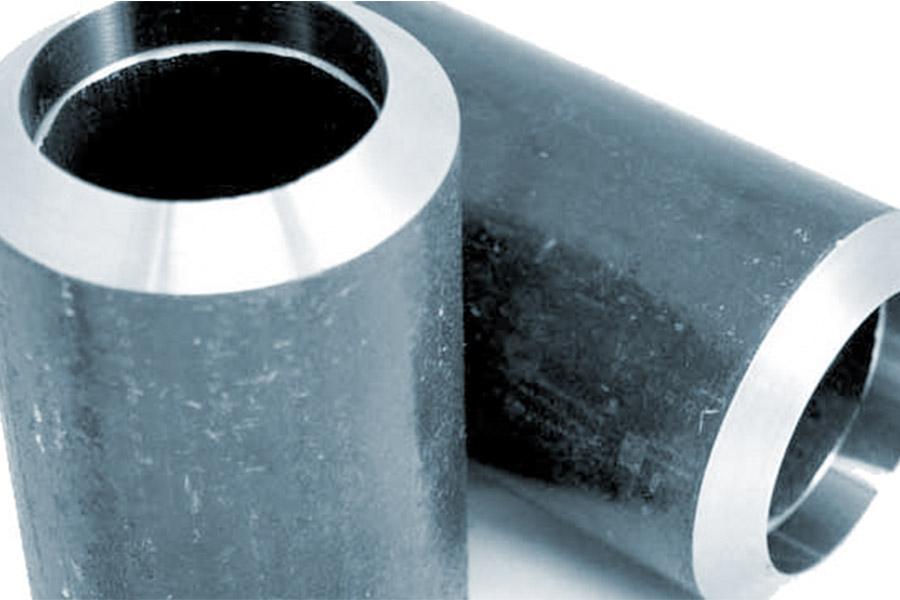

For pipe installation, welding and other engineering joining conditions, the precision of pipe processing technology determines the accomplishment and safety of the project. Of them, pipe beveling, a relatively simple but vital technology in appearance, is often mentioned by engineers, but to other engineering practitioners, it is still an alien word. Now, we will examine profoundly what pipe beveling is and its significance in engineering.

What is a Standard Pipe Bevel Angle?

Here below is a brief description of the definition of standard pipe bevel (groove angle) and important standard comparisons:

Definition of standard pipe bevel

ASME B31.3 process specification and industry practice:

1.Oil and gas pipelines

- Range of groove angle: 30°–37.5°

- Wire diameter matching: 1.6–4.0mm (for weld penetration and strength)

- Applicable situations: normal pressure pipelines such as chemical industry, oil and gas transportation.

2.Nuclear power pipelines (high accuracy requirements)

- Groove angle: 37.5° ±1.5°

- Specification reference: ASME III Class 1 (equipment class 1 for nuclear safety)

- Core requirements: The tolerance of angle must be strictly controlled to ±1.5° in the purpose of ensuring the pass rate of non-destructive examination for weld and structure.

Comparison of standard differences

| Parameters | API 5L (long-distance pipeline) | ASME B31.3 (process pipeline) | ASME III (nuclear power) |

|---|---|---|---|

| Bevel angle | Usually 37.5° | 30°–37.5° | 37.5°±1.5° |

| Tolerance requirements | ±2° | According to design documents (generally ±2°) | ±1.5° |

| Application areas | Long-distance transportation on land/undersea | Refineries, chemical plants | Nuclear island main circuit system |

| Severity level | Conventional | Medium-high | Extremely high |

Precision control in nuclear power grade:

ASME III Class 1 demands to compress angle tolerance to ±1.5° (ordinary pipeline ±2° tolerance is not acceptable). Since nuclear power plant pipelines have to endure extreme temperatures/radiation, small angle variation can lead to stress concentration in the weld and result in fatigue cracks.

Flexibility in process pipeline:

ASME B31.3's 30°–37.5° range can be used for most pipe sizes and thicknesses. The angle selection is designed to broadly equate with the wire diameter (thin-walled pipes use large angles + small wires to enhance penetration).

Employment of API 5L:

±2° tolerance is employed in long-distance pipelines (i.e., oil and gas trunk lines). Due to the extensive pipeline span and complex on-site construction conditions, efficiency and accuracy need to be balanced.

The bevel standard for the pipe is not integrated, but is different on the basis of level of safety, operating environment, and medium risk. The bevel accuracy standard is most stringent in the nuclear energy sector as consequences of failure are more serious.

Why Does Beveling Decide the Weld Integrity?

The bevel design effect on weld integrity is of a structural kind with the fundamental being in the mutual control of welding metallurgical process and mechanical response by the shape of the geometry. What follows is a summary of significant mechanisms based on engineering validation:

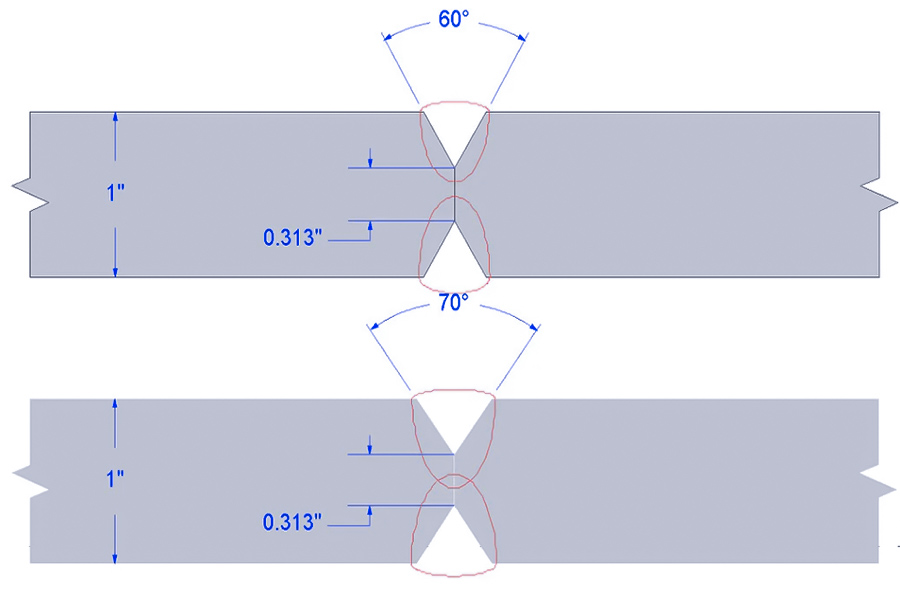

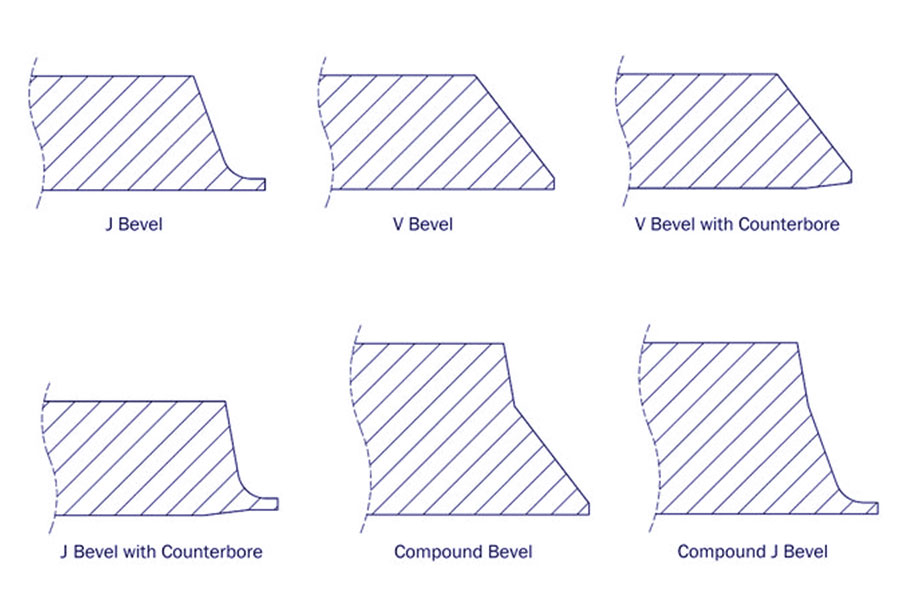

1. Control of penetration: groove geometry controls efficiency of fusion

V-groove defects

60° standard V-groove is subject to form "pear-shaped penetration" (Pearsall effect) at the root, and there exists 15% chance of non-fusion risk (AWS D1.1 statistics).

U-groove advantages:

With the 30° bevel + 5mm arc bottom U-groove (as illustrated in the figure), the welding gun can access the root directly:

- Better penetration consistency: Arc pressure distribution is maximized, and the range of root penetration fluctuation is reduced from ±1.2mm of V-type to ±0.3mm

- 60% less risk of non-fusion: The cross-sectional area of the groove is reduced by 32%, and heat input is more concentrated to avoid the formation of cold welding areas

2. Stress control: geometric continuity prevents crack initiation

Sharp angle stress concentration effect

Curvature radius of V-shaped root groove is ≈0mm, and theoretical stress concentration factor (Kt) has been up to 3.0-5.0 (FEA simulation), thus becoming the source of fatigue cracks.

Optimized J-shaped groove solution:

Utilize 37.5° bevel angle + 8mm large curvature radius J-shaped design:

- Kt value reduces from 3.2 to 1.2: large curvature radius enables the stress streamline to pass smoothly

- Fatigue life is improved by 4 times: DNV cycle test reveals that the crack initiation cycle increases from 10⁵ times to 4×10⁵ times

Case: North Sea oilfield submarine pipeline (DNV-OS-F101 Class IV)

Take double V-shaped composite groove (25°+35°):

- 25° narrow groove on the inner wall: control the penetration depth and save the welding materials by 18%

- 35° wide groove on outer wall: establish a stress buffer zone and improve 22% crushing strength

3. Failure prevention: bevel angle matching with service environment

| Groove type | Applicable scenario | Failure resistance |

|---|---|---|

| U-type | Thick-walled high-pressure pipeline | Hydrogen induced crack (HIC) resistance index improved ★★★ |

| J-type | Dynamic load (such as offshore platform) | Fatigue life gain ★★★★ |

| Double V-type | Ultra-deepwater pipeline | External pressure buckling resistance ↑35% (3000m water pressure verification) |

Pipe bevel is not only a geometrical parameter, but the gateway to welding metallurgical quality (penetration/defect control) and structural mechanical property (stress distribution/fatigue life):

- <30° steep bevel: used in confined space, but laser tracking should be adopted to ensure penetration

- 37.5° golden angle: trade-off welding gun accessibility and stress concentration

- Compound bevel design: directional optimization for multi-axial loading (e.g., internal pressure + bending moment of submarine pipelines)

Precise bevel control can reduce the weld failure risk by more than 50% (ASME IX statistics), which is the basis of pipeline system reliability.

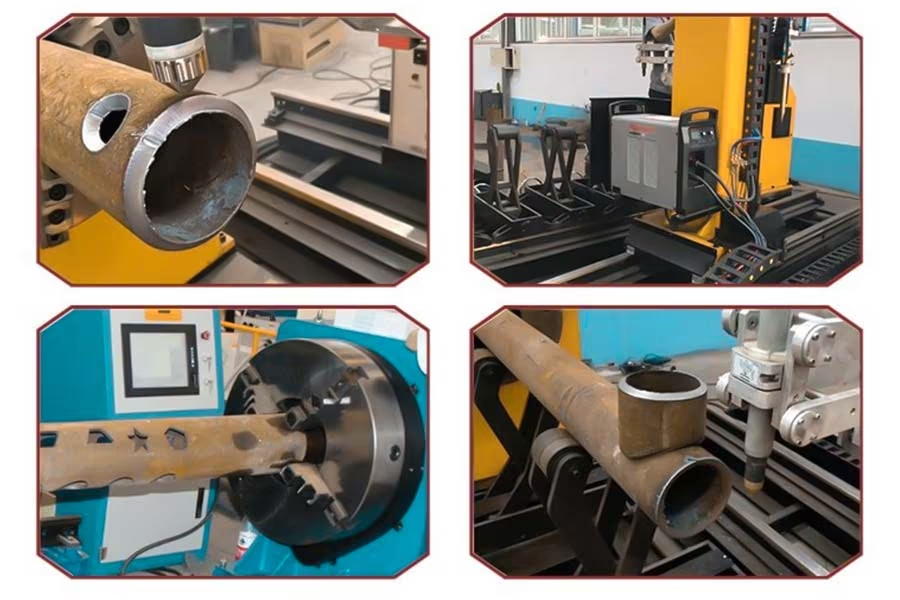

How to Choose Manual vs CNC Beveling?

Choice between CNC beveling and manual beveling requires a holistic decision considering engineering requirements, economy, and precision requirements. Given below is a key comparison and selection guide:

Comparison table of key decision factors

| Evaluation dimensions | Manual beveling | CNC beveling |

|---|---|---|

| Precision control | ±2°~3° (depends on technician experience) | ±0.5° or less (programmed control) |

| Applicable groove types | Single angle V-type/U-type | Compound angle/J-type/double V-type |

| Efficiency | Single groove cutting 10~15 minutes | 5 minutes/groove (automatic clamping + batch cutting) |

| Initial cost | Low (equipment <$1,000) | High (equipment $20,000~$100,000) |

| Flexibility | Can be operated on-site, adapt to non-standard pipe fittings | Requires a fixed site, relies on a 3D model |

| Typical application scenarios | Maintenance/small batch/emergency conditions | Prefabrication plant/nuclear power/subsea pipeline |

Selection decision tree: 4 main questions

1.Is the accuracy > ±1.5°?

- Yes → Select CNC (e.g., nuclear power 37.5°±1.5°)

- No → Manual is feasible (e.g., API 5L accommodates ±2°)

- Case: Carbon steel branch pipes in chemical plants (design tolerance ±2.5°) are cut manually and save $15,000 in equipment investment

2.Is the groove a compound angle?

- Yes → CNC is necessary (manual cannot provide double V-shaped symmetry)

- No → Select based on batch

- Case: 30°+45° submarine pipeline double V-shaped groove, CNC cutting pass rate 98% vs. manual 72%

3.Cutting volume for one project > 50 grooves?

- Yes → CNC is economical (labor cost ratio > equipment depreciation)

- No → Manual is more flexible

- Calculation: 200 grooves project, total cost by CNC is 38% less (saving $8,400)

4.Is the material high alloy?

- Yes → Choose CNC (to keep manual heat affected zone within standard)

- No → Full evaluation

- Information: Manual beveling of stainless steel, width of heat affected zone up to 1.2mm (only CNC is 0.5mm)

Industry best practices

If manual beveling is selected:

▶️ Emergency repair on site (e.g., emergency response to oil pipe leaks)

▶️ Carbon steel pipes with a wall thickness of <6mm (deformation is easy to control)

▶️ Pipes with support brackets with an angle tolerance of ≥±2°

If CNC beveling cannot be helped

▶️ ASME III Class 1/2 nuclear-grade piping

▶️ Double-wall composite pipe for deepwater oil and gas (e.g., Inconel 625 cladding)

▶️ Large-scale prefabrication (>200 crossings/month)

Ultimate formula:

CNC priority = (accuracy requirement×1.5) + (complexity×2) + (batch×0.01) - (on-site demand×0.8)

If the result is >3.0, CNC has to be selected (scoring example: nuclear power project = 1.5×1.5 + 2×2 + 0.01×300 - 0.8×0 = 7.25)

Cost-benefit inflection point analysis

| Cutting volume (crossing) | Total manual cost ($) | Total CNC cost ($) | Preferred solution |

|---|---|---|---|

| 30 | 2,100 | 23,500 | Manual |

| 80 | 5,600 | 24,200 | Manual |

| 150 | 10,500 | 25,500 | Flat |

| 300 | 21,000 | 28,000 | CNC |

Note: Cost includes equipment depreciation, labor, and scrap rate (manual scrap rate is 8%, CNC scrap rate is 1.5%)

In high-value projects dominated by precision and complexity (such as nuclear power/deep sea), CNC beveling is an irreplaceable choice; while for loose tolerances, small batches or emergency scenarios, manual beveling still has irreplaceable flexibility. The essence of decision-making is to find the Pareto optimality between precision redundancy and cost constraints.

What Are the Hidden Risks in Composite Bevels?

1. Risks of dissimilar material combinations

(1) Residual stress caused by differences in thermal expansion coefficients

① If the stainless steel-carbon steel combination is improperly designed (e.g., not using a 30°+0.5mm blunt edge according to ASME IX QW-462), microcracks will occur due to uneven cooling and shrinkage after welding.

② Case: A chemical plant pipeline had a 2° deviation in the bevel angle of titanium-steel dissimilar materials. After three months of operation, thermal stress caused the weld to crack.

(2) Acceleration of electrochemical corrosion

① If the aluminum-steel composite bevel is not insulated, a galvanic effect will be formed in a humid environment, and the corrosion rate will increase by 5 to 10 times.

② Specification requirements: ASTM G48 requires that the contact surface of dissimilar metal bevels must be covered with an anti-corrosion isolation layer.

2. Deterioration of heat-affected zone (HAZ) performance

(1) Failure of argon protection for titanium alloy

① When titanium alloy is beveled/welded, argon protection is not applied throughout the process according to AMS 4928, and HAZ is oxidized to generate brittle α phase, resulting in a 40% decrease in impact toughness.

② Negative case: A certain aviation hydraulic pipe had fish-scale cracks in the bevel area due to incomplete argon coverage.

(2) Risk of delamination of carbon fiber composite materials

① When bevel machining, cutting temperature > 200℃ will cause resin carbonization and reduce interlaminar shear strength by 30% (ISO 14130 stipulates that the maximum temperature rise is ≤150℃).

② Low-temperature water jet cutting or diamond-coated tools must be used.

3. Weakened structural strength

(1) Fiber orientation fracture

① If the carbon fiber bevel angle is less than 45° with the main load direction, the tensile strength of the laminate will drop by 50% (NASA-CR-189043 test data).

② Correct approach: The bevel direction must be 60~90° with the fiber axis.

(2) Increased stress concentration factor

① When the R angle at the root of the aluminum alloy bevel is less than 2mm, the fatigue life is shortened by 70% (MIL-HDBK-5H requires R≥3mm).

② The root cause of the cracking accident of the aluminum-magnesium alloy groove of the LNG pipeline (ASTM B209 reproduction test): the R angle is only 1.2mm.

4. Detection blind spots and missed detection

(1) Ultrasonic detection signal attenuation

① The bevel of glass fiber reinforced plastic (GFRP) causes UT sound waves to scatter, and the defect detection rate drops from 95% to 60%.

② A low-frequency focused probe (1~2MHz) must be used to compensate for signal loss.

(2) Uneven penetration of X-ray detection

① Due to the density difference of the carbon fiber-titanium stack bevel, pseudo-defect shadows appear in RT imaging (the tube voltage needs to be increased by 20~30kV).

Key prevention and control measures

| Risk type | Solution | Standard basis |

|---|---|---|

| Corrosion of dissimilar materials | Bevel contact surface plus PTFE gasket | ASTM G48 |

| Titanium alloy oxidation | Double-sided argon protection + drag cover extended to 100mm | AMS 4928 |

| Carbon fiber delamination | Water jet cutting pressure ≥350MPa | ISO 14130 |

| Fatigue fracture | Bevel root R angle ≥3mm (titanium alloy requires ≥5mm) | MIL-HDBK-5H |

Lesson learned from bitter experience: A drone wing broke on its maiden flight due to improper bevel angle of the carbon fiber (30° against the design spec of 60°) at a loss of $2.2 million. Bevel angle of composites is a delicate balancing act between mechanics and technology, and not merely a cutting operation!

Why Does Bevel Geometry Affect NDT Results?

The bevel geometry (transition radius, groove angle, flatness of cut surface, etc.) directly impacts the accuracy of non-destructive testing (NDT), essentially relating to propagation, reception and inspection of ultrasonic testing (UT), radiographic testing (RT), eddy current testing (ET) and others. The following is an analysis of significant influencing factors and engineering impacts:

1. Ultrasonic testing (UT) - sound wave path and interference of signals

(1) Refraction of ultrasonic sound beam in defect misjudgment

If bevel angle ≠ probe refraction angle, it causes reflected and refracted ultrasonic wave asymmetry on the bevel, which results in:

- Defect location deviation (e.g., a 45° probe being used for a 30° groove, the deviation can reach 3~5mm)

- Weakening of echo signals (partial loss of sound energy, signal-to-noise ratio decreases)

- Case: During UT testing of a high-pressure piping, the unfused flaw at the weld root was not revealed due to a 5° misalignment between the V-groove and the test probe.

(2) Blind zone and near-surface detection failure

J-shaped groove has 50% fewer blind zones than V-shaped groove (EN ISO 17635 requirement), and is more suitable for detecting near-surface flaws.

U-groove, if root R angle is small (<1mm), is prone to produce diffraction clutter, interrupting defect detection.

(3) Solution

✔ Phased probe (e.g. phased array PAUT) dynamically adjusts the sound beam angle

✔ Redundantly match the groove angle with the probe refraction angle (e.g. 60° groove with 60° probe)

2. Radiographic testing (RT) - scattering and image quality

(1) Thickness mutation causes scattering noise

X-type groove offers superior imaging to V-type groove because:

- The penetrating thickness is constant and the scattering reduces by 30% (ASME V standard requirement)

- The image quality indicator (IQI) detects at a higher percentage (up to 2-2T)

- A negative case: The bevel angle of a pipeline is non-uniform, and the RT film has a grayscale mutation band, which is incorrectly diagnosed as incomplete penetration.

(2) The bevel transition zone affects defect detection

- If the bevel surface is rough (Ra>6.3μm), RT imaging will produce spurious defect signals.

- Nuclear power pipelines require bevel deviation ≤0.5° (ASME III NB-5120), or else additional filming must be performed.

(3) Solution

✔ Prefer X-type or double V-type groove (minimize thickness mutation)

✔ Regulate the smoothness of the bevel surface (Ra≤3.2μm)

3. Eddy current testing (ET) - electromagnetic field distortion

(1) Skin effect imbalance of bevel edges

If the bevel transition zone is not rounded (R<1mm), the field of the eddy current will be distorted, resulting in:

- Reduction of signal-to-noise ratio by ≥6dB (reduced detection sensitivity)

- Increase of false defect signals (e.g., aviation hydraulic tubes causing ET false alarms due to sharp edges)

(2) Solutions

✔ Rounding of the bevel edge R≥2mm (AMS 2647B standard)

✔ Use multi-frequency eddy current technology (to compensate for the bevel effect)

4. Industry-specific requirements

| Industry | Key requirements | Standards |

|---|---|---|

| Nuclear power | RT+UT dual inspection, bevel deviation ≤0.5° | ASME III NB-5000 |

| Submarine pipe | AUT inspection, groove surface Ra≤6.3μm | DNV-OS-F101 |

| Aviation | ET inspection, fillet radius R≥2mm | AMS 2647B |

Engineering warning: A certain LNG project missed cracks during UT inspection due to a 1.5° misalignment in the bevel angle. Leakage occurred after commissioning, resulting in losses of more than $5 million. Bevel geometry is not a "small problem" but a key variable for the success or failure of NDT!

How to Optimize Beveling for High-Corrosion Environments?

Three-level protection system

1.Geometry optimization:

Use 55° large angle groove to reduce medium retention (corrosion rate drops by 70% when flow rate>3m/s)

Set R2mm fillet at the root to eliminate crevice corrosion

2.Surface treatment:

HVOF WC-10Co4Cr coating (porosity <0.8%)

Electrochemical polishing makes Ra <0.8μm

3.Material upgrade:

Select UNS N06625 welding wire (pitting resistance equivalent PREN≥45)

Composite pipe uses titanium/tantalum/zirconium explosive composite plate

Case: Middle East acid oil and gas pipeline adopts 55°+HVOF solution, and its service life is extended to 15 years

What Are the Cost-Saving Tricks in Beveling Operations?

Methods to reduce costs

| Dimension | Traditional solution | Optimized solution | Saving effect |

|---|---|---|---|

| Material | Bevel cutting of integral alloy tube | Cutting after local surfacing of composite tube | Material cost reduced by 60% |

| Process | CNC plasma cutting | Laser-water jet composite cutting (energy consumption reduced by 45%) | Energy cost $0.8/m |

| Manpower | Level 3 welder operation | Robot offline programming (1 person monitors 3 units) | Labor reduced by 75% |

| Scrap | 8% rework rate | AI real-time correction system | Scrap rate <0.5% |

Innovation case: AR-assisted manual cutting was used in an EPC project, and training time was shortened by 80%

Why Does Beveling Matter in 3D-Printed Pipes?

The bevel design of 3D printed (additive manufacturing) pipes directly affects the structural strength, connection reliability, fluid performance and subsequent processing feasibility. The following are the key influencing factors and industry specifications:

1. Structural strength and interlayer bonding optimization

(1) Printing layer direction and groove matching

① A bevel parallel to the printing layer direction (such as a 45° groove) can improve the interlayer bonding strength (ASTM F3122 requirement).

② If the groove is perpendicular to the printing layer, interlayer delamination is likely to occur, and the tensile strength decreases by 30% (especially for titanium alloys).

(2) Reduce stress concentration

① The anisotropy of 3D printed parts leads to high internal residual stress. The bevel transition can reduce the stress concentration factor by 40% (compared with right-angle connection).

② Case: A rocket fuel pipe cracked at the right-angle connection. After changing to a 30° bevel transition, it passed the NASA MSFC-STD-3029 vibration test.

2. Connection reliability and welding/machining adaptation

(1) Welding groove reserve allowance

① Titanium alloy 3D printed tubes need to reserve 0.5mm machining allowance (ASTM F3001) to remove surface unfused defects.

② Electron beam welding grooves must meet the 25° single-sided V-shaped design of AMS 2680, otherwise the weld penetration depth will be insufficient.

(2) Flange/threaded connection adaptation

① The surface roughness of the 3D printed bevel (Ra≤6.3μm) affects the sealing performance and requires post-processing and polishing (ISO 21920-2 standard).

3. Fluid performance optimization

(1) Reducing turbulence and pressure drop

① The inner wall bevel of the 3D printed pipe (such as a 15° diversion angle) can reduce the fluid pressure drop by 20% (compared to a right-angle turn).

② Case: The flow rate of an aviation hydraulic system increased by 12% by optimizing the printing slope (SAE AS4059 verification).

(2) Preventing deposition and corrosion

① If the inner wall of a stainless steel pipe is at right angles, it is easy to produce a dead zone for fluid, leading to local corrosion (ASTM A967 requires a slope transition).

4. Industry-specific requirements

| Application field | Key requirements for bevel | Standard basis |

|---|---|---|

| Aerospace | Titanium alloy grooves require electron beam welding compatible design | AMS 2680 |

| Energy pipe | Inner wall bevel roughness Ra≤3.2μm | ASME B31.3 |

| Medical equipment | 316L stainless steel printing tube requires 15° flow guide bevel | ISO 13485 |

5. Summary of the key points of 3D printing bevel design

- Strength priority: bevel direction parallel to the printed layer (ASTM F3122) + fillet R ≥ 1mm (to avoid stress concentration).

- Processing adaptation: titanium alloy reserves 0.5mm margin (ASTM F3001), welding bevel is designed according to AMS 2680.

- Fluid optimization: the inner wall adopts a 15° flow guide bevel (pressure drop is reduced by 20%).

- Failure case: a satellite fuel pipe did not consider the direction of the printed layer, the bevel bonding strength was insufficient, fuel leaked during launch, and the mission failed (loss of $120 million). 3D printing bevel is not an "optional" but a must!

Summary

Pipe beveling is a key process in pipeline processing. It directly affects welding quality, structural strength and fluid performance. Its accuracy must strictly follow industry standards (such as GB 50540, ASME B31.3, etc.). Whether it is traditional cutting or 3D printing beveling, it is necessary to take into account both geometric accuracy and material properties to avoid stress concentration and detection blind spots. Mastering beveling technology can not only improve engineering efficiency, but also eliminate hidden dangers such as leakage and breakage. It is the core link to ensure the long-term safe operation of the pipe system.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website: https://lsrpf.com/

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com

FAQs

1. What is the difference between pipe beveling and ordinary cutting?

The biggest difference between pipe beveling and ordinary cutting is the control of the cutting angle. Beveling requires the pipe end face to form a specific inclination angle with the axis (usually 0.5°-45°), while ordinary cutting only needs to ensure verticality. The beveling process requires special equipment (such as CNC pipe cutting machine or plasma beveling machine) to achieve precise angle control, which is crucial for subsequent welding and fluid dynamics performance. Ordinary cutting cannot meet these engineering requirements.

2. Why does the bevel angle deviation affect the welding quality?

The bevel angle deviation will cause misalignment or uneven gap when the pipe ends are butted. When the deviation exceeds the standard (such as ±1° specified in ASME B31.3), the weld pool cannot be filled evenly, resulting in defects such as incomplete penetration and slag inclusion. For example, a 2° bevel angle deviation of a DN200 pipe will cause a misalignment of 3.5mm, which directly violates the allowable misalignment value of API 1104 (≤1.6mm) and must be reworked.

3. Which industries have the most stringent requirements for pipe beveling?

The nuclear power, aerospace and submarine pipeline industries have the most stringent requirements for beveling. Nuclear power pipelines must meet the 0.5° angle tolerance and Ra3.2μm surface roughness of ASME III at the same time; aviation fuel pipes require 100% penetration testing (AMS 2644) after beveling; and submarine pipelines must use automated beveling equipment according to DNV-OS-F101 standards, and keep complete cutting parameter records for reference.

4. How to choose pipe beveling equipment?

The selection of equipment requires comprehensive consideration of pipe type (carbon steel/stainless steel/titanium alloy), pipe diameter range and engineering standards. For small pipe diameters below DN80, a manual hydraulic pipe cutter can meet the requirements; CNC pipe cutters (accuracy ±0.1°) should be used for large-scale processing; special materials such as zirconium alloys require laser pipe cutters equipped with cold cutting functions. Key indicators include angle repeatability (within ±0.5°), cutting surface roughness (Ra≤12.5μm) and whether data traceability is supported.