At first glance, it might just be a simple metal ring or washer. But a closer look reveals hidden complexity. How does this seemingly simple CNC-turned part go from a piece of metal bar stock to a finished product with smooth surfaces and precise internal features? This article will answer your questions. Using this unique ring-shaped part as a "living example," we'll take a deep dive into the world of custom CNC turning manufacturing. We'll also explain everything from basic turning operations to more advanced multi-processing techniques, ultimately revealing the key factors that influence CNC turning prices.

So, whether you're an engineer, product designer, or maker, this guide will equip you with everything you need to successfully manufacture high-quality parts through online CNC turning services.

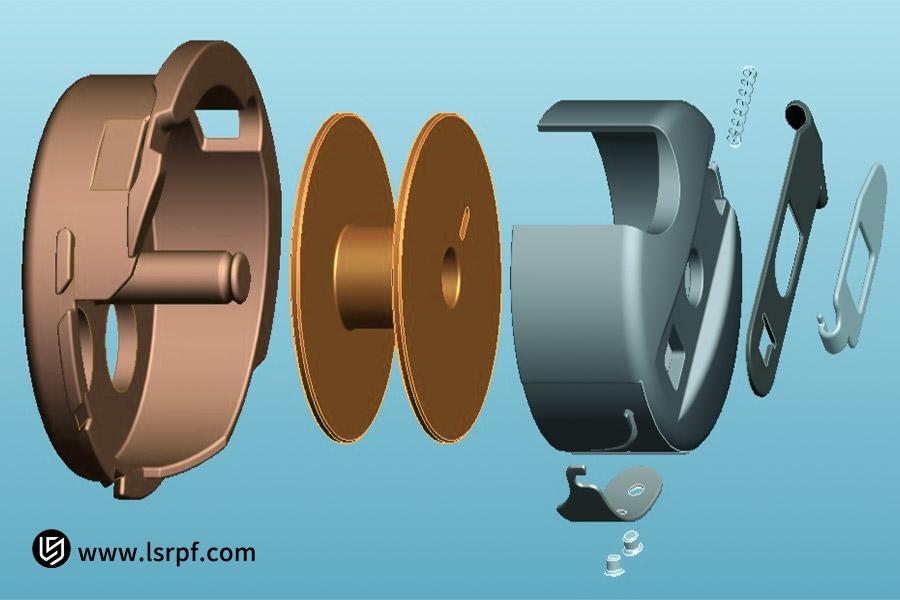

Interpreting Design Language From Pictures

Let us explain the design language from the pictures. We will introduce you to the core features (rotational symmetry), basic turning features, and advanced features.

Core Feature-- Rotational Symmetry

We can clearly see that the part is rotationally symmetrical. The symmetry of a part is the most important basis for judging whether a part is suitable for CNC turning.

Basic Turning Features

Smooth OD and Face: How are smooth OD and face surfaces achieved? This is achieved through standard external turning and facing, where the tool cuts through the rotating workpiece while stationary.

Internal Bore and Step: The part's internal bore and the small recessed step are created through drilling and internal turning.

Advanced Features

Internal Knurling/Serrations: The most interesting aspect of this part is the internal knurling or serrations. These axial serrations are impossible to machine directly on a standard CNC lathe! This indicates that this part was not simply turned.

Are you familiar with the concept of "mill-turn"? Mill-turn refers to a process that combines turning and milling capabilities on a single machine, allowing multiple machining operations to be completed on the same machine. To create this feature, you'd need a more advanced CNC turn-mill center. On this machine, the spindle (workpiece) stops rotating and is precisely positioned, while a rotating "live tool," such as a small milling cutter, mills the teeth.

Material Selection

Depending on industrial applications, turned parts can be made from a variety of materials. We need to choose the right material based on the intended use case, such as stainless steel, aluminum alloy, and alloy steel. The following briefly introduces the selection of these three materials.

Stainless steel is characterized by corrosion resistance, high strength, and some high-temperature resistance. It is commonly used in medical devices, chemical valves, food processing equipment, and marine components.

Aluminum alloy is characterized by lightweight, easy processing, good thermal conductivity, but lower strength. It is commonly used in aerospace structures, automotive parts, electronic housings, and radiators.

Alloy steel is characterized by high strength and wear resistance, and can be heat-treated to optimize performance. It is used in transmission or locking components requiring high strength and wear resistance, such as gears, bearings, tools, and heavy machinery transmission parts.

In short, choose stainless steel for corrosion resistance, aluminum for lightweight, and alloy steel for high loads.

The Core Process of CNC Turning

CNC turning is a type of numerically controlled machining technology that uses a rotating workpiece and a cutting tool to remove material, creating parts with specific shapes and dimensions. Similar to traditional lathe machining, CNC turning is controlled by a computer program, offering greater precision and efficiency. In other words, CNC turning is like a "high-tech potter's wheel," precisely controlled by a computer, but for metal.

Below, we present a breakdown of the manufacturing steps for this part:

1.Loading and Clamping

The operator precisely clamps a cylindrical bar (such as stainless steel, aluminum alloy, or alloy steel) into the lathe's three- or four-jaw chuck, ensuring the workpiece is stable and aligned to the required degree, avoiding vibration or misalignment during machining.

2. External Diameter and End Face Machining

Using carbide turning tools, the bar is rough-turned and finish-turned, cutting to the designed dimensions in stages. This ensures an external surface finish (e.g., Ra 1.6) and end face flatness, providing a reference surface for subsequent machining.

3. Center Drilling and Internal Hole Machining

First, a center drill is used to locate and pre-drill a pilot hole on the end face. A twist drill or deep-hole drill is then used to machine the internal hole. Finally, a boring tool or internal turning tool is used to fine-tune the internal diameter. Steps, chamfers, and other features are then added to ensure internal hole accuracy (e.g., H7 tolerance) and wall thickness uniformity.

Key control points: clamping concentricity, cutting parameters (speed/feed rate), dimensional tolerance and surface roughness.

Mill-turn machining (key step): The spindle stops rotating, and live tooling is activated, milling a knurled or serrated pattern onto the inner wall like a milling machine.

Parting off: A cutter is used to separate the machined part from the bar stock.

How to Use Online CNC Turning Services Efficiently

At LS. Precision Manufacturing, we're committed to streamlining your custom part machining process, enabling you to quickly and easily obtain high-precision turned parts. Our online service utilizes an intelligent system, allowing you to place an order in just three simple steps:

1. Upload a 3D model (supporting formats such as STEP, IGES, and STL)

Simply upload your part's 3D design file (e.g., in STEP format), and our system will automatically analyze the geometric features, identifying dimensions, tolerances, and machining requirements. We support complex features (such as internal holes, threads, and steps), ensuring accurate quotes and production.

2. Select machining parameters (material, quantity, surface treatment, etc.)

Material Selection: Choose from a variety of materials, including stainless steel, aluminum alloy, and alloy steel, to best meet your needs.

Machining Quantity: We support small-batch trials to large-scale production, with transparent pricing and no hidden fees.

Surface Treatment: Optional post-treatments such as anodizing, plating, sandblasting, and polishing enhance part performance and aesthetics.

3. Get an instant quote and confirm your order

Our quotes calculate machining costs within seconds and provide the best possible delivery time. Once the order is confirmed, our CNC workshop will immediately schedule production to ensure efficient delivery.

Key communication point: For parts with special features like the one in the picture, it is best to clearly indicate "inner hole knurling" in the remarks or provide a 2D drawing to ensure that we, LS. Precision Manufacturer, understand your key needs.

Four Factors Affecting CNC Turning Prices

In CNC turning, seemingly similar parts can have vastly different prices. This discrepancy is primarily driven by cost factors, which are influenced by four key factors: machining time, material cost, machine complexity or setup, and tolerances and precision. Adjusting even the smallest detail can significantly alter the final quote. Below, we'll delve deeper into how these factors impact machining costs.

Analysis of CNC Turning Price Driving Factors Table

| Factors Affecting Costs | Importance | How to Optimize |

| Processing Time | The biggest cost driver. Simple turning is very fast, but milling with live tools can significantly increase machining time due to the multiple positioning and slow cutting required. | If the internal serrations are not functionally necessary, replacing them with simple grooves or smooth inner walls can significantly reduce costs. |

| Material Costs | The price of the raw material and the diameter of the bar stock required. The more expensive the material and the larger the diameter, the higher the cost. | Choose the most cost-effective material that meets performance requirements. For example, if it is non-functional, use aluminum instead of stainless steel. |

| Machine Complexity/Setup | Simple parts can be made on a standard CNC lathe. However, the part in the picture requires a more expensive mill-turn center. Setup costs are a one-time expense before manufacturing. | Simplify your design so it can be machined on simpler machines. Spread the setup costs by ordering larger quantities. |

| Tolerance and Precision | The tighter the dimensional tolerances on a part, the slower the machining needs to be and the more complex the inspection, which increases costs. | Only mark strict tolerances on critical dimensions (such as inner hole diameter) and relax tolerance requirements on non-critical dimensions. |

| Conclusion |

Go beyond the surface and understand the manufacturing logic behind the design. |

|

Summary

CNC turning is a powerful tool for manufacturing rotationally symmetrical parts, but its capabilities extend far beyond creating smooth cylindrical shapes. Mill-turn technology enables the efficient manufacture of extremely complex designs, such as intricate geometries. Furthermore, by integrating milling, drilling, and tapping functions, modern turning centers can perform multiple machining operations simultaneously, significantly improving accuracy and reducing costs, making them a core solution for precision manufacturing.

Therefore, designers need to think about how each feature will be manufactured during the design phase. For example, a "small" internal knurl may mean upgrading from a regular lathe to an expensive mill-turn center. If you have this type of machining needs, upload your design drawings to our LS. Precision Manufacturing online CNC machining platform now. You'll experience and feel how your design choices impact the final quote in real time, and begin your precision manufacturing journey.

In the face of these higher challenges, LS's CNC turning service is your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instant CNC turning quote (cnc turning price), let LS be your strong backing in pursuit of ultimate woodworking precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com