Imagine: Just as the final minute of decisive assembly, when this unique connector is being inserted into the system core and must resist enormous loads, there is a thud noise, followed by abnormal movement of the mating surface. Time freezes.The expensive bill is before you: system downtime, hours of debugging, and even damage to core equipment.

These disastrous conditions are a consequence of tolerancing sacrifices in the machining precision of connectors. Being the center piece of mechanical assemblies, connectors bear the tremendous responsibility of precise connection and stability of force transmission. Even micron-order tolerancing misalignments within their mating interfaces will suffice to induce stress concentration, abnormally excessive wear, and even catastrophic failure.

Thus,precise CNC machiningis in no way a luxury, but a lifeline to ensure its mating accuracy, mechanical integrity, and final system dependability. Especially when you go forexpertonline CNC services, not only do you have this all-essential accuracy guarantee, but can also enjoy the significant advantage of process transparency and cost control.

So,why can speciallycustom CNC machinedcomponents precisely match this special connection bond?Three basic reasons hold the key.

Custom CNC Machining: 3 Key Reasons to Refine Your Unique Connectors

| Core reasons | Key elements | Core advantages |

|---|---|---|

| 1. Overcoming precision structures and stringent requirements | * High-precision machining capabilities (micron-level tolerances, such as ±0.015mm) * Complex geometric molding (such as U-shaped grooves, precise chamfers) * Material adaptability (high-strength alloys, stainless steel, engineering plastics, etc.) * Excellent surface treatment (high finish, low Ra value, enhanced wear resistance/corrosion resistance) |

Ensure that parts perfectly match the design, achieve seamless fit, reliable connection functions and long-term durability, and meet the needs of extreme mechanical environments. |

| 2. Enable efficient and agile customized processes | * Convenience of online platforms (quickly upload drawings, instant quotes) * Production flexibility (seamlessly support small batch trial production to large batch production) * Strict quality control system (CMM inspection, etc., to ensure that the size and surface meet the standards) * Transparent price and delivery time (CNC machining price is clearly visible) |

Significantly shorten the development cycle, reduce the cost of trial and error, flexibly respond to changes in market demand, and ensure stable and reliable quality. |

| 3. Directly hit the core needs of the industry and create value | * Meet the high-precision, high-reliability industry trend (automation, robots, precision instruments) * Adapt to modular design (simple structure facilitates quick assembly and maintenance) * Successful case verification (such as robotic arm connectors improve performance and accelerate market launch) * Comprehensive cost-effectiveness (precision processing reduces waste, transparent prices optimize costs) |

Directly improve the performance of terminal equipment (precision, speed, reliability), accelerate product launch, create verifiable business value and establish long-term cooperative trust. |

Structural Features And Process Complexity

Structural features:

- Single U-shaped slot:The structural demand meets the demand of quick snap-on coupling of robot arms/machine automation.

- Straightforward but rigorous specifications:Overall geometry is straightforward, but slot size precision (depth, width, angle, location) andsurface finishrequirements are very strict, with direct effects on assembly and performance.

- Multi-material compatibility:Should be compatible with a variety of materials such as steel,aluminum alloy, and engineering plastics to provide the overall strength and wear resistance required in a number of different mechanical environments.

Processing difficulties:

High accuracy of slots:

- Challenge:Correctly hold all important dimensional tolerances of U-slots. Susceptible tomachine toolaccuracy, tool wear, and clamping/cutting thermal distortion.

- Chamfering problems:Achieve a smooth, consistent, and accurate-size chamfering of the slot edge (especially on deep/skinny slots where space is at a premium) so as not to impact assembly, strength, or be a point of stress concentration.

- Stability Issue:Keep world shape and location of characteristic feature of the part stable after machining and under fluctuating working conditions. Encompasses relief of stress in material (heat treatment) and control of process sequence (minimization of deformation), especially in the case of thin-walled/asymmetric geometries.

Multi-material processing issues

Challenges:Optimization of machining parameters (feed, speed, etc.) in accordance with varied material characteristics (toughness, hardness, etc.) and proper tool selection (material, shape) must be implemented in order to control wear, avoid chipping/sticking, and achieve surface quality specifications in regards to cost-effectiveness.

LS's Custom CNC Machining Service Benefits

I am Gloria, and I am anLS engineer. I run ourCNC machinesdaily to assist customers with precision machining problems. These are the major advantages of our service in my own words:

- Convenient and time-saving, online:You can just post the drawings online and the system will be capable of generating a goodCNC machining quotationimmediately, saving you time for repeated inquiries. You can track the order online as it processes and benefit from the actual efficiency of onlineCNC machining services.

- Accuracy first, details matter:I do know that accuracy of the primary features (e.g., slots and edges) matters to us. We deliver state-of-the-art state-of-the-art precision high-endCNC machineryfor obtaining the realization of severe tolerances (e.g., ±0.01mm), which provide crediblecustom CNC machiningand manufacturing guarantees to your design.

- Flexible batch, smooth service:Whether a trial production of small batch to inspect the design, or huge batch of stable delivery, we can respond flexibly. From prototype to mass production, scheduling of production is efficient and smooth.

Strict quality check during all my daily activities is the bottom line. With equipment from professionals, we make sure that the dimensional tolerance and surface finish of every part perfectly meet your specification and industry standards, and deliver consistent quality.

Briefly,choosing LSwill provide you with: online convenience, highly specialized craftsmanship backed by state-of-the-art machines, the ability to respond rapidly to batch needs, and quality control in close supervision by engineers. This is the rock-solid support we provide for the success of your project.

Success Case: Tailor-Made Processing of Precision Industrial Robot Connectors

Project Background:

We just completed a key project to adapt the core connection module of the robot arm for an industrial robot corporation. The minimum requirement of the customer is to have the size and shape of the slots on the module extremely accurate (micrometer grade) to ensure the absolute stability and long-term performance of the connection when subjected to dynamic loads.

LS Solution

- Material Science Application:Given the high-wear requirements, we selected high-performancealloy materialsto significantly increase connectors' wear and fatigue life.

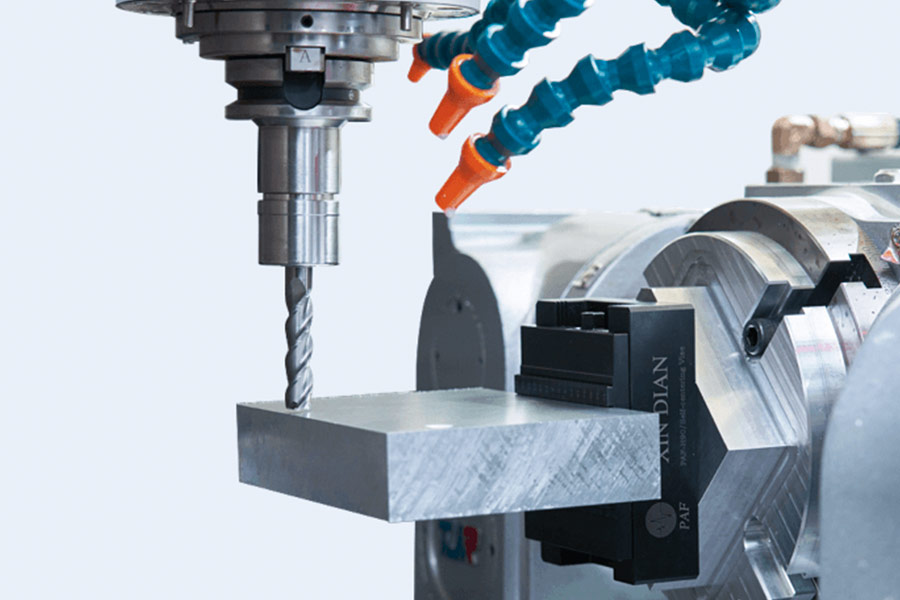

- Precision Manufacturing Process:With next-generationmulti-axis CNC machiningcenters, we accurately produce complex slot geometry, and complete high-demand edge chamfering and precision cutting to provide the perfection of critical mating surfaces.

- Digital Process Optimization:By means of our intelligent online platform, customers may be offered true real-time quotes and carry out efficient design rounds instantly, reducing the product development cycle time from manufacturing to design dramatically.

Project Benefits: - High Accuracy:The machining of the key dimensions of the finished parts is strictly managed to ±0.015mm accuracy to ensure that it meets the assembly needs perfectly and achieves a gapless and smooth connection effect.

- Efficiency improvement:By optimizing processes, we have succeeded in improving overall delivery speed by 20% in real life, enabling customers to speed up the release of their end products.

- Customer satisfaction:Customers are highly satisfied with the high quality of our products and our fast and cooperative service, and due to such successful experience, they will increase follow-up cooperation orders to LS.

This case is the optimal illustration of LS's professional strength in customized processing of high-precision and high-performance components, from material selection,precision machiningto digital services, and becomes a stable manufacturing partner for customers.

Why Choose LS?

For the precision machining industry, to select LS is to select a responsible, efficient and professional one-stop solution. We become your reliable partner with the following main advantages:

Digital convenience experience:

The revolutionary web-based platform provides open, real-time quotations and efficient order processing, makes the process simpler, and significantly lowers your cost and time of communication.

Superior quality and timely delivery:

Backed by highly advanced multi-axis CNC machining centers and stringent quality inspection systems and a seasoned expert team's in-depth process and accuracy understanding, assures high precision (e.g., ±0.015mm), high-quality and stringent delivery of components.

Variety of materials and complex process capabilities

High-level processing of extensive engineering materials (aluminum/stainless steel/titanium alloy/engineering plastics, etc.), experienced in processing intricate geometry, accuracy features (fine grooves, strict tolerances) and multi-process demands, flexible to meeting the production difficulties of diversified and high-demand parts in industries such as aerospace, medical, and automation.

Fair and open cost optimization

Ensure price transparency and no surprise charges. Through streamlining processes and optimized operation, we provide competitive prices to help you better manage supply chain costs.

Choosing LS means choosing a partner that combines top-notch equipment, expert technology, flexible manufacturing and cost-effectiveness. We are committed to enabling your product success and jointly coping with market competition with precise processing, reliable delivery and efficient services.

Summary

Unique connections require extreme precision and reliability, and general-purpose parts are often unable to meet this requirement. Choosing customCNC machined partsis your ideal solution for perfect connections for three key reasons:

- Micron-level precision, perfect fit:Ensure precise fit at connection points, eliminating the risk of failure due to tolerances.

- Material freedom, excellent performance:Optional metals/engineering plastics to meet specific needs such as strength and corrosion resistance.

- Mastering complex geometry:Multi-axis CNCcan easily achieve complex designs such as special-shaped contours and internal cavities, making creativity come true.

Act now to unlock the power of precision manufacturing!

Don't let connectors become a bottleneck for your project. Experience ourprofessional CNC servicesnow:

- Upload your design:Submit drawings or 3D models.

- Free consultation and sample support:Get professional evaluation, optimization suggestions and sample production possibilities.

- Fast andaccurate quotation:Transparent and efficient to help you make decisions.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com