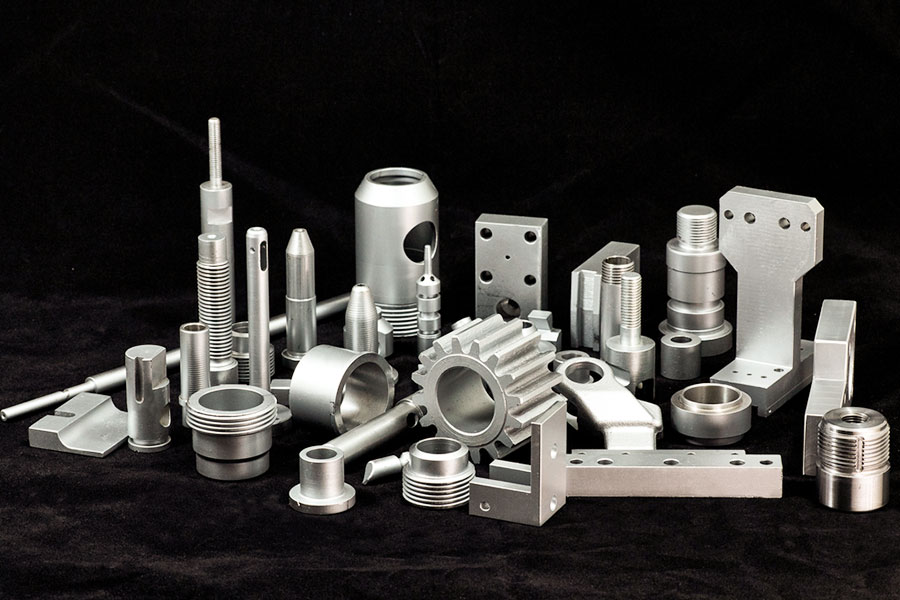

My daily work in LS is high-performance connection brackets. These parts may appear plain, but they are the "hidden champions" of main systems such as auto body chassis and robot joints, and they undertake critical structural support and accuracy connection tasks. Their strength, stiffness andprocessing precision- especially the size and position tolerance of main holes - have a direct impact on the stability and running accuracy of the entire equipment, and no looseness is allowed.

For this reason, we fully comprehend thathigh-precision hole processingis the most important condition for successful assembly. In LS, we strictly applyhigh-precisionCNC machining technologyto ensure the position of the hole in each customized connection bracket is accurate, so that it can be installed smoothly and operates reliably even in extremely severe working conditions. Today, not only is outstanding performance expected by the market, but also speed and cost-effectiveness. This is the beauty of ouronline CNC machining service:it is a perfect harmonization of speed, precision and flexibility. Customers can quickly customize the desired parts online, and we can make it efficiently and accurately, allowing customers to resolve the two greatest issues of efficiency and cost at the same time.

Therefore, for these four specially made connection bracket components specifically, how do they exactly move from design to manufacture, and then come to significantly improve the overall performance of the machinery? Let's dig a little further.

Key Points For Improving The Performance Of Custom Brackets

| Customization Focus | Key Performance Gain | Best Application Scenario |

|---|---|---|

| 1. Material and heat treatment upgrade | Significantly enhance strength, stiffness, fatigue life; optimize wear resistance, corrosion resistance or weight reduction. | Withstand high loads, impact, harsh environments (high temperature, corrosion); require lightweight moving parts. |

| 2. Topology and geometry optimization | Achieve optimal strength-to-weight ratio; eliminate stress concentration; improve force flow path; increase natural frequency (anti-vibration). | Space-constrained areas; require extreme lightweight; have vibration problems; key load-bearing nodes. |

| 3. Precision tolerance and surface treatment | Ensure perfect assembly and alignment; reduce friction and wear; enhance sealing; improve corrosion resistance/weather resistance. | High-precision transmission system; require tight assembly; friction pair contact surface; outdoor or harsh environment application. |

| 4. Integrated function and interface customization | Simplify assembly and reduce the number of parts; eliminate cumulative errors; provide dedicated interfaces; improve the overall rigidity and reliability of the system. | Complex component assembly; need for quick assembly and disassembly; provide dedicated mounting locations for specific sensors, cables or accessories; modular design. |

This guidebook will give each customization aspect a detailed look. We will not merely pause at simple part descriptions, but rather will reveal the engineering design basis forcustom CNC connection brackets,and show you how these optimizations can be converted into tangible competitive benefits through real examples and performance comparison figures recorded in our own workshop. You will have a good sense after reading this article ofhow bespokeCNC bracketscan be a considered choice to resolve equipment bottlenecks, improve reliability, extend life, and eventually reduce overall costs.

Analysis Of Parts Structure And Processing Characteristics

The connecting bracket is a key positioning and force transmission part of mechanical equipment. Its structure is simple, but strict requirements are imposed on the accuracy of manufacture. Its key design features and processing difficulties are as follows:

1. Structural features: the most critical positioning in simplicity

(1) Main structure:It usually employs a plate, block or simple geometric structure (e.g., L-shaped or U-shaped foundation), and the structure is simple with easy installation.

(2) Key elements:Two precision holes are completely core:

- Proper location:As a reference during assembly, it ensures proper location with other components (shaft, bearing seat, other bracket).

- Efficient transmission of force:It serves as a center for transmission of mechanical forces (static load, dynamic vibration, torque).

(3) Supporting structure:It may have weight-saving holes to save weight, stiffening ribs to enhance stiffness, and bolt holes or countersink holes for easy installation.

2. Processing core: precision determines success or failure

The primary challenge and excellence of processing are fully focused on theprecision controlof two key holes:

(1) Aperture size precision (IT7 or higher):

- Influence:Directly determines the clearance or interference with the relevant shaft/pin, which is linked with the transmission stability, wear life and vibration noise.

- Control:It should be acquired by precise reaming, grinding or boring, based on exact instruments and stable processes.

(2) Position accuracy of the holes (critical!):

- Position tolerance(e.g., Φ0.02mm):Restraint of the spatial position deviation of the two hole axes within the tolerance zone cylinder exactly is the key to ensure stress-free assembly and frictionless motion.

- Hole spacing tolerance (±0.01mm):Ensure the correct center-to-center distance between the two holes, affecting the overall accuracy of the assembly chain.

- Parallelism/perpendicularity:Impose standards on the geometric congruence between the axes or the axes and the installation reference surface in order to ensure satisfactory force flow transmission.

(3) Surface quality:Thesurface roughnessof the hole wall (Ra 0.8μm or less) has an effect on the wear resistance, sealing (if applicable) and fatigue strength.

3. Variety of materials and process choice

(1) Wide material range:From lightweight and corrosion-resistantaluminum alloy(6061-T6, aerospace, light industry), high-strength carbon steel with good cost performance (45#, general machinery), to wear and high-strength alloy steel (40Cr, heavy-duty transmission), corrosion-resistantstainless steel(304/316, chemical food), and even engineering plastics (POM, light load and low cost). The material selection fully meets the service environment (load, speed, temperature, corrosive medium).

(2) Process sequence:As per material and precision specifications:

- Conventional:Cutting ->Rough milling-> Locating holes drilling -> Reference surface fine milling/fine turning -> Precision machining hole system (drilling-reaming-reaming/fine boring) -> Tapping/other features -> Deburring -> Inspection (first inspection + random inspection, critical hole locations).

- High demands:Add coordinate grinding, precision EDM, etc.

- Key:Hole processing is often completed in one clamping, or uses precision fixtures/CNC systems to allow position accuracy.

What Are 4 Custom CNC Connection Bracket Parts Made To Improve The Performance Of?

When off-the-shelf brackets cannot meet stringent installation locations, unusual loading or complex vibration conditions, compromised parts usually become system performance bottlenecks. Choosing a customCNC connection bracketis a crucial milestone to overcome these shortcomings. This is how a custom solution can accurately improve your device performance:

- Strength and stiffness jump:Design the bracket geometry and wall thickness based on your actual-world force data and utilize high-strength materials such as 7075 aerospace aluminum ortitanium alloysuch that crucial joining points are stable and dependable with no possibility of bending.

- Micron-level accuracy fit:CNC machiningadopts ultra-high tolerance accuracy control of ±0.025mm to ensure that the bracket is exactly matched with the contact surface, eliminating assembly stress, and significantly reducing equipment vibration and noise.

- Lightweight design to the extreme:Based on topology optimization and simulation analysis, redundant materials are removed exactly with the assurance of strength, so that the moving parts are relieved, the equipment's dynamic response speed and energy efficiency are enhanced, and equipment weight is reduced to maintainability.

- Special adaptation for harsh working conditions:Either high temperature, harsh corrosive environment, or special electromagnetic compatibility requirements, special material selection (e.g., stainless steel 316L, PEEK engineering plastics) and special structure design can be performed to ensure long-term and stable running under extreme conditions.

LS's Custom CNC Machining Service Benefits

As an LS engineer, my usual primary task every day is to ensure that ourCNC machining servicescan precisely and efficiently meet your requirements. Our competitive advantages are reflected in several key links:

- Efficiency powered by web platform:With our web platform, after you upload the design drawings, the system can analyze and provide clear quotations quickly and smartly and in a very short time, significantly shortening the project start-up time and allowing your ideas to become a reality sooner.

- Multi-axis precision machining capacity:My trusted friends are the multi-axis (four-axis/five-axis)CNC machining centersin the workshop. They are able to perform complicated linkage processing and finish high-precision cutting of deep holes, special-shaped contours and key mating surfaces in one or less clampings. This ensures the accuracy of hole position and clear and sharp edges with rigid micron-level tolerance requirement.

- Flexible adaptation as per the requirements of manufacture:We are very familiar with different R&D and manufacture requirements. Starting from the prototype test (as low as a single piece), small batch pilot manufacture or large batch manufacture, our procedures and personnel can smoothly alter processes, improve processes, and place orders of different batches as seriously handled and supplied.

- Stringent quality control guarantees consistency:All components are strictly checked by me and the quality inspection team. Through first article inspection (FAI), process sampling inspection (IPQC) to final shipment inspection (OQC), we use precision tools to fully scan dimensions, geometric tolerances and surface quality according to your standards or generic specifications. This translates to the fact that all lot of components you receive have excellent consistency and reliability and fully live up to expectations.

At LS, we combine effective digital interaction, advancedmulti-axis machiningtechnology, flexible production models and rigorous quality control to deliver high-quality customized parts that you can depend on.

General Industry Applications And Market Demand Analysis

As LS engineers according to our experience ofprecision CNC machining, we analyze the general applications and market demand of connecting bracket parts as follows:

1. Automated robotic arms and transmission devices

- Applications:joint attachment, motor/reducer mounting, end effector attachment.

- Core requirements:ultra-high rigidity & dynamic stability. It must withstand the huge inertial force and vibration resulting from high-speed movement in a bid to offer long-time positioning precision and stability. The material is low-expansion high-strength aluminum alloy/alloy steel/titanium alloy. It requires high-precision geometric tolerances (typically up to ±0.02mm) and fatigue resistance. LS depends onfive-axis CNCand FEA analysis technology with high-rigidity to meet the requirements.

2. SMT/semiconductor electronic manufacturing equipment:

- Applications:Assist wafer transfer robots, lithography machine worktables, essential parts of precision dispensing/mounting equipment (optical components, linear motors, sensors).

- Core requirements:micron-level precision & ultra thermal stability. Small deformation or thermal expansion and contraction can result in equipment misalignment. It requires low-expansion materials (such as Invar, specialty aluminum), ultra-high cleanliness (in accordance with SEMI standards) and high-grade anti-microvibration performance.LS compromisesthrough means of constant temperature workshop processing, ultra-high precision equipment and strict clean processes.

3. Motor vehicle and robot manufacture:

- Applications:production line welding robot base, conveyor line bracket, fixture, service robot/AGV chassis structure.

- Core requirements:standardization, modularization & cost-reduction. Design will tend to serialize for rapid assembly and supply chain management. Medium and large lot demand is high, requiring efficient processing (multi-station, automation) and stringent quality consistency. Reduced light weight (aluminum alloy) and DFM collaborative optimization for reduced costs are the priority. LS meets this market with standardized process, batch manufacturing capability and DFM assistance.

The inherent driving forces of the market arestability (automatization), precision (electronics), standardization/cost (automobiles/robots). LS will continue to invest in high-precision/multi-axis CNC technology, improve special metal and composite material processing expertise, improve thermal management and clean processes, enhance batch efficiency and DFM service capability, and provide customers in industries cost-efficient and highly reliable connection bracket solutions, thereby securing our leading role in the precision manufacturing industry.

Good Case Sharing: A Connection Bracket Machining Project For An Automation Machinery Supplier

Project background:

The customer needs a core connecting bracket for its new generation automatic robotic arm research and development. This part is essential to the structural stiffness, movement accuracy and long-term stability of the entire robotic arm. The customer has extremely stringent requirements on the precision of the key holes and surface processing quality of the entire bracket.

Material selection:Based on the load-carrying capacity of components and service under long-term conditions in industrial processes, we jointly selected high-strength aluminum alloys that provide adequate strength, stiffness and resistance to corrosion with guaranteed lightness.

Accuracy machining:We fully utilized the technical advantage of thefive-axis CNC machiningcenter, and through high-precision programming and control of the process, we accurately completed machining the intricate outer contours and all critical holes of the parts at a single operation. And finally, the tolerance of the aperture was controlled accurately in the extremely high precision range of ±0.01mm such that there would be flawless assembly.

Efficiency maximization:Our advanced concurrent design andonline quotationsystem was employed end-to-end for the project. This facilitates efficient feedback from initial design review, real-time design revision based on test feedback, to final process plan validation and quotation, cutting product development cycle and delivery time significantly.

Results of the project:

- Performance improvement:Our precision connection bracket significantly improved the customers' robotic arm assembly efficiency, and its fine process quality (accurate hole position, high-quality surface) directly enhanced the overall operating stability and long-term reliability of the robotic arm.

- Cost controllable:Through the use of maximized processing technology and efficient process management, we maintain the processing cost at highly economical level with supreme quality, fully meeting the customer's cost objective on mass production.

- Deep cooperation:Based on the excellent implementation and amazing effects of this project, the client sincerely recognized our technical competency, quality control speed and response speed. Now, some following customized part orders are proceeding smoothly, and both sides forged a steady long-term strategic cooperation.

This case best demonstrates how LS leverages state-of-the-art material selection,precise five-axis machiningtechnology and effective digital methods in a bid to successfully meet customers' demands in core precision parts. Not only does it meet stringent performance requirements, but it achieves a balance between cost and speed of delivery, ultimately securing the deep trust and long-term favor of customers.

Core Reasons For Choosing LS

- Convenient and efficient one-stop shop:Provideonline CNC machiningservices that include modules such as instant quotation, order tracking, and progress monitoring greatly enhancing customer operations and cost savings.

- Professional and reliable quality assurance:We focus on control of detail with our experienced technical personnel and strongly identify with customer specifications (e.g., design intent and major requirements) to ensure that the processed parts are accurate and reliable and meet application specifications.

- Flexible and stable capacity of delivery:With flexible manufacturing capacity and scheduling power, we are able to adapt well to different batches and urgent orders, ensure strict delivery time, and maintain consistent and stable processing quality.

- Transparency and effective cost management:Employ an open and transparent price policy with no hidden charges to allow customers to clearly comprehend the costing model. Through efficient operation, we allow customers to benefit from cost-competitive prices in order to effectively save total procurement costs.

Choosing LSis because it incorporates the whole strengths of digital and convenient services (one-stop platform), technical professional strength (quality assurance), strong production guarantee (sound delivery) and cost competitiveness (transparent optimization), which can respond well to customers' main demands on efficiency, quality, delivery time and cost.

Take action now and unleash the potential of performance!

Provide a bracket design drawing or application requirements, and theLS engineering teamwill present to you:

- Free design guidance- extensive analysis and improvement solution

- Timely sample support- safe validation of design effect

- Reliable and live quotation- effective and transparent procurement

Clickto send the drawings to receive your custom performance improvement plan!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com