Small-batch CNC machining represents a revolutionary on-demand manufacturing approach that addresses key challenges in product development and market testing. Traditional manufacturing methods are constrained by cost and delivery time, while small-batch CNC machining, through digital on-demand manufacturing, breaks through these traditional limitations, providing flexible production capabilities.

LS Manufacturing provides comprehensive support from design to production, ensuring efficient small-batch manufacturing solutions. Understanding these fundamental advantages is crucial for leveraging this disruptive manufacturing methodology effectively in today's dynamic market environment. Before we can master this new model, we have to understand the very heart of this disruption to old logic. To save you time, here is a brief overview of the key findings.

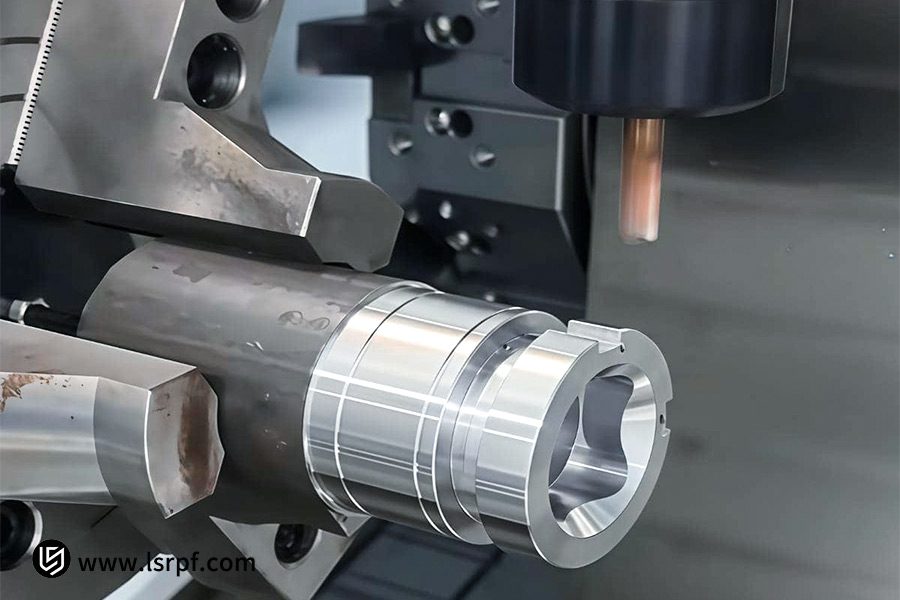

Figure 1: Industrial CNC equipment processing procedure by LS Manufacturing

Small Batch CNC Machining Core Value Quick Reference Table

| Module | Core Points | Specific Content |

| Pain Points Addressed | Traditional manufacturing lacks agility | High mold-making costs, difficulties in fulfilling small orders, and long delivery cycles are a hindrance to innovation. |

| Root Cause | Rigid cost model | Dependent on a mass production to spread costs; unable to accommodate the needs for small, fast, and flexible manufacturing. |

| Solution | Digital on-demand manufacturing | There would be no need to develop a mold; based on digital drawings, the process is directly done in order to ensure rapid response. |

| Key Benefits | Agile, flexible, and low-risk | For lower upfront investments, rapid delivery is exceptionally well-suited for piloting production and iteration. |

| Success Factors | Collaborative partners are key | It needs partners who can quote fast and have professional DFM analysis. |

| Typical applications | Product critical phase | It is mainly used for rapid prototyping, small-batch trial production and custom parts production. |

Small-batch CNC machining can efficiently solve the traditional model problems of high cost and long cycles through digitalization and moldless manufacturing. The flexibility in such a manufacturing model provides enormous reductions in innovation threshold and trial-and-error cost for enterprises to realize fast iteration and market validation. If an enterprise can choose a professional manufacturing partner with DFM analysis capability and quick response mechanism, then manufacturing can turn into a competitive advantage in the marketplace.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

With so much information on the internet, most of the theories sounded good but were hard to put into practice in the real world. Each and every suggestion in this guide was tested multiple times in our real workshop environment.

Our team has been serving the needs of small-batch manufacturing, from precision medical devices with very intricate structures to high-stability fixtures for semiconductor equipment. We have experience in reducing per-piece machining time, especially for small batches, by using tool path optimization and choosing the most economical machining strategy for prototypes in various materials.

In the last couple of years alone, we have completed tens of thousands of small-batch orders. These projects tempered not only our skills but also gave us profound experience in the balance of quality, cost, and efficiency in small-batch production. This guide shares those practical insights, tested by cutting and measuring instruments, in hopes of building your projects from the very beginning on a reliable manufacturing foundation.

What Is Small-Batch CNC Machining, And How Does It Redefine Parts Procurement?

Small Batch CNC Machining is far from traditional machining; this is a strategic innovation in the approach to supply chain management. In its very core, it changed "physical molds" to "digital models", turning manufacturing from a capital-intensive long-cycle predictive model to a capital-light, fast-response, on-demand manufacturing model. There are several points to explain its value of disruption.

1. Zero Initial Cost Constraints:

Small-batch CNC machining completely avoids the high investment required for mold development, and unit costs are no longer constrained by order volume. A company can start production by providing 3D drawings, which dramatically lowers the threshold to try a new product and conduct market validation, especially at the R&D stage or in scenarios where demand is uncertain.

2. Unlimited Design Freedom:

Advanced CNC technology has made it possible to manufacture effectively 5-axis linkages, complex curved surfaces, and irregular structures that integrate functional parts. If there is any revision in designs, only digital files are revised, and no adjustment in physical tools is needed. That truly makes "design as production" happen and shortens the product innovation cycle.

3. On-Demand Supply Chain Capabilities:

Production planning driven by digital files compresses the supply chain response into hours, allowing companies to place orders in batches according to actual demand, alleviating inventory stress, flexibly responding to changes in the market or urgent orders, and thus truly building a flexible supply system.

Small-batch CNC machining replaces "producing for inventory" with "on-demand manufacturing," turning the fixed supply chain into cloud-based capacity to be invoked in real time. Enterprises will no longer be bound by batch size constraints and mold costs but enjoy unparalleled market agility in using on-demand manufacturing capabilities to manage risks.

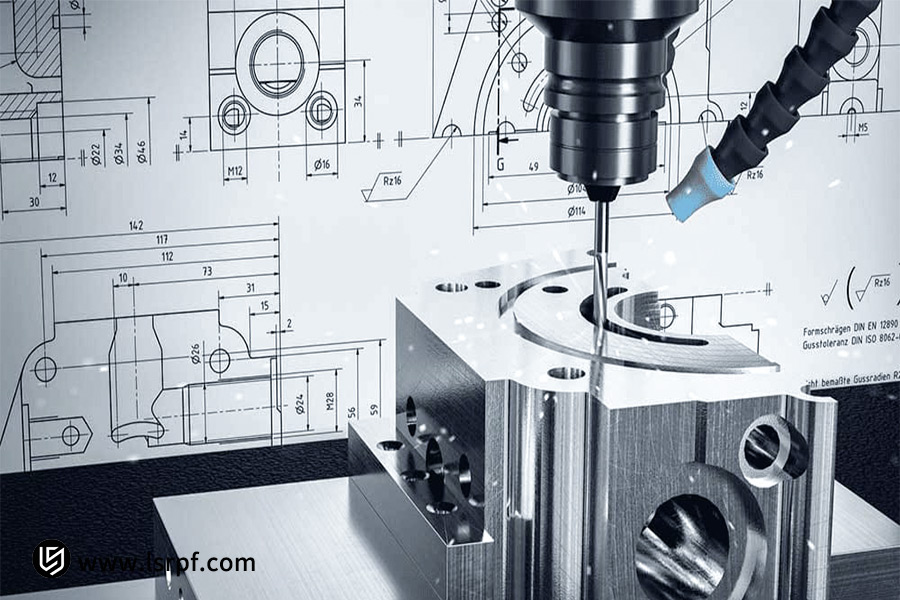

Figure 2: High-precision CNC machining of low-volume batches by LS Manufacturing

Why Is Small-Batch Production A Catalyst For Product Development And Innovation?

Small-batch production, flexible manufacturing models realized with the help of prototype CNC machining and low volume CNC machining forms a keystone strategy driving innovation and building resilience for modern enterprises. The value contribution of this approach goes throughout the whole life cycle of a product, from concept to the maSmall-batch CNC Machiningrket, which is indicated in the table below.

| Dimension | Core Value | Specific details |

| Product Development | Rapid iteration through prototype CNC machining significantly reduces trial-and-error costs and time. | Designs can be quickly validated without the need for mold investment, shortening the development cycle by several weeks and significantly reducing upfront costs. |

| Market Strategy | By using low volume CNC machining to test the market and verify real demand at minimal cost. | Market testing should be conducted in small batches of 50-500 units to assess product potential using real sales data and avoid inventory risks. |

| Operational optimization | Establish an agile supply chain to enable on-demand production and spare parts management, thereby reducing inventory pressure. | Adopting an on-demand production model allows for rapid response to changes in demand, significantly reducing inventory costs and enhancing supply chain resilience. |

Small-batch production solves not only the problem of "daring to try and iterate quickly" in product development but also can achieve low-cost and precise validation at the market level and agile and reliable supply chain resilience at the operational level. It can turn traditionally high-risk manufacturing investments into controllable strategic investments and become an important tool for enterprises to improve overall competitiveness in the new environment.

How To Choose The Most Suitable CNC Process For My Small-Batch Project?

The best choice of the CNC machining process for small batches depends on the exact matching of part features to the capability and cost-effectiveness of different processes. Proper selection not only assures quality but considerably enhances cost-effectiveness also.The following framework on how to choose CNC machining services analyzes key factors to help you make efficient decisions:

| Decision Dimensions | Process Selection Recommendations | Core Considerations |

| Geometrical complexity | 3-axis milling can perform well on simple structures, while 5-axis milling is very adept at complex surfaces and features in multiple angles. | The amount of freedom which machining requires is dependent on the particular complexity; 5-axis milling saves setup times by improving overall accuracy and efficiency. |

| Part Configuration | Turning is suitable for the rotating parts, while mill-turn is ideal for those parts with complex contours and hole systems. | Most of the operations in mill-turn are completed in one setup; hence, reducing delivery time and avoiding errors resulting from many setups. |

| Materials and Precision | Free-cutting materials are obtainable within a large range, but metals like alloys of titanium require equipment with high rigidity and process conditions, which are specially specified. |

Material hardness, toughness, and precision requirements of the final products determine directly the tool choice and cutting parameters and cost structure. |

In the selection of CNC machining processes for small-batch projects, a preliminary screening is made according to geometric complexity and basic configuration, followed by a final trade-off between material properties and precision requirements. Mill-turn machining, due to its high integration, very often reaches the best cost-effectiveness during the course of machining parts with complex features.

Figure 3: Automated precision machining in CNC centers by LS Manufacturing

What Is The Cost Structure Of Small-Batch CNC Machining? How Should Effective Cost Control Over It Be Done?

To effectively control the cost, one has to understand the peculiar cost structure of small-batch CNC machining. The cost of a small-batch order will largely depend on fixed costs such as programming, debugging of equipment, and unit machining time, rather than material cost. Therefore, though the unit price is relatively higher, the total investment and risk are much lower compared with mold-making production; hence, a professional CNC machining service partner can optimize the cost:

1. Standardized processes, intelligent programming:

This forms the basis for a library of established machining strategies and optimized cutting parameters, both by material and tool type. Leading-edge CAM software allows us to automatically generate efficient, collision-free toolpaths. The system significantly reduces programming time while eliminating human error, assuring consistency and quality from the first to the last part. This operates to spread the initial programming cost over the entire production run, thereby making small-batch manufacturing more economically feasible.

2. Shared Material Library and Flexible Material Selection:

We keep substantial inventories in many different sizes and specifications to immediately source material for small orders without the need to purchase full bars or plates. This helps you avoid premium costs and minimize material waste. Our engineers might recommend effective alternative materials that meet your performance requirements and help you optimize the balance between part quality and production costs. The flexible approach provides for the optimal use of resources while maintaining high quality.

3. Deep DFM collaborative optimization:

The most effective step in cost reduction is to have an experienced engineer review a design in advance of production by making minor modifications: optimize radii on corners to minimize special tool usage, standardize hole diameters, reduce tool changes, and reinforcement in thin wall sections to avoid complex secondary clamping. Optimization improves machining efficiency and directly reduces labor costs.

A better CNC machining service provider is a real extension of your own engineering department-a partner who is committed to transforming your manufacturing expenditure into maximum value by way of strategic standardization of processes, intelligent integration of resources, and proactive front-end design optimization. This comprehensive approach means you get agile manufacturing capability and the best possible overall economic return on your investment.

How Can Consistent Quality Be Guaranteed From Prototype To Small-Batch Production?

We understand that small-batch orders also deserve reliable quality. That is why we apply concepts of quality management applicable to mass production to each minute detail in our CNC machining services. Our quality assurance system consists of three critical parts:

1. Introduction of the effective first-article inspection process:

The first article will be subjected to rigid, independent inspection prior to mass production. To this end, highly advanced precision-measuring equipment shall be utilized to verify that each critical dimension and specification meets the design requirements and sets a qualified benchmark for further production.

2. Perform end-to-end quality monitoring:

Our quality assurance system has implemented a process for continuous monitoring: scheduled measurements of critical part features by trained personnel using calibrated instruments, so the detection of dimensional variability due to tool wear or other process variables can be made early enough to allow timely corrective actions against those variations.

3. Establishment of a complete quality traceability system:

We maintain a full digital traceability system whereby the whole manufacturing history of every lot produced is duly documented. Material certification, machine parameters, and inspection results ensure full traceability from raw materials to finished products and hence guarantee efficient root cause analysis when needed.

A quality control system such as this gives LS Manufacturing CNC Services the unique capability to create every small-batch order with the same high standard of quality. We make use of the same strict quality control on each unit of production and grant the customer the flexibility they seek in small-batch processing without sacrificing quality.

Figure 4: Technical drawings for precision CNC machining by LS Manufacturing

How Does The Small-Batch Service Offered By LS Manufacturing Help The Clients Overcome Bottlenecks?

Time has been one of the biggest challenges to developing innovative products. The following case shows how, through professional prototype CNC machining capability, LS Manufacturing CNC services helped a client out of this type of crisis:

1. Client Challenge:

A medical device startup was developing a new surgical instrument stent and urgently needed to make 50 functional prototypes within 3 weeks for clinical evaluation. They faced the typical problem in the industry: this small order volume, together with a tight deadline, got either quoted exorbitantly by traditional suppliers or rejected the order outright, bringing the project to a standstill.

2. LS Manufacturing Solution:

We immediately initiated the rapid response system. A large amount of experience had been accumulated from plenty of medical device manufacturing projects. The technical review and DFM analysis were completed within 24 hours, then kicked off production directly by using inventory medical-grade stainless steel. The CAM programming strategy was optimized for efficient machining; after coordinating with post-processing seamlessly, the machining and anodizing of all 50 precision parts could be finished within 10 working days and delivered 4 days in advance.

3. Results and Value:

Therefore, the client was able to conduct clinical evaluations on schedule and obtained very valuable feedback from first-line physicians that could enable rapid optimization of product design. Thanks to our prototype CNC machining services, clients resolved their supply chain crises, shortened the product development period by almost two months, and laid a sound foundation for seizing market opportunities.

We are far more than just suppliers of parts in this journey of innovation, from prototyping through full series production. We blend rapid response with professional processes, closely collaborating in the supply chain for small-batch production to enable our customers to turn seemingly impossible timelines into real-world competitive advantages.

A Simplified And Hassle-Free Collaboration Process: From Uploading Drawings To Receiving Goods, Four Steps

We have redefined the on-demand manufacturing process, allowing you to experience convenient and transparent CNC machining services. The entire process requires only four simple steps to transform your ideas into high-quality physical products:

- Online Inquiry and Intelligent Analysis: Simply upload your 3D drawings or model files online, and our system will instantly run an intelligent manufacturability analysis and deliver to you a preliminary online quote and process feasibility assessment.

- Expert Intervention and Exact Quotation: Our engineering team completes DFM analysis in as little as 24 hours and makes professional optimization suggestions for details in the design. Transparent quotations with all details included can be provided.

- Flexible Production and Visible Progress: Orders can be traced in real time after confirmation for their status of production on a dedicated platform. In this way, it truly realizes the visualization of manufacturing processes and shows in detail the process from programming, machining to surface treatment.

- Strict Quality Inspection & On-Time Delivery: Every batch of these products will be strictly quality-inspected and dispatched with a full set of quality inspection reports. We support flexible logistics solutions to guarantee that products are delivered to you on time and in good condition.

The on-demand manufacturing process like this one standardizes our years of service experience and is going to seek to provide you with a simple, transparent, and reliable small-batch manufacturing experience through digital tools and professional services. We simplify the process from drawings to finished products so that more of your attention can be directed to core innovation.

By Choosing LS Manufacturing, One Gets So Much More Than Just The Parts Themselves.

- Agility: Our production system operates with real flexibility, with no minimum order quantity restrictions. We offer fast production runs from single prototypes to small batches. Advanced production planning and digital workflows ensure speed and fast turnaround at all times.

- Professionalism: With a staff of experienced engineers, we can provide free DFM analysis throughout any phase of product development. We will be advising you on initial concepts through mass production on how to optimize design, material, and methodology for the specific manufacture of your product with the highest quality and efficiency.

- Price Assurance: We offer complete price transparency with detailed quotations, while delivery schedules are ensured through carefully planned production. In offering consistency of output through standardized processes and strong quality control systems, the outcome is reliable project planning certainty and predictable outcomes for whatever manufacturing project you may have.

- Partnership: We work as an extension of your team, deeply understanding your needs for the delivery of customized manufacturing solutions. This approach ensures that we support your products from concept through market launch and align the manufacturing strategy to achieve your business objectives for long-term success.

With LS Manufacturing CNC Services, you will have a CNC machining partner whose goal is your success. We offer agile service, professional engineering support, firm delivery commitments, and deep partnerships-all elements of value way beyond the parts themselves that will help you gain an edge over the competition.

Figure 5: Precision machined parts for small batch production by LS Manufacturing

How Do I Get Started With My First Small-Batch CNC Machining Project?

Starting your first small-batch CNC machining project is incredibly simple. We have boiled it down to only what you need to know. Take the first step, and we will handle the rest. Here is a how-to guide, clearly understandable, which sets you on your way in record time:

- Prepare your design files: Just provide the 3D model in STEP or IGES format, for instance, or detailed 2D engineering drawings. That is all we need to get started; our system supports mainstream design file formats.

- Submit your requirements and get professional analysis: Simply upload your files and related technical requirements, such as material, quantity, and surface treatment, on our website. Our engineering team will carry out a quick manufacturability analysis, give optimization suggestions, and provide a instant quote within 24 hours.

- Confirm the details and proceed with production: We confirm the quote and lock down the production schedule. Besides, there is a project manager in charge of coordinating the whole process and giving regular feedback to make the process transparent and controllable.

As a professional CNC machining service at TEAM Rapid, we make the complicated manufacturing process simple. We guarantee a collaborative experience through standardized online processes and professional engineering support that's easy and reliable. Just prepare your design files and get an instant professional manufacturing solution that will enable bringing your ideas into high-quality products swiftly.

FAQs

1. Why is the unit cost of small-batch CNC machining higher than that of large-batch production?

The cost is higher because the price also includes one-off fixed cost spent in programming, process planning, and debugging of the equipment, which needs to be amortized within the total output. Fewer parts in small batch orders result in a higher initial cost per unit. Compared with the high cost of mold making, however, CNC machining remains an economical option even in small-batch production.

2. What are the minimum order sizes that you support? Can you do just one piece?

We totally support single-piece production. Whether it is a prototype of the product, a functional test piece, or a customized part, we can accomplish orders from 1 to hundreds of pieces. The company is committed to zero-barrier manufacturing support for start-up and R&D projects, to help customers prove their ideas quickly and at a lower cost.

3. What is the average lead time for small-batch processing?

Regular orders take about 5 to 10 business days from confirmation of documents to shipment, depending on part complexity, process requirements, and the current production schedule. Urgent needs can be supported by expedited services that will minimize the delivery cycle.

4. Can material selection and surface treatment services be enjoyed on small batch orders?

When ordering materials in small quantities, the material library and surface treatment processes are the same as for large batches. The materials to be used include but are not limited to different metals and engineering plastics. Besides choosing appropriate materials, you might want to consider various options such as sandblasting, anodizing or electroplating to make sure the parts perform and look like you want them to.

5. Can you provide suggestions if my design has flaws?

At the quotation stage, our engineers will offer customers free DFM analysis, which will give optimization suggestions about all the details affecting molding, assembly, or function, with the purpose of risk reduction for customers in enhancing design rationality and production efficiency.

6. How are my intellectual property and design documents protected?

We securely protect the rights of our clients using a strict NDA. Design documents are stored in an encrypted management system, with access allowed only to personnel authorized. Protection of intellectual property is the very foundation for long-term cooperation with clients.

7. Does the quotation include all costs involved? Are there any hidden costs?

We believe in open and transparent pricing: the cost covers processing, standard post-processing, and packaging. Additional costs associated with design changes or new requirements during the process are always communicated and recalculated with clients; no hidden costs will occur.

8. How to get the progress of an order in real time?

For every client, we will assign only one project manager who updates the production progress by email or phone. You can also call us at any time to inquire; we will ensure you have a clear understanding of the status of your order and enable you to enjoy a worry-free and transparent service experience throughout.

Summary

Small-batch CNC machining is one of the most important strategies to have emerged in driving innovation and making supply chains resilient. In this dramatically changing market environment, it perfectly balances manufacturing flexibility, responsiveness, and cost effectiveness that enable product iteration and market testing with minimal risks. Whether prototype or low-volume production, this model has granted enterprises a strong counter to uncertainty and an accelerator toward quicker launches of products.

Do not let high barriers and long cycles of traditional manufacturing delay your innovation. Upload your 3D drawing now for professional and efficient "on-demand manufacturing" service at LS Manufacturing. We will present you with intelligent instant quotes and reliable production schedules to easily turn your ideas into high-quality products. Contact us and take action right now and create a new experience in effective manufacturing!

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .