Rapid injection molding services are at the very heart of the problem manufacturers face with twofold dilemma. The solution is to bridge the crucial gap between the cost and time of traditional tooling and the inadequacy of 3D prototypes and, thus, totally eradicating the 6-8 week typical delay that results in losing market opportunities. It is a good solution for functional production.

The main focus is on resolving the compromise between high tooling costs and low-quality prototypes. We are capable of facilitating an effortless transition from prototyping to low, volume production by implementation with the help of optimized molds, materials, and processes that lead to drastic cost and lead time cutting for market, ready parts.

Rapid Injection Molding Services: Quick Guide

| Section | Key Point in One Sentence |

| What It Is | This is a manufacturing method where aluminum molds are made quickly and used for injection molding parts which have production, grade qualities. |

| Core Problem Solved | It is a transitional product between the two extremes of traditional high, cost molding and non, production, ready 3D printing for low volumes. |

| Main Advantage: Speed | The company can have the first parts ready to be delivered in 5-15 days and this can help product launches be accelerated by weeks. |

| Main Advantage: Cost | The price of the mold is lowered by up to 60%, and the price of the part is also cutting down compared to the traditional methods. |

| Main Advantage: Quality | The product is functional and real material properties of the product are used in the production. |

| Ideal Volume | Best for production runs from 100 to 10, 000 units. |

| Key to Success | Design for manufacturability (DFM) is necessary to consider the limitations of the manufacturing process and design the product accordingly. |

We are the critical bottleneck from design to market. By providing a fast, low-cost tooling and true molded parts, we allow our clients to validate the designs, launch the products faster and make small batch injection molding orders without waiting for long and spending a lot on traditional production tooling. Hence, low volume manufacturing no longer becomes a compromise but a strategic advantage.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Hundreds of articles are out there describing rapid injection molding. Here, we share the real, world experience, the one that gets exposed every day on the shop floor. Our 15 years at LS Manufacturing are mostly not spent in a tidy lab but rather in a hands, on environment where we continuously solve real problems. We dont simply understand the process; we actually do it, making mistakes in cost or timing that directly impact client launches and thus learning from them. Every piece of advice given here is one of those learned under that kind of pressure.

Our advice comes from experience with 5, 000+ production projects. We know exactly how tight the tolerances have to be for aerospace connectors, what kind of surface finishes are necessary for medical housings, and how to get the most out of the budget when it comes to consumer electronics. Our approaches meet the highest industry standards as we not only rely on our internal rigor but also incorporate various required standards from organizations like the Metal Powder Industry Federation (MPIF) for ensuring the material performance and the National Association for Surface Finishing (NASF) for the quality consistency.

This handbook is a treasure trove of experience that has been gained the hard way. You will be introduced to the precise methods we employ: which alloy can give strength to the product while the tooling cost is reduced by 60%, the way to change the design to get a 10 days lead time, and how to balance cost and quality for orders of 100-10, 000 parts. This is down, to, earth knowledge, backed by thousands of actual parts, so you can take the next step confidently and efficiently.

What Is Rapid Injection Molding Service? What Are The Fundamental Differences Between It And Traditional Injection Molding?

This article focuses on the operational key difference between rapid injection molding services and traditional production. It offers a technical and financial comparison that is especially helpful to engineers and purchasing departments of companies working with low, volume, time, sensitive projects. The facts are there to help you make the right choice when buying new products and small, series production.

| Aspect | Conventional Injection Molding | Rapid Injection Molding |

| Primary Objective | Optimized for large, scale, high volume production runs. | Designed for low volume injection molding, and fast product launches. |

| Tooling Material | Employs hardened steel molds that are suitable for very long life. | Uses affordable aluminum tooling which drastically reduces the initial investment. |

| Tooling Cost (Typical) | Typically, initial cost is very high and frequently over 80, 000 RMB. | Greatly reduced, mostly between 20, 000 and 30, 000 RMB. |

| Lead Time (Tooling+Fab) | Long schedule, usually takes more than 6 weeks. | Shortened schedule, first parts in 7-10 working days. |

| Per-Part Cost (500-5k units) | At low volume cost is higher due to tool amortization. | 30-40% lower per, unit cost, the perfect choice for bridge production. |

| Mechanical & Surface Quality | Production, grade materials and finish. | True injection-molded performance at a level that is superior to that of additive manufacturing. |

| Economic Break-Even Point | Only cost, effective at very high production volume (>10k units). | The best choice for production volumes from 100 to 10, 000 units. |

Select rapid injection molding if you want to cut both the time, to, market and the unit cost of the product when your production volume is less than 10, 000 units. Also, collaborating with the factory through various stages of Design for Manufacturing (DFM) review will help you get the most out of aluminum tooling. This injection molding guide aims at offering the technical reasons to the staffs of high, value, fiercely competitive industries where precision, speed, and cost control are essential.

How To Calculate And Optimize The Unit Cost Of Small-Batch Injection Molding?

Accurately predicting and controlling the per, unit injection molding cost for small batches is a critical technical and financial challenge. This paper breaks down the cost equation by going beyond simple quotations and introducing a transparent, workable model for cost optimization based on the actual production data. The following methodology offers the basis for making well, informed decisions:

Deconstructing the Cost Equation

A detailed injection molding quote estimation rests on three variables: the depreciation of tooling cost per unit, the cost of material, and the time of machine processing. Lets take a 1, 000, unit ABS housing example, where a 25, 000 aluminum mold is depreciated at 25 per piece, juxtaposing directly with a 80, 000 steel tool. This elemental breakdown facilitates pinpointed cost engineering right from the start.

Optimizing Through Tooling Strategy

The chief means for low volume injection molding cost control is the investment in tooling. Complex activities are simplified, we use multi, cavity aluminum molds wherever possible, and we design for fast machining to keep the tooling cost low. Smart choices in gating and cooling channel design may cut cycle time by 10-15%, thus directly lowering the processing fee part of the final piece price.

Implementing Design for Efficiency

Cost optimization through collaborative design for manufacturability is the major aspect of injection molding cost optimization. The practice includes streamlining part geometry to get rid of undercuts, making the wall thickness uniform for an even cooling, and choosing the resin grades that are readily available in the market. These measures result in minimized cycle time, lowered scrap rates, and avoidance of costly mold modifications, thereby the projected injection molding cost can be achieved.

This framework enables technical teams to get away from price comparison to genuine cost engineering. Professionals who comprehend the connections between tooling strategy, design, and process parameters can tactically reduce the total cost of ownership for low volume injection molding projects, turning cost from a limitation into a competitive advantage in product development.

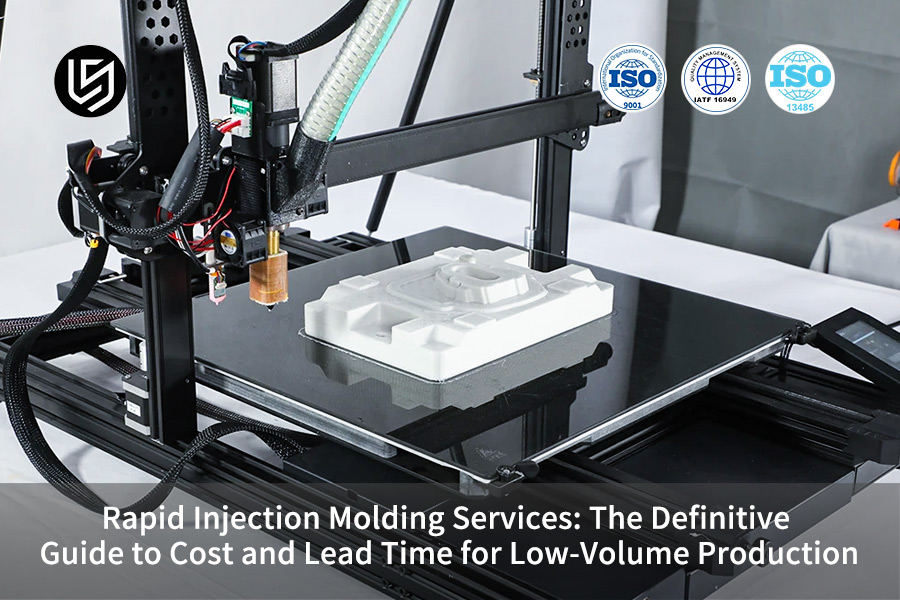

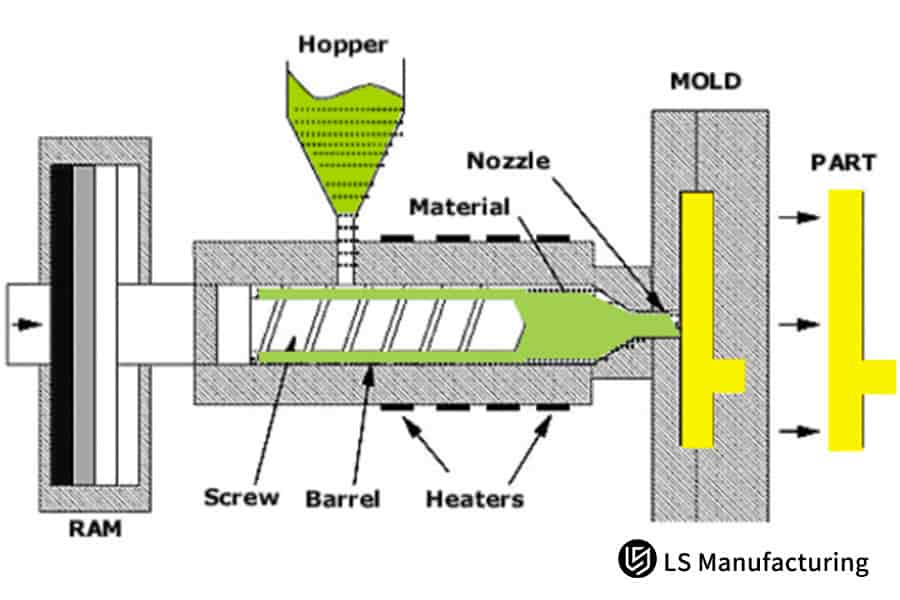

Figure 1: Illustrating the injection molding process diagram for prototype and small batch manufacturing.

What Are The Key Factors Affecting Injection Molding Lead Times? How Can They Be Reduced?

To meet very tight product launch schedules, a company will need to take a systematic approach to cutting out the injection molding lead time. One huge bottleneck is the traditional sequential operations. This paper explains the working methods for quick turn injection molding, giving evidence of how strategic process engineering can lead to a 50% reduction in lead times or more:

Process Overhaul: From Sequential to Parallel Engineering

We break down the traditional single, line process by making the most important phases happen at the same time.

- Concurrent Design & Procurement: Mold design and material sourcing start at the same time when the order is confirmed, thus 3-5 days are saved.

- Overlapping Machining & Preparation: The machining of mold bases is done in parallel with the detailing of core/cavity inserts and purchasing standard components.

Design & Tooling Strategy for Speed

Every move towards a faster delivery time is built into the tooling at the very start.

- Standardized Mold Base Library: We save 2-4 days in custom design and fabrication by using a library of pre, machined standard mold bases.

- Simplified Mold Actions: Parts are designed so that they require fewer slides and lifters, which leads directly to shorter machining and assembly times, thus offering faster rapid injection molding services.

Streamlined Production Launch

Prepared protocols accelerate the step of moving from the tool being finished to the parts being shipped.

- Scientific First-Shot Process: This is a well, planned trial that uses pre, set parameters for the most common materials and thus allows the approval after 1-2 shots, with the fewest adjustment cycles.

- Staged Post-Processing: As soon as the trial is successful, the processes of de-gating, trimming, and quality inspection are ready to start immediately, which facilitates the same, day shipment of the first articles.

It is through this very method of systematically breaking down and running in parallel each stage of the injection molding process that we can promise delivery in 10 days. Our method basically converts injection molding lead time from a random variable into a fixed, shortened schedule, thus giving a very definite competitive edge in quick-turn injection molding.

Figure 2: Operating an industrial injection molding machine for rapid prototyping and small batch production.

How To Select The Most Suitable Mold materials And Processes For Low-Volume Production?

This article serves as a technical guide for choosing injection molding materials and processes in low volume injection molding. A data-driven approach is presented to facilitate the most efficient use of tooling for production runs ranging from prototypes to mid, scale batches, helping engineers make cost, effective decisions.

| Production Volume | Recommended Mold | Material Key Characteristics | Typical Cost Range (USD) |

| < 1,000 parts | Aluminum Mold | Great choice for prototype injection molding as it has very fast lead times and can last for 10k-20k cycles. | $20,000 - $30,000 |

| 1,000 - 5,000 parts | Pre-hardened Steel Mold | This is a good solution between a very robust injection molding for small batches; lifespan goes up to 50k-100k cycles. | $40,000 - $60,000 |

| > 5,000 parts | Fully Hardened Steel Mold | Going beyond the first 100k cycles, the production has to be supported by the most durable tooling that can withstand these cycles. | Cost scales with complexity |

| Process Optimization | Moldflow Analysis | Design of cooling system by simulation, driven method can shorten cycle time by ~30% (e.g., from 40s to 28s). | Implementation cost varies |

Getting the tool strictly on the expected volume is the main focus while the data table has been provided for you to be your guide. Prioritize moldflow analysis to optimize cooling system and cycle time, which is the key factor determining the efficiency of all production tooling. This paper offers a fundamental and practical approach for engineering professionals involved in the high-value injection molding scenarios.

What Are The Special Considerations And Limitations Regarding Material Selection For Rapid Injection Molding?

Material selection is generally a major limitation of rapid injection molding services cycles because standard grades can negatively affect the fill time and the quality of the part. Here is a focused step, by, step guide on how to optimize your material selection that moreover addresses the main challenge of injection molding for small batches balancing performance, processability, and cost-effectiveness of the material.

Prioritizing High-Flow Materials for Fast Cycles

We deliberately prioritize engineering plastics with very low viscosity such as PP, ABS and unfilled PA66. These choices squarely tackle the problem which is typical in thin, walled or complex geometries of lack of complete filling, thus ensuring the cavity is filled rapidly enough to maintain short cycle times. This is foundational to efficient injection molding.

Managing Filler Content for Process Stability

In order to avoid prematurely wearing out the tools and at the same time achieve stable flow, we recognized the necessity of limiting filler content to 20% for materials used in injection molding for small batches projects. This helps to lower the chance of abrasive damage from the harder fillers to the softer tooling materials like aluminum, which is usually the main bottleneck, while at the same time obtaining the targeted mechanical properties.

Enabling High-Temperature Applications with Optimized Tooling

When we make parts that need to be used on a continuous basis at a temperature higher than 120C (e.g. PPS), we adopt an integrated material and tooling approach. We choose high, quality, durable, high, temperature aluminum molds and pair them with compatible materials, thus getting over 5, 000 cycles a 40% cost reduction compared to hardened steel for similar volumes and without giving up on performance.

We have come up with a solution that directly addresses the problem of cycle time limitations due to materials by chemically selecting and qualifying fast, cycle compatible resins in a prescriptive manner. This technically scientific way of working, extending from high flow material databases to proven high temperature tooling techniques, sets up a competition ground for a low volume injection molding supplier to offer both speed and functional performance in a dependable manner.

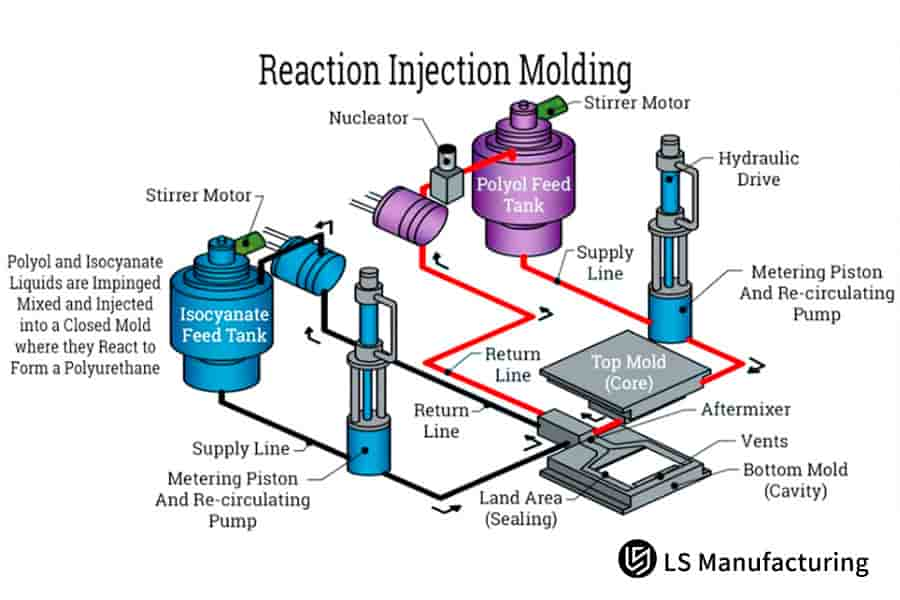

Figure 3: Producing plastic prototype parts for low-volume manufacturing and product development.

LS Manufacturing Medical Devices Industry: Disposable Sampler Injection Molding Project

This technical case study discusses how LS Manufacturing helped a medical device customer overcome a critical supply bottleneck through a tightly integrated process innovation. The company shifted from expensive, non-compliant prototyping to a fully validated, cost, effective low volume injection molding production method:

Client Challenge

A medical company was in need of 5, 000 certified, medical grade polypropylene (PP) viral sampler components. Traditional injection molding quote not only went over budget but also demanded a lead time of 35 days. The prototype injection molding alternative with 3D printing gave out non, compliant parts at a very high cost, resulting in product registration being stalled due to unsuitable biocompatibility.

LS Manufacturing Solution

We came up with a solution utilizing pre, hardened steel mold and medical grade PP with an 18 MFI. Through the use of an optimized cooling system, we were able to get a fast cycle time of 22 seconds. Our delivery of a fully validated production tool within 7 days therefore, perfectly resolved the lead time and compliance crisis.

Results and Value

Tooling cost went down by 52%, and the lead time was shortened by 80%. The final part cost was a 73% saving compared to additive manufacturing. This fast, compliant supply allowed the client to finish product registration 3 weeks ahead of the plan, thus confirming our position as a strategic low volume injection molding supplier.

This work is a case of how we can combine our technical accuracy and efficient injection molding to meet time, sensitive engineering challenges. Introducing certified parts to the market in a shorter time gives clients a real competitive edge in regulated, high-value industries.

When you need quick mold solutions to address urgent injection molding problems, we provide efficient and customized services.

How Can Design Optimization Reduce The Cost And Risks Of Rapid Injection Molding?

Rapid injection molding services design, related mistakes lead directly to extra costs and longer than expected delivery schedule. Here you will find a clear DFM method to first of all control and then even completely avoid these problems thus significantly reducing injection molding cost while at the same time improving first, run efficiency:

Establishing Foundational Design Rules to Minimize Iterations

We stick to a core set of DFM parameters: regular wall thickness (1.5-2.5mm), a minimum draft angle of 1°, and the removal of complicated undercuts. Giving this guidance in the form of a clear injection molding guide, we systematically decrease mold rework, thus typical sampling iterations being cut 3-5 down to 1-2. This directly tackles the main cost and schedule issue.

Applying Advanced Analysis for Warp and Sink Prevention

Besides fundamental laws, we use simulation to figure out the particular part integrity issues. Thus, in an electronics housing project, a 0.8mm warpage resulted in an 8% rejection rate. Our investigation identified the rib design as the factor and we set a rib base-to-height ratio ≤3:1. The design refinement warpage down to 0.2mm, reached a 0.5% scrap rate and kept the product both visually and dimensionally stable.

Integrating Gate and Cooling Design Early in the Process

Cost cutting is not only a matter of the part shape. During the first DFM review, we consider the integration of gate location and the design of conformal cooling channels. This way we avoid problems such as jetting, sink marks, and unnecessarily long cycle times, thus producing a high-quality injection molding from the very first trial and ensuring reliable project economics.

By shifting from general recommendations to a prescriptive, analytical, backed DFM method, our approach effectively addresses the problem complexities of cost and quality. The technique converts the initial part design into a production, ready blueprint, thus, the client who uses the rapid injection molding services will get a faster time, to, market and controlled costs, resulting in a significant competitive advantage that can be measured.

Why Choose LS Manufacturing As Your Rapid Injection Molding Partner?

Choosing the right partner for rapid injection molding services should be based on a combination of technical accuracy and process reliability. LS Manufacturing sets itself apart by guaranteeing first, pass success and delivering consistent results for low volume injection molding by means of combined technical systems and actual data:

Engineered for Predictable Speed and Quality

- Production Capacity: 8 high-speed machines (50-300T) give the option of machine matching perfectly for a wide range of part geometries, which is a good trade, off between the speed and clamp force.

- Process Control: Precise mold temperature control (±1°C) allows for a consistent flow of the material and crystallization which are the main factors for the nice appearance of the surface and the dimensional stability.

- Verification: On-site CMM (±0.01mm) allows in-process validation without delay, so no time is wasted on holding parts in an external lab and all the parts are always checked to the specification.

Data-Driven Process for First-Part Success

- Knowledge Base: Our unique injection molding process parameters database, accumulated from 286 projects, gives a set of reliable points of departure for new materials and designs.

- Risk Mitigation: The use of this empirical basis is the first step in the initial DFM analysis and injection molding quote when a new product is designed, which means that the solution of the possible production constraints is done well in advance of the tooling start.

- Outcome: A structured method as described here results directly in a >95% first, article success rate, hence dependable schedules and budget control.

Operational Reliability for On-Time Delivery

- Managed Workflow: Dedicated project management and internal tooling coordination make a closed, loop process from design to shipment that is flawless and seamless.

- Performance Metric: This combined operational discipline has allowed the firm to achieve a 98.5% on, time delivery rate, giving the schedule certainty that is essential for product development and launch cycles that move at a fast pace.

We bring certainty to rapid injection molding services by marrying specialized equipment, a data, validated process, and operational discipline. This comes to the core of timing, cost, and quality predictability, thus making LS Manufacturing a low volume injection molding supplier of strategic value for technically demanding projects.

Figure 4: Diagramming an injection molding machine for plastics manufacturing and process education.

How To Obtain Accurate And Fast Injection Molding Quotes And Technical Support?

Obtaining a reliable injection molding quote that can be acted upon is a very important first step in a rapid development pace scenario. LS Manufacturing solves this problem by changing the injection molding quote process into a collaborative technical review, thus ensuring transparency and unlocking the next cost, saving opportunities right from the start for rapid injection molding services:

Standardized Input for Immediate Technical Assessment

We ask for a standardized set: 3D file (STEP/IGES), target material, annual volume, and finishing requirements. Such organized information allows our engineers to carry out an instant, thorough manufacturing feasibility study that goes beyond the typical cost, per, part estimate to a component, specific feasibility evaluation. Thus, all subsequent planning is done on a factual basis.

Integrated DFM Analysis with the Initial Quote

With a couple of hours of getting full data from the client, we offer a detailed injection molding quote together with a free, efficient, and useful Design for Manufacturability(DFM) report. This report highlights specific design elements that affect the metal complexity, cycle time, and part cost. It is, therefore, very easy to identify and correct these features as the DFM report contains step-by-step instructions for halling these features.

Proactive Cost Optimization Before Commitment

Our DFM analysis provides concrete, data, backed recommendations. For instance, by changing the wall thickness to be uniform or making ribs with an optimized design, we have helped our customers reduce the costs of the final parts by 10-30% over and over again. Such proactive advice at the time of quoting assures that clients get their precision injection molding with a design that is already up to the mark in terms of manufacturing and cost.

Our quoting methodology overcomes the widespread issue of hidden surprises with delays and budget overruns by bringing engineering expertise to the forefront. This way, a price accompanied by a verified production strategy is delivered, making LS Manufacturing a transparent and technically capable low volume injection molding supplier for projects where predictability is crucial.

FAQs

1. What is the minimum order quantity (MOQ) for rapid injection molding?

LS Manufacturing supports orders as low as 50 pieces, there is no strict MOQ limit, but better unit price is only available for orders of 500 pieces or more.

2. What are the limitations of aluminum molds in terms of lifespan and applicable materials?

Lifespan of aluminum molds is 10, 000-20, 000 cycles and they are compatible with most general, purpose plastics (e.g., ABS, PP, PA). Use of glass fiber reinforced materials is not advised.

3. How long does it take from file submission to first article delivery?

7 days for simple parts, 10 days for complex parts. LS Manufacturing provides a rush service with delivery in as little as 5 days.

4. How do you arrive at the unit cost of small-batch injection molding?

Essentially, the unit cost tells the tale of the components that make up the process: mold amortization which can be 30-40%, materials 20-30%, and processing 30-40%. If you wonder how LS Manufacturing does it, they even breakdown the costs in detail.

5. How is quality consistency assured in the small-batch production?

SPC process control was implemented, along with first article inspection every 200 pieces, and CMM full-dimensional inspection were done to ensure CPK 1.67.

6. Do you provide surface treatment and post, processing services?

We provide a full range of post, processing services, including painting, screen printing, and ultrasonic welding, for one-stop delivery.

7. Is a new quote required after design modifications?

Free updated quotation will be given for minor modification; major modification will be re-evaluated. However, we will try to use the existing mold base.

8. How do you protect customers' design intellectual property?

By signing NDA agreements, using encrypted file storage, and having independent project spaces, we keep design security, and there is no leak.

Summary

Rapid injection molding services offer a great balance of cost and time savings for low-volume production by means of optimized mold strategies, material selection, and process flows. Through its comprehensive technical system and extensive project experience, LS Manufacturing helps customers make a seamless transition from prototype to small batch production thereby significantly improving product launch efficiency.

If your project is experiencing cost and lead time issues for small batch production you can always get in touch with the injection molding experts at LS Manufacturing. Simply upload your 3D files to get an accurate quote and a free DFM analysis. Submit your drawings now to get a tailored injection molding solution!

Our professional team will provide rapid injection molding optimization suggestions within 24 hours to help your project move forward quickly.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.