Manufacturing of gear is the core of precision transmission systems. Currently, many companies face common challenges such as insufficient gear precision, excessive meshing noise, and short fatigue life. These problems directly restrict the overall performance and reliability of high-end equipment. The root cause lies in the fact that gear manufacturing is a systematic engineering project, involving complex tooth profile design, micron-level machining precision, and strict heat treatment control. Companies lacking deep technological accumulation and advanced equipment struggle to guarantee batch consistency.

The LS Manufacturing will provide a systematic solution including high-precision CNC machine tools, professional design analyses, precision heat treatment process, and comprehensive quality control. Thereby, in this article, we systematically analyze the key technical aspects; we prove how to use our high precision, low noise, long life gear products reliably and securely. To save you time, here's a quick overview of the core conclusions.

Gear Manufacturing Quick Reference Table

| Partial Categories | Key Points Analysis |

| Current Situation | The pain point is usually faced within the gear manufacturing industry, balancing precision, noise, and life. |

| Core Root Cause | It is attributed to geometric design, the high level of machining processes, and subsequent heat treatment. |

| Solution Structure | Technology, equipment, process, and quality control are combined in a logical manner to overcome various manufacturing challenges. |

| Advanced Design Technology | With the special software for tooth profile optimization, it develops meshing stimulation and improves the performance from the source. |

| Precision Machining Process | High precision CNC machine tools ensure the tooth profile tolerances and surface quality. |

| Heat Treatment and Strengthening | Controllable heat treatment processes used for a drastic increase in the wear resistance and fatigue strength of gears. |

| Comprehensive quality control | The whole-process testing system, from beginning to end, is the guarantee of batch consistency. |

| Core Value | Eventually providing high precision with low noise, long-life gear products. |

Instead, they provide a comprehensive technology chain: from digital design simulation to precision gear machining services, customized heat treatment, to quality inspection. All this systematic approach serves to ensure that products, such as gears, can achieve best performances in several key indicators, like precision, noise, and lifespan. This is how the company provides customers with precision transmission components, exceeding industrial standards and ensuring stable and reliable performances.

Why Trust This Guide? Real Practical Experience From The LS Manufacturing Experts

Indeed, hundreds of theoretical articles on gear manufacturing are available online. The added value of this guide consists, however, of our practical experience in the real world: our workshop is engaged every day in cutting high-strength alloys with micron-level tolerance and complex tooth geometry. Each bit of knowledge influences product reliability and performance directly.

These ideas in the book are results of a series of processing practices and rigid tests, done within the precision principles of National Institute of Standards and Technology(NIST) and the quality control framework of the International Aerospace Quality Group(IAQG). We are not talking about empty theories, but practical wisdom refined through trials and tribulations in an attempt to help you avoid the pitfalls that we have gone through so as to jointly improve gear manufacturing reliability.

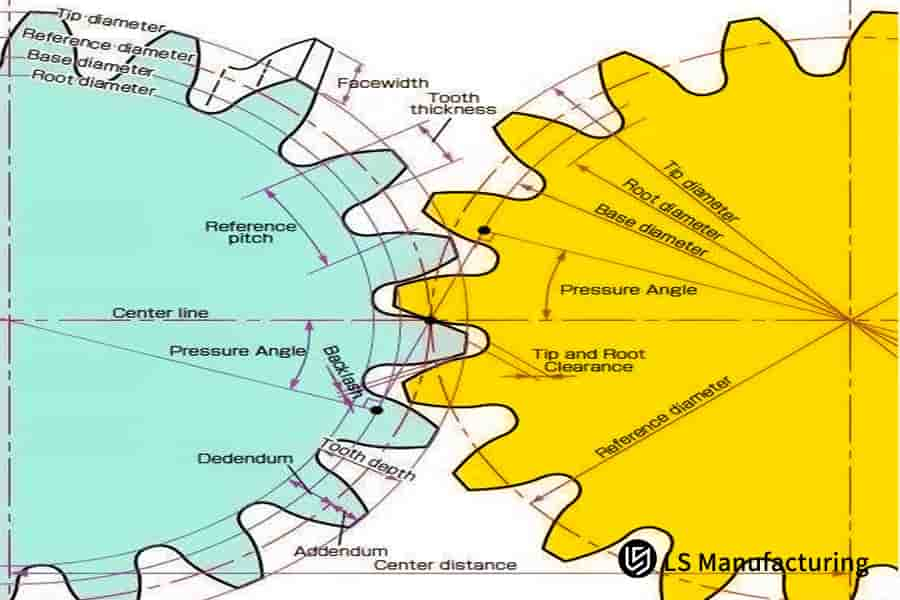

Figure 1: Core specifications for gear fabrication processes by LS Manufacturing

Why Is A Precision Gear A Core Transmission Component Of Modern Industrial Equipment?

What is gear manufacturing? Gears are hailed as the "heart" of modern industrial equipment, and their performance determines directly the technological level of the whole transmission system. Only by adopting a superior gears manufacturing process could one effectively guarantee the efficiency, quietness, and durability of gear transmissions. Below, let's analyze its irreplaceable value through core performance dimensions:

Transmission Efficiency

High-precision gears ensure minimal friction and energy dissipation during meshing, with extremely high tooth profile precision and surface finish, hence achieving over 98% transmission efficiency. In that respect, this contributes to substantial energy savings and performance improvements for new energy vehicle transmission systems and large wind turbine generators pursuing ultimate energy efficiency.

Noise and Vibration Control

Service Life and Reliability

Therefore, it is easy to see how precision gears became the core of high-end equipment with their excellent performance in efficiency, quietness, and lifespan. It goes without saying that such superior performance does not happen by accident but hails from a systematic rigid precision gear manufacturing system as a solid foundation, urging modern industry towards further efficiency, accuracy, and reliability.

What Are The Major Processes Used In The Manufacture Of Gears?

Gear manufacturing is a challenging systems engineering project. Its excellent performance originates from a series of interrelated precision gear manufacturing process. Precision control of each process, from conceptual design to the final product, directly affects the transmission efficiency, noise level, and service life of the gear. Scientific gear production methods as the basic guarantee for ensuring consistent quality in batch products. The core missions of each key stage are briefly summarized in the table below.

| Process Flow Stage | Core Content Summary |

| Gear design and optimization | Selection of appropriate software to design tooth profiles and simulate loads to achieve optimum performance right from the outset. |

| Tooth Machining | This is a process whereby the gear's basic tooth profile, by methods such as hobbing and shaping, is cut onto the gear blank with high accuracy. |

| Material selecting and pretreatment | Choose the right steel in accordance with the application scenes and forge to lay a good foundation for the subsequent process. |

| Heat treatment | This is a general increase in surface hardness, wear resistance, and toughness through such processes as carburizing and quenching. |

| Fine Machining | Correct the distortion after quenching by gear grinding and so on to achieve ultra-high precision grade as requested by the drawing. |

| Measurement and Matching | Checking in detail some finish gear parameters and contacting area on key pairs. |

In a words, it is a high-performance and high-reliability gear product after ruthless processes in gear manufacturing and all-around quality control. Digital design and material preparation, gear forming, heat treatment strengthening to finishing and inspection, these six key processes make up a complete and mature gear production methods.

How To Select The Appropriate Gear Manufacturing Process Based On Application Requirements?

Scientifically selecting the gear manufacturing process is a must to achieve a balance among performance, cost, and efficiency during gear product development. The types of gear manufacturing directly influences the required process, as the precision, efficiency, and application scenarios of various gears differ greatly. Therefore, correct gear process selection is critical; an incorrect choice may lead to substandard performance or wasted costs. For a clear comparison, the core characteristics of mainstream processes are summarized as follows:

| Process Characteristics | Forming Method, e.g. Die forging , Precision casting | Generating Method, e.g. Gear hobbing, Gear shaping |

Finishing Method Gear grinding, Gear honing |

| Precision Level | Lower, appropriate for applications that have less stringent tolerances. | High, economically achieving industrial-grade precision requirements. | Very high, for applications requiring ultraprecision transmissions. |

| Machining Efficiency | High, suited for high-volume and fast production. | Medium: reaches a good balance between precision and efficiency. | Lower, a necessary process to ensure the final precision. |

| Applicable Scenario | Agricultural machinery, home appliances and other products sensitive to the cost and batch. | General machinery, automotive transmissions, and other mainstream industries of the industry. | Aerospace, high-end CNC machine tools, and other cutting-edge equipment. |

| Cost Difference | High investment in mould, while the unit cost decreases substantially with increasing batch size. | Relatively balanced initial investment and unit cost, high effectiveness of cost. | High equipment and labour cost; the critical parts are considered to be suitable for that. |

In summary, correct gear process selection requires a consideration of various critical factors: load, speed, noise, lifespan, and budget. There is no best process but the most suitable types of gear manufacturing. To help you make the best decision, LS Manufacturing offers free process selection consultation services. The professional team recommends a comprehensive solution that is technically and economically viable, based on your particular needs.

Figure 2: Demonstration of our precision gear engineering expertise by LS Manufacturing

Figure 2: Demonstration of our precision gear engineering expertise by LS Manufacturing

Case Study for High-Precision Planetary Gear Manufacturing in the Aerospace Field by LS Manufacturing

In hi-tech industries, such as in aerospace, each component has a direct relation to the reliability and safety of all the equipment. We once faced an extremely challenging precision gear case: An aerospace equipment manufacturer was urgently in need of high-precision planetary gears for the new aero-engine whose performance requirements were very stringent.

Customer Challenges

The working conditions require this planetary gear to be stable in extremely low and high temperatures, at high speeds, and under heavy loads; the transmission accuracy must reach the highest ISO 4 standard. Traditional manufacturing processes for gears had bottlenecks in batch consistency and control of heat treatment deformation, failing to meet aerospace certification reliability requirements.

LS Manufacturing Solution

To address this challenge, a systematic solution was worked out by our engineering team. First, specialized software was used to optimize the tooth profile for impact resistance. Second, a German-imported CNC gear hobbing machine was employed for high-consistency rough machining, and controlled atmosphere heat treatment was carried out to precisely control tooth surface hardness and core toughness. Finally, we used CNC gear hobbing for final shaping and utilized a coordinate measuring machine to conduct full-dimensional inspection for each batch of products, so as to achieve traceability of data.

Results and Value

The gears delivered finally met and partially exceeded the accuracy requirements of ISO 4. Under extreme conditions, the service life of these gears improved threefold in the customer's bench tests, thus helping their engine products go through stringent aerospace certification. This solved not only the customer's current problem but also laid a good foundation for long-term strategic cooperation between the two parties.

The precision gear, a flagship product of LS Manufacturing gear, is a successful case that can fully illustrate how the company meets the highest standards in industry requirements. It incorporates advanced equipment and processes, fully performs quality control, changes superior design into reliable products, and provides value support for high-end fields like aerospace.

If there is a problem about gear precision or a gear's lifetime with your equipment, click to inquire and get customized solutions.

What Are The Common Problems In Gear Manufacturing, And What Are LS Manufacturing's Solutions?

In the process of gear manufacturing and use, many gear manufacturing problems are often faced by enterprises, which directly affect the reliability and service life of machinery and equipment. For typical failure modes of gears, a systematic solution is necessarily required. Some common problems and corresponding strategies are listed as follows:

Dental surface wear and pitting

This generally comes from inadequate surface hardness or poor lubrication. Our gear solutions optimize material selection, with deep carburizing and quenching processes that greatly improve tooth surface hardness and wear resistance. We also provide grinding or honing of the tooth surface in order to improve the surface roughness and thereby obtain an optimal oil film.

Tooth Breakage and Fatigue Fracture

Effective gear solutions result from the precise diagnosis of failure modes and comprehensive process control. The LS Manufacturing contribution goes beyond providing improvement solutions for the existing gear manufacturing problems but includes enabling preventive measures right at the design stage and offering integrated support from materials and processes to maintenance in order to ensure the stable long-term operation of the gear machining system.

Figure 3: Manufactured gear parts and assemblies for industrial applications by LS Manufacturing

How Does LS Manufacturing's Quality Control System Ensure Gear Precision?

Precision is the sole index for quality in the precision gear manufacturing field. LS Manufacturing has developed a whole-product-lifecycle quality management system. At the core, it is to adhere to a stringent gear quality control philosophy in every single step of manufacturing by virtue of data given by advanced precision gear testing technology. Core aspects are:

Full-process quality monitoring

Application of Latest Testing Technology

By using gear measurement centers and coordinate measuring machines, we provide precision gear testing. In addition, this can comprehensively evaluate key parameters such as tooth profile, tooth direction, and pitch, and generate the error maps in detail to provide precision data for process optimization.

Standardized System Guarantee

Namely, the precision assurance of LS Manufacturing does not come from any single step but is attained through a systemic gear quality control system by effectively integrating "preventive control, process monitoring, and end-of-line verification." We are absolutely confident that only by integrating rigorous precision gear inspection into every stage of the manufacturing process can we consistently provide high-precision gear products that create even greater customer expectations.

Figure 4: Critical high-accuracy gearing and engagement components by LS Manufacturing

How Does LS Manufacturing Ensure A Smooth Transition From Sample Development To Mass Production?

The leap from successful sample verification to stable gear mass production is a crucial leap that determines the ultimate success of a project. Equipped with a complete mass production assurance system, LS Manufacturing ensures that the quality and performance of mass-produced products are highly consistent with samples and achieves excellent production cycle control. This smooth transition largely hinges on three major initiatives:

- Process Standardization and Consolidation: This should be followed with the systematic conversion of validated manufacturing parameters, precise toolpaths, and optimized heat treatment curves into formal, detailed standard operating procedures. It has to be implemented in such a way that each process can be reproduced exactly and reliably in later mass production regarding product quality and manufacturing efficiency.

- Scientific Capacity and Supply Chain Planning: In this direction, we make strategic allocations of production capacity and stockpile main raw materials in advance to meet customer demands. More importantly, the company will establish a close collaborative mechanism with core suppliers to ensure the smoothness and continuity of the supply of key materials. This proactive approach lays a solid foundation for having control over a stable production cycle, reliably meeting market requirements.

- End-to-End Data Monitoring and Traceability: During mass production, we monitor every key dimension of the product in real time using SPC; meanwhile, we build a complete and systematic data archive for the products. Such an integrated approach enables traceability-from raw materials to finished goods-along the whole upstream and downstream supply chain to ensure consistency in quality control.

LS Manufacturing employs a systemic approach integrating process standardization, supply chain collaboration, and digital monitoring. This system tackles common issues like quality fluctuations and delivery delays from samples to mass production, ensuring excellence in every stage of gear design and manufacturing. It ensures gears reach high-volume manufacturing with consistent quality, minimizes project risks via tight cycle control, and enables faster, reliable product launches.

Why Choose LS Manufacturing As Your Gear Manufacturing Partner?

Choosing LS Manufacturing as your gear manufacturing supplier means choosing a reliable way that is driven by technology and based on quality. As a professional gear manufacturing supplier, we'll provide systematic value to our customers in design, production, and service. Advantages of LS Manufacturing are reflected specifically in the following core aspects:

- Expert technical team: We have a specialist R&D team that works in tune with customer requirements and proactive elimination of problems even at the design stage. Our gear solutions are optimized. From advanced material science down to precision mechanical design, to targeted heat treatment processes, we offer specialist knowledge in all areas to ensure superior product performance and reliability.

- Advanced manufacturing and testing equipment: Equipped with complete sets of German and Japanese imported CNC machining and heat treatment equipment, the workshop can meet various special-shaped product needs. Precision instruments, such as gear measuring centers and coordinate measuring machines, have been applied to make sure comprehensive quality monitoring is guaranteed, providing the products with high precision and consistency.

- Mature Industry Experience Combined with Efficient Project Management: With rich practical experience in industries such as automotive, aerospace, and industrial automation, we are able to accurately anticipate challenges in respective industries. Professional project management teams guarantee smooth transitions from sample production to mass production; hence, precise delivery cycle control is assured.

- Full aftersales technical support: We are committed to fast technical response and full aftersales support to ensure expertise for every inquiry and every solution, with enduring service. Now, the pledge of immediate assistance and continuous care cements our position as long-term reliable partners within the customer's value chain, fostering growth, reducing downtime, and earning trust beyond the initial transaction.

In summary, the advantages of LS Manufacturing are concentrated in integrating a professional team with advanced equipment, industry experience, and service systems into an effective and reliable collaboration platform. Therefore, choosing us as a supplier for gear manufacturing ensures not only your benefits from the standards-compliant gear products but also a solid guarantee for enhancement in performance of your end-user equipment and your market competitiveness.

FAQs

1. What is the minimum module and maximum diameter range during gear machining?

Since its establishment, LS Manufacturing has rich experience in processing and can reliably machine all gears within a module range from 0.5 to 25 with the maximum outer diameter up to 800mm. Equipped with different types of CNC machine tools, we can provide you with cost-effective customized machining according to your specific design parameters.

2. What heat treatment options are there available for gears?

We provide the full range of heat treatment processes, including carburizing and quenching, high-frequency quenching, tempering, and nitriding. Depending on the material that makes up your gear, along with the load that is going to be expected and wear resistance requirements, our engineers will recommend and implement the most appropriate heat treatment scheme in such a way that tooth surface hardness and core toughness are balanced.

3. How do you ensure gear precision grade?

Precision can be guaranteed by the dual system "machining + inspection". In manufacture, our company adopts advanced equipment such as CNC gear grinding machines imported from Germany and Japan. The quality inspection is done by using a gear measurement center to perform 100% full-dimensional tests and issue detail reports to assure that each precision index strictly meets customers' requirements for ISO or AGMA levels.

4. How to calculate the price for small-batch gear processing?

For small batches, detailed pricing is mostly based on the complexity of the gear structure, required precision degree, selection of materials, and heat treatment. We guarantee reasonable prices that are transparent and very competitive with quality assurance.

5. What's the normal lead time for gear processing?

Generally, if the product is a standard-sized gear, the lead time is about 7-10 working days. For complicated structural gears or gears with extremely high precision, it will be longer, at 15-20 days. Besides, for urgent customers' needs, an efficient expedited production channel can coordinate fully and meet your project schedule.

6. Is your company offering gear design and optimization?

Yes, we provide free gear design consultation and optimization. Our engineering team can participate in the early development of your project and give professional advice on tooth profile modification and parameter selection, thus helping improve your transmission efficiency, reduce noise, and prolong lifespan from the designing stage.

7. How to eliminate problems in gear noise?

Gear noise comes basically from the errors of tooth profile or from the impacts of meshing. Our solution is to ensure the basic accuracy of the tooth profile by high-precision grinding and then optimize the meshing contact area using professional techniques of tooth direction modification and tooth profile modification to effectively reduce the noise and vibration at the source of transmission.

8. What is the maximum size of gear that can be processed?

The maximum diameter of gears that can be processed by our equipment is 800mm at present. If your project needs a size greater than this, please discuss it with us. We will evaluate and develop a workable customized production plan for you.

Summary

Gear manufacturing is the core foundation of modern industrial equipment, and its performance and reliability directly decide those of the transmission system. The choice of a professional manufacturing partner who is proficient in technology and with rich experience is the key to guaranteeing the success of a project. LS Manufacturing focuses on precision transmission, relying on advanced technology and equipment, strict process control, and abundant industry application experience, to provide every customer with high-precision, long-life, highly reliable gear products and customized solutions.

If you are committed to enhancing product performance and market competitiveness, please feel free to contact our experienced gear expert team at LS Manufacturing. We will offer you free targeted technical consultations and rapid quotation services, injecting powerful performance into your products with our professional expertise, creating value together.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.