CNC machining services procurement often faces multifaceted challenges including inconsistent supplier capabilities, confusing pricing structures with hidden risks, and quality instability leading to project delays. These persistent issues typically stem from insufficient systematic evaluation criteria, where many buyers tend to focus primarily on initial pricing while overlooking critical factors such as technical capabilities, quality management systems, and long-term reliability.

LS Manufacturing will demonstrate how to effectively internalize these comprehensive standards as practical project delivery guidelines, ensuring your project's success from the very beginning. To optimize your time and focus, let's proceed directly to the core considerations by examining the first essential dimension when selecting a manufacturing partner.

CNC Machining Quick Reference Table

| Module Classification | Core Content Summary | Technical Specifications | Typical Applications |

| Machining Principle | Computer Numerical Control Cutting and Forming Technology | Positioning Accuracy ±0.005mm | Aerospace Components |

| Process Type | Covers Milling, Turning, Multi-Axis Machining | 5-Axis Linkage Accuracy ±0.02mm | Medical Device Manufacturing |

| Equipment Configuration | CNC Machine Tool and Automation System | Integration Spindle Speed: 24000rpm | Automotive Mold Machining |

| Tool Selection | Matching of Tool Parameters to Material Properties | Increase in Tool Life by 40% | Manufacture of Precision Parts |

| Quality Control | Online Inspection and Error Compensation Technology | Repeatability Accuracy ±0.003mm | Electronic Communication Components |

| Cost Optimization | Unit Cost Reduction by Parameter Optimization | 35% Improvement in Efficiency of Machining | General Machinery Manufacturing |

While considering CNC machining as one of the key technologies in manufacturing, where the digital system controls the machinery with high precision and highly effective processing, the technical system is multidimensional in nature and covers the principles of machining, process methods, configuration of equipment, tool management, quality control, and cost optimization. Such technology, therefore, plays a very important role in key high-end manufacturing sectors related to aerospace, medical devices, and car molds.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

It can help us to master the main technologies of high-temperature alloy cutting and deformation prevention of thin-walled parts through this project experience. The LS Manufacturing team has profound professional experience in CNC machining for fifteen years in high-end manufacturing industries such as aerospace and precision medical. More than 50,000 pieces of work of complicated workpieces lay a solid foundation for our technical system.

Our manufacturing system strictly adheres to the ISO 13485 for Medical Devices standard, ensuring full compliance with medical-grade production environmental controls and operational procedures. In terms of technological innovation, we proactively integrate the advantages of Additive Manufacturing (AM) with traditional CNC machining to break through the limitations of conventional processing through hybrid manufacturing technologies. Guided by this philosophy of balancing standardization and innovation, our machining efficiency has increased by over 35%, while maintaining a product qualification rate consistently above 99.5% for many years.

It established a whole CNC machining process library through massive accumulation of machining data. The solutions in this guide went through mass production and optimization of tool life, and verification was done in fields such as 5-axis simultaneous machining, aerospace, and medical equipment. Combining the most authoritative standards with practical experiences can make sure that each technical suggestion is helping customers to solve the real machining problems and improve the level of manufacturing.

Figure 1: Industrial grade flawless CNC machined sample by LS Manufacturing

Why "Lowest Price" Is Often The Biggest Trap In Choosing CNC Machining?

Firstly, the risks in quality are usually underestimated

Suppliers with low prices may cut corners on either material quality or process standards to maintain their profits. Once in a medical device casing project, there was a low-priced supplier that used non-standard aluminum materials. After batch processing, stress deformation took place. The cost for returning and remaking goods later was more than 200% of the quote by a professional supplier. True cost control should be based on quality assurance.

Secondly, delivery risks should never be underestimated

Poor production management usually brings about delays in delivery for enterprises due to chaotic scheduling or the failure of equipment. A case study in the automotive parts industry reflects that a low-priced supplier promised a two-week delivery time, which actually extended into a month and caused daily losses in millions of yuan due to line downtime in a customer's vehicle assembly line. Professional CNC machining quotes should include comprehensive delivery guarantees.

Finally, there is a serious lack of technical support

Generally speaking, low-priced suppliers lack professional process analysis and cannot make design optimization suggestions effectively. In one aerospace bracket project, a professional supplier reduced the number of parts from eight to three through DFM analysis. Although the unit price increased by 20%, the total cost was reduced by 35%, while the weight was reduced by 400 grams.

In the early stage, the value-oriented pricing model of LS Manufacturing uses in-depth process analysis and optimization to assist customers in optimizing their overall cost while ensuring quality. It has been proved in practice that although a professional CNC machining quote is 10-20% higher at the beginning, through quality stability, delivery guarantee, and value-added technical services, it can reduce customers' total cost by more than 30%. That's truly a scientific approach to procurement decisions.

What Are The Three Technical Capabilities To Focus On In The Evaluation Of A CNC Machining Supplier?

In selecting a precision CNC machining partner, it is far from enough to compare merely lists of equipment and price quotations. The core competitiveness of any high-quality supplier lies in all-around technical capabilities, which directly determine the machining accuracy, production efficiency, and ultimate quality of parts. Among the demands of precision CNC machining, three such capabilities listed below will make up the key dimensions of supplier evaluation:

Capabilities of equipment and precision control systems

Materials Science and Process Adaptability

In the process, there are great differences in performance for different materials, which forces suppliers to set up a complete database of materials. From aluminum alloys to high-temperature alloys, from engineering plastics to composite materials, professional suppliers are bound to analyze the trend of material deformation during processing and develop corresponding process countermeasures. We improved the part yield significantly by improving the cutting parameters and cooling methods, so as to control the deformation within 0.02mm for thin-walled parts of 7075 aluminum alloy.

CAM Programming and Process Optimization Capabilities

Advanced CAD/CAM software is just a tool; the real competitiveness comes from the process understanding and optimization capability of our programming engineers. Excellent programming takes into consideration not only the machining efficiency but even tool life, surface quality, and cost control. As a result of optimizing our toolpath strategy, a medical device casing had machining time reduced by 35%, with a surface roughness of Ra0.4μm, showing the perfect combination of software and

How Does One JudgeThe Reliability Of A Supplier Based On Quality Certification And Control Processes?

When selecting manufacturing partners, the certification of the quality system should not be just a piece of paper, but verification of how well it has been applied in practice. One of the most important characteristics of a responsible supplier is a traceable quality control system that systematically covers every process from order receipt to shipment and ensures accountability for all steps taken. The following are main characteristics of a systematic process of quality control and thus important criteria for evaluating responsible suppliers:

| Control Links | Core Activities - Brief Description |

| Incoming Material Inspection | Check all CNC machining raw materials and components stringently to weed out quality problems at the source. |

| First Article Inspection | Extensive verification of the first article in advance of mass production will confirm that the process parameters are set correctly. |

| In-Process Inspection | Regular spot checks shall be performed throughout production to monitor on a real-time basis the stability of key processes. |

| Final Inspection | Conduct 100% or AQL standard inspection on the finished products to ensure every product completely meets customer specifications. |

| Quality Traceability | This involves a chain of data from material right through to finish goods that permits rapid location and root cause analysis if there are problems. |

In summary, supplier reliability depends on whether their quality system is preventive rather than remedial. LS Manufacturing not only holds ISO 9001/AS9100 certifications but implements them through digitalized daily management. Our fully traceable closed-loop system proactively reduces quality risks, ensuring consistent delivery and forming the foundation for long-term reliable partnerships.

How To Ensure The Efficiency Of Communication And Project Management In CNC Machining Projects?

Effective project management and transparent communication are crucial for on-time, on-budget delivery in complex CNC machining projects. Traditional email-based information exchange often leads to delays and project risks. Modern online CNC machining services (embodying digital collaboration) address these challenges through digital tools and standardized processes. The following key mechanisms ensure communication effectiveness and project management efficiency in advanced digital platforms:

| Key Mechanisms | Core Role |

| Dedicated Project Manager | Provides a single point of contact thus providing one entry point for requirements and full accountability. |

| Regular Progress Reports | Reports on a week-to-week basis with images and videos, visually demonstrating processing progress and key quality control milestones. |

| Web-based collaboration platform | Real-time synchronization of design documents, process drawings, and comments on modification. |

| Rapid Change Response |

Creates a system for engineering change requests, ensuring all changes proposed are assessed, approved, and followed through. |

| Milestone Review Meetings | Organizes meetings at key milestones concurrently to align expectations and identify potential risks proactively. |

Great project management, in a nutshell, consists not only of planning but also of transparency and responsiveness in its execution. The online CNC machining service model at LS Manufacturing merges deep responsibility by a project manager with the real-time transparency of a digital platform, enabling clients to see every step of the progress clearly in their external supply chain as if they were managing an internal project. Thus, this systematic communication and project management is a robust foundation for ensuring the high success rate of complex projects and building long-term trust partnerships in CNC machining.

How Does LS Manufacturing Add Value For Clients And Reduce Client Costs With DFM Analysis?

Structural Cost Reduction by Design Optimization

Our engineers will do a thorough analysis of the product functional requirements and optimize the design by simplifying the structure and integrating components. For example, several sheet metal assemblies from the original design are optimized into one integral structural component through CNC machining, which reduces the assembling steps and maintains strength while directly reducing the processing cost and assembling time.

Precise matching of materials and processes

With deep knowledge of material properties, we recommend more economical alternative materials that meet the performance requirements. For instance, the use of free-machining alloys for some structure parts instead of high-specification alloys can reduce the cost of materials by more than 15%, while their performance can be adjusted by means of heat treatment processes.

Manufacturing-Friendly Tolerance Design

Our engineers differentiate between critical and non-critical dimensions, with recommendations for reasonable tolerance zones. Requirements regarding tolerance in non-mating areas are appropriately relaxed for avoiding unnecessary processing costs, while the precision control of critical dimensions is ensured to attain the best balance between quality and cost.

What that means in simple terms is that the core of LS Manufacturing's competency is translating DFM analysis into customer value. We are focusing attention not only on per-piece CNC machining costs but also on improvement in product manufacturability by design optimization in order to decrease the cost without sacrificing quality significantly.

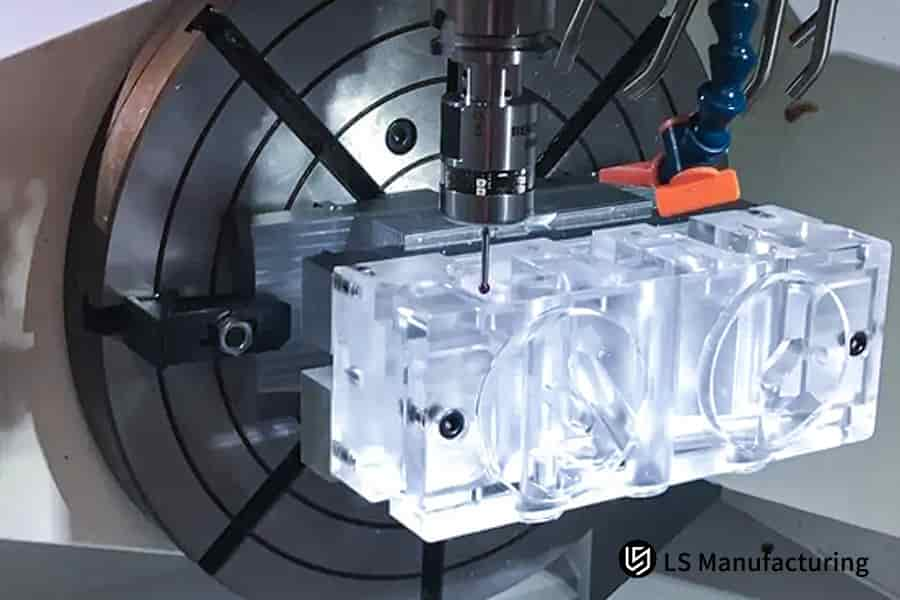

Figure 3: Modern CNC Machining Center in Operation by LS Manufacturing

Precision Machining Challenges Of Inconel 718 Turbine Housings In The Aerospace Industry

Precision machining of high-temperature alloy components in aerospace manufacturing directly determines power system performance and reliability. The properties of Inconel 718 material require deep integration of material science, tooling technology, and dynamic analysis to overcome machining challenges. This case exemplifies critical CNC service selection criteria for high-performance applications. The detailed analysis is as follows:

Customer Challenges

An aerospace equipment manufacturer was badly in need of solving several machining problems of Inconel 718 high-temperature alloy turbine housings. The part had complex internal cooling channels and thin-wall structure with a minimum of 0.8mm, which required dimensional and positional tolerances of ±0.025mm. The serious work hardening tendency and poor thermal conductivity of the material meant the yield rates of the two previous suppliers were less than 50%, which seriously delayed the project.

LS Manufacturing Solution

We customize special tool geometry and optimize coating parameters according to material properties through the organization of a dedicated technical team and the adoption of a multi-dimensional innovative approach. We use a combination of high-pressure internal cooling and microlubrication in innovating the cooling process. Finally, the cutting forces were reduced by 40%, with dynamic milling strategies and layered cutting schemes, while effectively controlling machining deformation and abnormal tool wear.

Results and Value

With systematic CNC machining process optimization, product yield increased to 98%, and delivery cycle was shortened by 35%. More importantly, we helped our client overcome technical bottlenecks, enabling their project to smoothly enter the next R&D phase and establishing a long-term strategic partnership.

This case study fully demonstrates the competencies of LS Manufacturing in precision machining high-temperature alloys. By fully utilizing the latest advances in material science, tooling technology, and machining dynamics, we solved some very critical manufacturing problems in the aerospace field. This success is reflected not only in a significant yield increase but also in helping our clients speed up the product development process and generate more value.

Get your custom CNC machining solution now by clicking the button below!

How Does The Strategy For The Selection Of Suppliers Differs For Small-Batch Prototyping VS Large-Scale Production?

The selection criterion for suppliers should be quite different at different stages of the product development process. In the small-batch prototyping stage, the focus is on rapid validation and technical collaboration, while large-scale production focuses on stable delivery and cost optimization. The ability to make such differentiation empowers companies to establish an efficient supply chain:

- Small-batch prototyping stage: Small-batch production may demand the rapid validation of design. The selection of suppliers should be based on their responsiveness and technical capability at this stage. Suppliers shall be quick and capable of providing engineering support; attention shall shift to their rapid prototyping capabilities, Design Optimization (DFM) suggestions, and a willingness to adapt flexibly rather than just competitive price comparisons.

- Large-Scale Production Stage: As soon as mass production starts, the evaluation focus shifts to quality consistency, assurance of capacity, supply chain management and total cost control. Suppliers should be selected with a solid quality control system, production planning, and management capabilities, and relevant experience in large-scale supply.

- The Value of Seamless One-Stop Service: The best model for cooperation is to choose a supplier that can provide one-stop service from small batch to large-scale production. In that way, it avoids the risks brought about by changing suppliers in the middle, such as repeated reviews of drawing and standard re-unification, which affect the continuity and consistency of product data.

In summary, the key is to choose R&D-oriented partners at the small-batch stage and manufacturing expert partners in large-scale production. Understanding how to choose CNC machining services is critical for seamless transitions between these phases. LS Manufacturing one-stop service fully meets this requirement by supporting rapid prototyping with engineering expertise while ensuring stable mass production through mature systems. This approach helps customers smoothly transition between development stages while significantly reducing supply chain management costs and risks.

Aside From Price And Delivery Time, What Are The Other, Often-Overlooked "Soft Power" Influences That Are Important?

- Intellectual Property Protection System: The foundation of cooperation is sound IP protection. A good supplier would set up strict confidentiality agreements, encrypted data transmission, and multi-tiered access control to guarantee security for customers' designs. We employ bank-level data encryption and tiered access control so that clients can confidently deliver core designs.

- Technical Support and Response Mechanism: The rapid response capability reflects the value of a service, including the speed of technical consultation response, problem-solving efficiency, and after-sales support system. We can provide a 15-minute rapid response mechanism and dedicate ourselves to the technical support channels to solve the problem in time.

- Financial health and long-term stability: A supplier's financial health directly impacts their ability to fulfill contracts and ensure continuity of service. We are well-structured financially, and we value transparency to guarantee stability in a long-term collaboration.

In addition to these hard indicators such as price and delivery time, there is an even greater need to pay attention to soft strengths such as the protection of intellectual property, service response, and the ability for sustainable cooperation when selecting a long-term partner. LS Manufacturing is devoted to being a trusted partner for customers. We build a comprehensive service system and invest continuously in innovation, creating value in the long run well beyond the expectations of our clients while building solid and lasting partnerships with them.

Figure 4: Advanced CNC machining process for precision components by LS Manufacturing

Why Choose LS Manufacturing As Your Next CNC Machining Partner?

In today's highly competitive manufacturing environment, the selection of a partner will decide the success or failure of a project. LS Manufacturing CNC machining service, with its comprehensive strength, has become many leading companies' first choice among various industries. We provide not only precision machining but full-value assurance; therefore, we are your best partner.

- Leading technology and equipment guarantee: In addition, we have 5-axis machining centers supported by digital manufacturing systems, allowing the precision machining of everything from a simple part to a complicated component efficiently, as per the exacting requirements of any industry.

- Strict Quality Control System: Starting from raw material warehousing to finished product shipment, by implementing the ISO 9001 and AS9100 quality systems, we have established a comprehensive quality control system that adheres to world-class quality standards in every step.

- Professional Engineering Support Services: Our engineering team provides full technical support from design optimization all the way to process planning. For instance, we use DFM analysis in optimizing product design for clients to achieve the dual goals of cost control and performance improvement.

- A transparent process of project management: We have implemented a dedicated project manager system and regular progress reports so that clients can track project dynamics at all times, therefore achieving full-process visual management.

In short, what can be deduced from the LS Manufacturing CNC machining service is that it contains the perfect combination of advanced technology, strict quality control, engineering wisdom, and transparent management. Instead of being just a supplier, we will become your best partner in mutual growth with clients. Whether it be complex technical challenges in dealing with the machining of high-temperature alloys in aerospace applications, or stability assurance in mass production, we provide reliable solutions for this.

FAQs

1. What is the LS Manufacturing Minimum Order Quantity?

We provide flexible production to support the smooth transition from single-piece prototypes to mass production quantities of up to tens of thousands. Minimum order quantity services, especially for startups and R&D teams, enable true barrier-free collaboration with "on-demand manufacturing."

2. How long does it take from inquiry to receiving a detailed quote?

Standard inquiries have responses within 24 hours, and complex part quotes are returned in their entirety with DFM analysis within 48 hours. We utilize an intelligent quotation system where 3D models are automatically parsed and preliminary process assessments are created.

3. How do you ensure the confidentiality of my design drawings and data?

We introduced hierarchical access control and bank-level encrypted transmission. Then we signed lifetime confidentiality agreements with all employees. Data is absolutely destroyed as agreed upon after the project, to wholly control intellectual property rights.

4. How would you handle it if one of the components has some issues while quality checking?

Initiate immediately the "Rapid Response Mechanism for Quality Issues": isolation of the problematic batch, failure analysis report within 8 hours, creation of a corrective action plan reproduction/rework within 48 hours, transparent communication throughout.

5. What type of commonly used file formats do you support in quoting?

The DDP supports mainstream 3D formats like STEP/IGES/X_T and is compatible with original files from SolidWorks/CATIA/UG. Besides, free format conversion is provided to make sure that data transmission will not lose any information.

6. Do you provide secondary processing like surface treatments that include anodizing and electroplating?

We integrate more than 20 surface treatments, including anodizing, electroplating, and sandblasting, among others, with end-to-end quality control from substrate processing down to final treatment, truly reaching one-stop delivery.

7. Can you assist with logistics and customs clearance for overseas orders?

With a well-developed international trade network, we can offer a full logistics service package: from DDP/DAP to certificates of origin, commodity inspection, and other customs clearance documents to ensure delivery across the globe.

8. How do I start placing my first order?

Please access the "Online Quote" webpage on our website for a quotation, uploading your drawings there and filling in your requirements. A dedicated Customer Service Representative will contact you within one business hour for full guidance, from technical consultation to placing your order.

Summary

Choosing a CNC machining service represents a holistic strategic decision that involves much more than comparing prices and lead times. You can explore all eight dimensions described here as one structured approach to assessing several different suppliers to find the expert who really can secure the success of your projects and long-term value for you.

Now you have the best standards to guide your selection process. Upload your part drawings to receive a complimentary DFM analysis and precise quotation from LS Manufacturing's experts. Reach out to us today and let our professional team ensure your next project's success with our specialized manufacturing expertise.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.