Custom CNC machining services play a pivotal role in addressing the challenge of separation between design and manufacture that characterizes this industry. This is a challenge that has been leading to a situation where there is a design of a product that is unmanufacturable, hence increased levels of production difficulty and cost. On the other hand, lack of overall design information among the individuals involved in the manufacture process has been affecting the quality of items.

However, with the desire to surmount such inefficiencies arising because the teams work in isolation and processes are integrated poorly, there arises a need for a scientific management principle-based solution that addresses every process from start to finish. From this article, it is clear that LS Manufacturing has an end-to-end process which has been totally integrated; hence, design consultation, prototyping, and mass production are done en masse in a manner that embodies design intent to perfection.

Custom CNC Machining Services: Quick-Reference Guide

| Aspect | Key Points |

| Core Value | Bridges the gap between design and manufacturing. Transforms design specifications into quality functional parts. Supports prototype rapid or mass-produced realization. |

| Common Pain Points | Design for Manufacturing (DfM) oversights. Miscommunication between teams. High costs/errors from rework. Prototyping bottlenecks delaying time-to-market. |

| Ideal Provider's Solution | Toyota Integrated E2E Service: To offer the design consultation, rapid prototyping, and batch production services in an integrated way; Scientific Process: Can have a well-integrated full process management system with smooth transitions. |

| Key Benefits | Reduce development time and cost. Improve quality of the part. Improve manufacturability. Faster product introductions. Accountability. |

| Applications | Functional prototypes. End-use volume parts - low to high. Complex, precision, aviation, automotive, medical, and technology parts. |

Custom CNC machining is a very important area in modern machining, as it addresses an imperative challenge between design and manufacture. This is a very important enabler of an end-to-end service strategy, integrating design for analysis for manufacturability expertise with prototyping and manufacture expertise. It addresses issues with communication silos, problems in error and rework, and brings perfection to interpreting design intent, enabling ultimately better time-to-market and parts performance.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Knowledge is power in the custom CNC machining world. Our team work within an environment on a daily basis that simulates an active workshop setting, regularly working with challenging alloys, tight tolerances, and geometries. The advice we provide has all been tried in real life with strict requirements by organizations such as ASTM International and SAE International.

We have over 50,000 custom CNC machined parts with precision-threaded components. Each piece offers a lesson to be learned when it comes to material properties and control processes. ASTM International standards, along with SAE International standards, are adhered to when machining stainless steel and optimizing titanium processes for our premium medical, aerospace, and automotive applications.

These findings here present the findings of both success and failure on the shop floor. Following the guidelines by ASTM International, we have converted guidelines to workable procedures. Take these findings here; these are knowledge gained from experience to offer workable solutions to CNC machining.

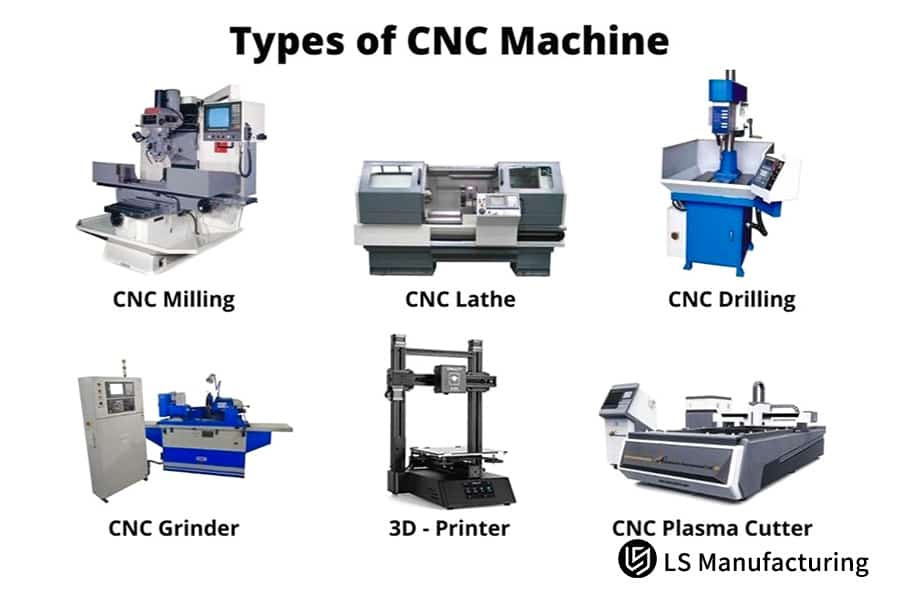

Figure 1: Six key CNC machines for bespoke production by LS Manufacturing

Why Can End-To-End CNC Machining Services Significantly Enhance Product Development Efficiency?

In today's competitive manufacturing environment, traditional fragmented models often lead to inefficiencies, delays, and quality issues. The key to overcoming these challenges lies in adopting a cohesive workflow, which is precisely what end-to-end CNC machining services provide, directly driving improved product development efficiency from concept to final part.

- Integrated information flow: Unlike the isolated information flows seen in multi-vendor systems, end-to-end CNC machining solutions allows for integrated information flow. This involves the uniform flow of information from where the design details are precisely translated in all processes.

- Single Source Accountability: As the design, prototype, and manufacturing work is being done by different people or firms, there may be a lack of accountability in the process. This is why the presence of end-to-end manufacturing solutions provider in the area of manufacturing can be a very good choice, as it allows accountability and a smooth transition from each step in a certain task.

- Optimized and Synchronized Processes: An integrated system provides for an uninterrupted feedback loop. The know-how generated in the machining floor area impacts the DFM process from the beginning. Synchronization is an essential aspect in optimizing the time for development to the tune of 30% or higher.

- Resource & Time Efficiency: The resource-intensive end-to-end CNC machining services minimizes the clerical, supply chain, and other waiting times as everything can be handled within the umbrella of the same system. Therefore, the available time for engineering innovation will be increased as less time will be spent on resource work. The effect is immediate as far as accelerated projects are concerned.

In conclusion, the shift to end-to-end manufacturing solutions transforms product development by replacing disjointed steps with a synchronized, accountable, and data-continuous process. This integrated approach, facilitated by expert end-to-end CNC machining solutions, is a proven strategy for achieving consistent improved product development efficiency, faster time-to-market, and superior final product quality.

How To Optimize Part Manufacturability Through DFM Analysis During The Design Phase?

Including the manufacturability design analysis within the early design phase has an important consideration in the development of functional and effective components. This step helps in determining the potential problems of manufacturing issues, thus facilitating the performance of theoretical components as optimized components in the machining process, which remains exactly the significant addition provided by professional DFM optimization services in the custom CNC machining task. There exist certain important focus areas for DFM analysis, which have been summarized in the following table:

| Focus Area | Key Considerations | Common Optimization Actions |

| Geometric Design | Wall Thickness, Internal Corners/Radii, Deep Cavity, Thin Rib. | Standardize thicknesses, specify machinable radii, avoid extremely deep or thin features. |

| Tolerances & Finishes | Dimensional tolerancing. Geometric tolerancing. Surface finish specifications. | Use small tolerances on critical dimensions. Specify common finishes. |

| Material & Tooling | Machinability of materials, based on size, accessibility, and tool clearance. | Should be taken into consideration while selecting material, keeping in mind machinability. |

| Assembly & Function | Part orientation, assembly interface, post-processing requirements. | Assemby; setup optimization; combine parts whenever possible. |

Through the integration of the power of all these analyses, better cost control during the design phase can be achieved. This means that the costs of redesign, as well as ineffective machining processes, can be avoided. Finally, the establishment of a partnership between organizations in the pursuit of professional DFM optimization services will assure one that the design produced not only encompasses an element of creativity, but the design itself has the capability of optimizing the efficiency of a custom CNC machining.

How To Validate The Design And Mitigate Risks During The Prototyping Phase?

CNC prototyping is a crucial step for validating designs and preventing costly errors before full production. It transforms digital models into physical parts, enabling practical design verification services and early implementation of risk mitigation strategies. This hands-on approach allows teams to test form, fit, and function directly, significantly reducing uncertainties in later stages.

| Validation Focus | Purpose | Typical Methods |

| Functional Testing | Check the functions of parts as used. | Load test, temperature cycle, pressure test. |

| Assembly Validation | Check that all parts are well assembled and compatible with each other as necessary. | Test assembled units by checking tolerancing. |

| Process & Material Suitability | Evaluate the manufacturing process and the materials used. | Examine the surface finish, workability, and nature of the materials. |

| User & Aesthetic Feedback | Collect feedback on the User Interface & Aesthetic look. | Ergonomic review & assessment of the visual prototype. |

Therefore, relying on high-precision CNC machining services or prototyping is a sound foundation for design verification services and as a risk mitigation strategies, it is a proactive measure to ensure that the end design is optimal before proceeding to batch production.

Figure 2: Four essential CNC methods for component fabrication by LS Manufacturing

How To Ensure Consistent Quality And Traceability During Mass Production?

For custom CNC machining parts, having quality traceability is an important requirement where mass production is a consideration. The method that is recommended to be adopted for addressing mass production quality control is aimed at producing consistent quality and providing a total production traceability system to ensure that all information of the component complies with tight specifications.

Hierarchical Quality Control System

It starts with First Article Inspection (FAI) where inspection of the first article produced is done to verify if the article meets all requirements in the definition in the design of the product. This is an essential step made possible through the availability of CMM coupled with optical scanning of an incredibly high order of accuracy to establish the production traceability system.

Statistical Process Control for Consistency

In order to maintain quality consistency assurance, statistical process control methodologies are also followed. The key machining parameters, such as wear on the tools, size accuracy, and surface finish, are also monitored in a predictive manner, beyond the limits of required mass production quality control. This applies in the context of high-quality parts.

Advanced Inspection & Traceability

After the completion of the basic inspections, the 100% critical dimension inspections can also be done at this stage. Alongside each consignment of custom CNC machining parts, there is a fairly large chain of information available related to the production traceability system.

Constant Feedback for Improvement within the System

One advantage which could be identified in relation to the production traceability system designed in the project is that the system will work to provide constant feedback information. Taking into account the result of the analysis in relation to the quality trend and feedback provided in the traceable production process, there will be an improvement opportunity in relation to the machining systems and quality consistency assurance.

Considering all the above aspects, the mass production quality control is also needed to work in conjunction with ensuring the quality consistency assurance. The integration of the quality control in the mass production components, whereby the quality is ensured actively and constantly, through the control of production traceability system in SPC, along with the production traceability system that is already in place, helps in the production of the accurate custom CNC machining parts.

What Are The Special Management Requirements For Multi-Variety, Small-Batch Production?

In small-batch, high-variety production, there are special management approaches that need to be applied. This is done by succeeding as a result of flexible manufacturing systems that maximize availability, precision, and quality; all these are ensured using flexible manufacturing solutions. Quick changeover technology is also a critical factor under special management approaches.

- Competition Winner: To ensure the speed of set-up performance, the following quick changeover techniques can be supported: modern quick-changeover techniques, such as the availability of standard equipment, tool presetting, or workholding systems that would significantly decrease the set-up time. Fast, repeatable setups are essential for profitable and responsive small-batch, high-variety production operations.

- Implementation of Agile Production Systems: At the core of managing diversity, flexible manufacturing solutions. are involved. These flexible manufacturing systems are created by offering multiaxis CNC machining centers as well as production softwares with adaptive properties. This involves complex shapes as well as batch sizes which do not affect efficiency throughout the CNC machining process.

- Ensuring Perfect Material and Data Flow: The issue of accuracy can be assured by means of perfect material availability and data flow. This means that each and every part number requires perfect delivery of materials, specific CNC programs for all, and specific quality plans.

- Creating an Adaptive Workforce: This would be extremely helpful in having an ever-prepared workforce that could design, install, and inspect components of all types. This would be extremely useful in an ever-changing environment and would form the basic groundwork needed in any flexible manufacturing environment.

Therefore, for small-batch, high-variety production, getting effective results is not possible without the help of quick changeover technology, as well as intelligent flexible manufacturing solutions with the use of skilled human resources. Even if both concepts are integrated, the entire process flow for CNC machining from design to production can be optimized, realized, and achieved successfully.

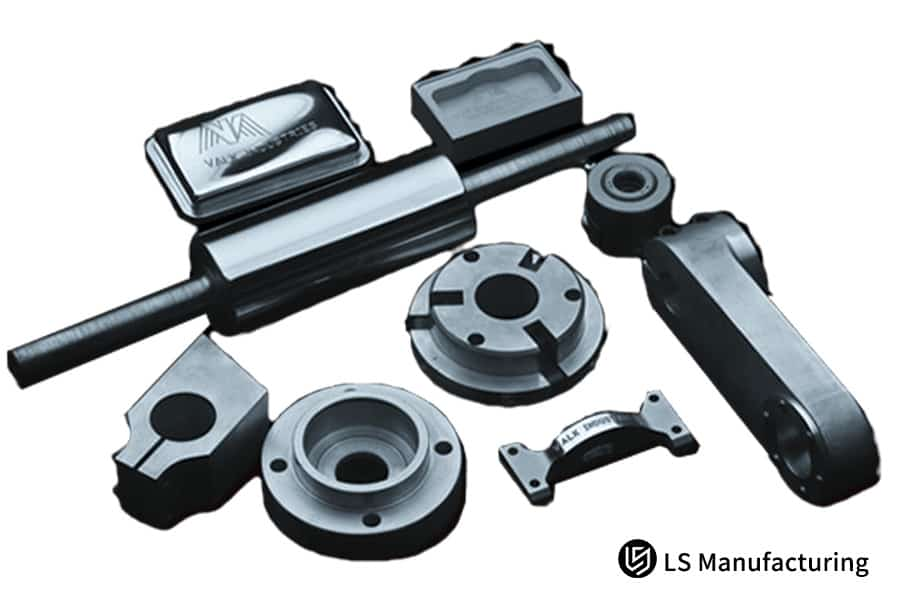

Figure 3: Specialized CNC-manufactured parts for international industries by LS Manufacturing

LS Manufacturing Medical Device Industry: End-To-End Manufacturing Of Precision Transmission Components For Surgical Robots

A prominent player in the surgical robots market faced issues regarding the important specifications involved in producing transmission components with a high degree of precision and were required by the system. The LS Manufacturing success case described its specific achievement with our capabilities as follows: Our client's design challenge became a manufacturable component with our precision CNC machining services.

Client Challenge

Though manufacturing transmission parts with high dimensionable stability was a problem in the company, the accuracy required in assemblage of these parts was also high. Though the conventional multi-venda setup in the client company introduced variations in quality, their defect/scrap rates are highly high and can never permit the strict medical standards during product launch.

LS Manufacturing Solution

This has enabled us to provide real value with respect to the end-to-end manufacturing services right from extensive DFM analyses with respect to optimized machining geometries all the way through to micro-scale precision levels using our most advanced 5-axis precision CNC machining services. Besides design, development, and deployment are involved in an in-process quality control monitoring system to ensure that parts are manufactured to exact specifications for medical devices precision machining.

Results and Value

This project will provide an impressive outcome with a staggering result of 99.9% improvement in the yield of the final product and a compression in development time of 40%. It will also provide an outcome of total cost of part development with a reduction in cost of 25%. This will enable the customer to concentrate on the time-to-market cycle with an emphasis on the improved expectations generated through the performance of the parts.

In the LS Manufacturing success case, it is demonstrated that, as an end result of the integration process, the above-stated benefits can be obtained completely. At LS Manufacturing, to win the confidence of our valued customers in terms of the required quality for the most intimidating jobs in medical devices precision machining, starts with precision CNC machining services in place.

Need specific high-quality precision transmission parts? Chat with us for any of your customized CNC machining services.

Why Choose LS Manufacturing As Your End-To-End Manufacturing Partner?

Its key concern is identifying who would be the best CNC machining partner. LS Manufacturing stands out as an outstanding completely integrated manufacturing expert because it leverages extensive knowledge in manufacturing together with advanced manufacturing technology. This is needed for handling complex tasks in manufacturing from start to finish.

- Experienced Engineering Team: With our experienced engineering team, DFM analysis is conducted for your product early in the engineering phase. This expertise, a core LS Manufacturing core advantages, ensures designs are optimized for manufacturability and performance, reducing risks throughout the CNC prototyping and production cycle.

- Highly Developed Technological Infrastructure: The multiaxis CNC machining centers and inspection systems, which we possess, give us a wide spectrum of technological development. This helps us to meet complex geometric requirements and tighter tolerance levels, thereby making end-to-end manufacturing expert.

- Strong Quality Management System: Starting right from the first article inspection to the statistical control of the mass-produced parts, the integrated quality management system enables traceability of the parts. This is LS Manufacturing core advantages and is an essential ingredient for any customer seeking precision.

- Record of Success in other Industries: With thousands of successfully completed projects in our portfolio, especially in very demanding industries such as the aviation industry and the medical industry, our company has the success record of a CNC machining partner, which helps our clients with the success rate of project completion.

In summary, choosing LS Manufacturing means partnering with a dedicated end-to-end manufacturing expert. We leverage our LS Manufacturing core advantages—experienced engineers, advanced technology, rigorous quality systems, and proven experience—to deliver exceptional value and reliability across all phases of CNC prototyping and production.

How To Establish An Effective Project Management Mechanism To Ensure Delivery Quality?

Manufacturing project management is very important to ensure successful timely delivery besides ensuring all requirements related to quality specifications. There should be effective project management with that kind of approach to planning, communication, or risk that is used mainly as delivery quality assurance.

- Establishing Milestones and Gates: It is assured that there is an standardized process management setup because there is a phase gate process with defined milestones. It encompasses rigorous design reviews, prototype checks, and readiness for production milestones to ensure that there is a tight management of quality and time at all stages of a particular project or task.

- Proactive Communication Protocols: Communication protocol planning based on cross-functional meetings and project sites are included under proactive communication protocols. The reason why this is important is that if everyone involved has the same understanding of what is happening, problem resolution becomes easier.

- Creation of Risk Mitigation, Contingency Planning: The other aspect that is central to effective manufacturing project management is the determination of the risks that are probable, for example, delay, technical problems, among others. Planning for the contingency of the key risks ensures that the start is immediate with either the mitigation or the challenge itself.

- Leverage of Technology in Tracking: The use of project management tools gives the ability to track progress in real time. This ensures that there is traceability in the quality of delivery through the use of digital technology. Delivery quality assurance can be monitored through digital technology.

To ensure delivery quality assurance in complex production projects, there should be an efficient system. By including effective process management, communication strategies, and risk management, there is implementation of a professional manufacturing project management system, which modifies the production process by providing timely results with high-quality production.

Figure 4: Rapid CNC machining utilizing a liquid coolant spray by LS Manufacturing

How Do I Get Started On My End-To-End Manufacturing Project And Get An Accurate Quote?

Initiating a successful end-to-end project initiation begins with a clear and collaborative partnership. This calls for a professional process from concept right through to production. The process of initiating a project brings innovation, and our prime focus is an understanding of your requirements, forming a basis for providing a manufacturing solution consultation and an accurate quotation acquisition.

Comprehensive Needs Analysis

This requires a lot of conversation efforts in order to try to understand your technological requirements, volumes, and demands pertaining to quality. The specific consultancy service is a very critical component in the manufacturing solution consultation, since it helps in defining the scope of the project correctly, including the appropriate route for the creation of a quote.

Technical Feasibility and Solution Design

This shall be the next phase in the process wherein our technical engineers shall be engaged insofar as the design of your product is concerned. This shall enable our technical engineers to provide technical solution advice insofar as Design for Manufacturability advice to you. Your design shall also have the role of ensuring that the same assists in the implementation of your technical economic solution.

A clear and detailed quotation process

At this stage, we embark on the process of preparing the proposal on the basis of the process for technical evaluation. It includes both the process for cost analysis and the process for evaluation. It is rather important to ensure that the process for obtaining a quotation does not create any discrepancies, since this might cause losses. It should be noted that this essay will focus on the levels of development that are best for mankind.

Final Review and Project Kick-off

This final step entails reviewing the proposal for finalization and kicking off the project. It is this step wherein there is actually a formal handoff in which the confirmation for the accurate quotation acquisition has been accomplished and commences the beginning of the end-to-end project initiation.

To conclude, the effective launching of your project needs a defined process, which must be clear or else everything else will be flawed as well, since being involved with the current manufacturing solution consultation process ensures that the process of accurate quotation acquisition, hence providing a very good basis for the required manufacturing partnership that will be needed based on the requirements.

FAQs

1. Is end-to-end service design optimization possible?

Additionally, we have skills involving design for manufactability analysis. This may include geometry optimization, tolerance recommendations, and so much more. The main reason why this is done is to make sure that your design is at its best as far as cost is concerned.

2. What is a typical cycle time in design and production?

The exact duration required in a cycle would depend on how complicated the work is. The general process cycle time would typically vary between 4 to 8 weeks. However, in some cases, by doing concurrent engineering, this timeframe can be shortened between 3 to 6 weeks, and of course, we could give you a plan in place so that you would be able to track this process.

3. What are some steps taken to protect design information to prevent a breach?

We also follow certain confidentiality agreements. Along with that, we are using a data encryption and accessibility system. This protects our client’s design information from being misused. This has been achieved through the end-to-end encrypted data transmission and accessibility system.

4. Do you handle design change management?

We have change management design processes that entail change requests, change impact analyses, process updates, and traceability of documents to ensure that all our change management processes are well-documented and processed appropriately.

5. Minimum Order Quantity?

Flexible order models are applied ranging from single prototype orders to mass orders. For orders that are not prototypes, there are no minimum orders needed. For prototypes, the minimum order needed is 1.

6. How are acceptance standards for quality determined?

The acceptance criteria, too, would be established in accordance with our specifications, technology, and process capability so that there may be quantifiability and/or measurability of results as far as achieving a certain quality is concerned.

7. Are there notifications for the progress of productions?

For transparency and visibility, weekly/production stage progress reports that show the status for critical processes, quality checks, and plans for the next stage are provided.

8. How does the problem-solving mechanism work?

We also have an incident response system that operates on a 24x7 model where the initial response to issues is provided within 4 hours, resolving the incident within 12 hours, and root cause analysis and preventive activities simultaneously commence.

Summary

Being an end-to-end CNC machining services provider can be considered an effective solution development strategy of any business entity in the market. This will be due to the involvement of all the functions of product design, development, and manufacturing within the solution development strategy of the entity.

At LS Manufacturing, our aim of providing end-to-end CNC machining services will help you acquire your two most trusted partners. This will be due to the skills and experiences that are involved within the projects of our company.

From blueprint to finished product, precision is paramount. Your customized CNC machining service starts now.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.