Rapid prototyping CNC service addresses the critical dilemma faced by product development teams. They have a dilemma of either using fast but inaccurate prototypes produced using methods of 3D printing or using accurate but slow prototypes produced using traditional machining methods. Moreover, companies with a quick response time and a good degree of accuracy are very few in the market.

The error in this thought is underestimating speed prototype CNC machining in an effort to attain the optimized speed, accuracy, and cost with a better solution. Secondly, in most cases, a scientific basis will not exist wherein a team will be able to make an assessment of suppliers. Hence, this paper will highlight how this service is most ideal in verification with a view to identifying an assessment system in order to pick a level of suppliers, such as LS Manufacturing, which will be able to provide a mill tolerance in a matter of days.

Rapid Prototyping CNC Service Guide: Quick-Reference Table

|

Section |

Key Points |

Purpose/Highlights |

|

Introduction: The Prototyper’s Dilemma |

3D Printing vs. Traditional Machining; Speed-Precision-Cost trade-off; No skilled vendors. |

3D printing technology solves this problem in terms of speed and cost. |

|

Why Rapid Prototype CNC Machining? |

Application example for function verification. Fills a gap which naturally exists between Rapid Prototype and Production. |

Explanation for why this is an attractive option: Speed of 3D Printing + Strength/Resolution of standard CNC. |

|

Core Advantages & Applications |

Speed: Weeks become days. Precision: Tolerances are tight. Material Selection: True engineering plastics/metal. Surface Finish: Production-quality finish. |

Refers to benefit of evaluation consideration in form, fit, and function with production-quality parts. |

|

Service Provider Evaluation |

1. Capability: Types of CNC machining, materials, and finishes available. 2. Lead Time: Offers guaranteed quick-turn capabilities. 3. Communication: Feedback on DFM analysis, communication. 4. Examples: As with LS Manufacturing. |

Refers to some checklist information on a partnering service provider in providing good work and quick production. |

|

Implementation & Best Practices Tab |

Design for Manufacturability (DFM); Communicate Critical Features Clearly; Plan for Multiple Iterations. |

Shows an example of how to apply this service in order to achieve all these benefits without production delays. |

Rapid prototyping CNC service gives a strategic implementation in doing function verification successfully in a time efficient manner with accuracy without damaging materials. One can very easily do an accurate prototype in a short span of days through an evaluation on capabilities, time, and working with a supplier.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

It is not a textbook but an application in an information sea. Our involvement in this application takes place in high-risk sectors where accuracy is not an option but a necessity. For instance, when it comes to prototype aircraft production, our application strategy is focused on ensuring these aircraft work within given parameters according to guidelines provided by the International Aerospace Quality Group (IAQG). Our guidelines in medical prototype application are based on guidelines in relation to tests involving functionality and biocompatibility.

Our expertise is honed from thousands of rapid-turn projects. Every prototype is one which has honed our expertise in parameter optimization, ranging from aluminum to advanced thermoplastics. Apart from this, our expertise in machining with sustainability in consideration, in relation to best practices in accordance with guidelines from the Environmental Protection Agency (EPA), is another part of our expertise. Our personal experience provides information in relation to our clients on how they can avoid costly mistakes.

In all essence, all recommendations forth henceforth have withstood battle tests. To date, over 50,000 custom CNC machined parts have been shipped, most of which have been prototypes in tight project timelines. As much as this puts us at risk of exposure to knowledge concerning the nuances necessary pertaining to speed without impeding accuracy and integrity, your trusted source to better efficiency in rapid prototype CNC service shall be gleaned.

Figure 1: Automating CNC prototype production with industrial robots by LS Manufacturing

What Are The Unique Advantages Of Rapid Prototyping CNC Machining Compared To Other Rapid Prototyping Processes?

While 3D Printing absolutely does have an edge in a given situation if speed is a factor in developing an idea model and in a situation if a small series with aesthetic prototypes is all you need, it would appear that rapid prototyping CNC machining simply can not be beat if a means to come up with elements which are very close to being in production is exactly what you are looking for. Those engineers with prototype elements which have to fulfill not simply aesthetic but practical functions will find this a dream come true. Some of the very important factors can be compared in the table below.

|

Feture |

3D Printing |

Vacuum Casting |

Rapid Prototyping CNC Machining |

|

Material Fidelity |

Photopolymers, filaments |

Urethane resins |

Real engineering plastics & metals |

|

Mechanical Strength |

This Mech Usually anisotropic, weaker |

Varies, not production-grade |

Isotropic, production-identical |

|

Dimensional Precision |

Good, may have layer lines |

Good, depends on master |

Excellent, with tight tolerances |

|

Surface Finish |

Requires post-processing |

Good, from mold texture |

High, often ready for assembly/use |

|

Primary Application |

Concept models, form studies |

Small batches of appearance parts |

Functional prototypes, pilot runs |

In summary, rapid prototyping vs CNC machining highlights CNC’s superior capability for functional verification. It delivers unparalleled material authenticity, structural integrity, and precision, making it the best rapid prototyping CNC service for scenarios where performance matters as much as form. This process bridges the gap between a prototype and the final product, de-risking the transition to mass production.

How Do You Determine If Your Project Requires Rapid Prototyping CNC Machining?

All prototypes are not equal, wherein your selection will be based upon your project plans. Perhaps your end project with your prototype is perhaps to have a vision of your prototypes looks. Perhaps you may have other projects with other prototyping companies wherein they may be better for you. Anyways, you will perhaps need a prototype with a performance indistinguishable from your end product, wherein this is where a proficient rapid prototyping CNC machining service provider. A checklist below will help you make your selection:

|

Requirement |

Choose CNC Machining If |

|

Material Properties |

You can be working in the real world with materials such as Al or SS or even engineering plastics like PEEK & Ultem. |

|

Functional Testing |

The daemon's mechanical, thermal, or chemical conditions should not destroy your component. |

|

Dimensional Fidelity |

This is going to be a job of putting together the part and other pieces in a very exact manner. And anyone may remember, may recall, the tight tolerance involved. |

|

End-Use Application |

Whereas the dimensionality tolerance relies almost exclusively upon the dimension involved and the type of tolerance specified by the dimension. |

In other words, understanding how to choose rapid prototyping CNC machining is actually realizing the need for functionality validation. If you ensure that your project checklist contains everything mentioned above, then trusting a reliable CNC machining service for a rapid prototyping job will be the most reasonable decision you will ever make.

How Can Professional DFM Analysis Save You Time And Costs For Rapid Prototyping?

The fact is, a highly efficient rapid prototyping CNC machining begins before a CNC machine ever starts. The right paths to successful time savings and control over your cost of rapid prototyping CNC services are in DFM analysis. A professional design for manufacturability analysis will point out potential issues which can affect your production and, consequently, will fast-track your path from file to finished part. Here is how this analysis adds value:

- Geometry for Max Machinability: While an expert designer would take into consideration deep cavities, corners, and thin walls, it would be advisable to follow recommendations by the service with regards to minor modifications that can be added to designs, such as additions which can be used in ensuring a safe distance from trouble during machining. This directly reduces machining hours and is a hallmark of the best rapid prototyping CNC service.

- Use of Rational Tolerances: It is a proven fact that over-specification of tolerance on all dimensions adds to the cost. DFM analysis performs a critical and non-critical evaluation of the elements and proposes achievable standard tolerances on non-critical elements. Thus, unnecessary machining operations are not performed. The cost and time are lowered without impacting the function of the prototype.

- Material & Setup Planning: Material selection and part setup in a machine bed is a very large consideration in this step. Some guidelines in DFM include selection of preferable stock size and planning for an efficient setup with fewer turn numbers/Refixture.

-

Proactive Feedback for Success: A service like LS Manufacturing rapid prototyping provides this analysis as a standard, collaborative step. Their engineers offer free DFM feedback, translating design intent into a machinable blueprint. This partnership prevents costly misunderstandings and revisions, ensuring your project stays on schedule and budget from the very first article.

This means that professional DFM is not an after-process but an investment in your project, and this will reduce the cost of rapid prototyping CNC services delivery in the end. With this in mind, you will now have two advantages: you will benefit from working with a company such as LS Manufacturing that holds such knowledge in the early stage, which will provide you with a good prototype and a fast and predictable stage of development, thus solidifying them in becoming among the best rapid prototyping CNC service partners.

What Key Details Should Be Paid Attention To When Obtaining A Quote For Rapid Prototyping CNC Machining?

A complete and clean set of information is necessary for a right and competitive rapid prototyping CNC quote. A quotation request with more information will require less rounds, will not include unforeseen expenses, and will allow service providers to actually evaluate your project, which will have a massive effect on a total cost of rapid prototyping CNC services. The good beggars are half begged.

- A Complete and Clean Digital Model: Every quotation for a product starts with your 3D CAD file. Your model can be transmitted in a neutral file format, such as STEP or Parasolid, with a complete, clean geometry. A model with unclear and/or broken geometries will mean manual work on your part in a manufacturer, resulting in increased time and increased cost of rapid prototyping CNC services.

- Specify Material and Post Processing Needs: Let us know where you are with materials, such as 6061-T6 aluminum or 316L stainless steel, and any post processing requests you have, such as anodizing, bead blasting, or heat treatment. Such kinds of considerations mean massive fixed expenses. Being specific upfront allows the supplier to provide a comprehensive rapid prototyping CNC quote that includes all finishing steps, avoiding "surprise" add-on fees later in the project.

- Critical Dimensions, Tolerances, and Inspection Requirements: A product is not a product in all respects. Could you please point out which dimensions are important in function and which tolerances these dimensions need on a 2D drawing or model. Additionally, please inform us if an inspection report is needed, such as when using some of the symbols in GD&T. Please detail your requirements in critical dimensions so a machinist can work towards a goal of critical quality, but prioritize ensuring a low cost of rapid prototyping CNC services with non-critical dimensions.

- Specify Quantity, Lead Time, and Other Specifications: Describe your requirements in terms of quality, time, and other specifications such as certifications pertaining to matters of materials and packaging. Quantity affects machine setup directly, and shortening lead time can influence shipment. Transparency on all fronts enables the provider to structure the optimal and most transparent rapid prototyping CNC quote for your specific needs.

In total, all these explained facts make a way for getting the most precise rapid prototyping CNC quote in the shortest time length possible. A service provider will need a clean model, specific specs, and right expectations to provide you with a fair and accurate competitive cost of rapid prototyping CNC services. It is from this disciplined approach that securing assistance in deriving a way to control total cost of rapid prototyping CNC service delivery is achieved.

Figure 2: Integration of rapid prototyping in the advanced manufacturing domain by LS Manufacturing

Case Study Of An Aluminum Alloy Prototype For An Autonomous Driving LiDAR Bracket: How LS Manufacturing Achieves Delivery Within 7 Days

Rapid iteration is a critical consideration in a very rugged environment such as self-driven vehicles. The case study will show how a win-win relationship between a given entity and a responsible responsive rapid prototyping CNC machining provider with critical time limits successfully sidestepped an imminent obstacle in competitive superiority.

Client Challenge

A customer faced an impossible time constraint of just 10 days when they were unable to get dozens of light and strong aluminum brackets to install lidar devices in a manner fit for a real-world inspection test. Although conventional machine shops did not have a sufficient time window to fulfill this order, 3D-printed components were not stiff and robust enough.

LS Manufacturing Solution

LS Manufacturing rapid prototyping initiated a 4-hour DFM analysis immediately upon receipt of a CAD model. They proposed a series of minor rib modifications to improve machining speed with a negligible impact on rigidity. Based on this analysis, subsequent parallel programming and preparation work using a fast-turn production line were carried out– all work accomplished quickly. Machined in continuous shifts, day and night, using multi-axis CNC machines with fast anodizing, part completions occurred by day six.

Results and Value

The client received the fully finished, performance-qualified prototypes on the seventh day. This not only allowed them to proceed with the critical road test on schedule but also validated the design under real conditions. The success of this rapid, high-fidelity prototype directly paved the way for a follow-up order of 500 units for pilot production, establishing a foundation for volume manufacturing. This exemplifies the value of choosing the best rapid prototyping CNC service for mission-critical functional validation.

Finished performance-qualified prototypes were delivered to the customer on day seven. In this way, they not only fulfilled their critical road test on time but were able to validate their design under operating conditions, which worked wonders in securing a follow-on order for pilot production of 500 units nearly with an immediate after-effect, securing volume production. This exemplifies the value of choosing the best rapid prototyping CNC service for mission-critical functional validation.

Your project facing a tight deadline? Contact LS Manufacturing immediately for an expedited solution!

What Core Capabilities Should Be Considered When Evaluating A Rapid Prototyping CNC Machining Service Provider?

Partner selection is a key ingredient in any successful prototyping effort. In a comprehensive evaluation of a service provider in prototyping, you would want to look much beyond a price tag that considers a skill set existing underneath a service provider, and can validate them qualified in terms of speed, quality, and cost. A good rapid prototyping CNC service provider can become an extension of your research team.

Mechanism of Rapid Response and Dedicated Capacity

Check in what way they specialize in their rapid response. A specialist will have an efficient mechanism set up for rapid quotes, which are dished out in hours, not days. To put it another way, they will have rapid response production capacity rather than adding capacity to an already high volume of production. This focus ensures your prototype project receives immediate priority and predictable scheduling, a key factor in how to choose a rapid prototyping service effectively.

Engineering Support & DFM Know-How

The goal here is to try to have any idea of how much you might be able to offer each other. They will or might be very interested in your free DFM analysis. The LS Manufacturing rapid prototyping service within this context provides all of the above information together, though they do not offer any redesigns. The purpose of a very good service is simply that it is supposed to offer a source of a speed boost to your project.

Quality Assurance/Readiness of Material

Then, it shall be necessary that you begin the pre- qualification process for your functional prototypes. Then shall commence the issue of inspectability, whereby it shall begin to be relevant within the context of your research that shall possess the requisite element that shall be relevant to the issue that relates to your function. Then shall also be relevant the materials that have been used for your prototypes of aluminum series, POM, as well as PEEK series. Then shall also result that your readiness of material within a night shall Render null and void every readiness that you now possess.

Communication and Project Managementwzoremus

This is where they could have elaborated on the communication level, both from your side and from their side, pertaining to your question pertaining to every aspect of any project, as this was in response to your question from your project engineers as to how they will provide you with full and complete transparency pertaining to the communication from their side regarding every aspect of the projects they tend to deal with since they already have your project registered in their database.

Thus, in order to finally finish the procedure for the determination of the rapid prototyping CNC service provider, the practice of the holistic method in relation to the operational DNA will be applied. The most prominent attention will be focused on the partners that possess the capability for the stiff response mechanism. By applying this framework in how to choose a rapid prototyping service, you can confidently identify capable partners like LS Manufacturing, ensuring your prototypes are delivered on time, to specification, and at the optimal value.

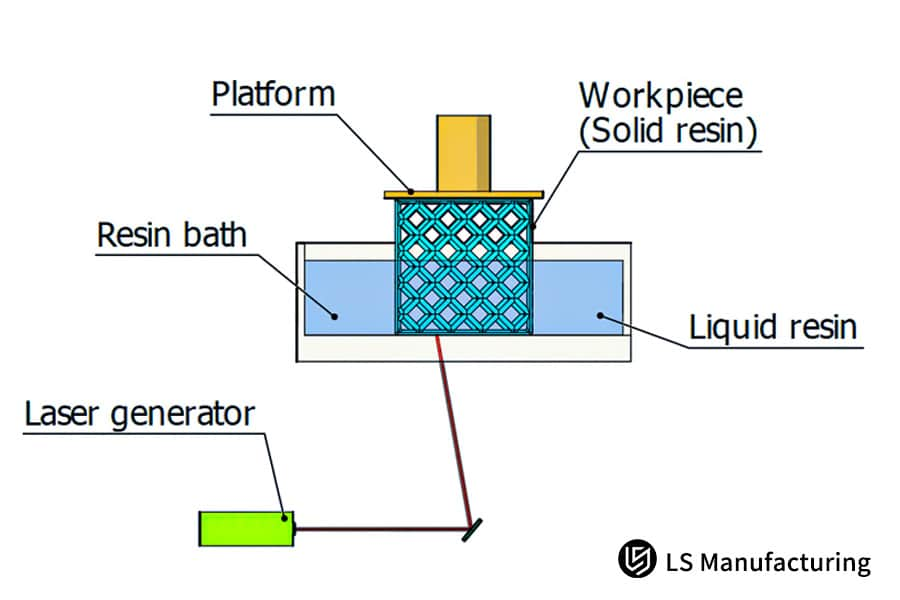

Figure 3: SLA / Stereolithography rapid prototyping system schematic by LS Manufacturing

What Is The Typical Cost Structure And Cycle Time For Rapid Prototyping CNC Machining?

The other party involved within the planning stage of the job or the project will likewise include the understanding of the division of time and the cost ability. The rapid prototyping CNC machining will include diverse lead times ranging from 3 to 7 weeks depending on the cost of rapid prototyping CNC services:

Cost Drivers

The general estimate for the expense incurred in the cost of rapid prototyping CNC services will include the following division of the costs, which are mainly incurred in the process. There are three kinds of costs, mainly involved in the costs incurred within the process. Of which, this is mainly involved in the materials and the sizes. The programming and preparations are not ROI-free in relation to the activities involved in the path preparations of the CNC machines. The third kind, mainly related to the machine times and high variability, is calculated in relation to the total processing time of the CNC machine.

Key Influencing Factors

The parameters are diverse, mainly involved in the final rapid prototyping CNC quote and the times involved in the process. They include part sizes and complexity, materials, and the finish processes like anodizing, and sizes of the orders, in relation to the dissemination of the costs of setup. The costs in units decrease, and thus the larger orders will result in the diminution of the costs.

Competitive Value Realization

Both the companies, in this case the LS Manufacturing and the contract manufacturers, largely emphasize cost and time efficiency for the production system processes. They demand large knowledge of the DFM of components requiring easy machining. There is also a stress point regarding the positioning of parts on a sheet that would result in minimal wastage of material. These demand large tool path programming that would facilitate quick turnaround of production of complex profiles for machining.

A clear rapid prototyping CNC quote should outline the breakup of the cost regarding the components depending upon the material involved in the cost of the CNC services project. Keeping this point in mind, it would become relatively simpler for you to assess the quote regarding your project involving customized components that differ regarding the material and size. Therefore, the most suitable partner for the project would essentially remain one that would continually endeavor to optimize the cost of rapid prototyping CNC services.

How Does The Process Differ When Working On Rapid Prototyping Projects With LS Manufacturing?

The availability of the real expert will ensure that the whole process involved in the rapid prototyping would stay smooth and rapid in nature, which is against the process involved within the transaction due to the acquisition of the prototypes that would take place from the source which remains unknown. The whole process starting right from the ordering process till the delivery of the prototypes will thus remain involved within the clean environment differing to the rapid prototyping CNC machining cooperation process.

Instant Interaction & Professional Feedback

That would involve uploading your files easily for a rapid prototyping CNC machining quote. This will, however, follow an instant engagement on a complimentary manufacturability analysis of your design. In this case, in order to address variables of both time of processing and cost of manufacture, LS Manufacturing rapid prototyping engineers will engage or alter your design free of charge.

Fast Production and End Visibility

It shall qualify for inclusion on its own right for fast production for specialists in this area. The most critical component, however, is your having an interface for an entirely transparent project management system. There thus shall exist an entirely transparent production process flow for your regime concerning machine operation and their completion for the implication of an optimized rapid prototyping CNC machining cooperation process.

Integrated Quality Assurance and Logistics

One of the most significant aspects of quality assurance and control is that these processes will not form the final process procedure but will instead become an integral part of the same. The most critical sizes will then become objects of scrutiny in this process, and finally, the entire process will verify the piece before finally delivering them out to their destinations. All your paperwork from the completion of the point of inspection report to the tracking report will then become a reality as an integral part of your interface and will therefore ensure your reception of the piece in the exact same way as agreed for the very initial commencement of this project.

The very crucial difference here, then, is based on holism and rapid procedure-based operational undertones from the very onset, every stage optimized for rapid procedure operational undertones and ease of understanding and comprehensive undertones too. What differs from here with respect to maintaining partnership for LS Manufacturing rapid prototyping then relates to your having the interface for the optimal procedure to facilitate cooperation with your scheduling and uncertainty reduction—pieces and confidence in competitiveness.

Figure 4: Showcasing high-tolerance black CNC prototype parts by LS Manufacturing

FAQs

1. How swift is your 'swift' delivery service?

With your need for speedy turnover in relation to the delivery of your prototype, considering standard complexity and materials used for aluminum, we ensure our commitment will definitely be within 3-7 working days. As to urgent needs that you have pointed out, this will become clear as we discuss the facilities available for production.

2. What is the minimum order quantity (MOQ) for rapid prototyping CNC machining?

In the area of application wherein the intense focus of product development is applicable, it is flexible support wherein acceptance of an order for a single piece and MOQ unlimited. Trust me, it is strictly ideal for prototype development and testing of batches, which will surely help you develop with minimum development costs.

3. How do you verify the accuracies on your prototype parts?

It is, yes. The rapid prototypes are offered in the company with a stipulated quality control process meant to ensure that the tolerance level of a huge majority of our service prototypes is close to ±0.05mm. Critical dimensions of prototypes developed are precise to ensure the prototypes work just like they are intended to work when they are assembled.

4. Do you provide supporting documentation and quality inspection reports?

Of course, we do this for you and your products. In case of need, we also go one step further by providing an inspection certificate for the critical dimensions.

5. How, if at all, will functionality change once the refresh is implemented based on submitted suggestions using DFM?

You can rest assured that as a service provider for a DFM solution, advice-which will invariably be on top of all others in terms of product functionality-will specifically relate to the optimization of manufacturability vis-à-vis other process aspects.

6. How can I ensure the security of my design intellectual property?

One of our most serious concerns is to protect your rights of intellectual property. We totally respect every agreement of confidentiality that we conclude. The availability of all your designs was also coded through an encryption algorithm in order to guarantee that from the very beginning up to the end of our agreement, your designs and personal details are well-protected.

7. How would a new customer initiate the process in terms of his first projects?

Finally, from the customers' point of view, all that they would have to do is log in to our website and provide us with their files through our online quote page. In addition, their first order would be followed up by a call from our project manager within an hour.

8. Is small-series production possible based on prototype test results?

Of course, it will be very easy for us to provide a transition process smoothly for your prototypes and then for your small product batches so that your smooth market entry is ensured.

Summary

Hence, the right rapid prototyping CNC service for your project might just become an important point to reckon with in reaching the target for innovation in the product that could have been easily validated within an impressively short timeframe with a huge amount of precision. Not to mention, it is not only your research and development process that benefits from this, but quite a good foundation for the whole production procedure would also have been laid.

As goes the saying, "Time waits for no man!" Let our expertise in rapid prototyping CNC service make your product do an about-face in no time. You simply need to click "Get Instant Quote and DFM Analysis" and submit your 3D file, and in four hours we will come out with the complete solution to keep your product ahead.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.