In the product development sprint, are you faced with an agonizing choice between 3D printing and CNC rapid prototyping? Determining the best combination of material performance, delivery speed, and project cost is a core dilemma facing most engineers and procurement managers.

The intrinsic difference between 3D printing and CNC lies in their technology principles: 3D printing does free-form modeling extremely fast with layer-by-layer addition, and its strength is intricate structures as well as rapid iterations; CNC, however, manufactures dense material and excellent mechanical properties according to mass-produced parts through subtractive machining.

CNC or 3D printing selection for rapid prototyping involves more than one-over-the-other choosing. As your strategic manufacturing advisor, LS Manufacturing, with its long-term dual-track technical experience, is committed to providing objective process selection and integration solutions. Our advantage lies in exactly analyzing your project requirements and guiding you towards optimal cost, efficiency, and quality balance. To save you time, here’s a quick overview of the core conclusions.

CNC Rapid Prototyping vs. 3D Printing Core Quick Reference Table

| Comparison Dimensions | CNC Rapid Prototyping | 3D Printing |

| Core Technologies | Subtractive manufacturing, material removal with a tool | Additive manufacturing, layer by layer adding material |

| Material Properties | Isotropic, identical to final part, high strength, wide selection (metals, engineering plastics) | Anisotropic, weaker interlayer strength achievable, limited selection of material by technology (photosensitive resins, nylon, some metals) |

| Geometric Complexity | Limited by tooling availability, difficult to machine extreme undercuts and cavities. | Semi-limited, quite proficient at multi-camera complex geometries, hollowing, and combined molding. |

| Prototype Accuracy/Surface Quality | Extremely high, to ±0.025mm, excellent surface finish, suitable for direct functional testing. | Medium to high, typically post-processing to create a smooth surface, layer marks would be visible. |

| Speed v. Cost | High per-part cost, lengthy setup time, suitable for small runs (1-10 pieces), no per-part cost savings for large production. | With fixed per-part cost and extremely brief setup time, it is ideal for individual and complex parts. |

- With no tooling fee and high economic efficiency for small runs, the following short reference table forms a convenient decision-making scheme.

- Where your prototypes must endure high strength and heat resistance and undergo intense functional testing, CNC rapid prototyping is preferable.

Where high speed, design flexibility, and complex geometry integration are your top requirements, 3D printing has unbeatable advantages. The correct choice begins with the understanding of the inherent nature of both.

Why Trust This Guide? Real-World Experience From LS Manufacturing Experts

The remarks we make here are not scholarly; they're the combat-proven expertise LS Manufacturing has acquired through 20 years of doing thousands of rapid prototyping jobs. We're not just a contract service bureau for the two technologies; we're your manufacturing planning navigator. Our technical team completely understands the boundaries between CNC and 3D printing and has walked customers through hundreds of thousands of junctures.

As an example, why would one specific auto intake manifold prototype have to be CNC machined for high-pressure and temperature testing when another medical stent prototype with complex conformal water channels achieves unmatched performance through metal 3D printing? It is this vast experience based on real projects and balancing cost, efficiency, and quality that provides us with the special ability of analyzing and combining dual-track procedures from an objective viewpoint.

Trust LS Manufacturing and let us use our tried and tested experience to ensure that your next high-risk project is a success.

CNC vs. Industrial 3D Printing: How Do Principles Determine Part Performance?

The major distinction between CNC and 3D printing is their corresponding "subtractive" and "additive" manufacturing principles, respectively, which have direct implications for the performance limit of the finished part.

1. CNC: Derived from the Density and Isotropy of the Substrate

CNC rapid prototyping uses a cutter to take away material from a solid substrate through cutting. Its basic advantage is that the part that remains has the same dense internal structure and uniform mechanical properties as the original material. That means that regardless of the orientation of applied stress, its strength, stiffness, and thermal resistance are isotropic, like in traditionally machined components as well as end-of-line mass-produced components, and therefore an ideal candidate for high-reliability functional validation.

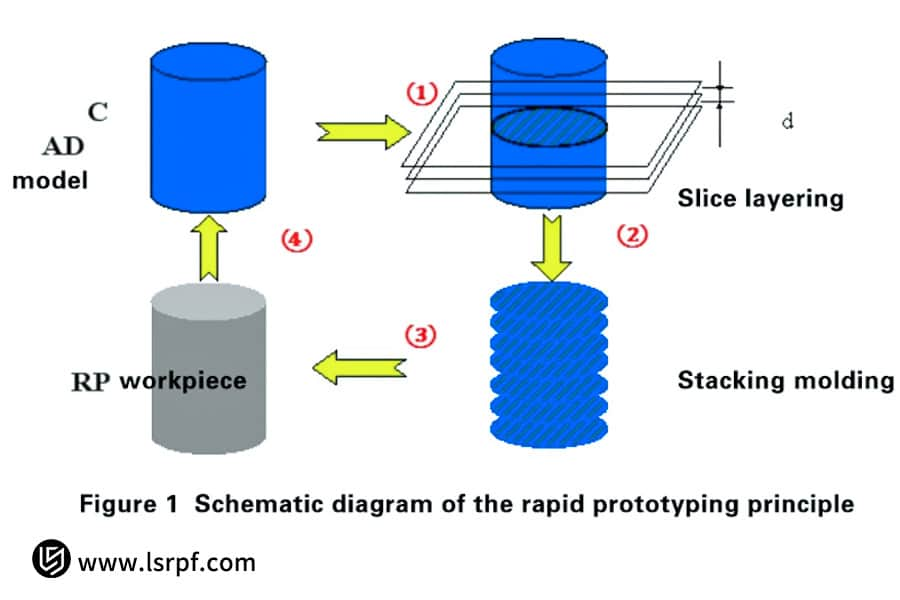

2. 3D Printing: The Potential and Challenges of Layer-by-Layer Deposition

Industrial 3D printing builds parts by material deposition (melting/solidification) in layer mode. Such an approach provides unparalled geometric freedom but may also be responsible for microscopic problems, e.g., bond strength between layers slightly lower than that of the bulk material. This causes anisotropy in some directions and microscopic internal porosity. It is based on highly developed calibration of equipment, materials, and process parameters.

This is the key to comparing rapid prototyping technologies. CNC provides real material properties by "subtracting" from the material, whereas 3D printing allows infinite design freedom by "adding." To comprehend this basic difference is the starting point for choosing the appropriate process for your mission-critical application.

When Is CNC Rapid Prototyping The Best Choice For Functional Testing?

When your prototype needs to be able to simulate the real operating conditions of the end product in the field, CNC rapid prototyping is generally the most reliable way of functional testing. So then what technology is suited to functional prototyping? The answer lies in very high requirements for real material properties.

1. Handling Severe Mechanical and Thermal Loads:

When prototypes are subjected to high mechanical loading, shock, rubbing, or high temperatures over a long period, CNC-machined parts, because of their compact inner structure and isotropic mechanical properties, can exhibit equivalent fatigue strength, stiffness, and thermal resistance to production parts, ensuring test data integrity and reproducibility.

2. Matching Specific Engineering-Grade Materials:

Most of the functional testing requires prototypes to be built with some particular engineering plastics (such as PEEK and ULTEM) or high-strength aluminum alloys (such as 7075) in order to provide the required strength, chemical resistance, or heat deflection temperature. CNC rapid prototyping and direct machining off such solid billets maintains the very inherent superior properties of the material itself intact, whereas 3D printing is generally limited by the spectrum and nature of available materials.

Where functional test success is crucial to product design failure or success, CNC rapid prototyping is the choice for performance dependability and assurance. It ensures your prototype not only appears as the final product, but behaves like it as well.

When Should You Turn To 3D Printing For Speed And Design Freedom?

When prototyping basic needs shift to revolutionary speed and geometric constraint-breaking, it's an irrefutable signal to consider 3D printing. In considering CNC vs. 3D printing for prototyping, if your product contains the following characteristics, 3D printing will exhibit unprecedented advantages.

1. Breaking the bottleneck of design complexity:

3D printing has essentially no geometrical limitations, and it is easy to print prototypes with extremely complex inner flow channels, honeycomb lightweights, or embedded, hidden moving parts. Such structures simply cannot be created at all, or are prohibitively expensive to manufacture, using CNC and multi-axis machining and fixturing. This inherent design freedom is a natural progression for topology optimization and generative design verification.

2. Pursuing Unparalleled Iteration Speed:

From digital models to tangible parts, 3D printing saves the laborious front-end work of programming, setting up fixtures, and aligning tools. For proof-of-concept ventures or designs that take several iterations within a day or two, 3D printing can create a tangible part in a matter of hours to more than a decade. Its speed and cost-effectiveness are most essential during the early stage of development.

This rapid prototype technology categorically says that if your biggest concern is to have the ability to test form and confirm intricate functional structures quickly, then 3D printing is a better option. It breaks free of conventional manufacturing methods so that designers have the freedom to think and work on something new.

How To Quantify The True Costs Of CNC And 3D Printing?

In order to make an informed process choice, one must move beyond the per-part price quotation and look at the total cost of CNC and 3D printing. The key is understanding their varying cost structures: 3D printing cost increases linearly with volume and complexity, while CNC cost is characterized by "unit setup costs" and "unit processing time." To illustrate, the following table describes the cost structure of a typical part:

| Cost Structure | CNC Rapid Prototyping | 3D Printing |

| Per-Part Cost Model | High initial cost (programming and setup), but then per-part cost increases incrementally. | Very low initial cost, but per-part cost increases linearly with amount of material/printing time. |

| Small batches (e.g., 50 sets) | Initial costs are distributed, reducing overall per-part cost significantly, making them less expensive. | No cost amortization advantage, total cost is approximately "per-part cost x quantity." |

Therefore, the greatest cost distinction between CNC and 3D printing is complexity and quantity:

- When rapid verification of 1-10 parts is required, 3D printing is generally less expensive.

- When small quantities of 10-50 functional prototypes or pilot production components are required, the amortization advantage of CNC rapid prototyping will generally result in total cost of ownership being lower.

How Does LS Manufacturing Optimize The Machining Process For Robotic Joint Components?

Faced with a customer's opposing dual requirements of strength and complex internal cavities in an articulated arm housing prototype robot, LS Manufacturing, through a careful combination of processes, provided the optimal answer to the question, "Which technology is best suited for functional prototyping?"

1. Client's Dilemma:

A robotics company needed to finish designing an articulated arm casing within three weeks. The component required high-strength aluminum alloy for handling heavy loads and internal sensor cavities requiring rapid testing. The period was short and the performance demands were extremely stringent.

2. LS Manufacturing Solution:

Instead of merely recommending a single technology, LS Manufacturing designed a phased, optimized process strategy:

- We first used SLS 3D printing to rapidly produce nylon prototypes with three various internal cavity designs so the client could select the optimum sensor layout in a matter of days.

- After the electrical design was frozen, we initiated CNC rapid prototyping immediately, using the identical aluminum alloy of production quantity to produce a working, high-strength prototype for structural load testing of the critical structures.

3. Results and Value:

This solution perfectly addressed the question, "Which technology is best for functional prototyping?"—and the answer is not one option. The client finished both electrical and structural verification on budget, reducing the design iteration cycle by 50%. The extremely confident CNC prototype passed key safety certifications, providing a strong foundation for a rapid time to market.

LS Manufacturing's core philosophy is to be your strategic manufacturing advisor. With our comprehensive dual-track technical capabilities and wealth of real-world know-how, we provide unbiased analysis and end-to-end solutions that are greater than the whole of one technology.

What Are The Surface Quality And Accuracy Commitments Of The Two Technologies?

In a comparison of rapid prototyping technologies, surface finish and accuracy are significant indicators that fuel the suitability of prototypes. CNC rapid prototyping and 3D printing differentiate themselves in this regard at a fundamental level, and understanding this difference helps in establishing realistic expectations for quality.

1. CNC: Out-of-the-box Surface Quality and Accuracy

CNC rapid prototyping is actually a very accurate cutting process, obtaining the finishing quality of the final product. It is capable of directly obtaining mirror finishes or specific textures, with ease retaining dimensional accuracy of ±0.025mm or higher. It means that prototypes can be used for presentation outside the company, assembly checking, or as master patterns for investment casting without post-processing steps.

2. 3D Printing: Reliance on Post-Processing to Meet Application Requirements

Components produced using 3D printing usually exhibit surface wrinkles that are apparent when they come out of the machine, an inherent artifact of the layer-by-layer building process. Plus, curing/cooling shrinkage can give them minute deformations. The absolute accuracy can be extremely high, but a surface finish that is smooth requires post-processing treatments such as grinding and sandblasting, and this takes time and money.

This rapid prototyping technology teaches us that if your project requires out-of-the-box, high-gloss finish and tight dimensional tolerances, CNC rapid prototyping is a safer bet. But precision of 3D printing is predominantly required for the achievement of the shape, and its surface quality has to be completely taken into account with post-processing.

Why Is LS Manufacturing's "Hybrid Manufacturing" The Preferred Choice For Complex Projects?

When a single production process is confronted with technical hurdles, LS Manufacturing's "Hybrid Manufacturing" strategy proves its value in determining ultimate success. It goes beyond simple comparison of rapid prototyping processes, acquiring supplementary benefits through intelligent integration. The Limitations of Traditional Manufacturing and Our Breakthroughs:

For injection mold design, conventional CNC machining is unable to produce conformal cooling channels with high conformity to the product shape. Going all the way with 3D printing also is failing to deal with the extremely high surface hardness and accuracy requirements of the mold cavity. Faced with the dilemma, LS Manufacturing's solution is:

- 3D Printing for Functional Innovation: LS Manufacturing first uses metal 3D printing to produce core inserts directly with complex conformal cooling channels, achieving cooling performance unattainable using traditional manufacturing methods.

- CNC Offers Basic Accuracy: We obtain the use of high-accuracy CNC rapid prototyping to machine the mold cavity, delivering last-stage dimensional accuracy, surface finishing, and strength to handle loads.

By incorporating 3D-printed functional inserts in the CNC rapid prototyping manufactured mold body, we practically achieved a 40% reduction of cooling time as well as significantly reduced product deformation for our customer.

This is the essence of LS Manufacturing's "hybrid manufacturing" philosophy—we do not just provide processes but also an optimal manufacturing environment tailored to your specifications, based on an intimate understanding of comparative rapid prototyping technologies.

How Can I Obtain LS Manufacturing's Process Recommendations Based On Project Parameters?

When faced with the difficult decision of whether to prototyped via CNC or 3D printing, you don't have to go it alone. LS Manufacturing offers a simple, professional, and completely free "Manufacturing Feasibility Assessment" service, deconstructing complex technology choices into an objective report based on your project specifications. To get started, you simply provide the following simple project information:

- 3D Model File and Accuracy Requirements: Provide your design information as the basis for our geometric complexity, wall thickness, and rapid prototyping technology comparison evaluation.

- Material Properties and Usage Environment: Specify your requirements, e.g., the strength, temperature stability, or biocompatibility the material is required to have, and whether the prototype will be used for visual display, assembly inspection, or functional test.

- Budget, Quantity, and Timeline: Share your target quantity, project budget, and desired timeline with us. This is necessary to allow us to accurately suggest 3D printing solutions or CNC rapid prototyping services.

Once we get your information, our knowledgeable team will conduct a detailed analysis and provide you with a comprehensive assessment report within one business day that includes proposed processes, combined solutions, transparent pricing, and assured delivery timelines.

Whether you're torn between prototyping with CNC or 3D printing or simply need to balance the benefits of hybrid manufacturing, tell us your challenges. Send us your project parameters today to access our exclusive, expert manufacturing plan for effective and safe decision-making.

FAQs

1. I need a prototype that can withstand high-temperature environments. Which technology should I choose?

CNC rapid prototyping is my choice. This technology processes engineering plastics having high temperature resistance like PEEK and ULTEM, and metals like titanium alloys straight away. The resulting product consists of a densified microstructure with heat resistance and mechanical properties similar to the final part, and can withstand over 150°C of temperature. 3D-printed parts, nonetheless, are plagued by interlayer bonding and porosity issues, which lead to performance degradation and reliability issues during prolonged exposure to high temperatures.

2. If my design is likely to change frequently, which method is more cost-effective?

3D printing is very recommended in the early phases. At proof-of-concept phase, the design would most probably have to be changed many times. 3D printing eliminates re-manufacturing tooling and fixtures; modifying the digital file means the revisions can be very quick, with low cost per revision. If the design is eventually frozen, and extensive functional verification is required, then CNC can be utilized to produce high-performance prototypes. This dual approach makes maximum total cost.

3. Can CNC rapid prototyping produce the same complex internal lattice structures as 3D printing?

Direct manufacturing is not generally possible. Physical accessibility of CNC tools is limited by machining pathways, and hence they cannot access closed cavities and machined integral internal meshes. This is the intrinsic advantage of 3D printing technology. But for complex shape or multi-component assembly structures, CNC can break the part into individual parts to achieve precision machining and then high-precision assembly to obtain the ultimate function.

4. Does LS Manufacturing offer both services?

Yes, we do, and this is our key strength. We have a full scope of CNC machining centers and industrial-level 3D printing facilities. This allows us to give you fully objective process recommendations on your project needs (for example, performance, cost, and delivery time), without skewing recommendations in favor of our own equipment capabilities, so you always get the best manufacturing solution for your needs.

Summary

In choosing between 3D printing and CNC rapid prototyping, there is no one-size-fits-all response. The key is to accurately match the performance needs, the time need, and the budget scenario of a particular project to the inherent strengths of each process.

As your trusted manufacturing guide, LS Manufacturing applies its two-path technical acumen and significant real-world experience to provide you unbiased process comparison and complete solutions. This ensures that every prototyping decision attains the ideal balance of cost, efficiency, and quality, making for a solid foundation for product success.

Contact LS Manufacturing today and provide your 3D files and project specifications to benefit from our expert manufacturing consulting services. LS Manufacturing promises to return to you with a full "Process Comparison and Proposal" within 24 hours, consisting of clear process recommendations, open pricing, and delivery schedules guaranteed.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.