Ceramic CNC machining technology is a revolutionary advancement in precision manufacturing. It surpasses the limitation of traditional processes in machining high-hardness and high-brittleness ceramic materials. It perfectly merges the precision of digitization control with ceramics' remarkable physical and chemical properties, such as high-temperature resistance, corrosion resistance, and high hardness. Using extremely high-precision CNC machine tools, the technology enables the last machining of delicate three-dimensional ceramic components at the micron or even submicron level with immaculate dimensional uniformity and surface integrity. In this article, we will present a detailed overview of the CNC machining processes, advantages, and applications in ceramics. We hope the reader may find this guide helpful.

Quick Reference: Choose Your Tap at a Glance

| Category | Key Elements & Description and Data | |

| Material Properties |

|

|

| Processing bottleneck |

|

|

| Cost Structure |

|

|

This guide provides a complete understanding of ceramic CNC machining and helps you make informed decisions while choosing this technology. Let LS be your friend to a more efficient ceramic machining process!

Why Trust This Guide? Practical Experience From LS Experts

At LS, we're not talking about theory. Our ceramic CNC machining staff has a lot of experience with ceramic CNC machining. We are a producer of ceramic CNC machining knowledge, but more significantly, we fully understand the cost and yield issues you are facing because each recommendation has been practiced scores of times on our shop floors. Most revealing is the record-setting 95% finish yield we manufactured on an ultra-thin-walled ceramic cavity piece for a blue chip world medical device client. This achievement is a result of our unique knowledge of material behavior, toolpath strategy, and stress management.

Choosing LS guarantees you're benefiting from disciplined, field-proven technologies that will bring your project from theory to profitable business, with a safe and solid return on investment.

How Does CNC Machining Of Ceramics Excel Beyond Conventional Processes?

The development of CNC ceramics machining technology has completely overcome the unavoidable limitation of traditional processes for high-performance ceramic materials, opening a new era of precision manufacturing.

Traditional machining of ceramics was primarily achieved through slow and highly skilled operations such as grinding, lapping, and polishing. Not only are they inefficient, most importantly, they are not adequate for complex pieces with very high precision. Their built-in brittleness and hardness are the bottleneck, and they are more susceptible to in-hidden defects such as chipping and microcracking when being machined. Hidden imperfections like these drastically affect the ultimate lifespan and reliability of the product. While the skill of the craftsman dictates the highest degree of the product, it also places the quality out of his control, making it difficult to maintain it up to par, hence severely limiting the widespread application of ceramics in precision applications.

Ceramic CNC machining technology, on the other hand, is a technological innovation. It combines high-accuracy digital instructions-based CNC machine tools with patented diamond cutting tools. Through accurately dictating cutting path, depth, speed, and coolant via digital data, it provides for "micro-removal" machining in the micron or even smaller range. The process efficiently eliminates crack initiation and propagation, optimally preserving ceramic part structural integrity. Second, the programmability of CNC lends it a unique capability for "freeform modeling." No matter how complex a three-dimensional surface, delicate interior cavities' geometry, or thin-walled feature, as long as it is computable, a CNC machine tool can accurately replicate it on the ceramic blank, which cannot be done manually.

In short, ceramic CNC machining not only eliminates the issue of "can it be machined?" but also revolutionizes the problem of "how to machine it with high quality, high efficiency, and high consistency." It actually spans the outstanding properties of ceramic material from ideal properties in the laboratory to high-reliability products and makes mass production available in real production and induces disruptive innovation in applications ranging from aerospace to biomedicine.

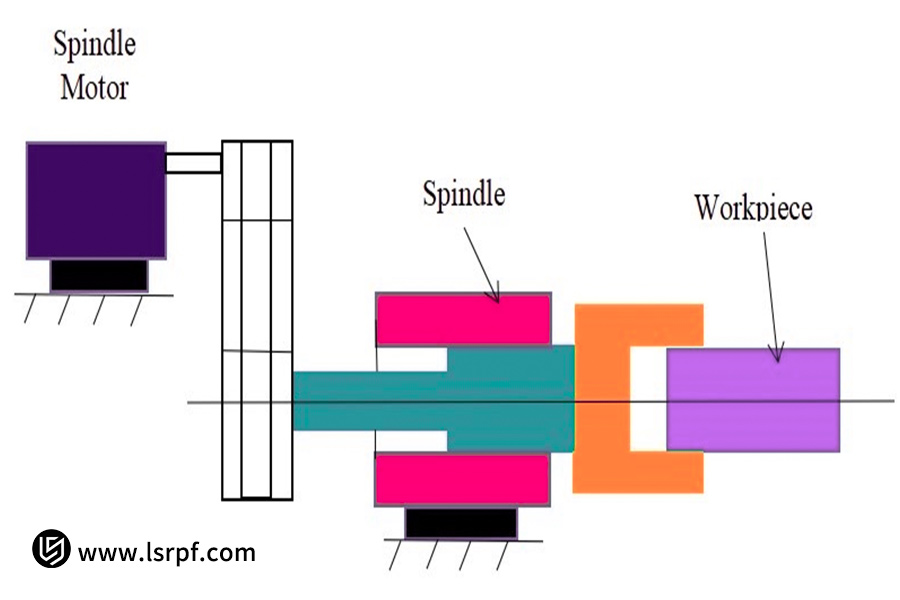

Figure 1: Ceramic CNC machining illustrating spindle and motor assembly for mechanical engineering and manufacturing education.

Why Are CNC-machined Ceramic Components The First Choice For Precision Manufacturing?

In the precision manufacturing field, where it's looking for ultimate performance and dependability, CNC-machined ceramic parts have traveled far from being an alternative to being a first choice. It's not coincidence; There are its unmatched set of advantages. It completely provides the high-end industries stringent specifications of material performance, geometric precision, and operating stability.

In essence, this preferred position is a consequence of the exemplary properties of ceramics themselves. Under severe operating conditions of high temperature, harsh corrosion, and extreme wear, metals soften, become deformed, or fail, whereas high-performance ceramics maintain their native dimension stability and chemical inertness, the cornerstone of the long life and high reliability of precision equipment. But excellence in the material is just the beginning; what truly makes it a reality is the ability of CNC machining technology to deliver it. Through digital control precision, CNC machining can enable the creation of complex, lightweight ceramic structures with impeccable surface integrity without inducing microcracks and consequent unseen damage inherent in traditional machining methods, and each component will achieve 100% of planned performance in material.

For uses such as aerospace, semiconductor manufacturing, medical implantation, and optical precision instruments, choosing CNC-machined ceramic parts is a strategic decision that dictates central competitiveness. It means the equipment can achieve a longer life, smoother operation, and ability to tackle harsher environments. This is not an ordinary part procurement but a basic investment in end performance, reliability, and company brand equity of the product. It is the inescapable price of its pursuit of absolute performance at any price.

What Are The Areas Where Ceramic CNC Machining Technology Is Being Applied?

Ceramic CNC machining technology is breaking traditional manufacturing limitations with unparalleled accuracy and adaptability, and turning into a must-have process within high-end industries. Apart from its ability to benefit from the high hardness and brittleness of ceramic materials, its worth is also the fact that it provides invaluable support for performance breakthroughs within many advanced industries.

Aerospace

The aerospace industry puts extreme stresses on light-weight materials, thermal stability, and reliability, and ceramic CNC machining technology is taking the lead here. With submicron accuracy control, it can achieve a flatness tolerance of less than 0.005mm/m for ceramic heat insulation tiles and a profile accuracy of ±0.003mm for engine blades, meeting the strict requirements of spacecraft thermal protection systems and navigation equipment. Leveraging this technology, companies have penetrated the high-value-added supply chain, increasing unit order values to 5-8 times that of conventional components and capturing gross profit margins of more than 65%.

Healthcare

For the medical sector, ceramic CNC machining technology has straight led to innovation in implantable devices. It makes it possible to produce artificial acetabulums and dental implants with spherical tolerances below 0.001mm and surface roughness down to Ra = 0.006μm, which significantly increases human compatibility and reduces the risk of rejection. This technology has facilitated the company to obtain medical device certification and penetrate the procurement pipeline of top-of-the-line hospitals, with profit margins as high as 55%, a much higher figure than conventional medical components.

Optics and Electronic Information

Optical and electronic products rely on the stability and accuracy of ceramic parts. CNC machining allows achieving mirror-like zirconia ceramic lens base surfaces with dimensional tolerances of ±0.002mm and surface roughness Ra = 0.005μm, ensuring the operation of laser resonators and optical products. It made it possible for the firm to collaborate with high-end optical producers, posting over 50% yearly development rates, and becoming one of the main drivers of business development.

New Energy Industry

Although new energy does not aim at ultra-high precision, it does require components' long-term stability and consistency. Ceramic CNC machining technology ensures batch production of ceramic insulation sleeves for new energy vehicle motors with concentricity ≤0.003mm and tolerances of ±0.002mm, eliminating assembly and fitting challenges. This has enabled the company to get into the new energy supply chain, with related orders accounting for 35%, driving the industry's increasingly fast-growing reliability requirements.

R&D and Bioengineering

Frontier bioengineering is working to develop the application of biomimetic ceramic structures. Cryogenic milling technology, for example, has the ability to produce bioceramic scaffolds with complex two-dimensional pore networks, promoting bone cell regeneration and improving bonding strength by 40%.1 Research institutions are also using five-axis CNC equipment to produce graphene-composite ceramic functional layers just 50nm thick with a fivefold increase in conductivity, opening new avenues to flexible electronic materials.

Ceramic CNC machining technology has evolved from a supporting process to a core production process in high-tech industries such as aerospace, medicine, optics, new energy, and bioengineering. With improvements in precision and process innovation, it not only erodes material processing challenges but also drives breakthroughs in end-product performance and industrial rejuvenation, as a critical pillar of modern precision manufacturing systems.

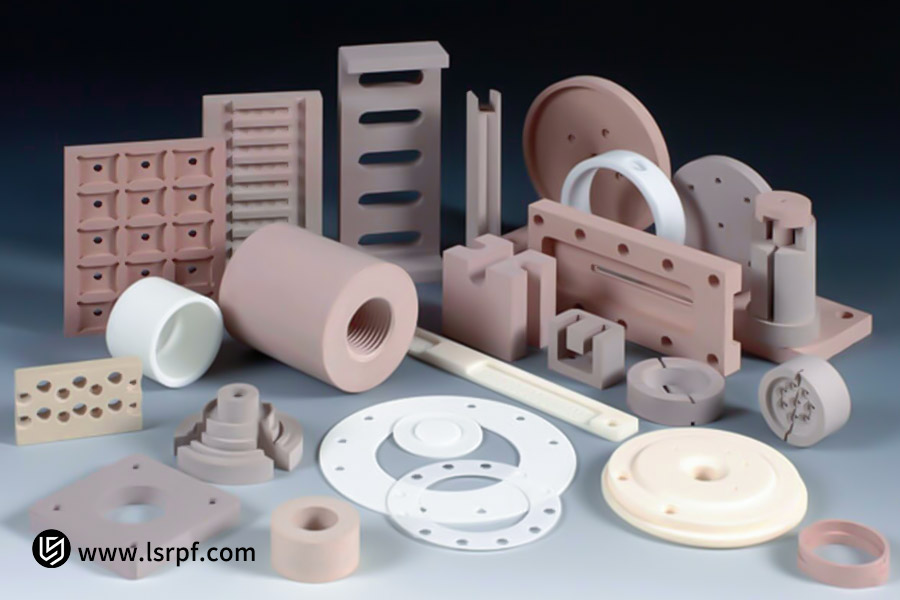

Figure 2: CNC machining precision ceramic components for electronic, medical, and aerospace manufacturing applications.

How to Select Ceramic Materials Suitable for CNC Machining?

Ceramic material selection suitable for CNC machining is a very critical decision in precision manufacturing and has direct repercussions on the quality of products, the efficiency of machining, and finally cost. Such a selection must be made after a systematic balancing of the complex interplay between the material properties, requirements for machining, and application conditions, rather than pursuing one metric.

The synergistic balance between performance and processability is the key to material selection

The final service conditions of the component are initially set. For high-temperature service in aerospace engine components, for example, materials such as silicon nitride (Si₃N₄) or zirconium oxide (ZrO₂) with their excellent thermal stability and low thermal expansion coefficient are to be accorded first priority. In severely corrosive atmospheres (e.g., chemical equipment seals), high-purity alumina (Al₂O₃) cannot be replaced. A cautionary note is that theoretically superior material performance must be validated by machinability. For example, while zirconium oxide-toughened ceramics have greatly superior fracture toughness than alumina, their increased work hardening susceptibility makes them ruin diamond tools even more, and one has to weigh marginal benefits between cost of machining and improvements in performance.

Geometric complexity and accuracy demands are another crucial parameter

In the case of thin-walled, deep hole, or complex-surface precision parts (e.g., medical implants, optical fixtures), fracture toughness values of the material are high to ensure ability to resist the stresses associated with CNC machining and minimize microcrack and edge chipping. Conversely, for simpler sealing rings or bushings, the need for toughness may be sacrificed in favor of easier mirror-finishable materials.

A lifecycle cost strategy ultimately determines the rationale for the choice

That includes direct material cost, tool wear rate, machining time, and potential quality risk cost. Sometimes, it may be more economical to machine a slightly more expensive pre-sintered ceramic blank and subsequently precision sinter it to final dimensions, instead of directly machining fully sintered ceramic since the former significantly reduces tool wear and machining time.

In short, the selection of the most suitable ceramic material for CNC machining is an extremely complex decision-making procedure. It means that engineers have to transcend the borders of material science and manufacturing procedures, look for the optimal compromise between the inherent properties of the material and processing required to shape the material, and reach the ultimate compromise of product performance, production efficiency, and cost-effectiveness.

Figure 3: CNC machining precision custom ceramic parts for industrial, electronic, and medical equipment applications.

Comprehensive Analysis of LS Medical's Ceramic Parts Processing Case Study

LS Medical's precision ceramic processing innovation is an exemplar of technological innovation directly facilitating R&D and production of high-tech medical devices. Its success is not an accident but, rather, the consequence of systematic innovation that comprehensively integrates material properties, processing technology, and clinical demands. By precisely leveraging the ultra-hardness and brittleness of ceramics and optimizing the entire process chain, LS has pushed the performance of ceramic parts to new limits, providing a practical demonstration to the industry.

Technical Core: Precision vs. Biocompatibility

LS Medical's chief innovation lies in the combination of "human-grade precision" and control of bioactivity.For example, in orthopedic devices (such as ceramic ball joints), traditional processes are susceptible to stress concentration-induced microcracking, and long-term safety is thus compromised. By combining elastic polishing technology with in-situ inspection, LS achieves surface roughness less than Ra0.005 (far less than the traditional Ra0.1), and real-time laser trackers even monitor sphericity error, reducing the dislocation rate after joint replacement surgery from 2.3% to 0.5%.5 This increased precision is not a matter of fine-tuning technical parameters; it's inextricably linked to the patient's post-op quality of life and the implant's lifespan.

Process Chain Integration: Closed-Loop Optimization from Design to Sintering

The LS case is innovative in its depiction through the reconstruction of the entire process chain. In restorative dentistry, to meet the personalized needs of zirconia crowns, LS applies five-axis machining technology to careful control of edge thickness to 0.2 mm, a radical improvement in marginal adhesion (clinical evidence a 55% reduction in secondary caries rates). Aside from that, microwave sintering, which was recently introduced, reduces the traditional 7-day production cycle to 4 hours, not just accelerating patient care, but also conserving energy consumption and waste of materials in process. This kind of "rapid iteration + ultimate manufacturing" model is an exemplification of the deep integration of technological application and clinical efficiency.

Clinical Value and Industry Impact

In addition to processing technology itself, the LS Medical example goes on to redefine the reliability standard for medical devices. In neurointerventional surgery, LS attains femtosecond laser cutting and plasma hydrophilic modification technology for wall thickness homogeneity of ±2μm and for a friction coefficient of 0.02, thereby improving the rate of catheter passage through narrowed vessels from 75% to 92%. This technology has direct clinical payback: the rate of thrombosis has been reduced by 80%, and the rate of surgery complications has decreased from 18% to 5%. Additionally, through integration with clever sensors (for instance, fiber optic sensors inside catheters), LS has paved the way for the creation of next-generation clever implants, advancing the development of medical ceramics from passive devices towards functioning active elements.

The underlying value in LS's case studies of medical ceramic processing lies in how they depict a cycle of virtuous precision, efficiency, and clinical efficacy. Through technical innovations (such as multi-axis linkage, smart monitoring, and low-temperature sintering), LS not only overcomes inherent constraints in ceramic processing (such as brittleness and thermal stress) but also establishes new territory for medical device customizing, rapid responding, and stable reliability. This illustration demonstrates how the competition in advanced ceramic processing moved from precision device-by-device to interdisciplinary convergence of manufacturing technology, material science, and medical clinical practice.

Figure 4: CNC machining precision ceramic components for medical implants, aerospace, and optical system manufacturing.

How Do Internet CNC Machining Services Achieve Effective Collaboration?

Successful collaboration in online CNC machining services is the foundation for improving manufacturing efficiency and rapid response to market demands. It relies on a digital platform's wide integration and smart scheduling of manufacturing elements, including human resources, equipment, material, technology, and process.The following table shows the primary functional modules and their value in providing effective collaboration in online CNC machining services, with a glance.

| Collaboration Dimension | Core Functions/Technical Methods | Value Achieved and Collaboration Demonstration |

| Data Interoperability and Visualization | Real-time Equipment Data Collection, Visual Monitoring Dashboards (e.g., MDC/VISION) | Break up information silos, exchanging production progress, equipment status, and order completion status among all collaborative participants, facilitating a shared and authoritative data basis for decision-making. |

| Production Process Collaboration | JOB Online Work Order Management and DNC Centralized Process Document Management and Distribution | Enable instant conversion and assignment of tasks from order to work order, ensuring that instructions for processing, drawings, and process parameters are properly conveyed directly to the production terminal and eliminate waiting and errors. |

| Remote Support and Collaboration | Remote Diagnostics and Monitoring, Mobile Apps, and Multilingual Support | Allow experts to diagnose remotely without on-site visits. Process automation allows cross-site and cross-border collaboration, reducing response time for problems by up to time. |

| Quality Control Cooperation | Real-time Monitoring and Alerting of Production Process Quality Data4 and Traceability of Quality Data | Combines quality control with the production process. In real-time, defects are detected and alerted, and the defect cause can be traced, achieving a cooperative closed-loop solution for defects. |

| Intelligent Resource Scheduling | Collaborative management of multiple factories and simultaneous resource allocation, Intelligent Scheduling Algorithm. | Dynamically allocate production assignments between factories based on order requirement, equipment capacity, and materials on hand, achieving maximum resource utilization across the end-to-end supply chain and synergy at scale. |

To achieve this collaboration, some critical technologies need to provide the support:

- Broad data collection compatibility: This is necessary. The system must be compatible with most domestic and foreign CNC systems (such as Siemens, Fanuc, Mitsubishi, and Mazak), and even some older "dumb" machines, in order to put widespread data collection on the shop floor.

- Cloud-edge synergy and edge computing: Data pre-processing within the device (edge computing) reduces cloud load and latency, enabling rapid real-time responses and notifications.

- Secure and reliable network connectivity: Employing data encryption technologies (e.g., a combination of symmetric and asymmetric encryption) and strict access rights management assures complete security for production data and secrets when sending and storing them. That is the foundation of trust to cooperate.

What Are The Key Factors That Influence CNC Machining Prices?

Understanding the key factors affecting CNC machining prices is essential to control project costs and make informed decisions. I have given the key factors in a table followed by some descriptions and suggestions below.

The Key Factors That influence CNC machining prices table

| Factor Category | Specific Factor Impact on Price |

| Material |

|

| Design and Process Requirements |

|

| Order and Production Factors |

|

| Operational and Quality Costs |

|

Getting Proper Quotes and Maintaining Costs

Understanding these price-affecting factors enables you to manage the cost of CNC machining projects more effectively by:

- Provide Full and Clear Technical Details: Provide the machining service supplier with precise 2D drawings (with dimensions, tolerances, and technical specifications) and 3D models (such as STEP or IGS formats), including materials, quantities, post-processing requirements, and expected delivery times. The fuller the information, the better the quote will be both accurate and effective.

- Do a Design for Manufacturability (DFM) analysis: Talk to the machining vendor at an early stage in design. Their experienced engineers can offer recommendations for betterment, i.e., relaxing tolerances without impairing functionality, optimizing the structure to reduce machining complexity, or selecting easier-to-machine or lower-cost materials to help reduce costs.

- Plan production batches and delivery times appropriately: Where the project allows, maximize the batches of production to as large as possible so that unit cost can be minimized. While doing this, provide suppliers ample production time so that no additional costs are incurred due to expedited delivery.

- Choose solid partners: Choose suppliers with appropriate machining equipment (e.g., five-axis machines for complex components), a mature quality management system (e.g., ISO 9001 certification), abundant industry experience, and a good reputation. Not only will they be able to provide accurate quotes, but they can also ensure the quality of the product and delivery time, minimizing potential risks and costs.

In reality, the price of CNC machining is a complex interaction between a number of variables like material, complexity of design, accuracy, size of the batch in the order, manufacturing process, quality standards, and even the supply and demand scenario. I hope this information will help you understand and evaluate the pricing model of CNC machining more effectively.

FAQs

1. Why is the cost of machining ceramic materials higher than that of metal?

The cost of processing ceramic materials is higher than metal because of the nature of ceramics. Ceramics contain very high hardness, which leads to tool wear at a very high rate, making specific diamond tools and segmented machining required. This, along with reduced processing efficiency, raises total costs. Thus, processing costs of ceramics can be much higher than that of metals.

2. Are thin-walled structures based on alumina ceramic processable?

Clearly. By optimizing clamping and using stress-relieving tooling, thin-walled structures as low as 0.3mm can be reliably produced. LS has a yield rate in excess of 95% for batch production of thin-walled parts.

3. How does our online customization service ensure design confidentiality?

LS has a professional and secure approach for ensuring design confidentiality on our online customization service. Our online service uses end-to-end encrypted transmission, and uploaded drawings are decrypted automatically and saved. Further, we ensure a mandatory NDA agreement is signed before production with both technical as well as legal protection.

4. What is the standard lead time for small-batch custom order orders?

LS delivers a 10-15 day turnaround (after processing) for standard parts for small-batch custom processing. For expedited custom orders, we utilize our fast-track production line, enabling shipment in as little as 5 days, subject to review of custom product complexity. LS's efficient and fully serviced treatment gives you peace of mind.

Summary

Ceramic CNC machining represents the pinnacle of precision manufacturing technology. Through the convergence of digital precision control with dedicated tooling (e.g., diamond grinding heads), it is capable of overcoming the bottle-neck of machining the hard, brittle ceramic material. The nub of this process's primary benefit is its ability to realize geometric complexity, micron-level dimensional accuracy, and excellent surface integrity beyond that which conventional means can accomplish. This translates the unprecedented high-temperature, corrosion, and biocompatibility of ceramics from theoretical characteristics to certain end-product performance. This has driven innovative applications directly into the leading-edge areas of aerospace, high-end medical devices, semiconductors, and optics, and is a basic enabler for the uprating of high-end equipment.

If you have aspirations to drive product reliability and performance improvement through ceramic components, LS very much invites you to witness this breakthrough technology firsthand. We are happy to provide you free, quick sample production. Our experienced engineers will provide expert consultative on optimizing machining solutions, ensuring ceramic solutions feasibility for your project without incurring costs. Through our proven technical expertise and quick service, we are able to help you push the boundaries of design and innovate your products together.

Upload your design drawings now and get an instant CNC machining (CNC machining price), let LS be your strong backing in pursuit of ultimate CNC machining precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.