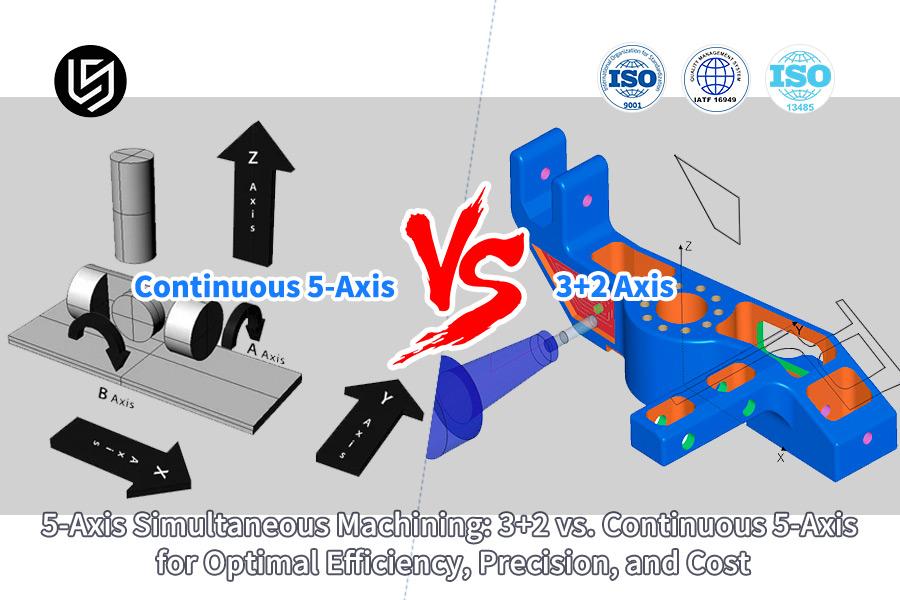

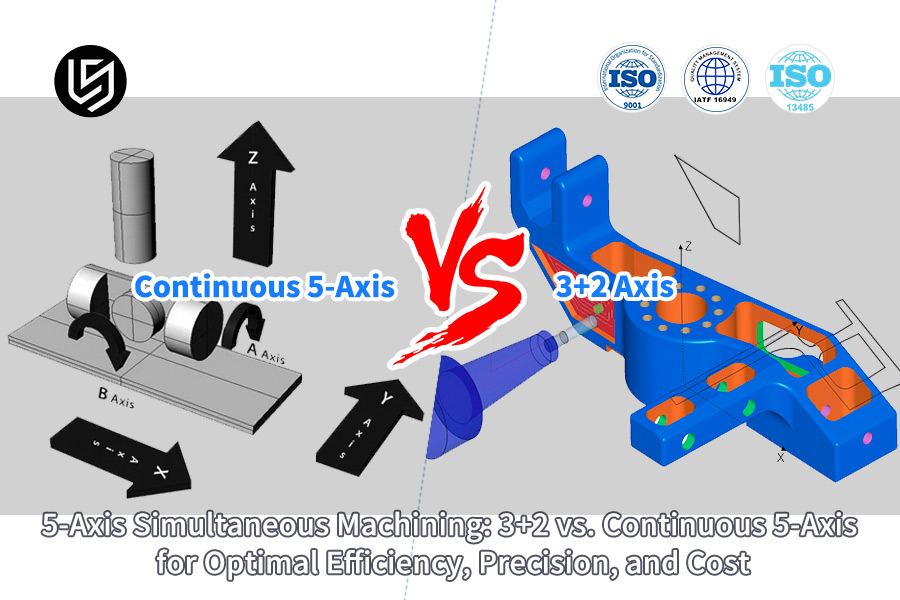

5-axis simultaneous machining is the most advanced in handling complex contours; however, it could not find acceptance due to increased cost and complexity of process planning. Today, most of the existing manufacturing businesses are facing the challenge of making a choice between the efficient machining method of 5-axis machining and economically viable machining using 3+2 indexed machining. All this normally results in an ineffective use of the machine rate of less than 30% or the product not meeting the precision standard.

The underlying issue is the complexity of specification sheets in opposition to a decision model with metrics. The conventional methods of decision-making do not consider important dynamic factors such as true torque curves and thermal accuracy maps. Our system resolves this issue in its utilization of a proprietary database with in excess of 2000 complex components with a view towards developing a decision model with metrics in ensuring an exact correlation between capability and a particular set of requirements and costs in a production scenario.

5-Axis Simultaneous Machining: Quick-Reference Guide

| Section | Core Content |

| The Dilemma | Producing complex surfaces presents perimeters: economical but constrained 3+2 indexing, as opposed to all-at-once precise 5-axis simultaneous machining, if the choice impacts below 30% utilization. |

| Root Cause | Selection is a function of specification sheets that do not change. There is no measurable model. Such highly important dynamic parameters like process match, torque, and thermal accuracy do not apply. |

| Our Solution | Our offer is a data-driven selection system based on a database over 2,000 complex parts, with calculated processing torque curves and heat maps for precision, linking machining requirements to an accurate technical specification. |

| Tech Comparison | 3+2 machining: For multifaceted models that incorporate complexity. 5-axis Simultaneous: Required for continuous models with high complexity. |

| Decision Framework | Process: 1. Determine part geometry & tolerance. 2. Analyze cutting paths & loads. 3. Coordinate with kinetic & thermal characteristics of the machine in such a way that it enables precise cutting even in practical machining sessions. |

| Outcome & Impact | Facilitates well-informed and optimal decisions pertaining to investments. Maximizes resource utilization in relation to machines/components manufactured based on capabilities. |

We will address the current huge variance of cost between 5-axis investment casting and production. Our innovations will no longer require guesswork, and thus we will also consider your components and your processes in order to determine what will be the best fit for you to ensure that we are able to provide what you need: precision and productivity, but not wastage.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Today, there exist thousands of texts on the internet about 5-axis CNC machining. The fact is, this particular article is one of the few texts compiled by individuals who have been involved in this particular activity, as opposed to individuals who were knowledgeable about it. Our knowledge, no matter how refined with experience, must be extracted from him.

These are based on more than 50,000 successful production runs of complex components. We supply impellers to the aerospace industry, which needs precise and continuous motion of the cutting tool, and we supply medical device enclosures whose surface finish needs to be perfect. All this has been a means to an end, a process to develop our capabilities in every aspect, from correcting thermal drift to engagement with PCD tools.

For the purpose of our procedure and method assurance, we will ensure, with emphasis, that our procedures and methods meet the standards of our industry as accepted by credible sources such as the American Production and Inventory Control Society (APICS), and TWI Global, with regard to business excellence and technical competence. Our passion and experience with real-life manufacturing standards and experience, as above, go a long way in ensuring the advice you seek on this site is correct and thereby useful as guidance to help you succeed.

Figure 1: Advanced 5-axis machining process precisely executing by LS Manufacturing

How Does 5-Axis Simultaneous Machining Redefine Efficiency In Complex Part Manufacturing?

5-axis simultaneous machining transcends the limitations in that it can accomplish the 5-axis complex parts manufacturing in one setting. However, its major advantage does not derive from its capability to carry out machining in a number of axes concurrently but from its capability to address systemic inefficiencies and lack of accuracy in the multi-step process.

- Eliminating Setup-Induced Error: Although the error issue basically focuses on the error accumulated in the fixturing process, the blisk finish process must be completed through 5-axis simultaneous machining process in an attempt to machine all surfaces of the blisk in one clamping process, thus not having any errors in aligning the blisk during the machining process, because the contours must be accurate in a given tolerance of 0.025mm.

- Optimizing Dynamic Tool Engagement: True efficiency optimization is in maintaining ideal cutting conditions. We program the tool vector to keep the cutter's effective diameter engaged, preventing poor tip contact. This technique stabilizes cutting forces, improves surface finish directly on the machine, and increases tool life, thereby reducing machining time and cost per part simultaneously.

- Minimizing Non-Cutting Motion: Inefficiency can be observed in air cuts, where several cuts comprise a great deal of the total path length in parts with a lot of features and walls that are too short. Proprietary CAM programming is involved in a dramatic reduction in rapids and repros through the calculation of an optimal path in one step, reducing non-cutting moves such as rapids and repros, which can be reduced by as much

- Ensuring Stability Under Load: The fundamental approach to overcome this challenge is to ensure that there is high accuracy in complex and dynamic motions. Simulations are carried out prior to processing in order to model machine kinematics and loading during the process of cutting in order to overcome such difficulties. This ensures the high-speed motion delivers the intended accuracy, making the efficiency gain both real and reliable for complex parts manufacturing.

The white paper will provide a strategy guide that will ensure successful execution of 5-axis simultaneous machining. Our competitive advantage is centered around the focus on technical integration among programming strategy, tool physics, and machine dynamics in our quest to continuously provide the best performance in terms of speed, quality, and cost regarding the use of advanced machinery.

What Are The Accuracy Differences Between 3+2 And 5-Axis Machining?

The choice between 3+2 vs continuous 5-axis machining significantly impacts the achievable precision of complex components. This accuracy comparison is rooted in the fundamental differences in their motion control principles. This document provides a data-driven analysis to guide the selection process, moving beyond theoretical specifications to measurable performance outcomes.

| Aspect | 3+2 Indexed Machining | Continuous 5-Axis Machining |

| Core Principle | Discrete positioning. Uses high-accuracy rotary tables locked in place during cutting. | Continuous toolpath interpolation. All five axes move simultaneously under RTCP control. |

| Accuracy Driver | Capability and repeatability of rotary axes down to 0.001°. | Accuracy of dynamic movement paths and compensation for volume errors in coordinated movements. |

| Typical Application | Multi-sided, prismatic parts with planar surfaces. | Complex, sculpted surfaces and deep cavities with undercuts. |

| Key Limitation | Accuracy degrades on complex 3D contours due to fixed tool orientation. Excels in 2.5D milling. | Performance depends on machine kinematics and control system. |

| Performance Data | When the tool tilt angles exceed 30°, the contour error will be increased substantially compared with the nominal values. | Maintains consistent accuracy; laser tracker data shows error reduced to ~40% of 3+2 at high angles. |

Carefully, the most optimal strategy has to follow, beginning with an examination of the most common geometry type that exists in the part: either 3+2 indexing for multifaced prismatic parts and stressing the set-up integrity concept and 3D surfaces that continuous 5-axis to avoid the accuracy loss that the multifaced set-up entails. The overall strategy depends on the performance measures described by the guidelines for the motion control.

How To Scientifically Select The 5-Axis Machining Mode Based On The Geometric Features Of The Part?

Selecting the optimal 5-axis strategy is a core challenge in high-value manufacturing. Arbitrary or rule-of-thumb choices lead to significant inefficiency or inadequate precision. The solution lies in a systematic methodology for how to choose 5-axis machining, shifting the decision from intuition to a quantifiable analysis of part geometric features. This scientific selection process directly correlates geometry to the most effective and economical machining mode:

Classifying Geometry: The Foundational Step

The first step of this process involves an analysis of object and breakdown analysis. First of all, it is necessary to distinguish between discrete planar geometry, as in angled areas of mold inserts, and complex shape objects, as in airfoils of blisks. This, of course, is only feasible in a normal project by analysis of curvature by means of CAD, computer-aided design.

Quantifying with a Decision Matrix

Ambiguity is resolved with reference to the use of a quantified selection matrix. For product components where the prismatic characteristics are predominant, 3+2 indexed machining is adopted. The locked-axis stability method of this machining ensures high accuracy in volumetric accuracy in planar milling machining; hence, optimal cycle time design directly translates into achieving targets of 15 minutes for each piece.

Mandating Continuous Motion for True 3D Contours

With confirmed dominant non-prismatic surfaces, continuous 5-axis machining becomes an imperative. The physical principle that supports an imperative for continuous 5-axis machining is that for optimal engagement and control of the vector of cutting on the sculptured surface, simultaneous interpolation of axes is the only option available. This is for a surface finish of a given specification, for instance Ra 0.4µm.

Leveraging Software for Objective Recommendation

To maintain objectivity in the process as much as possible and to eliminate any personal want or preference regarding what the project manager and manufacturing engineer would like to have as opposed to what they are able to accomplish, analysis software for CAM and curvature is used to objectively determine areas of geometry in the component which would require the use of tilt above a certain threshold. This software will objectively recommend areas of geometric complexity that would require certain solutions.

This methodology provides a direct, actionable framework for how to choose 5-axis machining. The advantage offered by this process in relation to all other processes, which have subjective logic, entails objective logic, which is geometry-driven, eliminating all guessing, leaving only a decision tree through which the manufacturers have to make decisions regarding matching the capability of the technology with the specifications required by the part, thus ensuring optimal cost of manufacturing.

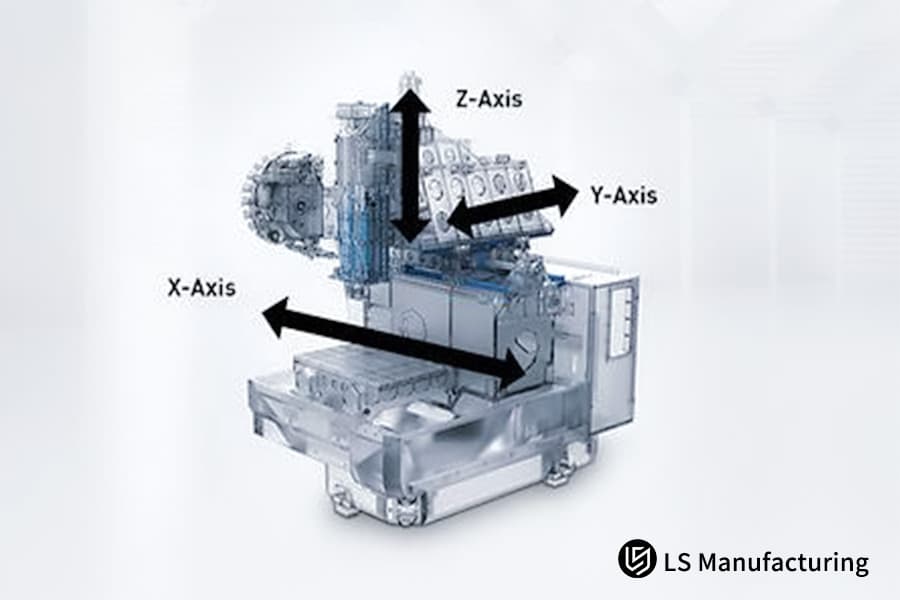

Figure 2: A 5-axis cutting operation on a Mikron machine by LS Manufacturing

What Unique Cost Advantages Does 3+2 Positioning Machining Offer In Mass Production?

While continuous 5-axis machining offers unparalleled flexibility, 3+2 machining provides decisive economic benefits in volume manufacturing. Its suitability for high-volume batch production stems from inherent technical simplifications that translate directly to lower operational costs. This analysis quantifies the cost advantage, presenting a clear rationale for its strategic deployment.

| Aspect | Impact in Batch Production | Measurable Outcome |

| Programming & Setup | Simplified, fixed-angle programming. Cycles are standardized 2.5D cycles. | Programming time is ~60% faster than for complicated 5-axis cycles. |

| Tool Wear & Life | Locked orientation prevents vibrations. | Avoid making intermittent cuts as it increased tool life by 20-30% in car mold testing. |

| Machining Efficiency | Machined with high MRR in a given environment. | Reduced cycle time for surfaces in a prismatic component because of allowable increased feeds. |

| Cost-Per-Unit | The optimised total cost for programming, fixtures, and cycle time. | Reduced by up to 45% compared to continuous 5-axis machining for qualified part geometries. |

| Optimal Batch Size | High setup efficiency amortized over many identical parts. | Delivers maximum ROI typically for batches exceeding 500 units. |

In a situation whereby components are dominated by prismatic features, using 3+2 machining to perform batch production would be ideal since this technology derives its cost advantage by simplifying the control logic to 2.5D, enabling more stable cuts to achieve maximum tool life and processing at higher feed rates. A data-driven method to make decisions on technology selection would further suggest that the effectiveness and stability that 3+2 machining has to offer would reduce costs.

How Can Micrometer-Level Precision And Stability Control Be Achieved In Continuous 5-Axis Machining?

Reaching micron-level precision becomes difficult in continuous 5-axis machining due to the potential obstruction caused by the effect of dynamics, drifts, and errors. The difficulty therefore may arise from the implementation of the process that provides a closed-loop process for realization of the feedback and predictions for all processes that are connected with the stability control. The process undertakes the following implementations:

Establishing a Hardware Foundation with Direct Feedback

The first step that has to be carried out in order to meet the criteria of the competition report is the implementation of the glass scales in the linear axes of the machines. The feedback of the axes’ position up to 0.0001mm resolution would be available for usage in the CNC system upon installing the glass scales in the machine axes and would give rise to a full closed-loop system.

Actively Compensating for Thermal Drift

Machine tools naturally develop heat that, left unmonitored, could result in such extreme levels of distortion as to threaten the negation of accuracy altogether. Against this, we use a number of in-situ temperature sensors that follow key points on the structure, feeding data to compensate in real time by adjusting the axes against thermal drift through an algorithm. It is thus possible in this active compensatory scheme to hold drift within a narrow range, such as within ±0.005mm.

Calibrating for Dynamic Kinematic Accuracy

Although it is true that it is accurate in its fixed condition, it is definitely not sophisticated enough in its complicated motion. For this, we perform volumetric accuracy calibration by employing a laser tracker to establish an error map in space for its full operational area. This full error map is then loaded into the CNC machine. During continuous 5-axis machining, the controller uses this data to dynamically pre-correct the toolpath, compensating for inherent kinematic inaccuracies in real-time.

Validating Stability with Process Control Metrics

Proof and results verify capabilities. In order to show this on a statistical process control basis, the critical part sizes are measured at regular times. This is our assurance that stability control process is achieved, for instance, a 72 hour machining cycle for an aerospace impeller has a size retaining 0.015mm and a process capability of greater than 1.67.

This document details the multi-layered technical system required for micron-level precision in continuous 5-axis machining. Based on the ability to harness the power of metrology and statistical analysis for verification, the methodology applied in this study is capable of translating machine theory to reality.

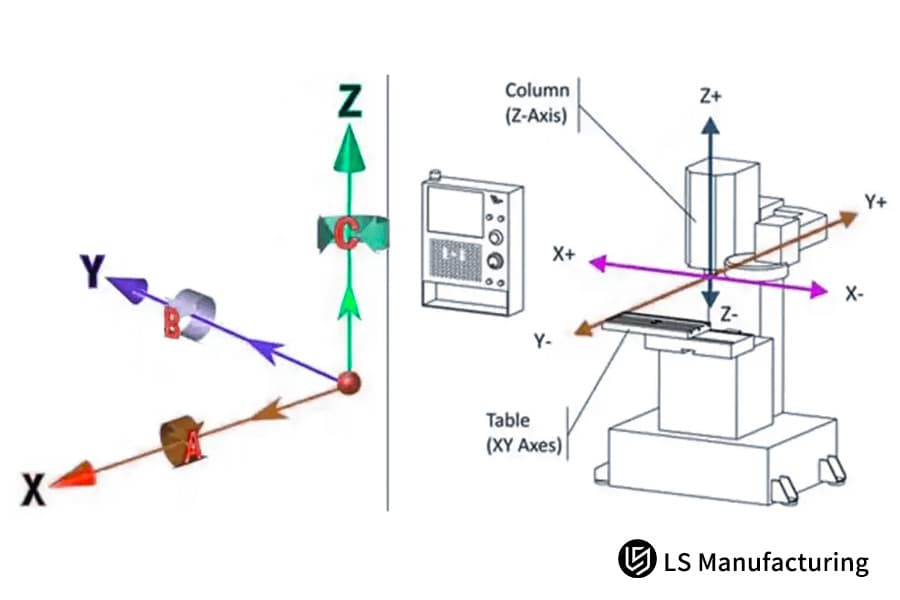

Figure 3: Core axis setups for both indexed and simultaneous 5-axis operations by LS Manufacturing

How Can 5-Axis Machining Efficiency Be Quantified To Assess ROI?

Though it has been shown that high-performance machines can offer certain benefits, it is hard to determine a return on this investment in financial terms. It becomes difficult to determine the return on an investment in financial terms through traditional methods of investment analysis and return determination. This document provides a structured, data-driven methodology for ROI assessment, moving beyond theoretical benefits to model tangible savings in fixtures, labor, and total throughput. The model addresses the following key areas:

- Quantifying Cycle Time Reduction and Throughput Gains: The primary lever for 5-axis efficiency is the dramatic reduction in non-value-added time. Analysis of the process is done, and the reduction in the elimination of the secondary setup is determined. For instance, in an aero bracket, an optimization from 3+2 to continuous 5-axis reduced the overall time for handling and setup by 65% and affects the system throughput, which is the foundation for return on investment.

- Modeling Savings from Fixturing and Workholding Simplification: We considered one of the most critical but less-emphasized regions in terms of savings for the fixture reduction area in our investment analysis to make a comparison between the impact of the complexity and number of specialized fixtures used. For example, in the region of turbine blades, it came down from a reduction to how one specialized fixture could be a 5-axis machine that offers a saving of 15% in programming related to tools and fixtures.

- Calculating the Impact on Scrap, Rework, and Quality Costs: The impact of the loss of accuracy during machining in single set-up has a substantial effect in the current cost of quality. The scrap and rework value has been taken into consideration in the given case study. The reduction of handling and set-up error directly due to the 5-axis machining has resulted in the decrease of suffering from the defect of first pass yield of 40% for a given case that relates to the medical implant. This itself forms a good base for the value stream improvement.

- Performing a Holistic Total Cost of Ownership (TCO) Comparison: This framework supplies a sound methodology for the ROI assessment of 5-axis efficiency, changing speculation with a quantifiable model of all cost drivers-from cycle time and tooling to quality and throughput-enabling a confident, data-driven investment analysis for capital equipment decisions in high-value manufacturing.

This way, it provides a reliable approach to implementing the ROI assessment of 5-axis efficiency. In fact, it replaces conjecture by allowing the creation of a model of all of the cost drivers, from quality to speed, by means of which one can arrive at definitive and data-driven decisions regarding capital equipment investment analysis in high-value manufacturing.

What Is The Balance Between 5-Axis Machining Accuracy And Cost?

In order to obtain the required 5-axis precision, there is a nonlinear cost balance, which exponentially increases as the accuracy reaches zero. Based on the data collected, the cost escalation to go beyond ±0.02mm accuracy to ±0.01mm accuracy is 80%, and the objective is to determine the economic tolerance or just-right tolerance, which will deliver the task function of the component rather than throwing good money after bad on specifications. This is achieved by engaging in:

Defining Functional vs Aesthetic Tolerances

The type of tolerance requirements is then categorized. In critical pairing and Aerodynamic surfaces, it is necessary to obtain high 5-axis precision, but for non-critical surfaces, there are large tolerance allowances. Additionally, cosmetic surfaces are where no specified requirement exists. Through functional methods of verification in relation to the type of verification, it can be concluded that in functional methods, there is no overspecification, and as such, cost must be added where it matters in relation to providing an economic accuracy solutions scenario.

Quantifying the Exponential Cost of Precision

This costing curve is graphed using data from previous projects. This is not a linear process but rather, for each step increase in precision, the spread of costs between alternatives increases: more expensive machines to more complex kit, longer cycles to more advanced metrology. For example, to plot a tolerance of ±0.01mm may involve 300% longer cycles than to plot a tolerance of ±0.05mm, which is crucial information when considering a cost balance test.

Implementing a Tiered Manufacturing Strategy

In our organization, we use the multi-tier system. The components are categorized depending on the tolerance level that must be on those components. In the case where there is a high demand for precision, the process is done using the thermal stability special machines. This strategy optimizes overall equipment effectiveness (OEE) and prevents the high cost of ultra-precision from being applied to all work, preserving the cost balance.

Validating with In-Process Measurement and Control

To make our conclusion complete, we also include statistical process control or in-process probing. This ensures that the machine has the ability to perform at an economic accuracy level that it is set for. It also keeps it from going to a higher level of accuracy in terms of precision or tiers that it has to pay for.

This report presents a method to determine economic truth and realize a optimal cost balance for 5-axis precision through the competitive insight, which is a data-driven process ranging from functional analysis and modeling through production and control and ensures that each micron of precision has a pay-off in its benefit to the components.

What Are Some Often Overlooked Hidden Factors In The Cost Structure Of 5-Axis Machining?

In considering the 5-axis machining cost, strict financial underestimation occurs when only the initial capital investment is considered. There are vital, often overlooked, and hidden factors that comprise specialized tooling down to sophisticated maintenance that determine the real total cost of ownership. The paper presents a structured way of carrying out proper lifecycle assessment, which goes beyond the purchase price to model the full financial engagement. The process will consider the following:

- Accounting for Specialized Tooling and Workholding: Normally, the 3-axis tools might not be sufficient. The dynamic forces and locations in 5-axis machining demand more balanced tooling as well as the extension thereof. The price thereof could be twice as high. For the above challenge, we consider and provide for the entire set of tools that are required in 5-axis machining.

- Factoring in Advanced Maintenance and Calibration: This requires a high maintenance standard in terms of accuracy. The maintenance of calibrations and volume verification of the laser interferometer, estimated at $30,000 to $50,000 a year, can in no way be compromised for micronaccuracy. The maintenance and recalibration contracts will not cause unscheduled budget breakdowns in our model.

- Budgeting for Skilled Labor and Specialized Training: For 5-axis machining center, there would be a requirement for a higher skill set when working with it. We would also take into consideration the cost attributable to 40% of qualified 5-axis CAM programmer and training cost for such machining center. It would also include start-up cost in relation to cost of qualified human resources for such machining center in relation to the cost of the lifetime of such machine.

- Modeling Energy Consumption and Facility Requirements: 5-axis machines require more power. This goes for faster rotating tables or complicated cooling. Energy audits are part of our lifecycle assessment. It also takes into consideration improvements in existing buildings, which could involve improved power distribution or special foundations. These are crucial, yet invisible, factors which have a large impact.

This framework provides a methodology for a complete lifecycle assessment of 5-axis machining cost. It empowers a realistic financial analysis by systematically identifying and quantifying the major hidden factors—from tooling and calibration to skilled labor and utilities—ensuring investment decisions are based on total cost, not just purchase price.

Figure 4: Exploring the basic movement axes within 5-axis machining systems by LS Manufacturing

LS Manufacturing Aerospace Division: Engine Turbine Blade 5-Axis Machining Process Optimization Project

The precision and quality involved in the manufacturing related to the aviation industry are particularly high when it comes to the major components of rotors. Against this, the problem related to LS Manufacturing related to process optimization for an aero-engine OEM for a challenge related to quality and efficiency in turbine blades. The problem statement was related to designing a changeover strategy for shifting from 3+2 to a superior continuous machining process w.r.t. processing 718 Inconel blades by 5-axis machining.

Client Challenge

The problem with the client was related to a serious quality and efficiency issue in the machining of their turbine blades of Inconel 718. The current 3+2 indexed machining process in their setup was showing witness line-step overs of 0.03mm on their blending region for different machine setups. The effect on the fatigue life of their component had been serious, as it is below the specified level. Moreover, the inefficient process takes more than 6 hours for making one component.

LS Manufacturing Solution

In our application, we chose to machine the airfoil surface completely in one setup by using continuous 5-axis simultaneous machining to avoid blend lines. In turning operations in Ni alloys, we employed trochoidal milling and optimized process parameters to maximize cut speeds of 90 m/min and depth of cut of 0.2 mm to turn out the best results. In our application here, we chose to be aggressive and completely controlled in machining to fully exploit Inconel 718 by completely removing any quality-related machining concerns and tooling costs.

Results and Value

The process optimization resulted in a paradigm shift in the results. The precision of the final blades increased to the order of 0.015 mm, while the surface finish attained an Ra of 0.4 microns. The Witness lines in surface finish became nonexistent. The machining cycle time decreased by more than 58%, with a machining time of just 2.5 hours per part. Add this to the increased tool life by a multiple of 3 as a result of process optimization, and the annualized savings to the tune of more than 2 million RMB has led to the rapid acceleration in the growth process of the customer.

In this case study, it has been revealed that the skill sets applied in LS Manufacturing have been used for overcoming certain challenging situations. However, going above the call of duty, which involves the optimization of continuous 5-axis machining, it has been possible to make our position stronger regarding challenging aerospace tasks related to manufacturing.

Explore the limits of 5-axis precision manufacturing, receive your personalized technical assessment, and embark on a journey towards efficient production transformation.

How To Maximize 5-Axis Investment Value Through Process Innovation?

Simply acquiring a 5-axis machining center does not guarantee a return; its high potential is often underutilized. The key challenge is transforming this advanced hardware into predictable, high-value output. This document outlines a methodology focused on process innovation to maximize investment value by systematically elevating machine technology utilization from average levels to over 75%:

- Optimizing Material Removal Rates (MRR) Through Advanced Toolpaths: At present, we are currently employing cutting-edge computer aided manufacturing technology for the trochoidal and peel mill processes. This technology is guaranteed to keep the cutting tool at an optimal chip load at all times. Upon a structural aluminum item, the material removal rates of 35 cm³/min were optimized by more than 40% in the roughing cuts.

- Implementing Closed-Loop, In-Process Metrology: To minimize non-cutting time for setup and inspection, we integrate touch probes and laser tools on the machine. This enables automatic workpiece alignment, tool setting, and mid-process feature verification. The system applies real-time offsets, turning inspection time into productive cutting time and ensuring first-part correctness, a key driver of technology utilization.

- Standardizing Knowledge for Repeatable Efficiency: We capture optimized processes for families of parts—including fixturing, tooling, and proven parameters—into digital work instructions. This process innovation slashes programming and setup time for repeat orders. It allows less experienced operators to run complex jobs efficiently, dramatically improving overall equipment effectiveness (OEE) and protecting the investment value.

This methodology provides a blueprint for transforming 5-axis potential into profit. The competitive insight is the integration of advanced toolpaths, in-process control, and knowledge standardization—a proven system for elevating technology utilization and securing a rapid, defensible return on a major capital investment value.

FAQs

1. What are some of the components that can be machined using 3+2?

Polyhedral or hollow system parts, mold bases, and box-shaped parts. The accuracy is ±0.01 mm, the surface finish is Ra1.6μm.

2. What are the demands with respect to CAM-programming in continuous 5-axis machining?

It requires RTCP function, collision avoidance algorithms, and smooth toolpath optimization. Programming time increases by 40% compared to the 3+2 mode, but machining efficiency increases by 3 times.

3. What is the typical return on investment period for 5-axis equipment?

Depending on the complexity of the parts, it is generally 12-24 months. For complex curved surface parts, the investment can be recovered within 18 months due to efficiency advantages.

4. How to determine if a company needs to replace its 2-axis by 5-axis machines?

In cases when the complexity of curved surfaces is above 30% of the volume of the product or when machining on a 3-axis machine, more than 3 clamping cycles are needed, hence an upgrade to a 5-axis system is required.

5. What is considered to be the greatest error contributor in 5-axis machining?

Spindle thermal expansion and angular errors. Laser calibration is required every 500 hours to control the overall error within 0.015mm.

6. Is it possible to achieve the same level of surface finishing with 3+2 machining as with continuous 5-axis machining?

Ra 0.8μm is obtained in the plane features, but there are marks from joints with a value of 0.02 - 0.05mm in free-form surfaces at the intersections.

7. How to control tool vibration in 5-axis machining?

The hydraulic tool holder of balance quality G2.5 and optimal speed-feed ratio can control the vibration within 5μm.

8. What sort of training would be needed for the new operators who would work on the machines with 5-axis capability?

The trainee has to understand the principles of RTCP, collision safety, and accuracy compensation in a hands-on practical training session of 2-3 months.

Summary

Scientific selection and optimization through the 5-axis machining technology can result in maximum efficiency and quality in the manufacture of complex components for enterprises. LS Manufacturing is an example of a company with a complete technical system and service experience. It provides competent manufacturing solutions for its customers.

Please feel free to contact the LS Manufacturing technical support team for customized 5-axis machining solutions or further process evaluation. We can evaluate your part geometry to produce a techno-commercial proposal for customized support from us, right from process feasibility to the final process validation.

Unlock the ultimate potential of complex contour manufacturing immediately. Click to get your customized 5-axis simultaneous machining solution.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.