In daily life, the majority of people confuse "resin" and "plastic" and even refer to some plastic products as "resin" for short. Actually, the two are similar to raw materials and products. Resin usually refers to unprocessed high-molecular polymer raw materials, both natural (e.g., rosin) and synthetic, viscous organic matter. Plastic, however, is a solid material created through the process of heating, pressurization, and addition of additives such as plasticizers and stabilizers, with synthetic resin as its main constituent. One can say that resin is the "prototype" of plastic, and plastic is the "final product" of resin. Is resin plastic? No—just like flour does not constitute bread, resin needs to be processed to become plastic. While the two go hand-in-hand, they are in different phases. As a time-saving measure, a summary of the key findings is included below.

Resin vs. Plastic Core Quick Comparison Table

| Dimensions | Resin | Plastic |

| Source | Raw materials: Natural (e.g., rosin) and synthetic (e.g., polyethylene) | Finished products: Made primarily from synthetic resins with additives |

| Appearance | Mostly viscous liquids or solids with relatively simple properties | Processed and formed, these materials offer diverse and stable properties |

| Main Applications | Basic raw materials for the manufacture of plastics, coatings, and adhesives | End products in packaging, building materials, and daily necessities |

Resins (especially synthetic resins) are main raw materials for manufacturing plastics, and plastics are the final synthetic products after resin modification and shaping. The two materials indicate the relationship between the "upstream basic raw materials" and the "downstream end products" in the material industry.

Why Trust This Guide? Practical Experience from LS Experts

At LS Precision Manufacturing, we've been deeply embedded in the world of polymer materials for over a decade. Our engineers spend every day tackling the most difficult material challenges for customers in medical, automotive, and electronics markets. We understand firsthand the great divide between textbook knowledge and real-world experience. Every observation and comparison made throughout this guide is based on our experience of providing material solutions for hundreds of client projects, which has given us in-depth understanding of the entire resin and plastics supply chain, from raw material to finished product. We share this knowledge to spare you from common material selection errors and allow you to make more informed, cost-reducing decisions.

A medical device startup client was experiencing issues with the biocompatibility and dimensional stability of its most critical components. It had attempted a number of "general-purpose" plastics on the market, without success. Our materials experts were called in and, rather than jumping in to specify a given grade, initially reviewed the sterilization process, loads, and regulatory compliance requirements of the company. Eventually, they developed a custom-designed PEEK (polyetheretherketone) specialty resin solution, which they were able to mass-produce using our precision injection molding process. This case study, one among many in our daily business, demonstrates that the right material selection is the key to product success. We believe this record based on real projects is worthy of your trust.

What Is A Resin? Is It A Plastic?

To answer the question, "What is resin?", let us first define what resin is. Resin is generally a high-molecular polymer plastic. It is of two general types: natural resins (e.g., rosin and amber, both of tree origin) and synthetic resins (e.g., epoxy resin and polyethylene, both of which are produced through chemical processes). These resins are generally viscous liquids or solid and are the raw materials for many industrial products.

Therefore, "Is resin plastic?" No. The opposite, in fact. Resin is where plastics come from. Plastic products we use daily, such as containers of mineral water and the casings for appliances, all make use of synthetic resin as the primary component. Additives of one sort or another are mixed in, then the final product is obtained by means of heat, pressure, and molding.

Therefore, resin is not a plastic; rather, plastic is one application of resin. Their connection is one of raw material and product, not two sibling members of the same family. This distinction will allow us to properly distinguish between these much-misunderstood terms.

What Are Resins Made of? The Primary Difference Between Natural And Synthetic Resins

To respond to the question, "What are resins made of?," the key is to separate them into their two broad sources: natural and artificial. Artificial resins notwithstanding, natural resins are mostly derived from plant secretions, and more particularly from trees. The most common natural resin is pine resin, for instance, as is amber, which is created by fossilization over immense geological time scales. They are organic compounds created directly in nature.

Synthetic resins, in contrast, are predominantly petrochemical-based. Through cracking and refining of petroleum and natural gas, monomers such as ethylene and propylene are derived. Monomers are polymerized into polymers with varying properties, e.g., commodity polyethylene and epoxy resins.

Thus, knowledge of the response to the inquiry, "What are resins composed of?" is contingent on familiarity with their fundamental differences: natural resins as a gift from nature, and synthetic resins as products of the modern chemical industry. This variation in origin brings about gargantuan differences in purity, performance, and applications.

Plastic Resins: The Transformation Process from Raw Materials to Finished Products

Principal raw materials in the form of plastic resins undergo physical and chemical transformations in a predetermined sequence to become various types of plastic products. Molding and modification form the essence of the process.

First of all, raw synthetic resin pellets are not usually applicable in that form. In order to achieve the necessary properties, various additives are precisely added to the system, e.g., plasticizers for improved flexibility, stabilizers for resistance to aging, and masterbatches for deep coloring. This operation, named "modification", defines the fundamental properties of the end material.

The modified plastic resin is then shaped to its final shape through high-pressure and high-temperature molding processes such as injection molding, extrusion, and blow molding. For example, LS Precision Manufacturing, through its advanced injection molding technology, has the ability to precisely transform high-performance engineering plastic resins into dimensionally stable, complex precision components that have common application in high-end electronics and automotive applications.

The quantum jump from the base resin to high-performance end products is a process. LS Precision Manufacturing thoroughly comprehends the inherent technologies and processes in this transformation process to provide consistent quality and reliability for every product.

Performance Comparison: What Are The Characteristics Of Resins And Plastics?

Although both resins and plastics are polymer substances, differences in use and form lead to their having some very distinct performances amongst them. We can compare them across a number of dimensions.

1. Hardness and mechanical strength

Raw synthetic resins are either viscous liquids or granules. They are low in hardness, toughness, and impact resistance in nature. However, compounding with fillers (e.g., glass fiber) and toughening agents in finished plastics makes them much harder with high tensile strength and impact resistance. These finished plastics can meet diverse requirements ranging from flexible films to rigid structural components.

2. Temperature resistance

Most of the base resins have poor heat resistance and easily soften or degrade when heated. However, plastic products with stabilizers and other additives greatly enhance the thermal stability of plastics. For example, modified engineering plastics (such as nylon and PC) can be utilized for long periods of time at temperatures above 100°C, which is difficult to achieve with raw resins.

3. Processing performance

As a raw material, resin is prized for its high "plasticity," in the sense that it may be melted and formed through heating, injection molding, extrusion, and so on. Plastic, though, is the name given to products that have a permanent shape after processing, with stable properties that cannot be remelted and reformed (thermosets) or can be reprocessed with degraded properties (thermoplastics). That is, resin is flowable and formable, while plastic is of fixed shape and use.

The attributes of resin are "raw" and "single," which is where the material comes from; and the attributes of plastic are "designable" and "complex." Through modification techniques, various excellent properties can be integrated to ultimately meet the demands of complex and diversified application circumstances.

Application Differences: When To Use Resins And When To Use Plastics?

Because they exist in such different forms and with such different properties, resins and plastics perform different roles in actual applications. In the following, LS Precision Manufacturing will detail their differences in several fields of application. Hopefully, this will make your choice simpler.

1. When to choose resins?

Resins are primarily used as building blocks. If you are going to make a finished product, the first thing you buy is some synthetic resins. Resins are also an unbeatable choice for applications that require on-site molding or specialized curing. For example:

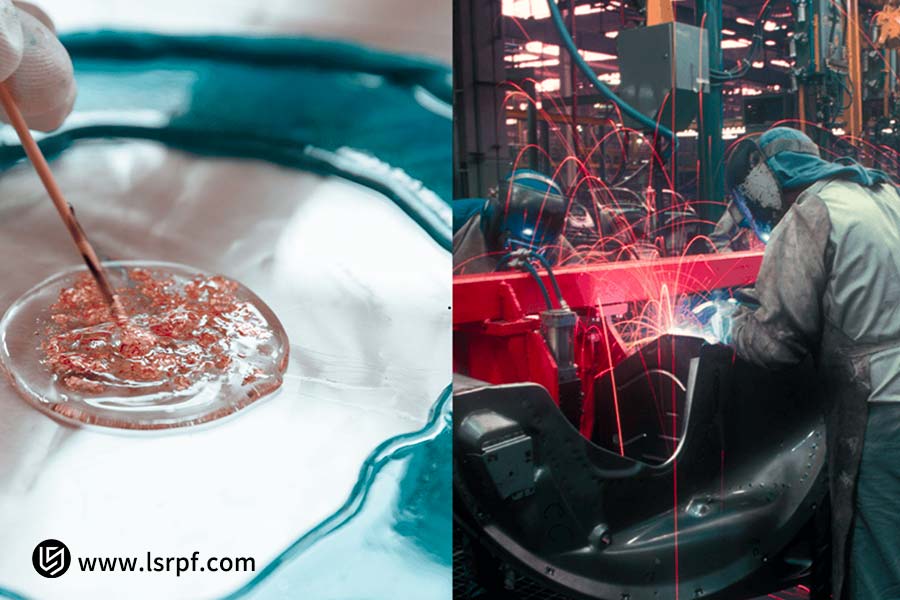

- As a raw material: They are used in the production of plastics, coatings, adhesives, and synthetic fibers.

- Direct Applications: They are used in the creation of art work (such as amber jewelry), the formulation of specialty paints and coatings, and as encapsulants for electronic components (such as epoxy potting compounds). In these, their fluidity when liquid and their stability when cured are being put to use.

2. When to choose plastics?

Plastics are finished end products. When you need to directly obtain a part or object with determinate shape, size, and stable properties, plastic products are appropriate. For example:

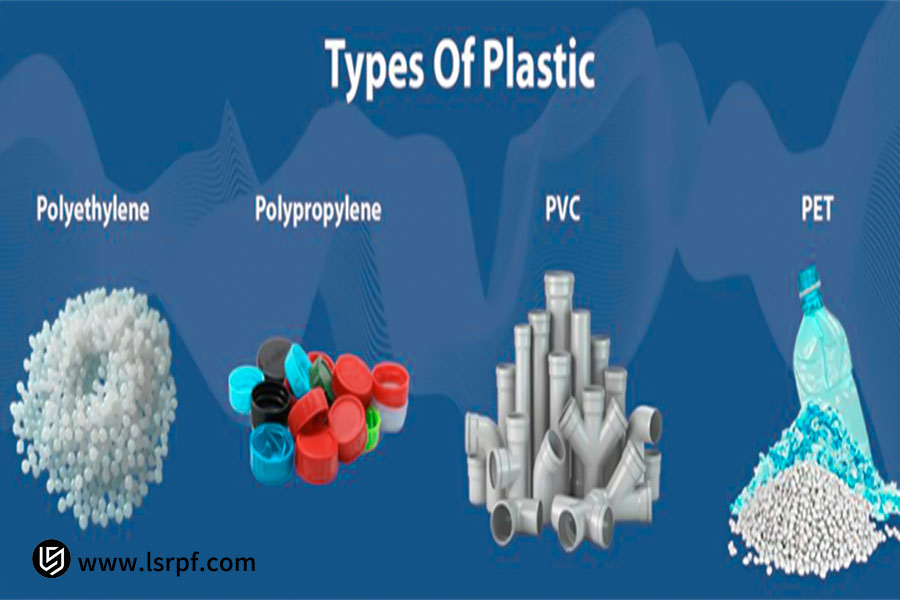

- Daily necessities and packaging: mineral water bottles, food packaging film, toys, furniture, etc.

- Industrial components: car bumpers, appliance housings, electronic equipment components, etc. These products directly utilize the general properties of plastic molding, such as lightness, strength, and insulation.

Summary of selection criteria: The manufacturing process is the determining factor for selection.

- If the product is upstream in the manufacturing process and requires reprocessing of basic chemical raw materials, then resin has to be used;

- If the product is downstream and requires direct application of the end product, then plastic has to be selected.

Environmental Considerations: Sustainability Comparison Of Resins And Plastics

In terms of sustainable development, the environmental impact of plastics and resins is quite different. The intrinsic differences lie in their origin and chemical structure. Then, LS Precision Manufacturing will contrast the differences between them from three environmental perspectives: biodegradability, recycling difficulty, and green production.

1. Biodegradability comparison

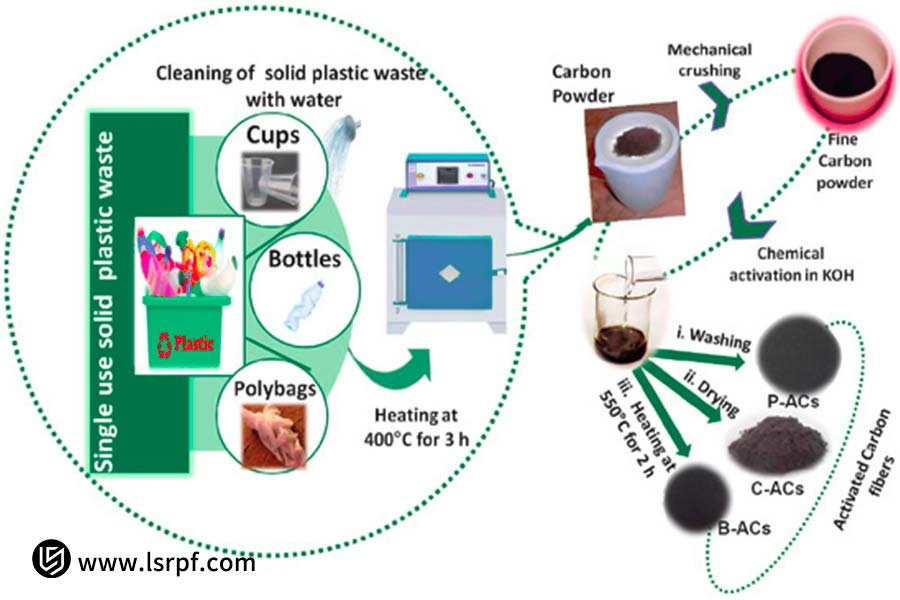

Natural resins are the product of plant secretions and are organic matter, theoretically biodegradable. Most synthetic resins and the plastics they form are petroleum-derived. Their stable polymer structures are not readily broken down by natural microorganisms with ease. Plastics, in particular, can persist in the environment for centuries and are therefore a major source of "white pollution."

2. Recycling difficulty analysis

The recyclability of plastics depends on their type. Thermoplastics (e.g., PET and PP) can be melted and reprocessed and possess high recycling value. Thermoset plastics (e.g., epoxy resins), however, are not reshapable once set and recycling is extremely problematic and usually restricted to landfill or energy conversion. The resins themselves, the raw materials, do not present recycling issues.

3. Green manufacturing recommendations

The driving force for the green transformation of the industry lies in:

- Source substitution: Research and develop biodegradable plastics, switching from petroleum-based to renewable raw materials.

- Process innovation: By employing advanced processes such as LS Precision Manufacturing, design is optimized to reduce material consumption and improve production yield, thereby reducing waste generation at the source.

- Circular economy: Strengthen the sorted recycling mechanism, prioritize thermoplastic materials with recyclability repeated use, and strengthen the use of resources.

As a conclusion, from the point of view of the environment, natural resins are superior to synthetic resins and plastics. The future lies in the reduction of the use of fossil raw materials and the application of green management for the lifecycle of products.

LS Case Study: How To Select The Most Suitable Resin Material For Medical Customers?

1. Client challenge:

In medical practice, the question "what is a resin" is far more than a theoretical one; it's a critical practice with direct applicability to patient safety and product functionality. The following challenge faced by one long-time medical device client illustrates this--they needed a material for a critical component of a new in vitro diagnostic device that has to possess excellent biocompatibility, be capable of withstanding multiple gamma-ray sterilization, and maintain outstanding dimensional precision and stability.

2. Limitation of traditional solution:

Conventional choices are limited by the fact that general-purpose plastics (such as ABS or general PP) can't simultaneously meet stringent medical standards. They may age and become brittle after sterilization, or contain trace amounts of extractables, which may interfere with test results and biosafety.

3. LS Precision Manufacturing's innovative solutions:

LS Precision Manufacturing's innovative solutions are based on a deep understanding of the nature of the raw material itself: "What is resin?" Our materials engineers went beyond off-the-shelf plastics and returned to the upstream specialty synthetic resins. We narrowed down two high-performance medical-grade resins for the client: gamma-ray-resistant polypropylene (PP) resin and PEEK (polyetheretherketone) resin, and submitted a comparative study in detail. The first, which is very cost-saving with excellent chemical resistance, is used for device housings and other structural components; the second, which has high strength, heat, and dimensional stability, is used to manufacture core precision valve seats and connectors.

4. The result and value:

Via LS Precision Manufacturing's cleanroom molding and precision injection molding that is state-of-the-art, these specialty resins are optimally transformed into medical-grade components. The result and value were realized in: the product passed all biocompatibility certifications (e.g., ISO 10993) with a single sterilization, with no loss in performance via repeated sterilization, and significantly increased yield, successfully enabling the client's product to access the global market in a short while. This case study firmly demonstrates that innovation based on fundamental resin material science is the answer to high-end medical manufacturing challenges.

Cost Analysis: How Significant Is The Price Difference Between Resins And Plastics?

The price difference between resins and plastics is not a question of numerical comparison, but it varies according to raw materials, depth of processing, and added performance. The basic relation is: resin is the price of the base raw material, and plastic is the price of the final product, including the price of modification and processing.

Typically, the price of commodity plastic, general-purpose resins (for example, PP and PE raw materials) of the same weight is lower than the price of standard plastic products (for example, typical plastic parts) manufactured from them. This is because the price of plastic includes not only the price of raw resin but also the advanced processing expenses such as additives, equipment depreciation, power, and labor. However, the high cost of high-performance specialty engineering plastics is largely due to technical challenges in producing the resin itself (i.e., PEEK resin) and the more exacting purification and modification costs. The main factors affecting the costs of both are detailed in the table below:

| Cost Structure | Resin | Plastic |

| Main Cost Sources | Petrochemical raw materials, monomer synthesis, and the complexity of the polymerization process. | Resin raw material cost + additive cost + processing energy and loss + mold and equipment amortization |

| Performance-Cost Relationship | Basic general-purpose resins are cheap; specialty and medical-grade resins are extremely expensive. | The higher the performance requirements (such as high-temperature resistance and creep resistance) and the more precise the dimensions, the greater the proportion of processing and modification costs. |

| Procurement Method | Pellets or powdered raw materials are typically purchased by the ton. | Customized finished products are usually purchased by the piece or per order. |

Material Selection Recommendations:

- Prefer finished plastic items: For standardized requirements (such as universal housings and packaging), it is easier and less expensive to directly purchase plastic items, without having to make heavy in-house R&D and production investments.

- Bespoke resin solutions from the source: Where there are unique performance requirements (e.g., medical or high-strength) to be fulfilled, we work with suppliers who possess material development competencies (e.g., LS Precision Manufacturing) to engage at the resin selection and modification stage.

Although there is a greater initial investment, this can provide improved overall cost-effectiveness in mass production through design optimization, increased yield, and improved product performance.

FAQs

1. Is all plastic made from resin?

Yes, virtually all plastic products make use of synthetic resin as the basic raw material. Unadulterated resin is rarely used by itself, however. It typically must be mixed with additives such as plasticizers, stabilizers, and fillers, and then be processed and transformed through means such as heating and pressurization in order to achieve desired properties in the final plastic product. Thus, resin is plastic's "mother," and plastic is the refined resin-based composite material and final product.

2. Is epoxy resin plastic?

Epoxy resin is a general thermosetting resin, not a finished plastic product. However, it is an important raw material in the plastics industry. With the cross-linking of a curing agent, it forms an infusible, insoluble, three-dimensional network structure and becomes a thermoset plastic product. These products have widespread uses in electronic packaging, composite materials, coatings, and adhesives with excellent mechanical properties and chemical stability.

3. Which material is stronger?

Generally, reinforced and modified engineering plastics (nylon with glass fiber, for example) are much stronger than base resins that have not been treated. Yet certain specialty resins, such as liquid resins, can be reinforced with fibers (carbon fiber, glass fiber) to create high-performance composites. Their specific strength and modulus even exceed those of most metals, so they're utilized widely in aerospace and high-performance industrial applications.

4. How do I choose the right material for my project?

LS Precision Manufacturing offers free professional material selection consulting services. Our engineers will completely consider your product's operating environment, mechanical performance requirements, chemical resistance, sterilization, and cost budget. We'll recommend the optimum choice from among hundreds of resins and engineering plastics, help you achieve a balance between cost and performance, and accelerate project realization.

Summary

Plastics and resins are not simply synonyms; rather, they speak of a very closely related relationship between "raw material" and "finished product" along the industry chain. Resins, particularly synthetic resins, are the precursors to plastics; plastics, however, are end-use materials of varying properties, derived through the modification and processing of resins. This realization of the fundamental difference is the origin of making the right decision. In material selection, consider the end use, performance, cost budget, and environmental regulations, rather than simply deciding on its superiority. An intelligent decision begins with a clear understanding of the material's nature and finally relies on whether or not the material meets your project's particular demands.

If you're still confused by material selection, summon the materials experts at LS Precision Manufacturing. We can not only provide you with professional, complimentary consultation to clarify the mysteries of "resins" vs. "plastics" selection, but also single-source service, from specialty resin selection and formula development to precision molding, tailored to your product design, performance criteria, and production environment. This ensures your project is brought to life at optimum cost and with peak efficiency.

Upload your design drawings now and get an instant plastic injection molding (plastic injection price), let LS be your strong backing in pursuit of ultimate plastic injection molding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com