A perfect pipe bend may be ruined by a bad joint.

Imagine that you use aprecision CNC pipebender to make a handrail pipe with perfect curvature and smooth lines, and the only thing missing is to weld the vertical column accurately. When processing the end of the column, you may subconsciously choose the taper bit when faced with the familiartaper bit and the peculiar saddle bit. But this choice determines the success or failure of the project.

If you choose a taper bit, the end of the column will be a flat or slightly inclined plane afterdrilling, and there will be a gap when it fits with the surface of the bent handrail pipe. It is difficult to conduct heat evenly duringwelding, and the solder must "bridge" the gap. As a result, the joint is full of gaps, stress concentration, and easy to crack and fail, and the perfect pipe bend is lost.

Choose a saddle bit, whose unique curved surface profile is specially designed to match the curvature of the outer diameter of the target pipe. After processing, the concave surface of the end of the column is almost the same as the curvature of the handrail surface. When docking, it fits tightly and has a large contact area. During welding, the heat is evenly distributed, the solder can penetrate firmly, and the joint is strong and can withstand loads.

The core difference between a taper bit and saddle bit is that one creates a "gap" and the other creates a "fit", which determines whether the elbow joint is strong and reliable or fragile and vulnerable. Understanding this difference is the first step to avoid the tragedy of "a perfect elbow ruined by a bad joint". Next, we will deeply analyze theprinciples and application scenarios of the two drill bitsand why the saddle bit is the preferred tool forpipe butt welding.

Quick Reference Table Of Key Information Of Taper Bit And Saddle Bit

| Tool Name | Core Function | Machined Geometry | Typical Applications |

|---|---|---|---|

| Taper Bit | Creates a taper (flare) in a flat surface or hole | A conical hole or depression | Countersunk screws, valve seats, tapered pin holes |

| Saddle Bit | Creates a concave cut at the end of a tube | A "saddle"-shaped groove | Connects one round tube to another at a vertical or angle |

This guide will thoroughly clarify the differences between these two tools, take an in-depth look at the uses of each, and use a real-world manufacturing example to show you why understanding the ‘tube opening’ is more important than you think when working withbent tube parts.

Here’s What You’ll Learn

- The ultimate difference in core mission:Why is the taper bit a "hole finisher" and the saddle bit a "pipe tailor"?

- Analysis of key structures and functions:the cutting principles, design features and fundamental reasons for the two drills' non-interchangeability.

- Fatal misunderstanding of safe connection:Why does using a taper bit instead of a saddle bit to connect pipes cause structural risks?

- Industrial-grade practical case:How can a 50-meter safety handrail project achieve a 30% increase in strength and a 50% reduction in construction period with a saddle bit?

- Authoritative answers to frequently asked questions:Selection of alternative solutions for pipe openings, and the logic of the order of bending and opening.

Now, let us uncover the essential differences between these two key tools inprofessional metal processingand completely avoid connection risks!

Why Should You Trust This Guide? Practical Wisdom From LS Pipe Bending And Manufacturing Workshop

Hi, I’m Gloria, an engineer atLS Tube Bending.At LS, we know thatbending a tubeis much more than just setting angles and radii. Our goal is to deliver custom tube bending components that aretruly “ready-to-use”—precision is the basis, andensuring they fit perfectly with the rest of the project is the key.

This focus comes from bitter lessons. I’ve seen too many industrial safety handrails fail due toimproper handling of welded joints. A cruel fact:90% of the strength of a handrailis tied to the joints! Improper design often leads to bloated, ugly welds, which are not only ugly, but also bury huge hidden dangers of insufficient strength.The root of the problem is often not the welding itself, but the failure of the early tube bending design and manufacturing to create ideal conditions for welding.

This is where LS goes beyond ordinary “online tube bending services”.What we provide is thepractical wisdomaccumulated from countless independent tube bending into solid frames. We know how to design the ends (grooves, allowances) to make welding smoother and the welds more beautiful and solid; we know how to control rebound to ensure accurate alignment; we can select materials and processes to ensure the final joint strength.

This guide is the result of sweat and insight from our workshop floors.It is about how to make your products - whether handrails or complex systems -truly safe, reliable, and beautiful.At LS, we are responsible for your success and safety. I am Gloria, and I am here to answer yourbending integration challenges!

Tool Analysis #1: Tapered Bit - Hole Finisher

“The core task of a tapered bit is not to make a new hole, but to transform an existing hole.”

Working principle and purpose of tapered drill

Functional core:Precision machiningof tapered cutting edge

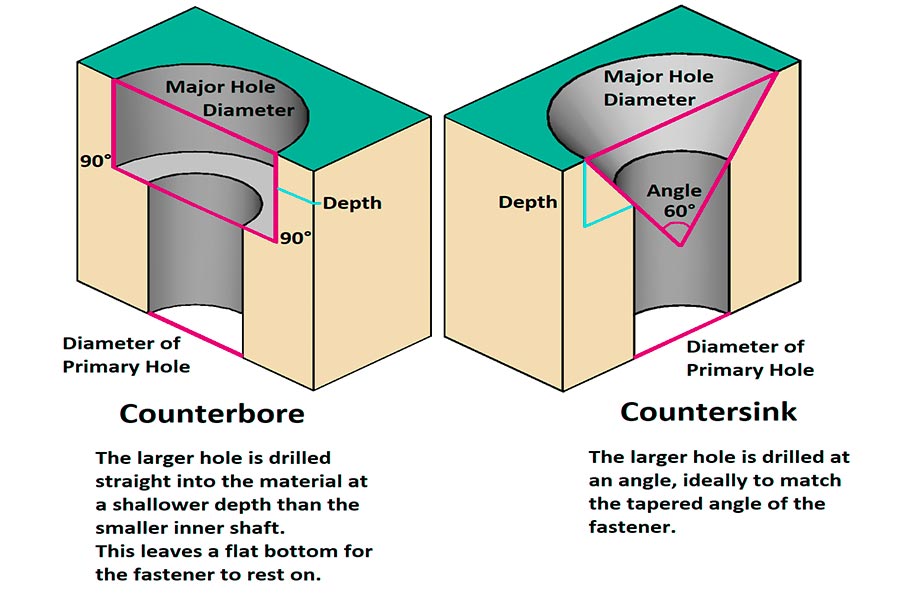

The core design of tapered drill is its tapered conical cutting edge (common angles are 60°, 82°, 90° or 120°). When thedrill rotatesand cuts into the edge of the pre-drilled straight hole:

- Multi-stage cutting:The tapered structure makes its cutting edge start from the edge of the hole mouth and gradually expand the hole diameter from shallow to deep;

- Forming control:By controlling the feed depth, a smooth and consistent tapered bevel is accurately machined at the hole mouth;

- Material removal:Only the local material of the hole mouth is removed to form a smooth transition tapered surface without changing the original depth of the hole.

Fundamental purpose:To create a matching geometric structure for subsequent assembly or functional requirements, and to improve the practicality and process quality of the hole.

Application scenarios: Accurately solve the three major assembly pain points

| Scenario | Functional realization | Value |

|---|---|---|

| 1. Countersunk hole | Processing conical "seats" for flat head screws and countersunk rivets so that their heads are flush with the workpiece surface. | Avoid bulge interference, improve aesthetics, and reduce friction of moving parts (such as aircraft skins, furniture assembly). |

| 2. Deburring | Quickly remove sharp metal burrs or flanging produced by the hole mouth after drilling. | Improve operational safety, protect cables/pipes, and provide a flat base surface for painting/electroplating. |

| 3. Conical pin hole | Processing high-precision conical surface (usually 1:50 taper) forms a self-locking fit with the conical pin to achieve zero gap alignment. | Used for mold positioning and precision mechanical assembly to ensure reset accuracy after repeated disassembly and assembly. |

Key difference from taper tap: Clarification of the essence of function

Taper drillsare often confused with taper taps (Taper Tap). Although the two have similar names, their functions are completely different:

| Comparison dimensions | Countersink | Taper Tap |

|---|---|---|

| Core functions | Change the shape of the hole: cut out a conical concave surface. | Process internal threads: cut out a spiral groove on the hole wall. |

| Output results | Smooth taper (no threads) | Threaded hole (taper refers to the guide structure at the front end of the tap) |

| "Taper" Meaning | Describes the shape of the drill body (conical) | Describes the progressive thread design at the front end of the tap (easy to tap) |

| Typical applications | Provide a flush mounting surface for screws/rivets | Pre-processing a taper-entry threaded hole for bolts/screws |

Key summary:

Taper drill = taper | Taper tap = tapping

"Taper" in a tap only refers to the progressive thread design at the starting end (reducing the risk of chipping), and the final hole is still a cylindrical threaded hole, not a tapered hole. There is no overlap in the processing goals of the two.

Practical significance

As afinishing tool, tapered drill bits are indispensable in the fields of manufacturing, woodworking, and aviation maintenance. Understanding the difference between them and tapered taps can avoid scrapping workpieces due to incorrect tool selection (such as misusing tapered drill bits to process threads). Its value lies in solving big problems with micro-operations - through millimeter-level surface modification, assembly accuracy, safety, and life are greatly improved, perfectly interpreting the engineering philosophy of "details determine quality".

Tool Analysis #2: Saddle Bit - Tailoring Tubes

In the delicate world of tubular framing and construction, there is a tool that experienced craftsmen consider a “secret weapon”: thesaddle drill bit(more generally known as a tube notcher or tube notcher). It’s not the most visible piece of equipment, but it’s often the key to creating a strong, beautiful, professional-grade connection.

How Saddle Drills Work and Their Purpose

Core Function:The fundamental function of a saddle drill is to solve one of the most common issues inpipe joining: how to place the end of a pipe squarely on the concave outside surface of another pipe. Assume that when connecting two pipes in a Y- or T-design, the end of one of the pipes (the connecting pipe) needs to be cut off to a "concave" profile that perfectly fits the outer diameter curvature of the carrier pipe (the main pipe). This is where the saddle drill bit excels.

How it works:

It is essentially a hollowmilling cutteror drill bit specifically designed. Its cutting edge geometry is precisely designed to match the concave shape of the target main pipe outer diameter. When in use:

- Saddle drill bit must be attached to a drill press,milling machine, or slotting machine.

- Secure the pipe to be joined (the pipe to be notched) on the drill press table or specialized fixture.

- Locate the saddle drill so that its center line will match the position where the attached pipe needs to be grooved, and its concave curve matches the main pipe outer diameter design.

- Start the equipment, the saddle drill rotates and feeds in a downward direction, and its special concave cutting edge will mill away the material at the end of termination of the joined pipe exactly, with a "saddle" or "notch" that matches exactly the curvature radius of the outer surface of the main pipe.

Result:This well-cut concave cut-out leaves space for the end of the joined pipe to "sit" on the curved surface of the main pipe solidly and steadily like a saddle. This intimate bodily contact is the basis for subsequenthigh-quality welding.

Indispensable Applications

Saddle drills are used in many applications, and can be used wherever round tubes (and occasionally square/rectangular tubes) need to be overlapped tightly in order to form solid nodes:

- Bicycle/Motorcycle Frame Manufacturing:This is another long-time standby use for saddle drills. The T/Y-shaped joint regions of the main beams of the frame, downtubes,top tubes, seat tubes, rear triangles, etc. must achieve high strength with minimum stress. Saddle mouth enables tube ends to fit into the main tube closely, an important operation for making light, strong, high-performance frames.

- Roll cages and safety guardrails:Whether it is racing, off-road vehicles or work areas, the basic need of roll cages and safety guardrails is unyielding strength. The joints operated by saddle drills provide the greatest area of contact, and the weld can absorb humongous impact loads as well as cyclic loading, which is the basis of ensuring safety.

- Handrails and railings:In interior design and architecture, the structural fit of handrail crossbars on railing posts, and the fit between complex handrails not only needs to have a stable structure, but also a frail and smooth look. The saddle mouth makes the transition in joints natural, and grinding work after welding is less, which can show a clean and professional appearance.

- Any such assembly requiring T-shaped or Y-shaped pipe connection:

This covers an extremely wide range of applications, including:

- Metal furniture (frame, tables and chairs)

- Booths, shelf frameworks

- Small building frames (pavilions, canopies)

- Art works

- Agricultural equipment frames

- Pipe structure custom projects.

Why is it so important? The character of pro-grade connection

The precise "concave" cut made possible with the saddle drill bit is not a cosmetic requirement, but rather a performance and quality-improving feature ofpipe connections:

- Maximize joint strength and welding area:This is the most significant and central benefit. With perfect fit, the two pipes' contact area comes to a theoretical maximum. When welded, the molten solder can evenly and continuously fill the whole joint surface to create an entire, deep penetration weld. This uniformly spaced weld encourages actual transfer of load from the source pipe to the receiving pipe and, as a result, substantially enhances the overall strength, stiffness and rigidity against fatigue of the connection. In contrast to this, having only the flat-cut pipe end on the main pipe (point contact or line contact) has some amount of weld area and stress concentration, which is a structural deficiency.

- Significantly reduce solder filler:Unless there is a precise notch, there will be unsightly and irregular gaps between the pipe end and the top of the main pipe. To cover these gaps to achieve structural stability and seal, welders have to use a lot of welding rod orwelding wireto fill. This not only wastes expensive welding material and doubles the time for welding, but more importantly, excessive filler metal creates stress concentration points and may conceal welding faults such as lack of penetration.Saddle drillsseal these gaps and utilize minimal solder to produce high-quality welds.

- Much improve aesthetics and professionalism:The fits together seamlessly, and the welds formed in the welding process are natural, smooth, and thin. No unnecessary, ruinous grinding is required to strip away deposited solder or create low areas. Finished joints are clean, smooth, and merge naturally, evidence of exceedingly high quality workmanship and professionalism, reducing the effort and time of post-finishing processes much.

- Improve assembly accuracy and efficiency:Accurate notching enables simpler and more accurate positioning and clamping of the pipe before welding. The pipe "sits" in correct position, conserves adjustment time at assembly and aids in the dimensional integrity of the entire structure.

The saddle drill bit (tube opener) is more than a "hole-making" tool. It is a high-precision "tailor" that forms high-strength, high-efficiency and high-aesthetic jointing between tubes. Through the duplication of the outer diameter curvature of the main tube precisely, it generates an exact fitting surface, giving a solid base for the subsequent welding process. Whether it is an extreme-performance frame, a life-safety-related roll cage, or a detail-conscious railing, the secret to its success lies in the saddle drill bit behind the strong construction and good looks. To any serious tube processor, it is truly a "secret weapon" of great importance.

Practical Case Analysis: Customizing "Seamless Connection" Safety Handrails For Industrial Platforms

LS engineerssaid that the reliability of platform safety handrails in industrial environments is related to the safety of workers' lives and regulatory compliance, and is a touchstone for testing the professionalism of manufacturers. The case shared this time reflects this point.

Customer Challenge: Create a beautiful and sturdy handrail system

Serving a large modern warehouse, it is necessary to install a safety handrail system with a total length of more than 50 meters on the edge of the second-floor working platform. The handrail needs to make multiple 90-degree turns and a vertical column support is set every 1.5 meters. The customer's core demands are as follows:

- Absolute strength:meet and exceed OSHA lateral thrust standards, which is a hard safety requirement.

- Modern beauty:As a modern facility, avoid rough and bloated on-site welds that affect the appearance.

- Cost and efficiency:The construction period is tight, and the customer compares the prices ofpipe bending processingfrom multiple suppliers to seek a cost-effective solution.

Most suppliers may only focus on the needs of a single part, but what customers really need is a complete, prefabricated, efficiently installed, sturdy and beautiful handrail system. The key to the success of the project lies in dealing with dozens of connection points between horizontal handrail pipes and vertical columns, where problems such as insufficient strength, difficult installation, and poor appearance are prone to occur.

LS's solution: CNC bending + precision opening = perfect joint

Based on a deep understanding of customer pain points, we did not just provide "bending services" or "cutting columns", but designed the following solutions from the perspective of system integration:

- Precision CNC bending:We first used a high-precisionCNC pipe bending machineto accurately bend all horizontal handrail pipe sections with 90-degree bends in strict accordance with the design drawings. This step ensures that the lines of the entire handrail are smooth and the size is consistent, laying the foundation for subsequent perfect docking. We are well aware that the accuracy of pipe bending directly affects the difficulty of on-site assembly and the straightness of the final structure.

- Choose the "connection artifact" - saddle drill bit:This is the core highlight of the solution. We did not simply cut the top of the column tube flat (a common but ineffective practice). Instead, we used an industrial-grade saddle drill bit (tube opener) for the top of each vertical column tube. This tool can precisely machine a concave "saddle mouth" at the top of the column that is exactly the same as the outer diameter of the horizontal handrail tube.

- Prefabricated ‘ready-to-install’ kits:All horizontal support components with precision bending and vertical columns with perfect ‘saddle mouths’ on the top, together with necessary connectors, are delivered to the customer’s on-site installation team as a complete, pre-assembled ‘kit’. This means that the on-site workers get parts that are ‘tailor-made’ for each other.

Final result: installation efficiency increased by 50%, and structural strength passed the acceptance in one go

"The effect of the solution exceeded the customer's expectations and brought about a dramatic change:

- Installation revolution:The customer's installation team reported that when they opened our kit packaging, they were pleasantly surprised to find that all joints were perfectly prefabricated. The horizontal pipe can be directly "sat" on the saddle mouth at the top of the column, and it fits perfectly. There is no need to perform any time-consuming and labor-intensive cutting, grinding or adjustment on site to adapt the interface.Welding workhas become extremely simple, just weld along the perfect seam, and the weld is naturally uniform and beautiful.

- Quantified benefits:

- Efficiency leap:On-site welding and overall assembly time are shortened by an astonishing 50% compared with traditional methods. This saves customers a lot of expensive labor costs and valuable project time, and the project can be completed on time or even ahead of schedule.

- Strength guarantee:Because the saddle mouth provides a large contact area and a perfect force transmission path, the strength of thewelded jointis extremely high. The final structural strength test result is 30% higher than the OSHA mandatory standard, and it passed the acceptance in one go, which makes the customer and us feel at ease.

- Overall value wins:Although our initial quotation (especially the price of the pipe bends alone) may not be the lowest in the market, the customer finally did the math: our solution brought about a significant reduction in installation time, one-time acceptance to avoid rework, and the excellent quality and aesthetics of the final product, making the total project cost (TCO) and final value significantly better than other options. The customer clearly stated that our solution provided the highest comprehensive value.

Key revelation:

When choosing a manufacturing partner, please focus on the full life cycle cost rather than the quotation of a single process. Professional manufacturers will save you excess costs in subsequent links through key pre-processing (such as saddle opening) - this is the hidden value that LS creates for you.

FAQ - Answers To Your Tube Processing Questions

1. Is it acceptable to use a tapered drill bit to connect pipes?

Absolutely not! It is a very wrong and unsafe practice to utilize a tapered drill bit to drill a hole in the end of a pipe to connect to another horizontal pipe. The joint formed in such a way is only a highly unstable point contact or line contact, rather than an ideal stable surface contact. This will produce gigantic local stress concentration, and the weld will have a strong tendency to crack and fail at this stress concentration point when subjected to loading, which is a very severe structural safety hazard. Such a technique must be strongly discouraged for pipe joining.

2. Apart from saddle drill bits, are there any other ways of making pipe openings?

Yes, there are several other ways of making holes in pipes (such as saddle mouths). In production settings, some of the commonly used techniques include hole saws paired with special location fixtures, vertical mills capable of high precision, and the most productive and highly automated laser tube cutting machines. The specific method to employ is dictated by the production run, the accuracy of opening required, and the overall cost budget. For small-scale production or the individual DIY user, hole saws with special location fixtures tend to be the most affordable and convenient means of achieving reasonable accuracy.

3. Do I bend the pipe first or open it first?

There is no single answer to this question, it all depends on the circumstances. For a simple T-joint, it is the common operation sequence to complete the required opening (e.g., the saddle mouth) on the straight pipe first, then weld and assemble it, which is very convenient. However, when designing a frame with complex geometry, a frame or a structure requiring high-precision matching, it is more common to bend the main pipe into shape and fix it in place first, and then measure and process the opening of the branch pipe on site with accuracy according to the real space position and angle of the main pipe after being bent, in order to obtain the best fit and matching accuracy between the branch pipe and the main pipe.

Summary

The basic difference between a saddle bit and taper bit is use: taper bits are used in finishing holes (e.g., chamfering), while saddle bits are used for pipe connection (making precise saddle mouths).In the construction of structures, this is no small thing, it is a leap from "part thinking" to "system thinking.". Ignoring the process of connection (correct use of saddle drills or similar technology, for example) will compromise the strength of the joint directly - even the most perfect bend will not satisfy the purpose due to an inferior point of connection, becoming the Achilles' heel of the project. Correct selection and application of the connection process is the cornerstone of structural safety and success of the project.

Perfect bends require perfect connections!

Is your project calling for complex pipe bending and connections?

Don't let the joint be your weak point!

LS understands the importance of "system thinking."We don't just providehigh-precision pipe bendingparts, but complete manufacturing solutions, anticipating future assembly issues to provide accuracy and reliability of critical connection points (such as saddle mouths).

- We understand:The potential of pipe bends has to be released by good connections.

- We are good at:Core technology for ensuring joint strength.

- We provide:One-stop service ofpipe bending+ connection point preparation to eliminate hidden dangers.

Act now and experience the value of system-level manufacturing!

Upload your design drawings now.Our engineers will use "system thinking" assessment based on your needs (including pipe bending shape and connection demands) to provide an accurate quotation that combines precision bending and quality connection assurance.

Choose LS,use professional system and technology measures to construct a strong and stable pipe framework together!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com