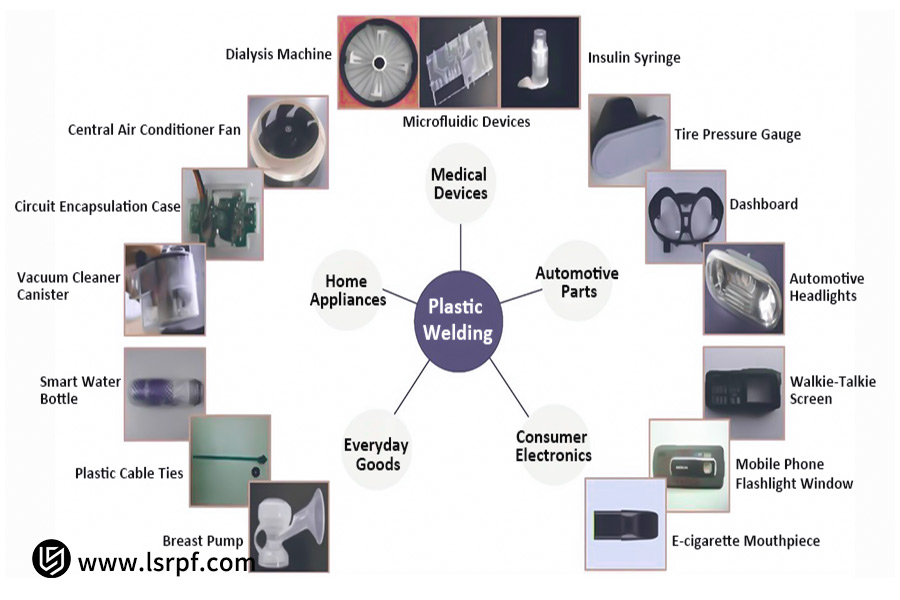

For plastic welding technology, the most often asked question is "What's the best method?" As much as one might be surprised, the question itself already includes a fallacy—no welding process is the very best. So-called "best" is extremely relative to a global compromise among so many variables: the plastics melting characteristics and chemical nature to be welded, component geometric shapes and application conditions, the plant cost limitation and economy demands, and the service demands of finished products. Particular processes like ultrasonic welding, hot plate welding, laser welding, etc., have respective material application scopes as well as respective process merits. In turn, the choice must be made on the basis of a scientific experiment on specific requirements and limitations. The following article will introduce the usage conditions and characteristics of major welding technologies to serve as a preliminary basis on making the right decision.

Quick Reference: Choose Your Tap at a Glance

| Welding Method | Applicable Materials | Main Advantages | Main Limitations | Typical Applications |

| Ultrasonic Welding | Thermoplastics, especially hard materials (such as ABS, PC, PS) | Fast speed (seconds), high degree of automation, clean and consumable-free. | Requires high part geometry and welding head design; not suitable for large components. | Electronic housings, medical devices, small automotive parts. |

| Vibration Welding | Most thermoplastics, including semi-crystalline materials (such as nylon, PP). |

High strength, capable of welding large/complex irregular parts, low material compatibility requirements. |

Expensive equipment, requires part fixation during vibration, and may produce flash. | Automotive intake manifolds, appliance components, liquid containers. |

| Hot Plate Welding | Almost all thermoplastics, especially large or simple geometric parts. | High weld strength, simple and reliable process, capable of welding very large parts. | Long cycle time, possible flash, requires hot plate cleaning. | Automotive taillights, battery boxes, plastic pipe fittings. |

| Laser Welding | Thermoplastics with matched light transmission and absorption properties. | No vibration stress, extremely high precision, aesthetically pleasing, and high degree of automation. | Extremely high equipment costs and stringent requirements for material color and optical transparency. | Precision medical devices, electronic sensors, and consumer electronics. |

| Spin welding | Circular or near-circular thermoplastic parts. | Simple equipment and low cost, high weld strength, and a stable and reliable process. | Limited to rotatable, axisymmetric parts. | Bottle caps, filters, and pipe fittings. |

There is not any one "best" solution. The final solution will be an outcome of the specific mix of material, part shape, volume usage, cost, and final required strength.

Why Should You Trust This Guide? Practical Experience from LS Experts

This paper is based on the accumulated experience of the working personnel of LS. Not just their theory-educated technical personnel are adequately trained, their personnel also have vast practical exposure ranging from commissioning on the front line to production. Their solutions operate both on diverse industrial applications and not on theory.

The LS group overcame the very challenging problems of very airtight environments (to exclude microorganisms) and smooth surface finishing. This technology can deliver watertight welds by managing the energy down to the micron level to create both reliable devices and aesthetics, promising to translate expertise to tangible value.

Is There No One "Best" Plastic Welding Method?

To the plastics joining trade, it is an exercise in futility to search for a lone method. The selection process isn't a yes-or-no proposition; it is a multi-variable optimization process, based on the interplay of five key variables: type of material, part size and part design, sealing and strength needs, volume produced, and cost allocation.

Plastic welding refers to localized melting of the interface of joining by applying heat to the thermoplastic polymers. When stressed, with diffusion and blending of molecular chains, with solidification when cooled, the tight molecular bond is established. There are several processes (e.g., ultrasonic, laser, and hot plate welding) with very dissimilar mechanisms of heat generation, heat transport efficiency, and application of force. For instance, ultrasonic welding is sensitive to geometry and material hardness, while laser welding needs the upper and lower surfaces to have light transmitting and absorbing properties that are opposite.

Thus, it is meaningless to try and estimate the value of a method independent of the particular application. The best welding process is the result of determining what the best compromise is among the numerous restrictions, appropriate to the particular product requirements. There is no single best method, but the most suitable solution.

How Do I Select The Most Suitable Welding Technology For My Project?

The initial step towards selecting the most suitable joining technology for your project is to learn a crucial fact: TIG welding, MIG welding, and arc welding are essentially variants of fusion welding processes on metals, using a high-temperature arc to melt the base material to create a joint. Any one of these processes has absolutely no relevance to the joining of thermoplastics because the resultant higher temperatures cause the decomposition and carbonizing of the same, making the material worthless to form an efficient joint. Knowledge of this fundamental difference is the initial step towards the right choice.

Plastic welding involves melting and re-solidifying the plastic material using heat and pressure. Your decision is based on what your project requires. The next table shows the ideal application conditions for common plastic welding processes that can be used as a preliminary guide:

| Welding Method | Applicable Materials | Best Applications | Key Advantages | Key Considerations |

| Ultrasonic Welding | ABS, PS, PC, Nylon, etc. | Small, hard thermoplastic parts, mass production. | Extremely fast (seconds), automated, and clean. | Part design must be optimized for ultrasonic welding; unsuitable for large parts. |

| Laser Welding | Various thermoplastics (requires light-transmitting/light-absorbing matching). | High-precision, particle-free products (e.g., medical devices, electronic sensors). | Non-contact, vibration-free, seal-resistant, aesthetically pleasing. | High equipment cost, material color and matching requirements. |

| Hot Plate Welding | Most thermoplastics (e.g., PE, PP, ABS). | Large, simple geometric parts (e.g., automotive taillights, radiators). | High weld strength, simple and reliable process. | Long cycle times, possible flash. |

| Vibration Welding | Most thermoplastics, including semi-crystalline materials. | Large, complex, irregular parts (e.g., automotive intake manifolds). | High strength, capable of handling complex curves. | High equipment investment, possible flash and particulate generation. |

| Spin Welding | Thermoplastics, especially round parts. | Axisymmetrical parts (such as bottle caps, filters, and pipe fittings) | Offer low equipment cost, high strength, and stable processes. | Limited to rotatable circular parts. |

- The ultimate choice is a general assessment of material characteristics, part configuration, volume to run, cost allowance, and quality specification.

- Rather than pre-screening, we strongly advise thorough consultation with seasoned plastic welding vendors or designers, process prototype runs, to produce the most efficient and repeatable result on the project.

What Are The Important Determinants Responsible For The Success Of Plastic Welding?

Material Compatibility

The effectiveness of plastic welding most often transcends the ephemeral nature of the actual welding process itself and reduces down to a list of greater, more fundamental process considerations. Basic material compatability is absolutely necessary, dictating whether or not diverse plastics even may be placed together on the molecular level. Like materials, those that possess the same melting points and chemical polarity may be welded solidly, an initial step which LS engineers must take extreme care to guarantee early on in a project.

Part Design

Second, part design is important, especially the weld joint geometry. Consider the part design of the "energy directors" applied with ultrasonic welding. Triangular in shape these are that focus the energy and direct the temporary plastic melt. Accuracy of their location and size determine weld strength and reliability. LS, due to its extensive database of experience and simulation software, designs to customer specification for day-one consistency in welding.

Accurate Control of Surface Cleanliness and Processing Parameters

Also, the key aspect of stable volume production is the tight control of the surface cleanliness and the conditions of the process. A minute level of oil, dust, or moisture will produce an interface weakness and result in the seal failure. LS takes the control over the clean shop environment and employs the latest welding machines featuring real-time energy feedback and close-loop control systems to control the pressure, time, and amplitude on the timescale of milliseconds and abolish any kind of human intervention to ensure each final output meets pre-specified higher levels of quality.

- That is, the higher-quality and reproducible plastic weld is the product of materials science synergy, accurate mechanical design, and smart process control.

- It is through complete control of these all-important variables that LS turns what would otherwise be an ostensibly ordinary welding process into quality benefit that is consistent.

How Does LS Overcome Difficult Plastic Welding Challenges? – A Medical Device Enclosure Sealing Case Study

1. Client Challenge:

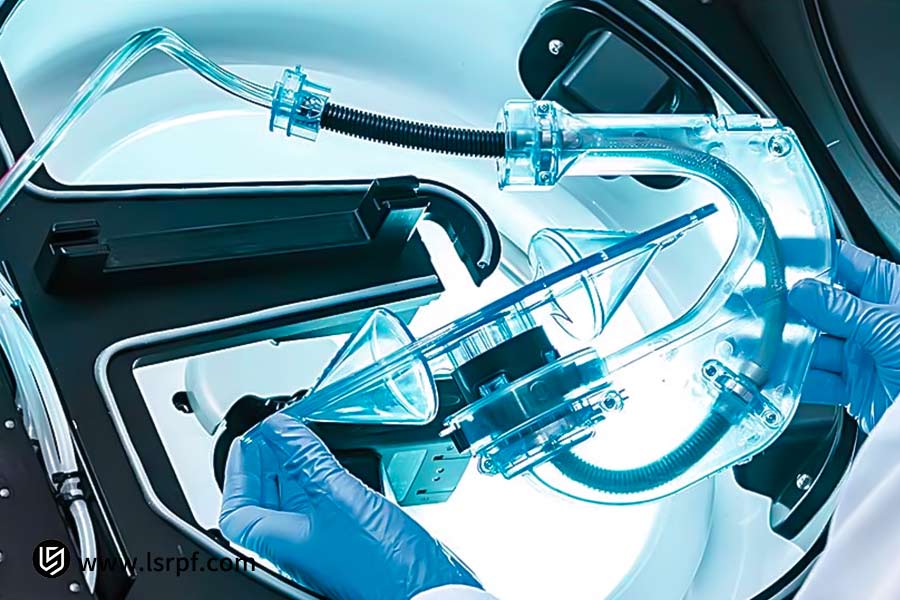

The giant medical equipment manufacturer was faced with the insurmountable task: creation of a permanent full seal in the ABS complex plastic housing of an in vitro diagnostic device. The seal must be very firm in order to maintain a sterile condition while providing a perfect-looking finish. Primarily, the welding process must not have any particles or dust on it in order to prevent contaminating sensitive sensors and fluid channels that would cause the failure of the device. Existing adhesives were eliminated by the risk of aging and the formation of chemical contaminations.

2. LS Innovative Solutions:

Confronted with this hurdle, the LS engineers did not suggest traditional ultrasonic or vibration welding owing to the reason that these would create vibration-generated particles. In keeping with a solid foundation on material properties and process maturity, the LS team creatively suggested laser transmission welding as a particle-free technology. The technology precisely controls laser energy, hence penetrating the outer translucent ABS component. The laser energy is taken in by a specific light-absorbing material below, transforming the same into heat leading to localized melting only on the weld interface. The whole process is vibrationless and contactless and almost escapes particle formation.

3. Final Results and Value:

Lastly, LS attained a part that ideally met every stringent requirement. The weld was smooth, solid, 100% hermetic sealing, clean, smooth, and no secondary processing. The part underwent many rigorous validations, e.g., ISO 10993 biocompatibility tests, which provided precious assurances to the customer's product reliability and rapid market entry. This is the full expression of LS's inherent capability to transform challenging engineering hurdles into valuable advantages.

Should I Buy My Own Plastic Welding Machine Or Hire The Services Of A Professional Welding Company?

It's a cost, technology, and strategy choice for the majority of small- to medium-sized companies. Both options have pros and cons, and the tipping point comes down to the issue of knowing your needs.

Buying Equipment with Confidence

Purchasing equipment on one's own is suitable to situations when the line of products is simple, the annual volume of manufacture is large, and the welded process is very secret and should be kept within the firm. It entails a huge initial equipment expense, ongoing consumable expense and maintenance expense, and the expense of personnel for the training of skilled operators and process engineers. And there is the cost risk of trial-and-error development of processes and the standstill risk of equipment.

Find a Qualified Welding Company

By comparison, the option of a commercial welding service such as LS provides the ideal solution to volume-high, small- to medium-volume manufacture or fluctuating demand businesses. There is neither upfront assets invested nor any initial expense, just pay-per-piece costs with immediate entry into the latest welding technology, top-shelf equipment, and an unmatched quality assurance process. That keeps initial costs and business risk low while providing repeatable welding consistency with the flexibility to manufacture to more towards the aging of the product as well as to market growth.

- In summary, where most small-scale producers of goods are concerned, it is cheaper, a better gamble, and more adaptable strategic move to work with a specialist service provider.

- It converts an expensive specialist installation into a stable, reliable chain relationship to deliver the best outcome with a minimum of danger.

What Are Other Typical Joining Methods For Plastics Aside From Welding?

Aside from welding, the plastic parts may be attached using mechanical fasteners (e.g., screws and clips) and adhesives.

- Mechanical fasteners possess quick installation and removal properties and should thus be applied on parts that should be frequently maintained or replaced.

- Adhesives should be employed where attachment of dissimilar material or complicated geometries is required and should possess adequate stress distribution.

Where strength matters, permanent sealing (waterproofing & dustproofing) & absolute dependability are required, welding possesses unparalleled core competencies. Previous employed adhesives or mechanical fasteners are subjected to stress concentration sometimes, but welding redefines the material at the molecular level to develop an even-graded bond matching the parent material strength. It becomes the best method to attain an air-tight sealing & structural stiffness.

- Therefore, the choice of the best joining solution entails an overall evaluation of the product performances, productions, and economy needs.

- As a one-stop welding solution supplier, LS possesses expertise in a series of welding processes, yet can also evaluate the feasibility of mechanical fastening and adhesive bonding on the customers' part, thus selecting the best overall joining approach to meet the requirements of product quality and market competitiveness.

FAQs

1. Are all plastics weldable?

Not necessarily. The fundamental principle of plastic welding is to heat and subsequently solidify locally the material. Thermoplastics only will be weldable. Upon heating, such will melt and soften, and upon cooling, can reharden and will be reusable. Conversely, on the initial heating and curing, thermoset plastics establish an irreversible cross-linked network in the molecular structure. Further heat treatment will carbonize and decompose only, rendering them useless and therefore not weldable. LS's materials engineers will perform a material compatibility analysis upon project initiation to ensure process feasibility.

2.How long will a welded joint last?

Ideal weld on plastics, ideally controlled and optimised design-wise, achieves strength virtually equal to the parent material (original plastic part). This is because an extremely good weld allows scope for interdiffusion and molecular chain entangling leading to a strong and dense interface bond. LS utilises the most recent machinery and stringent process controls to achieve every weld to its ultimate possible structural strength.

3.Where do I find a credible local plastic welding company?

For a service provider to be effective, project experience and process proficiency mean little when pitted against being near a facility. A service provider such as LS offers a wide spectrum of welding technology (e.g., ultrasonic, laser, vibration welding) and is able to offer the best technical solution given the material, the design requirements, and the volume of production. LS, through its reputation and expertise in the field, has rendered effective cross-region service support to many customers across the country.

4.Should I buy a plastic welding machine myself or subcontract it?

Unless welding becomes a part of routine daily function within your mass production industry business firm, outsourcing to a seasoned service firm like LS is a wiser choice. Outsourcing provides the flexible pay-per-use approach providing on-demand access to newest process technology, consistent quality of manufacture, guaranteed quality control with no premium on a cost model allowing the deployment to the manufacturing of the goods and their sale.

Summary

Finding the "best" way to weld plastics is a fantasy; the key is really finding the best technology for the job you actually do. It is part design, material science, cost-versus-benefit, and requirements for the line; there is no "right" one.

When plastic materials lack a solution in joining, LS provides the ultimate solution in its full capacity. We have a set of multi-process machines, huge library of materials, in-house experienced engineers, and a complete-scale quality inspection system. Do it now! Upload 3D drawings and specs absolutely free, and we will provide the best welding process, expert DFM (Design for Manufacturability) suggestions, and a clear & concise quote within 24 hours. Let our industry expertise transform your designs into strong products.

Upload your design drawings now and get an instant welding quote (welding price), let LS be your strong backing in pursuit of ultimate welding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com