That breathtaking, perfect arc that is arranged like fish scales.

If you are a welder who pursues excellence, you must understand its value. It is not just a weld, but a badge of craftsmanship. However, behind this perfection that is almost a work of art, it is not just a pair of skillful hands - it relies on aTIG welding machine systemthat works together like a precision instrument. A parameter error or a poor condition of a component can turn the expected "fish scales" into chaotic "ripples", or even cause welding failure, leaving the delicate workpiece with flaws.

This feeling of frustration from falling from the peak is what every TIG welder wants to avoid. But the fact is that many problems that plague welders - such as unstable arc, poor molten pool control, weld oxidation or poor forming - are often not due to poor skills, but from a basic blind spot:a lack of thorough understanding of the key components and their synergy that constitute the "lifeline" of the TIG welder.

The good news is that this fog can be completely cleared.Mastering the core components of a TIG welder and understanding their respective responsibilities and the precise logic of their cooperation is the key step for you to leap from "being able to operate" a TIG welder to "truly mastering" the art of TIG welding.

To help you quickly establish a global understanding, the following are theseven core protagoniststhat constitute a typical TIG welder and perform this "arc ballet" together:

A quick guide to the 7 most important parts of TIG welding

| Component Category | Core Component Name | Core Function |

|---|---|---|

| Host System | Power Source | Provides and accurately controls welding current (AC/DC), and is the "heart" of the system. |

| Shielding Gas System | Provides inert gas (such as argon) to form a protective layer, isolate the air, and prevent oxidation of the molten pool and tungsten electrode. | |

| Work Clamp / Ground Clamp | Reliably clamps the workpiece to build a complete welding current loop. | |

| Control and Execution | TIG Torch | Guides welding current to the tungsten electrode and delivers shielding gas, which is an extension of the welder's hand. |

| Foot Pedal/Amperage Control | Real-time and accurate adjustment of welding current to achieve fine control of the molten pool, which is the "throttle" and "brake". | |

| Consumables | Tungsten Electrode | The core that generates and maintains the high-temperature arc (it does not melt during the welding process). |

| Filler Rod | Add material as needed to fill the weld and create a full weld bead. |

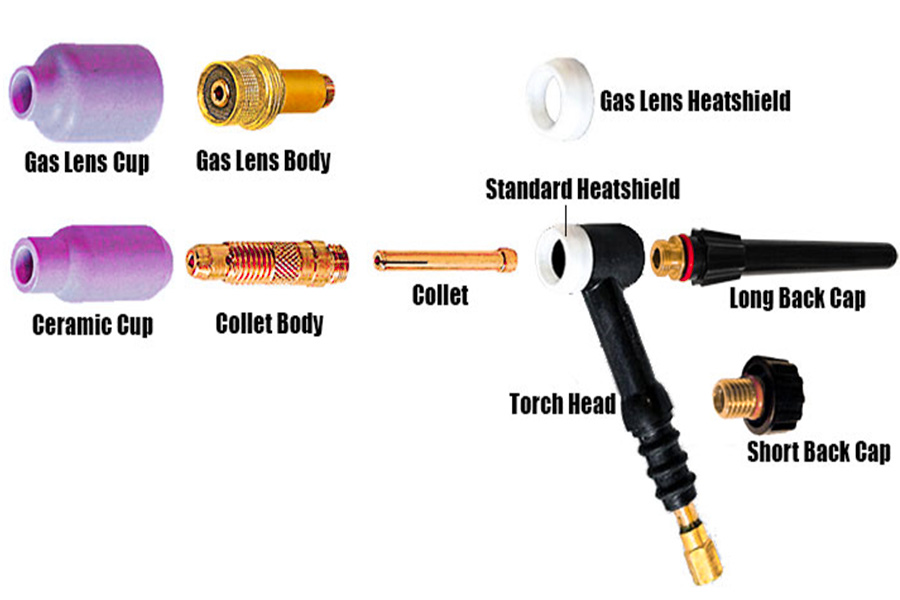

This guide will introduce you to the various components of a TIG welder and their functions. We will then use atig torch parts diagramto take you deep into the internal structure of this "scalpel" and use a real case to show how important it is to choose the right components.

Here’s What You’ll Learn

- Four core pillars of TIG welding system:In-depth analysis of how the four major components of power supply, inert gas system,welding torch /workpiece clamp, and current controller work together to form a complete welding circuit and protection.

- Precision anatomy of TIG welding gun:From tungsten electrode to porcelain nozzle, detailed disassembly of key internal components of welding gun (tungsten electrode, chuck, chuck body, porcelain nozzle, back cap) and their functions, and reveal the secret of gas lens upgrade.

- Professional skills to achieve perfect welds:Master key operating points such as tungsten electrode grinding, inert gas protection optimization, and precise heat control (foot pedal/control switch application) to avoid weld oxidation and deformation.

- Real world combat case:How does gas lens savemedical grade stainless steel welding? By means of a real high-enduring project (thin-walled 316L stainless steel housing), it shows how the right component choice (e.g., gas lens upgrade) and parameter tuning can suppress blackening and weld deformation and achieve "zero defects".

- Clearing the fog:Expert answers to TIG welding core questions (FAQ): Clarifying main questions, for example, thecore process of TIG welding, key advantages and disadvantages, and the fundamental differences in components from MIG welders.

Now let's start to penetrate deeper and know the secrets of the accurate production of TIG welders and master the secret of making ideal welds!

Why are you to trust this guide? Practical experience of LS qualified welding engineers

The value of this guide is actual knowledge tempered in the furnaces of hard practical struggle byLS qualified engineers,and not abstract accumulation.

In LS,TIG welding is the focal point of precision manufacturing. We don't just know how to weld, but we have mastery of the precise matching of parameters and components for different materials and thicknesses. We successfully welded 0.8mm aviation specification titanium alloy thin-walled tubes and created mirror-polished 316L stainless steel housings required in medical equipment - these are just samples of the degree of experience and reliability.

We understand the most critical details:

The delicate difference in arc initiating stability between lanthanum tungsten electrode and cerium tungsten electrode.

The vital function of gas lens in welding of materials such as aluminum alloy.

This is not a copy of the manual, but the real solidification of our pursuit of "zero defect" welds: It is a deep understanding and working acquaintance of pieces that have been proven and distilled millions of times.Choosing this guide is to imbue thewelding skillshoned by top-classand severe conditions to lead you to the pinnacle level of craftsmanship.

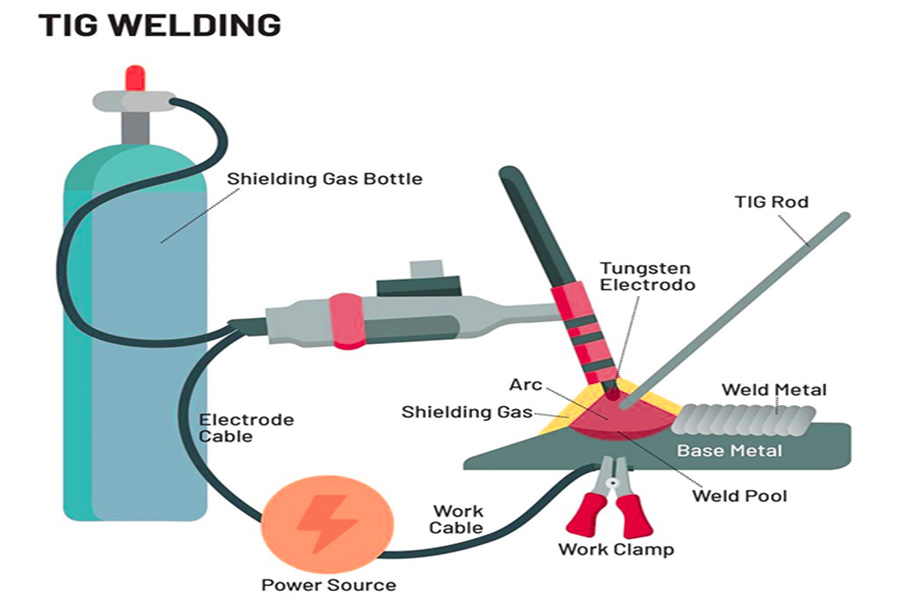

The four main components of TIG welding system

A complete TIG welding system consists of four interrelated parts: power source, inert gas system, workpiece clamp and welding gun, and current controller.

1. Power Source - Brain and Heart

(1) Function:As the core component of the entire system, the power source (i.e.main chassis of the welding machine) has two significant responsibilities:

- Energy conversion:converts the input electrical power from the grid into the regulated and precise current (DC or AC) employed for welding.

- Control unit:allows the operator to choose and control all critical welding parameters, including welding current type (AC/DC), magnitude of current, gas pre-flow/post-flow time, high-frequency arc ignition parameters, etc.

(2) Key knowledge points:

- DC (direct current):widely applied to weld steel, stainless steel, copper, titanium and other metals, with steady arc and deep penetration.

- AC (alternating current):largely applied to weld dense oxide film on metal surface like aluminum and magnesium. The unique "cathode cleaning effect" of alternating current can easily annihilate the oxide film, so the melted metal can be thoroughly mixed together.

2. Inert Gas System - Protective Barrier

(1) Composition:The equipment has mainly three core components in different series:

- High-pressure gas cylinder:Generally filled with high-purity argon (purity should generally be ≥99.99%). Helium (He) or argon-helium mixture is sometimes used to meet specific needs.

- Regulator/Flowmeter:Installed on the outlet of the gas cylinder, to safely reduce the high-pressure gas in the cylinder to working pressure, and also to show and adjust the flow rate of the shielding gas to the welding gun (the unit normally is liters per minute, L/min).

- Gas pipe:Installed between the regulator/flowmeter and the welding gun, to supply the shielding gas to the welding gun head.

(2) Function:The shielding gas (mainly argon) leaks continuously and uniformly from the nozzle of the welding gun, generating a "shield" of inert-gas protection around the tip of the tungsten electrode, the arc zone and the pool of moltenweld metal. This shield jacket totally isolates the air (mainly oxygen O₂ and nitrogen N₂) from the environment such that the hot molten pool is not oxidized or nitrided. This is the unqualified assurance to obtain clean, bright, pore-free, inclusion-free and otherhigh-quality welds.

3. The Torch and Work Clamp - Beginning point and end point of the circuit

(1) TIG Torch

Function:This is the chief tool that the welder uses and holds directly, e.g., a "pen" for fine script.

Action:It transfers the welding current from the power source through the cable to the tungsten electrode at the tip; at the same time, it guides the shielding gas through the internal gas pathway to the nozzle. The welder adjusts the workpiece and thetungsten electrode distance by controlling the welding torchaccurately to create and maintain a steady arc, thereby welding.

(2) Work Clamp - Ground Clamp:

Function:Also referred to as the "ground clamp," it is an important part of the welding circuit.

Action:It must be clamped securely and snugly around the workpiece to be welded (or its successfully conductive fixture). Its function is to allow a route for the welding current to return: the current flows from the positive terminal (+) of the power source → welding torch cable → welding torch → tungsten electrode → arc → workpiece → workpiece clamp → return cable → negative terminal (-) of the power source.

Key requirements:It is most crucial to ensure that the contact point between the workpiece clamp and workpiece is rigid (sufficient clamping force) and clean (free of paint, rust, oil, etc.). Weak connection will cause arc instability, difficulty in igniting the arc, poor welding quality, and even damage the equipment.

4. Current controller (The Amperage Control) - "Accelerator pedal"

(1) Form: There are two common control modes:

- Foot pedal:The most common, the welder regulates the current using his foot.

- Finger-tip control:Attached to the welding gun handle, the welder regulates the current by pressing or sliding his fingers.

(2) Function:The "accelerator" for achieving fine thermal regulation of TIG welding,offering the welder a means of controlling the welding current dynamically and steplessly in real time during welding.

Analogy of operation and purpose:

- Smooth "start":Moderately stamp on the pedal or switch on and off when starting the arc to slowly start the arc with a lower current to avoid workpiece or tungsten electrode contamination.

- Increase the "horsepower" at the right time:Throughout the welding process, increase the current at any time according to the size, fluidity and thickness of the molten pool for the desired welding speed and penetration depth.

- Smooth "oil reduction" on termination:Gradually decrease the current smoothly on termination to fill up the arc pit (the termination pit of the weld bead), avoid arc pit cracks, and create a smooth transition of the weld.

Key value:To achieve ultimate and dynamic control of welding heat input, following complex weld contours (e.g., corners, arc end points), different thickness material and special process requirements (e.g., thin plate welding), is a primary method of operation to produce high-quality,aesthetically pleasing weld appearance and excellent internal quality.

The power supply and control of energy comes from the source, the inert gas supply provides a shielding atmosphere, the work piece clamp and welding gun are the current path and conduct energy and gas, and the current controller gives the welder the tools to accurately control heat in real time. These four elements work closely together to form the system that must exist to createquality TIG welding.

Anatomy of a TIG welding torch: Inside the "scalpel"

Let's now take apart the internalcomponents of a TIG welding torchand observe how its delicate internal organs work together.

Brief overview of the inner components of a TIG welding torch:

| Component Name | Main Function | Key Materials/Features | Assembly Position/Relationship |

|---|---|---|---|

| Tungsten Electrode | The core "needle tip" that generates and maintains the arc | High melting point tungsten (W), Specific diameter and ground shape | The front end, clamped by the chuck |

| Collet | Clamps and fixes the tungsten electrode of a specific diameter | Slit copper sleeve | Located inside the chuck body |

| Collet Body | Holds the chuck and directs the gas flow to | Copper parts with internal/external threads and air holes on the side | Connects to the welding gun handle, and the porcelain nozzle is installed at the front end |

| Cup/Nozzle | Constrains and guides the shielding gas to form a protective shield | High temperature resistant ceramic (usually pink/white/brown) | Screwed on the front end of the chuck body |

| Back Cap | Presses the chuck system and closes the rear end | Insulating material (ceramic/plastic) | Screwed on the back of the welding gun handle |

| Gas Lens(upgraded) | Makes the shielding gas flow smoother and covers a wider range | Components with multiple layers of precision stainless steel mesh |

Replaces standard chuck body and porcelain nozzle |

Intense description of the essential components (from inside to outside in typical assembly order):

1. Tungsten Electrode - the "heart" of the arc

(1) Function:This is the functional component of the welding torch designed to create and maintain the welding arc. It is tungsten or a tungsten alloy of fantastically high melting point (approximately 3400°C) and will not melt it on exposure to hot arc temperature (but will burn slowly/gradually disintegrate).

(2) Main characteristics

- Diameter:There are numerous standard diameters (e.g., 1.6mm, 2.4mm, 3.2mm, etc.), which must be chosen based on the welding current. The higher the current, the heavier the diameter to be used.

- Tip shape:The tungsten electrode tip shall have to be precisely ground. DC welding is mostly ground to a conical point to produce a focused and stable arc; AC welding aluminum tends to be ground to a ball in order to stand up to the extra heat and cathode cleaning effect of the alternating current. Shape directly influences the degree of focusing there will be, stability and penetration capacity of the arc.

2. Collet - Tungsten Electrode "Tightener"

(1) Application:It is a to-be-cut copper sleeve. Its major function is to grip strongly and secure the tungsten electrode of a particular diameter strongly in the collet body for the purpose of efficient conductivity and stability.

(2) Important points:

The inner bore of the collet must be exactly the same size as the tungsten electrode. A miss-matched collet will result in loose clamping, poor conductivity, unstable arc and even tungsten electrode falling off.

The copper used possesses extremely high current conductivityand low flexibility so it might hold the tungsten electrode securely.

3. Collet Body - "Relay Station" for Gas and Current

(1) Function:It is a copper part threaded (most commonly, external threads are attached to the porcelain nozzle and internal threads are attached to the handle of the welding torch). It serves two significant purposes:

- Fit the collet:It is installed in its internal hollow.

- Direct the shielding gas:The collet body face will usually be an assembly of one or more rings of small holes. The shielding gas fed in from within the welding torch handle enters the space inside the collet body and porcelain nozzle through the holes and subsequently passes to the welding area.

(2) Major Features:The copper material utilized ensures good flow of current from the torch handleto the tungsten electrode and collet.

4. Cup/Nozzle - "Shaper" of shielding gas

(1) Function:This is an element commonly built of high-temperature resistant ceramic (commonly colors like pink, white, brown, etc.) and screwed to the front of the chuck body. Its main functions are:

- Constraint and directional control:Restrict the shielding gas that is emitted from the chuck body to its interior and guide it towards enveloping the tungsten electrode tip, arc and pool area of molten metal.

- Construction of a shield:By its precise inner diameter and size, it assists in the construction of a good inert gas "shield" to contain the air.

(2) Main features:

- Size (inner diameter/length):Various sizes (e.g., #5, #6, #7, #8, etc., where a higher number equates to a larger inner diameter). The size will be determined by the amount of gas coverage needed (large coverage with large nozzles) andlevel of accessibility for welding(application of gas welders in areas that are difficult to access with small nozzles).

- Material:Ceramics offer excellent insulation (won't short to the workpiece) and heat-resistant at high temperatures (resistance to arc heat radiation and spatter).

5. Back Cap - The "covering cap" at the rear end

(1) Function:It is a screw-on cap on the rear end of the handle of the welding gun, usually made of insulating material (e.g., ceramic or heat-resistant plastic). Its major functions are:

- Clamping system:By tightening, it pushes against the inner chuck and chuck body so that the tungsten electrode is clamped and held firmly.

- Closed back end:Protects against gas leak and external contaminants from entering welding torch.

- Adjust to space:Providing rear cap lengths in different dimensions (long, medium, and short) allows welders to adjust the tungsten electrode exposure length from the welding gun according to the spatial limitations of the area to be welded (deep grooves, tight corners).

Upgrade Option - Gas Lens - Gas Flow Refiner

Function: This is an optional upgrade element to replace the standard chuck body (possibly in combination with the ceramic tip). Its basic function is to place a number of layers of stainless steel precision metal mesh inside the channel of gas flow or in front of the standard chuck body.

Key Benefits:

- Laminar gas flow:The metal mesh conditions the shielding gas that may be turbulent (turbulent) into a uniform, smooth, parallel laminar flow regime.

- Enhanced protection:Laminar gas flow can travel farther, offer wider and more consistent protection region of the weld pool, significantly reducing the threat of air entrainment.

- Extended Tungsten:Due to the less turbulent gas flow, the tungsten electrode is able to be longer extended beyond the ceramic tip (up to 2 times the normal setup), significantly enhancing the welding gun's flexibility and accessibility when welding in deep grooves, corners or constricted areas.

Common Applications:In welding low-oxidation metals such as stainless steel, titanium alloys, or welding in awkward positions where more elongation of the tungsten electrode is required, the gas lens can significantly improve the weld's quality and purity.

From the rear cap in back to press down to hold the system in place, to the inner chuck to hold the tungsten electrode, to the chuck body to conduct current and guide gas, to the front porcelain nozzle to form and protect the airflow - these essential componentsblend to make the TIG welding torch, a sensitive "scalpel". The gas lens is a more advanced option that further optimizes the protection and stability of the airflow, and is a valuable instrument for the attainment of the highest weld quality. Understanding the role of each component and how they interact with each other is the guiding principle for effective utilization and upkeep of the weld gun as well as welding fault troubleshooting.

Case Study: Manufacturing of "Zero-Defect" Stainless Steel Casings for Medical Devices

Theoretical knowledge must ultimately serve practice. Let us consider an example that illustrates how the proper selection ofTIG components directly contributes to the success or failure of high-value products.

Customer Challenge:Thin-walled stainless steel housing welding deformation and black weld

Project Background:A medical device producing company is required to weld a significant amount of equipment housings made of 316L stainless steel plates that are 1.2mm in thickness. The weld should be non-deformed, non-oxidized (not blue or black) and smooth to meet the hygiene as well as visual requirements.

Dilemma:The samples that the customer's first supplier sent have major issues: there is visible thermal deformation warping in the area of the weld, and the color of the weld is dark, indicating oxidation. That certainly doesn't pass the standards for medical-grade products.

LS Diagnosis and Solution: From "Standard Configuration" to "Fine Adjustment"

Root Cause Analysis:

We learned that the previous supplier used a "one-size-fits-all" generic TIG setup, which resulted in two problems: 1) Inability to control current accurately, excessive heat input leading to distortion; 2) Poor gas shielding, which resulted in oxidation of the weld at high temperature.

Our Solution - Tailored Component Upgrade and Parameter Tuning

Gun Component Selection:Instead of the standard chuck body, we utilized a welding gun replacement featuring a gas lens (Gas Lens) and a large porcelain nozzle. This gave a more stable and broader argon shield that can fully envelop the weld pool even when the tungsten electrode slightly projects.

Tungsten Electrode Choice:

We employed a 2% lanthanum (blue) tungsten electrode and ground it into a fine and long tip in order to get a focused and stable arc and avoid unnecessary heat dissipation.

Current control:We make use of the foot pedal to control the current through the process. The current is low while initiating the arc, and it is precisely controlled during welding. The current is gradually decreased at the termination, and the gas delay shutdown facility is used to allow there to be gas protection before the weld cools down.

Final result: The weld is as bright as silver, and the product passes the acceptance at one time

- Dramatic transformation:The weld of the new sample we delivered shows the silver-white bright color unique to stainless steel, without any signs of oxidation. When touched by hand, the weld area is smooth and almost no thermal deformation can be felt.

Quantified benefits:

- The product qualification rate has increased from nearly 0 to 100%.

- The subsequent pickling and grinding processes have been completely eliminated, saving a lot of man-hours.

- Helped the customer successfully launch its high-end medical equipment and won market credibility.

Key Takeaway:In TIG welding, the devil is in the details. A simple gas lens upgrade can make a world of difference in critical applications. True professionalism is reflected in the ability to select and optimize every small component for a specific task.

FAQ - Answers to all your questions about TIG welding

1. What are the 11 steps of TIG welding?

Experts pointed out that instead of memorizing the 11 steps, it is better to grasp the four core stages: the first is the preparation stage, including thoroughly cleaning the workpiece surface and correctly grinding the tungsten electrode shape; the second is the setting stage, which requires selecting AC or DC according to the material, setting the appropriate current value and adjusting the shielding gas flow; then the execution stage, which requires the welder to hold the welding gun steadily, accurately control the arc length, skillfully use the foot pedal to adjust the welding heat in real time, and smoothly and coordinately feed the wire manually; finally, the finishing stage, the key is to gently converge the arc and maintain gas delay protection to prevent high-temperature molten pool and tungsten electrode oxidation.

2. What are the disadvantages of TIG welding?

TIG welding has three main disadvantages: first, the welding speed is relatively slow, and its production efficiency is significantly lower than other fusion welding methods such as MIG welding; second, it requires high technical requirements for welders, requiring stable control of the welding gun and precise wire feeding at the same time, strict coordination of both hands, and is difficult to learn and master; finally, the operating environment is demanding, and the workpiece must be extremely thoroughly cleaned before welding to remove all contaminants, and it is difficult to carry out in a windy environment because the flowing air can easily blow away the shielding gas, causing weld oxidation and defects.

3. What are the differences between the components of TIG and MIG welders?

Both contain a power supply and a clamp (ground wire clamp) to connect the workpiece. The core difference lies in the welding torch and wire feeding system: the function of the TIG welding torch is to guide the inert shielding gas and establish and maintain the arc, and the filler wire needs to be fed into the molten pool completely independently and manually with the welder's other hand; while theMIG welding torchis completely different, with an automatic wire feeding mechanism integrated inside, and the welding wire is continuously and automatically fed through the conductive nozzle in the welding torch. This welding wire acts as both electrode and filler material during the welding process.

Summary

A TIG welder is more than just a machine;it’s a complete system of precision components. Understanding every component, from the power source to the tungsten tip, is key to unlocking the full potential of TIG welding and creating the perfect weld. You don’t have to spend your energy delving into every detail of your equipment—that’s exactly what we do!At LS, our team has internalized and applied the finer points of TIG welding. We not only have cutting-edge equipment, but we also know how to use it to achieve the most precise, stable, and reliable results.

When you have demanding requirements for your welded product—whether it’s strict industrial standards, precise tolerances, or the pursuit of outstanding aesthetics—give us your design blueprint.Contact the LS team today!Let us use our deep expertise and persistent pursuit of details to efficiently and reliably transform your exquisite design ideas into a durable and impeccable weld reality.

📞 Phone: +86 185 6675 9667

📧 Email: info@longshengmfg.com

🌐 Website:https://lsrpf.com/

Disclaimer

The content of this page is for informational purposes only.LS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the LS network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseLS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:www.lsrpf.com