In the purchase of injection molded inserts, even a small error in calculation can create a chain reaction that leads to batch scrapping, significant project delay, and significant cost overrun. Most buyers are typically blinded by unit cost, ignoring more critical concerns such as total cost, reasonableness of product and mold design, and the overall capability of the supplier.

These myths directly determine project failure or success, and profitability in general. In this article, the five most common mistakes in the procurement process will be extensively examined, and realistic avoidance tactics will be outlined to allow you to make better choices and obtain neat, efficient, and inexpensive project implementation. To save time, a brief overview of the principal conclusions is given below.

Top 5 Insert Molding Buying Mistakes Core Reference Table

| Misconceptions | Possible Risks | Major Avoidance Measures |

| Unit Price Trap | Initial low price, balanced by later repairs, inefficiencies, and wasteful scrap. | Conduct total cost of ownership (TCO) analysis, with diligent examination of mold cost, unit price, volume production, yield rate, and after-sales maintenance. |

| Design Disconnect | Excessive scrap, cracking of product, bad performance, or malfunction in assembly. | Joint design review and mold flow analysis (CAE) optimization are included in early design for manufacturing (DFM). |

| Process Confusion | It leads to complete failure of a project, i.e., products lack essential functionality or are faulty. | Define the technical term: Insert molding is insert molding of a metal part into a mold; overmolding is secondary molding another part onto a substrate. |

| Fragmented Supply Chains | It leads to delayed projects, loose assignments, and unbelievable communication cost and delayed reaction to issues due to hundreds of interfaces. | Use integrated service providers (molds + inserts + molding) or create a solid collaborative partnership for effortless integration. |

| Lack of Verification | It makes quality unstable, intermittent defects in mass production, and cannot guarantee stable delivery. | Consider a rigorous PPAP process, review the supplier inspection record and process control history, and perform small-lot pilot production for verification. |

The key to successful insert mold purchasing is to look beyond the unit cost horizon and keep the eye on total cost. Hope this table points out the five most prevalent traps and approaches utilized that are key milestones to reduce a smooth project start-up and regulate overall cost and risk.

By collaborating on early design and selecting partners with vertical integration capabilities and stable quality systems, we can avoid technical and supply chain risks at the source.

Why Trust This Guide? Practical Experience From LS Experts

This guide shows LS Precision's years of technical expertise and experience in precision injection molding insert application. Not only does LS Precision provide equipment, but also comprehensive technical services including mold design, material specification, process development, and automation integration. With the latest mold flow analysis software and rigorous process control, we help customers plan total cost and project risk methodically so their products can meet high-precision specifications.

LS Precision's solutions are based on deep real-world experience. For example, in working with an automotive sensor customer, LS Precision was able to eliminate deformation problems in small insert molding by innovative gate design and ejection systems. In eliminating insert molding problems with heat-sensitive parts, LS Precision applied a special low-temperature process in successfully shielding the electronic devices. This front-line experience allows us to give you true reliable answers, and the methods for avoiding tricks that we present in this handbook result from invaluable front-line experience.

Misconception 1: Only Asking For Part Price, Ignoring Overall Costs

Most of the buyers of injection molded inserts fall into the trap of hunting lowest price only at the time of purchase. This short-sighted custom can result in a net cost disadvantage.

1. Misconception 1:

Reluctance to pay the lowest cost of insertion has a tendency to develop a number of other types of hidden costs. Customers will enjoy a clear low price and overlook a nice string of additional charges: increased defect rate due to lowered quality consistency, additional cost of quality inspection, increased labor cost due to increased assembly complexity, and additional shipping and administrative fees. The hidden costs are usually a number of times higher than the initial saving in cost.

2. Avoidance strategies:

You need to perform a rigorous analysis using a total cost of ownership (TCO) model. The TCO model includes all the costs through the product's life cycle, as compared to the acquisition cost alone. It is critical to choose a supplier like LS Precision that has end-to-end insert molding solutions.

LS Precision integrated molding technology integrates the metal insert into the plastic component with no seams, reduced downstream assembly steps, and significantly reduced labor and time expense, resulting in authentic total cost optimization for customers. When purchasing injection molded inserts, it is important to look beyond price-only comparisons and consider the total cost of ownership more in a whole-systems context.

Choosing a partner that provides complete insert molding solutions ensures not just product quality but also overall cost minimization, which translates to long-term economic benefit to the company.

Misconception 2: Ignoring The Compatibility Of Insert Design And Injection Molding Process

In insert molding operations, most companies are apt to overlook the inextricable link between product design and manufacturing operations, and this tends to lead to a very critical issue of quality. Insert design parameters, such as the chamfer angles, knurl profiles, and the distribution of wall thickness, must be well correlated with injection molding process parameters; otherwise, product defects are most likely to occur.

1. Misconception 2:

Common issues are:

- Inserts with an unsuitable lead-in angle, which become hard to insert;

- Improper design of knurling affecting the coating strength;

- Ignoring the different thermal expansion coefficients of materials, which can create internal stress upon the product when it cools down and can lead to cracking or warping.

Such type of design flaw typically becomes known only when mass production is in progress, which involves enormous scrap and project delay.

2. Avoidance strategies:

The ideal approach is to engage expert manufacturing know-how at the very early stages of the design process. LS Precsion provides expert insert molding design recommendations for critical features such as material selection, structural design, and tolerance matching.

Further, LS Precision's Design for Manufacturing (DFM) solutions utilize mold flow analysis techniques to forecast and mitigate future process issues before they occur, thereby ensuring that the design meets functional requirements and possesses higher manufacturability. The success of an insert molding project demands precedence in the harmonization of design and process.

Through strict adherence to professional insert molding design guidelines and leveraging solidly documented insert molding process expertise, quality issues are averted at the source with successful project execution and product reliability.

Misconception 3: Confusion Between Overmolding And Insert Molding

In injection molding, the majority of customers confuse overmolding and insert molding, two important processes. This most times translates to choosing the wrong process, then affecting product quality and production cost.

1. Misconception 3:

They are two totally different processes:

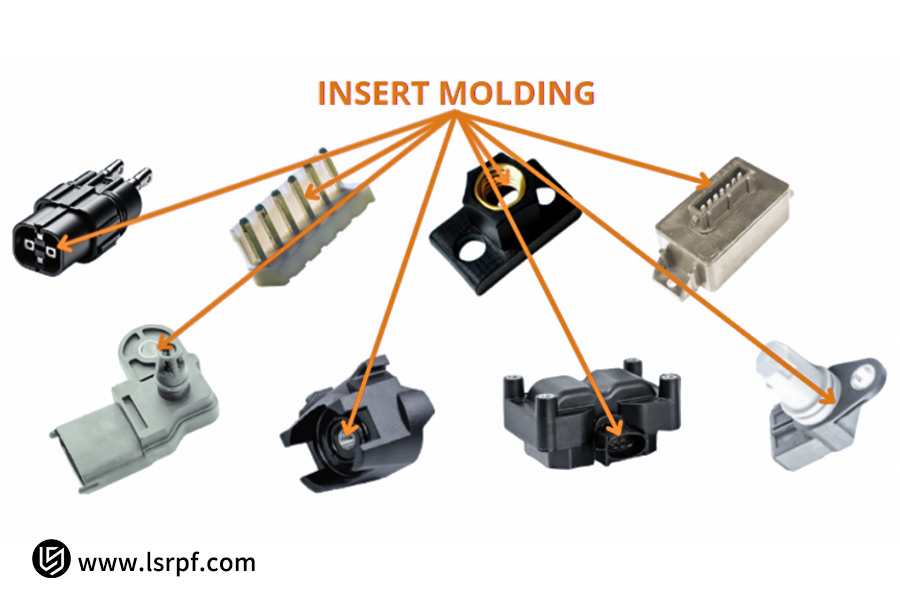

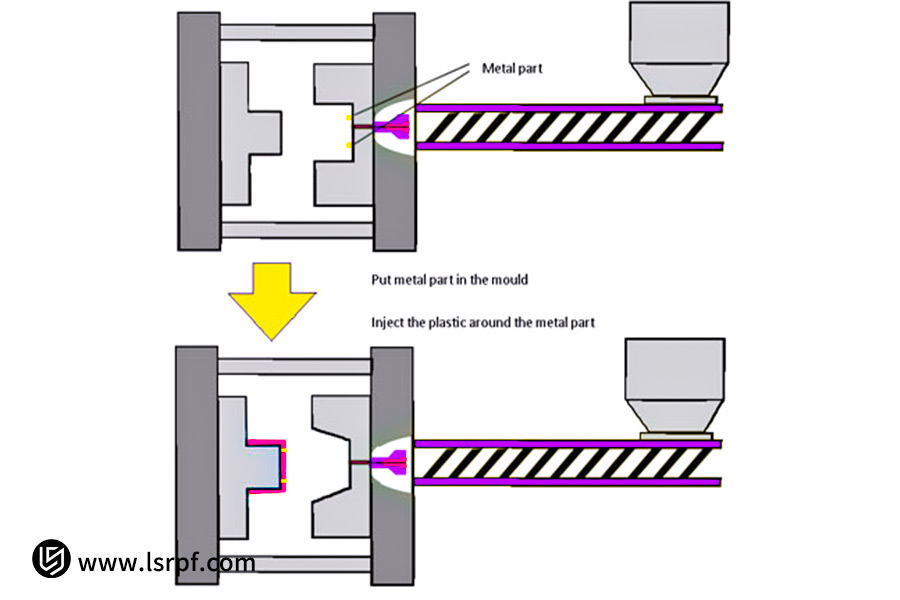

- Insert molding involves precisely placing a metal insert into a mold and then injecting plastic material to encapsulate it, thus creating a structurally sound, assembled part. It is commonly used to create plastic parts with metal inserts.

- Overmolding, however, typically involves additional injection molding onto a specified substrate (which could be plastic or metal) to create a distinctive functional layer such as a soft adhesive layer, non-slip surface, or sealing structure.

Error in distinguishing among these two processes can lead to incorrect production process, creating less than satisfactory structural strength or impossible functionality.

2. Avoidance strategies:

Most importantly, it should be able to correctly define the product functional requirements and application conditions.

- LS Precision has professional engineering staff who are experienced in both processes and can provide customers professional comparative analysis of overmolding and insert molding and recommend the most efficient and cost-effective process solution based on specific product needs.

- Through carrying out thorough comparative analysis of insert molding and overmolding, LS Precision are able to help clients avoid additional development costs and quality risks resulting from incorrect selection of the process.

Accurate identification and distinction of overmolding and insert molding variations are extremely critical to project success. From qualified evaluation and comparative analysis of insert molding injection molding processes, LS Precision can assure the utilization of the most appropriate production process that meets product functional specifications and minimizes cost-effectiveness.

Advisably, find a professional team in the early stages of the project to avoid unnecessary loss due to process selection.

Misconception 4: Insufficient Assessment of the Supplier's Vertical Integration Capabilities

When selecting an insert molding supplier, companies will often highlight the processing capacity of a single process while ignoring the ability of the supplier to deliver an end-to-end solution. This focus should lead to numerous follow-up problems.

1. Misconception 4:

Choosing a vendor that has only one process (such as a factory that has only metal insert-making or a company with only injection molding) will lead to a number of problems. Coordinating with multiple vendors requires a lot of communications resources, leading to simple blame assignment when there is a problem with the process and it becomes difficult to locate the root of the quality problem. This decentralized production process not only incites greater management difficulty but also the risk of unbalanced product quality and delayed delivery.

2. Avoidance strategies:

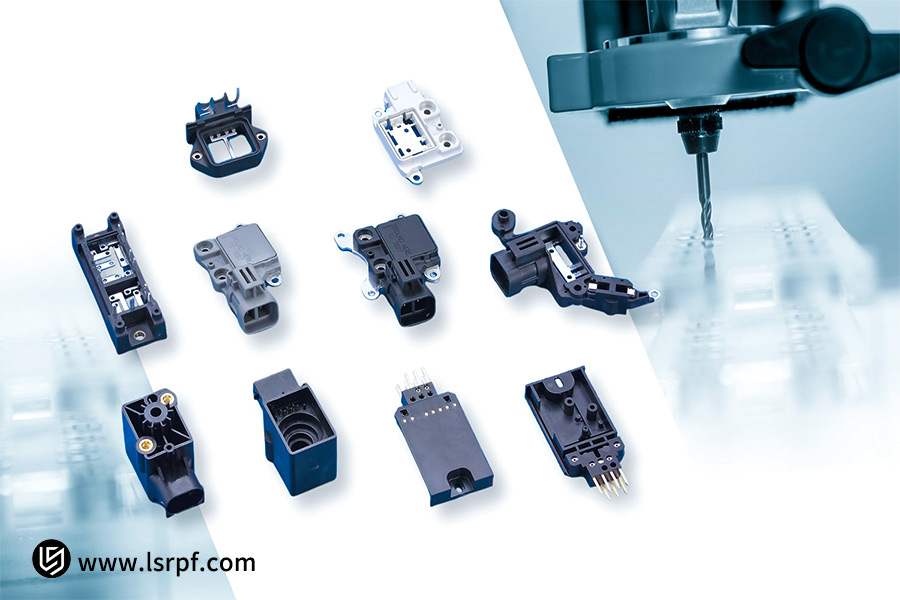

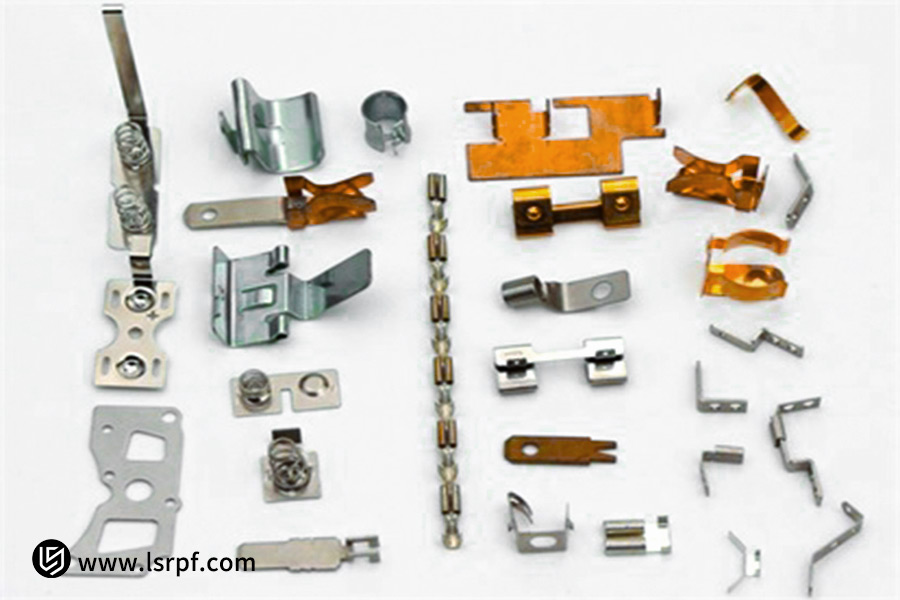

The best option is to select an insert molding solutions firm that has comprehensive vertical integration capacity. As a professional insert molding solutions firm, LS Precision manages the entire process in-house, from turning and stamping to injection molding of precision metal inserts.

Such vertically integrated production is that there is seamless integration among every process, improving manufacturing efficiency and concurrently maintaining quality of product and traceability. LS Precision can provide customers with single point of responsibility for an entire solution with reduced coordination and management cost.

In selecting an insert molding manufacturer, it is crucial to appreciate their vertical integration capability. Choosing an insert molding solution provider such as LS Precision, which possesses full industry chain integration capabilities, not only ensures the product quality and delivery time but also greatly reduces overall management costs, actually reducing customer effort and stress.

Misconception 5: Failure to Conduct Effective Sample Verification And Process Audits

On insert molding manufacturing, some of the clients, in a bid to minimize development times, will overlook sample checks and supplier audits. In the majority of instances, this results in significant quality risks.

1. Misconception 5:

Skirting or shortcuts on the sample testing and huge-volume purchase decisions based on supplier certifications and verbal guarantees are highly risky. Skimping on this can result in prospective design or manufacturing faults that may never be found until mass production begins, resulting in enormous financial losses and project delays. The lack of a strict quality control process makes it impossible to ensure insert molding process stability and product consistency.

2. Avoidance strategies:

There must be a proper sample verification process and check-up system for suppliers:

- LS Precision recommends customers to conduct rigorous sample testing, including pull-off tests (to verify cover strength), torsion tests (to verify structural integrity), and X-ray inspections (to detect internal defects).

- LS Precision also encourage customers to come to our factory themselves to learn more about our insert molding process and quality control system. We provide comprehensive test reports and process parameters to enlighten customers with maximum knowledge on product quality.

Essentially, rigorous sample testing and process audit are the guarantees for the success of insert molding projects. Through a comprehensive quality control system and complete management of the insert molding process, quality risks in mass quantity can be nicely eliminated.

LS Precision always insists on open cooperation and invite customers to supervise and audit to ensure each product reaches predefined quality levels.

Case Study: How Did LS Precision Solve A Customer's Automotive Sensor Insert Molding Challenge?

Automotive electronics sensor housings have extremely challenging sealing and connector strength specifications. A top-ranked auto electronics industry company was faced with an urgent problem: the existing supplier's sensor housings had a low yield rate, leaked after injection molding, and were prone to easy looseness at the connector, seriously impacting product reliability.

1. Customer Challenge:

The firm required a sensor housing that can withstand high sealing (IP67 rating) and very durable connections under harsh environments. The former supplier's product yield was only 85%, and the injection molding process repeatedly suffered from incomplete encapsulation and microcracks caused by internal stress, resulting in sealing failure. Furthermore, the metal insert-plastic substrate joint had poor bonding and therefore was prone to vibration-induced loosening.

2. LS Precision's Creative Solution:

To address this issue, LS Precision provided a complete insert molding solution:

- LS Precision engineers, with long experience of insert molding, re-designed the structural metal insert and surface knurling in the design phase to greatly enhance the plastic-to-metal bond strength.

- In plastic insert molding, LS Precision added the application of multi-stage injection and high-temperature control to precisely regulate mold temperature and injection pressure to properly relieve inner stress and obtain an optimal plastic-metal bond.

Taking advantage of LS Precision's vertical integration, we produce precise metal inserts in-house, with each insert being within strict dimensional tolerance and surface finish requirements, a solid foundation for subsequent injection molding.

3. Distinguished Outcomes:

LS Precision's insert molding solution increased the production yield of this car sensor housing from 85% to 99.8%, and 100% of products successfully passed IP67 sealing tests. The pull-out strength of the connector was improved by over 40%, meeting the full requirement for use in automotive vibration environments. Such optimization guaranteed the stable supply of volume to the customer, generating over one million yuan in annual savings and greatly improving the market competitiveness of the final product.

LS Precision employs technological innovation and vertical integration to provide customers with one-stop service from design to production to create high-quality plastic insert molding projects.

This case precisely demonstrates the advantage of specialized insert molding processes and integrated insert molding solutions in solving high-end automobile sensor production problems.

FAQs

1. What are the main advantages of insert molding?

The biggest advantage of insert molding technology is its maximum compatibility among material properties. It keeps the strength, conductivity, and wear resistance of metal inserts but enjoys plastics' high end molding property, insulation, and light weight. The technology achieves high functional integration in a single molding operation, eradicates subsequent assembly processes, man-hours, and supply chain complexity, reducing overall product cost significantly, as well as enhancing production efficiency and consistency.

2. How to select a metal material suitable for insert molding?

In selecting a metal metal, three considerations are essential: first, its thermal expansion coefficient shall be identical with that of the plastic substrate such that cracking or fastener loss will not occur due to differential shrinkage; second, upon assembly, it must possess sufficient mechanical strength to withstand tensile and torsional stresses; and third, corrosion resistance and environmental compatibility. Typical materials are brass (satisfactory conductivity), stainless steel (high strength and corrosion resistant), and aluminum alloy (light). Personal choice shall have a general check against the application case.

3. What are the most critical factors when designing metal inserts?

Positioning accuracy and anti-rotation in molding are the most critical considerations in metal insert design. The appropriate positioning features and anti-rotation devices (such as knurling, grooves, and flat spots) should be used to prevent rotation or movement of the insert during injection molding. Sharp corners should be reduced, but smooth ones and correct rounded corners should be used to reduce stress concentrations. The effect of the plastic flow channel on the insert also needs to be considered to create encapsulation integrity as well as bonding strength.

4. What additional services does LS Precision provide to support my project?

LS Precision provides one-stop project support services, ranging from early-stage insert molding design consultation advisory and Design for Manufacturability (DFM) analysis to improve product design; mid-stage rapid prototype and mold trials to reduce the development lead time; and late-stage mass production and one-stop quality inspection. Besides that, we also provide one-stop after-sales technical services to assist in solving the issues during the process of production, to realize smooth transformation from design to mass production, to provide the final one-stop service for customers.

Summary

While purchasing injection molded inserts, avoid the five most prevalent pitfalls identified in this post. Choosing a seasoned and reliable partner keeps you out of such traps as well as giving end-to-end value to your project. As a one-stop insert molding solutions provider, LS Precision Manufacturing leverages an experienced technical team, vertical integration capability, and extensive project history to provide end-to-end technical services from planning to mass production, success in every project, and ample room for customization.

Is your project in trouble? Contact LS Precision's technical experts today for free technical consultation and bespoke solution price quotation so that your product will succeed in the first place! Upload your design drawings now and get an instant insert molding quote ( insert molding price), let LS be your strong backing in pursuit of ultimate insert molding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com