Though typing "stainless steel sheet metal processing near me" in the search engine gives the impression you are looking for one in the immediate area, in fact you are looking for reliable quality, timely response and fair price."Near" proximity does not necessarily mean "near" value.

In 2024, the global logistics network is well-formed, digital collaborative networks are mature, and next-generation capability of manufacturing is spread all around the world and reshapes thenotion of the "best" partner.The processor most suitable to the requirements and with the best solution may not be nearby.

In the new world, proximity to the"best" stainless steel sheet metal processing service is measured in terms of physical distance, or "value distance" such as capability alignment?

To help you make wise decisions, we analyze the critical factors of choosingstainless steel fabrication services, give you the golden principles to judge the "best" partners, and select the "Top Ten Best" list to help you find a strong partner who is "close to your heart."

The Key To Choosing A Manufacturing Partner Is Capability, Not Location

| Evaluation criteria | Characteristics of an ideal partner (real "close") | Signals to be wary of |

|---|---|---|

| Stainless steel expertise | Clearly explains the difference between 304 vs 316L and provides welding and surface treatment recommendations. | Vague about the characteristics of different grades of stainless steel and lacks application recommendations. |

| Equipment and technology | Owns fiber laser cutting machines, CNC bending machines and professional TIG welding equipment to ensure high-precision processing. | The equipment is old, the tolerance control capability is limited, and the technology is backward. |

| Quotation speed and transparency | Provide instant online quotes and free DFM (design for manufacturability) analysis, and the price structure is clear. | It takes several days to provide a quote, and the price structure is opaque and vague. |

| Quality assurance system | Passed ISO 9001 and other certifications, can provide complete material certificates (COC) and quality inspection reports. | Lack of standardized quality control processes and inability to provide effective quality certification. |

| Project management and communication | There are dedicated engineers to follow up on the project, communication channels are unobstructed, responses are timely, and progress updates are proactive. | If communication is not timely, project progress updates are delayed and problem feedback is slow. |

Here’s What You’ll Learn:

- How the true meaning of “nearby” has been disrupted in the digital age?Understand why speed, service and information flow define the “best supplier” more than geographic distance.

- Why stainless steel processing is an expert’s domain?Uncover the unique challenges posed by material properties (work hardening, thermal conductivity), grade selection (304, 316, 430) and key risks (cross-contamination).

- A golden 10-point checklist for rating any supplier.Master a workable set of criteria (from case history, instant quotes, free DFM analysis to certifications, open pricing and customer reviews) to accurately gauge who is "best".

- An actual case study:How web-based collaboration beats local suppliers. Read about how a California medtech startup sourced high-precision 316L housings through an online platform, achieved early delivery and saved 25% in cost.

- An item-by-item breakdown ofstainless steel productioncost.Glass-clear splitting of material cost, processing (cutting/bending/welding), post-processing (brushing/mirror, etc.) and NRE so you can clearly see how much you are using.

- Local factories vs online portals:a truthful discussion of pros and cons. Balanced discussion of the trade-offs between in-person interaction and real-time quotes/DFM feedback/scale benefits to help you make an educated decision.

- What do you really need when searching for "LS Manufacturing"?Investigate the hidden needs behind the industry-renown name - do you need a bulk producer or a nimble, tech-enabled R&D collaborator?

- How to get started:From CAD file to having parts in hand in a matter of days. Add a clear and simple operation manual to begin your project immediately.

- Frequently Asked Questions (FAQ):Describe key suspicions around world shipping rates,quality control, and design support.

- How can LS be your true "best neighbor"?Tell us how we redefine the optimal stainless steel sheet metal solution "near you" with technical prowess, online efficiency and zero-delay service.

Now, let's start to burrow deeper and find out the most crucial factors that truly define the best stainless steelsheet metal fabricationpartner "near you".

Redefined "Nearby" in the Digital Age of Manufacturing

What you truly need to occur when you search for "stainless steelsheet metal fabrication near me" is timely, cost-effective, and quality services, yet not exactly proximity. Reality in 2024 is thatthe ideal possible collaborator might physically be far away but is "near at your fingertips" thanks to digitalization.The "proximity" of physical nearness is being replaced with a new value norm:

- Distance dissolves:logistics prevails: All the highly lubricated worldwide network built by DHL, FedEx, et al. ensures spare parts are delivered intact from the remotest part of the world in a few days. From the cities, the network of choice extends to the world, and "close by" is a matter of time of delivery, not place.

- Communication revolution, zero-distance collaboration:Cloud-based collaboration software, instant messaging, and high-definition video conferencing allow you to communicate sketches and debug in real time with engineers thousands of miles away. This is far more efficient and accurate than a car trip to a local factory with poor communications. "Near" is defined in terms of zero delay and high fidelity of communication.

Efficiency leap, wise drive:Advanced computer systems use strong algorithms that provide instant quotes and DFM analysis in real-time within minutes, thus minimizing the long test and start-up cycle of conventional systems. The entire process of ordering, making, and testing for quality is open and seen. Such data-driven efficiency is just not feasible in conventional systems. "Near" signifies proximity of decision and response.

Redesign the middle equation of "near"

We are in the era of digital manufacturing, and the gold standard for measuring stainless steelsheet metal fabrication services' "near" has changed radically:

"Near" = no delay in responding to service + no barrier to information exchange + high value acquisition efficiency

Looking for the "best" partner is no longer about finding the nearest point on the map, but about finding the node that can provide the most convenient, responsive, and value-added service in the networked digital world. With digital technology and worldwide collaboration, you will find more and higher quality "nearby" manufacturing web. The true "near" is the zero distance between information and service.

The 10-Point Checklist For Screening Any Fabricator

Your supplier choice is vital to your product's success. No more sales pitches! Positively and systematically utilize this golden checklist to screen any potential suppliers so that they fulfill your needs properly and turn out to be a strong, long-term partner.

How to use

- Quantitative scoring:score each item 0 to 5 points (5 = excellent, 0 = poor)

- Evidence verification:request suppliers to present solid evidence (not promises)

- Decision red line:★ items are the most essential capabilities, and those scoring less than 3 points will be disqualified immediately

| Evaluation Dimension | Verification Method & Key Questions | Weight | Evidence Requirement |

|---|---|---|---|

| 1. Industry Specificity | ► Require to view 3 cases with the same material/process ► "Show the most difficult stainless steel parts to process?" |

15% | Case drawings/actual photos |

| 2. Transparent Quotation★ | ► Online system test (upload drawings to get quotes) ► Ask about the logic of the tiered price difference |

12% | Quotation sample within 24 hours |

| 3. DFM Collaboration★ | ► Deliberately provide drawings with design defects ► Check the depth of feedback reports (≥3 modification suggestions) |

15% | Free DFM report sample |

| 4. Certification Completeness | ► Check the authenticity of ISO9001 certificate number ► Ask about the rectification record of unqualified items in the annual inspection |

10% | Certification + rectification documents can be checked on the official website |

| 5. Process Coverage | ► Clear requirements: "Can mirror polishing + passivation + laser engraving be done?" ► Require process parameters |

8% | Surface treatment samples/parameter tables |

| 6. Technical Responsiveness | ► Simulation problem: Technical support process for sudden design changes ► Engineer background check (LinkedIn) |

10% | Technical team resume/response SOP |

| 7. Cost credibility★ | ► Contract states "no secondary charges" ► Written confirmation of logistics/mold and other surcharges |

12% | Format contract with detailed cost information |

| 8. Delivery guarantee | ► Write in the overdue compensation clause when signing the contract ► Ask about the capacity buffer mechanism (such as insert order processing) |

10% | Production schedule + compensation agreement |

| 9. Scale flexibility | ► Request to visit small batch production line → large batch workshop ► Check the equipment list (small CNC vs automatic line) |

8% | Factory video/equipment list |

| 10. Word of mouth credibility | ► Ask for customer reviews that are not actively provided ► Undercover peer reviews (industry community) |

10% | Customer contacts + undisclosed cases |

Best practice use tips

- Red, yellow, green mechanism:★All green areas (≥4 points) + overall score ≥80% = priority collaboration

- Trap test:Introduce obvious design flaws (e.g., unnotated tolerances) into the DFM process to stress-test feedback strength

- Competitive benchmarking:Employ the same drawing to ask 3 vendors to quote and cross-reference capability gap

Case: A company in the medical device industry used this table to evaluate 5 suppliers of stainless steel shells and found that:

- Factory A, which touted "professional stainless steel processing", did not provide a medical-gradesurface treatmentcertificate (dimension 5 was 0 points)

- Factory B's Web quote was 22% below the final price under contract (dimension 7 was red-marked)

- Finally, Factory C was selected because its optimization solution on DFM report achieved 15% cost saving (dimension 3 got full mark)

This tool makes the subjective experience reproducible as a system of decision-making, lowering the risk for selecting a supplier by an enormity. Refine your weight for each evaluation (e.g., the weight of "scale elasticity" is increased to 20% for mass production) and continue refining your gold standard.

Why Do We Need Experts To Produce Stainless Steel?

The table below shows the primary reasons why stainless steel production requires expert handling:

| Key areas | Core challenges/requirements | Expert value |

|---|---|---|

| Material characteristics | Work hardening (easy-to-wear tools), poor thermal conductivity (welding deformation) | Accurately control parameters and optimize processes |

| Grade selection | Different grades have different performances (304 general purpose/316 corrosion resistance/430 magnetic) | Match the best material according to the application scenario to avoid failure |

| Pollution risk | Easy to be contaminated and rusted by carbon steel | Establish dedicated work areas/tools and strictly prevent cross-contamination processes |

| Surface treatment | #4 brushed/8K mirror and other processes affect appearance and function | Select the process according to demand to ensure that the processing quality and performance meet the standards |

1. Material property issues

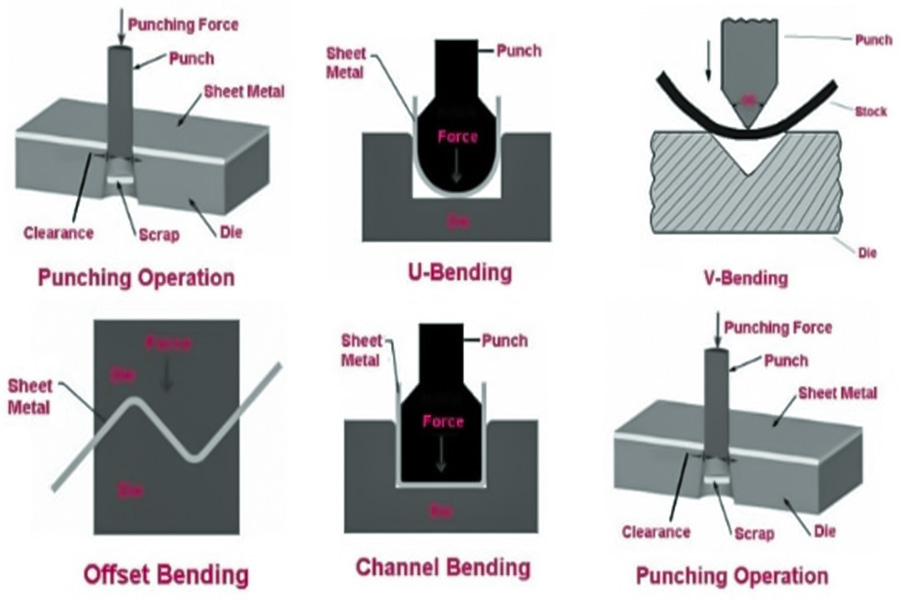

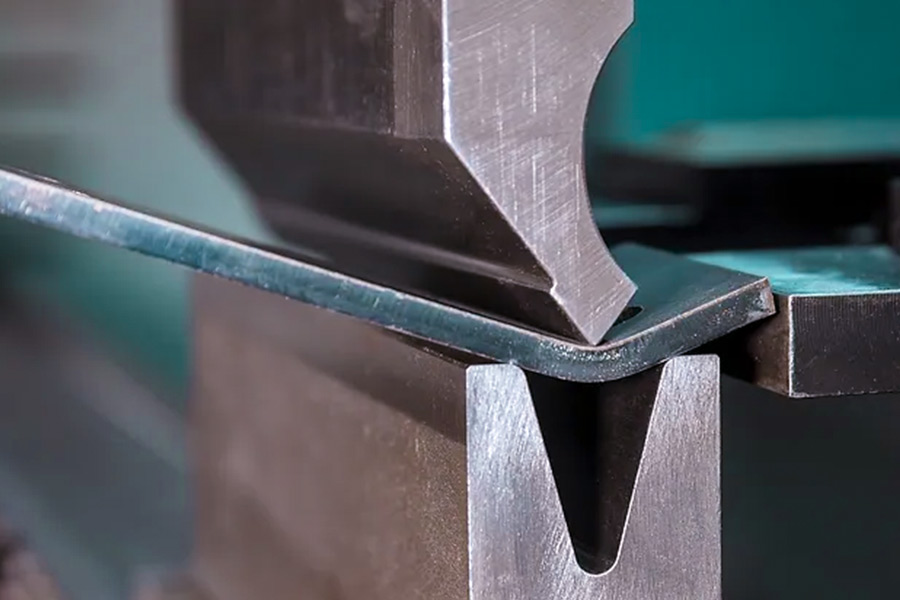

Work hardening: Excessive hardening during cutting/bending, causing tool wear and even workpiece cracking. Experts need to select special tools, parameterize optimally (speed/cooling), and use a reasonable process.

Low thermal conductivity: Heat accumulation during welding, tendency to deform, coarse grain, and even intergranular corrosion. Experts need to precisely control heat input, use special welding processes (e.g.,pulse welding), and design anti-deformation fixtures.

2. Grade selection key

304: General application, corrosion/shape/weldability resistance → food machinery, architectural decoration.

316: Resistance to corrosion with molybdenum-contained chloride → ship, chemical, medical equipment.

430: Magnetism, low cost, oxidation resistance at high temperature → home appliance cover, automobile exhaust.

Work of professional: Select materials properly according to the environment of medium (acidity/temperature), mechanical requirement, and budget of cost in order to avoid failure.

3. Control of pollution hazard

Special area and equipment: The processing of carbon steel must be segregated, and special equipment (cutting discs/wire brushes/shelves) must be used so as not to contaminate and damage the passivation film with iron filings.

Cleaning process: Pickling and passivation are required after production to remove contamination and strengthen the protective film. The anti-pollution process is expertly designed and controlled.

4. Selection of surface treatment

#4 Wire drawing: scratch and abrasion resistance, scratchproof, nice texture → home appliances, elevators, building decoration.

8K mirror: non-stick, easy to clean, light → precision instruments, medical instruments, luxurious decoration.

Experts' job: Determine the appropriate process based on product application (scratch-proof/easy to clean required or not), appearance requirement, and cost.

Stainless steel manufacturingrelies on professionals. Due to its particular processing difficulty, high material selection reason, anti-pollution environment stringency, and multi-requirement for surface treatment, professional experience and knowledge are required to ensure product performance and quality.

Case Study: 316L Stainless Steel Housing For Medical Devices

Background:A California-based medical devices company recently collaborated with us. They needed us to produce 50 precision 316L stainless steel housing sets for their latest product. Seamless weld and surface brush treatment were the key requirements.

Customer Challenge:They were having herculean difficulties in finding local suppliers: the price quote was too expensive, the lead time was too lengthy, and the other party could not guarantee the consistency and smoothness of finish of areas that had undergone welding, which has a direct impact on the performance and appearance quality of the product.

LS's web-based collaboration solution:

1. Instant quote:The customer uploaded theCAD filethrough our web portal and received an accurate stainless steel sheetmetal fabrication quotewithin 30 seconds, which served as the foundation for hassle-free collaboration.

2. Design optimization (DFM):Our intelligent DFM system automatically cross-checked the design, identified a sharp corner with a risk of welding cracking, and suggested optimizing it to a rounded corner on auto. I notified the customer immediately as an engineer to validate this enhancement, which ensured the manufacturability and ultimate reliability of the product was better.

3. Manufacturing execution accuracy:

Fiber laser cutting offers excellent part contour accuracy.

CNC bending machineis used to give high consistency to all bending angles.

TIG welding is performed by experienced welders to give high-quality welds.

Special grinding tools and techniques are used to achieve the "seamless" weld effect that the customer requires.

Finally, brushed surface treatment is performed to meet the appearance requirements.

Results and Value:

Ahead of schedule: All 50 sets of shells have been delivered to the client one week earlier than scheduled.

Substantial cost saving: Overall cost was reduced by 25% compared to quotation of local suppliers.

Quality control: The shells all meet rigorous demands of precision, welding qualityand surface treatment, solving the greatest pain points of customers.

Core inspiration: This project wholly proves that in the manufacturing world today, the best partners are "neighbors" in a technical capability and response to service sense, not geography. With our efficient web working platform, mature engineering support (DFM) and advanced manufacturing methods, we can provide speed, cost and quality advantages over local vendors even when we are on the other side of the ocean.

Local Factory Or Online Manufacturing Platform: A Guide To Making The Smart Choice

| Features | Local Factory | Online Manufacturing Platform (Like Us) | Best-Suited Type of Requirement |

|---|---|---|---|

| Communication Method | Face-to-face communication (suitable for simple, non-urgent initial communication) | Efficient online communication (email, platform message, phone/video conference) | Local: Simple requirements with preference for face-to-face communication |

| Quotation speed | Usually slow (manual calculation and repeated communication are required) | Instant online quotation (accurate price is obtained quickly after uploading the file) | Online platform: Need for quick budget and decision |

| Design feedback (DFM) | Limited or lacking (depends on individual engineer experience) | Instant, professional DFM feedback (automation + engineer review, optimize manufacturability) | Online platform: Complex parts, hope to optimize design to reduce costs/improve yield |

| Technical capabilities | Usually limited (small range of equipment, process, material selection) | Strong technical capabilities (extensive processes, advanced equipment, diversified materials, professional engineer team) | Online platform: Complex, precise, special process or material requirements |

| Price | Usually high (high operating costs, weak economies of scale) | More competitive (economy of scale, process optimization, cost transparency) | Online platform: Pursue cost-effectiveness, especially mass production |

| Quality stability | May be unstable (depends on the level of individual technicians and equipment status) | Stable and reliable (perfect quality management system, standardized process, strict quality inspection) | Online platform: Professional applications with high requirements for consistency and reliability |

| Physical visit | May be supported (on-site inspection of factory environment) | Usually not possible (but detailed factory certification, process video, etc. can be provided) | Local: Strong demand for on-site factory inspection (need to weigh other factors) |

| Production speed/efficiency | May be slower (schedule opacity, limited resources) | Usually faster and more predictable (online scheduling management, capacity optimization) | Online platform: Projects with clear delivery requirements |

| Transparency and convenience | Low (process tracking is difficult, communication may not be smooth) | High (online order tracking, centralized document management, clear communication records) | Online platform: Projects that require full control and convenient management |

| Best application scenarios | Very simple part prototypes, very small quantities and no rush, and customers extremely prefer face-to-face communication and are willing to sacrifice speed/cost/stability in exchange for local feeling. | Most professional manufacturing needs that pursue efficiency, quality, cost-effectiveness, technical strength and professional services (from prototypes to mass production, especially suitable for projects with complex parts, clear delivery and budget requirements). |

For business needs:If you want efficiency, repeat high quality, competitive prices, great technical support (such as real-time DFM feedback), and simple and transparent process management, online manufacturing platforms (such as us) are the better and more reliable choice. We can better meet complex, demanding, delivery and cost control needs.

When to visit local factories:Best suited for small lots or prototypes that are relatively simple, not time-critical at all, and you put great importance on face-to-face communication and are willing to accept the potential risks of slow speed, great variation in price and quality. Be careful to closely evaluate their actual technical capability and quality systems.

Wise decision:When choosing a supplier, be sure to weigh the core factors such as speed, cost, quality, technical capabilities and communication efficiency. For the vast majority of professional needs in modern manufacturing, online manufacturing platforms provide significantly higher comprehensive value with their technology, efficiency and scale advantages.

Choose us, choose a professional, efficient and reliable manufacturing partner!

Understand your stainless steel manufacturing price

1. Material cost:

One of the basic costs of stainless steel production comes from raw material. The prices vary extensively for different grades (such as common 304, 316 and more corrosion-resistant 2205 or special alloy) and different thicknesses of plates. The processing cost generally accounts for a high proportion of the total cost, and its fluctuation also has a direct impact on the final quotation.

2. Processing cost:

The processing fee is mainly based on the complexity and time of the manufacturing process, for example, time spent on laser/plasma/water jet cutting (according to cutting length and contour complexity), how many times the bending machine operates (each bend is a separate step), the length of welding, and the difficulty of welding (e.g., ordinary welding, argon arc welding or complex structure welding). The complexity of and time involved in these processes are the basis for determining the processing fee.

3. Post-processing costs:

Surface treatment to achieve a special appearance, texture or corrosion resistance is a major cost driver. Common operations such as brushing (creating textures), polishing (to achieve mirror or other finishes), sandblasting, passivation (improving rust resistance), electroplating or spraying, etc., cost according to the complexity of the process selected, area of processing and level of requirement.

4. Non-recurring costs (NRE):

If the product requires custom-designed fixtures, molds or complex programming and first-piece inspection, there is a one-time non-recurring expense (NRE). This cost element is typically independent of the unit cost of the batch product and is mainly used to cover the pre-development, verification and commissioning of custom chemical equipment.

This study clearly shows the major cost drivers ofstainless steel productsfrom raw material to finished product, which helps to achieve more accurate understanding and estimation of the end cost.

How can LS help you?

Get professional support anywhere, anytime:No matter where customers are, they can get timely professional guidance and technical support through online media and engineer teams, which solves the problem of local factory searching or inconvenient communication.

Solve the problem of stainless steel processing:With professional experience and equipment technology, high-quality stainless steel parts with stringent processing demands are manufactured to meet customers' needs for special materials.

Improve procurement efficiency and controllability:Under the mode of open and efficient network service, waiting, communication costs and uncertainties that are common in traditional manufacturing processes are greatly reduced, making customers' procurement procedures more smooth, plans more guaranteed, and saving time and effort.

LS uses its online, professional and in-depth focus on core products (stainless steel) to allow customers to transcend geographical constraints, overcome complex material processing issues, and achieve more efficient, transparent and manageable production procurement experience.

FAQs

1. Will the shipping cost be high if I am not in your country?

No. Thanks to our mass production and strategic alliance agreements with large logistics companies, we are able to obtain very competitive international shipping rates. Generally, our more advantageous manufacturing price can effectively offset the shipping cost to a great extent, so that the final product you receive still has an excellent overall cost benefit, which is why many customers worldwide come to us.

2. How do I ensure the components that I receive are of the wanted quality?

We strictly implement the ISO 9001 standard for quality management systems to ensure the entire production process is in control. To protect your rights and interests, we can provide the most essential quality documents such as full-size inspection report (FAI), material certificate (COC/MTR) and mechanical performance test report along with the goods without any cost as objective evidence that the product meets your specifications so that you can be more assured.

3. I only have a vague notion, can you help with the design?

Our main service is accurate production based on the final CAD file you provide to us. However, during your designing phase, our engineers are happy to provide you with professional manufacturing feasibility (DFM) analysis feedback, pointing out the potential problems and providing optimization suggestions to help you revise design details for improved manufacturability, cost-effectiveness, and quality assurance. The consulting service is normally free of charge.

Summary

After browsing the "Top 10 Best Stainless Steel SheetMetal fabrication CompaniesNearby", we can clearly realize that the real "best" is not an issue of location or size. The crux of the decision is who is able to truly achieve "zero distance" with you - this is reflected in first-rate and stable technical processes, smooth customer service, and smooth and open communication and collaboration. The value of this list is to help you focus on reliable partners who can turn physical "nearby" into "zero distance" in service experience.

No more waste of energy in searching and comparison, it's time to turn your creative idea into reality! Upload your CAD file to our smart quotation platform now and experience the ultimate efficiency brought by "zero distance" partners:

Receive precise quotesin 30 seconds - bid farewell to waiting.

Free deep manufacturability analysis (DFM) - preclude risks beforehand and design for optimization.

Initiate effortless collaboration - allow the expert team to become a project extension.

Click upload and allow the finest partner around to enable your project to commence quicker with velocity and proficiency!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com