Simultaneous 5-axis machining can solve the manufacturing difficulties of complex parts. It basically eliminates the loss of precision and efficiency due to geometric challenges such as deep cavities and negative angles through dynamic and continuous oscillation of tools and workpieces. It is a revolution in manufacturing philosophy, not a technological upgrade. It makes "one-clamping perfect forming" true and lets you boldly adopt the best design solution without having to make any compromise on machine capability.

True multi-axis machining means choosing to turn manufacturing challenges into core advantages. It can reduce a long process chain to a minimum, thereby strengthening market responsiveness and profit margins directly. We will shorten your learning curve as we look more deeply at how this technology is changing the rules of the game in precision manufacturing and helping you achieve a leap in manufacturing capability.

Figure 1: Precision multi-axis CNC center performing intricate machining by LS Manufacturing

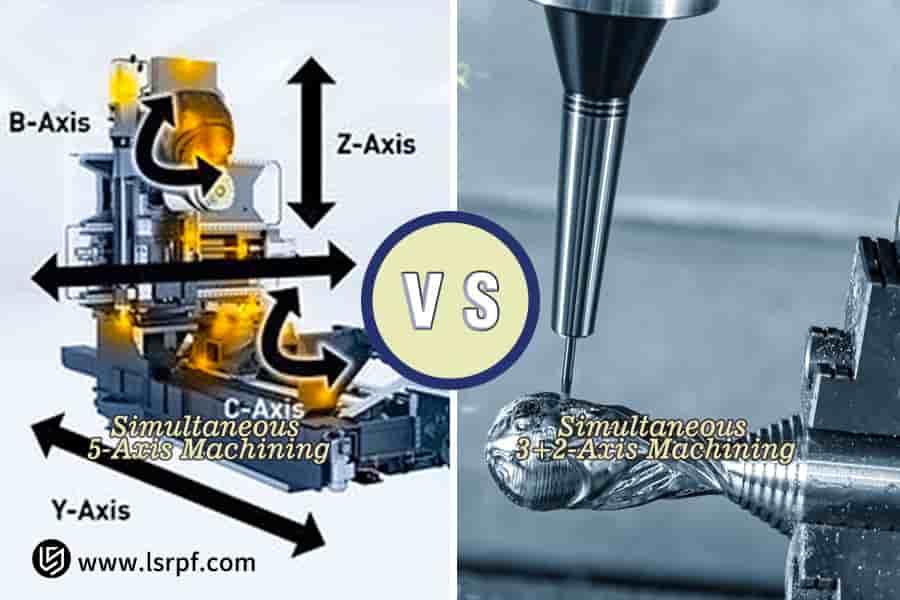

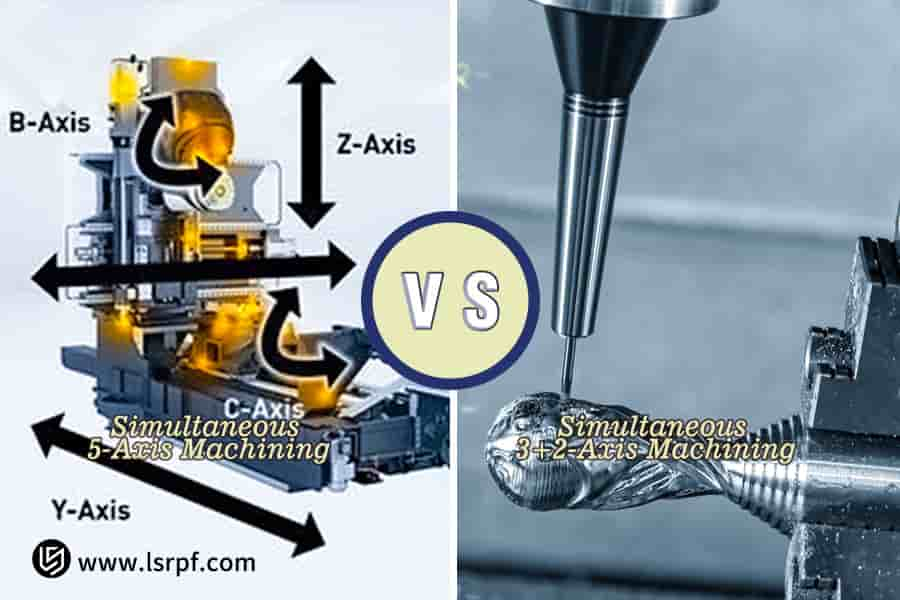

Simultaneous 5-Axis Machining vs. 3+2 Axis Machining Quick Reference Table

| Comparison Dimensions | Simultaneous 5-axis Machining | 3+2 axis machining |

| Basic Principle | 5 axes move continuously and simultaneously, maintaining the best posture of tool and workpiece for the cut. | Rotary axes are positioned and then locked prior to 3-axis milling; this is a "static" machining process. Also known as Indexed 5-Axis Machining or positional 5-axis. |

| Machining Accuracy | The machining of everything in one setup eliminates repeated positioning errors. | Multiple setups can result in cumulative errors that may affect the stability of the critical dimensions. |

| Machining Efficiency | Optimized tool orientation allows for efficient cutting with shorter tools, thus shortening the cycle time. | This typically involves a number of processes; therefore, a number of setups and adjustments result in a long total production cycle. |

| Complexity Capability | Capable of machining special geometric features, such as deep cavities, negative angles, and complex free-form surfaces with good efficiency. | Since the tool is long and at an angle, its geometrical capability in machining complex geometries is very limited. |

| Surface Quality | The adjustment of the tilt angle provides an opportunity to keep the optimal tool contact point and thus to increase the surface quality. | In the machining of the curved surfaces, the ball end mills have low point contact efficiency. Residual height is considered one of the disadvantages. |

| Cost Structure | While equipment and programming are expensive, savings in tooling and debugging time means unit cost can be lower. | On the other hand, dedicated tooling and repeated debugging can result in overall higher cost. |

| Design Freedom | Allows for optimal functional design without regard for manufacturing issues. |

Many product designs are constrained to utilize simplified geometry because of the state of machining technology. |

|

Applicable Scenarios |

High-end manufacturing of impellers, precision medical devices, and complex aerospace components. | It is also suitable for simple plate-type and box-type parts or situations where dynamic machining is not required. |

The essential difference between simultaneous 5-axis machining and 3+2-axis machining is "dynamic" versus "static." Simultaneous 5-axis machining can finish all complex machining processes by the continuous and dynamic alignment of tool and workpiece in one setup, not only ensuring extremely high machining accuracy from its very nature but also greatly improving efficiency by simplifying the process flow. More importantly, it changes manufacturing from a "constraint" of design to an "empowerment" where engineers can fully realize the performance potential of a product.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

This will guarantee that the methods shared in this guide are highly operable and reliable, because it has delivered more than 50,000 complex workpieces and brought along a mature technical system.

From ultra-precision machining of aerospace engine blades to manufacturing biological contours for perfect, bone-fitting medical implants and multi-angle irregular hole systems for core structural parts of precision optical equipment, we have personally experienced it all. Such real-world exposure has taught us how to turn 5-axis machining technology into reliable solutions for specific problems.

This is a team that has strongly embedded metrological traceability of NIST and the process spirit of the IATF 16949 quality management system in each process from programming to inspection. This itself is the guarantee that in every machining result, quality and consistency are maintained at a high level and you can assure the professionalism and rigor of this guide.

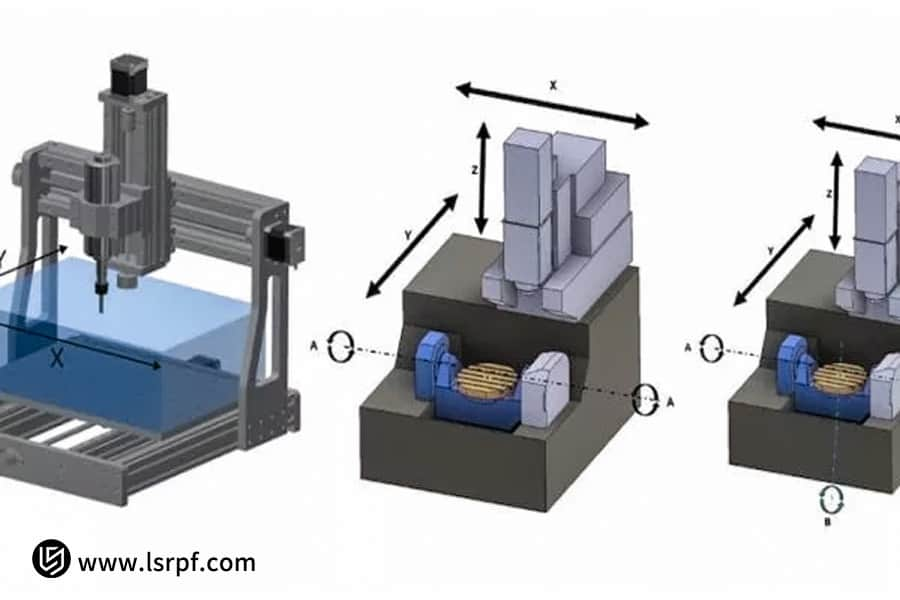

The Difference Between True And False 5-axis Machining: What Is True "Linked" Machining?

Moving and fixed are the keys to distinguishing between true and false 5-axis machining. 3+2 axis machining means that after the cutting angle is fixed, it is then locked while true simultaneous 5-axis machining involves continuous synchronous movement, achieving dynamic optimal matching between tool and workpiece. This continuous 5-axis machining mode brings 3 core advantages to the complex parts manufacturing:

- Optimize the Cutting Conditions: The constant yawing of the tool so that the tool tip always contacts the workpiece at the best angle can greatly improve cutting efficiency and, at the same time, effectively ensure the consistency of dimensions complex parts manufacturing.

- Obtain Superior Surface Quality: Dynamic adjustment can effectively avoid the "stripe-like" tool mark in the process of ball-end mill machining; at the same time, using shorter tools to suppress chatter lays the very foundation for a mirror finish.

- Breaking through Geometric Limitations: Deep cavities and negative angles can be completely machined within one setup. simultaneous 5-axis machining fully liberates design constraints and enables product innovation.

What is important about true simultaneous 5-axis machining is not the technology itself but reshaping process logic when complex parts manufacturing. It promotes the machining process from discrete steps to continuity-a leap in manufacturing toward "perfect shaping in one setup," which represents the core competitiveness of modern precision machining.

3+2 Axis vs. Simultaneous 5-Axis: Which Should Your Project Choose?

When developing a project process plan, adequately choosing 5-axis machining will be the key to finding a balance between technical demands and cost-effectiveness. Please find below the 5-axis vs 3+2 machining based on part features for an accurate decision:

| Decision Dimensions | 3+2 Axis Machining | Simultaneous 5-Axis Machining |

| Machining principle | Angular positioning belongs to discrete indexing cutting and can realize multi-facet machining. |

5-axis synchronous continuous motion can optimize the posture in real time. |

| Applicable Parts | The regularly shaped polyhedral parts suitable for medium to large batch production, precision parts with complex curved surface, deep cavity, and narrow slit. | It has an accuracy performance of steady precision at single angles, and multiple clamping may result in accumulated errors. It does all the machining in one clamping, ensuring the integrity of complex surfaces. |

|

Accuracy Performance |

Stable accuracy at single angles; cumulative errors may occur with multiple clamping. |

Completes all machining in a single clamping, ensuring the integrity of complex surfaces. |

|

Economy |

Lower equipment investment and programming costs, suitable for standardized batch production. |

Higher initial investment, but more advantageous in unit cost for complex parts. |

|

Process Characteristics |

Relatively simple programming, moderate skill requirements for operators. |

Can machine complex geometric features that are difficult to achieve with traditional processes. |

In general, it is very cost-effective to make batch parts of regular shape by way of 3+2 axis machining. For a part with complex curved surfaces and strict requirements for geometric tolerance, Simultaneous 5-axis is the best way to guarantee the quality of machining. If professional evaluation is required, please start LS Manufacturing Machining Consulting. Our experts will provide you with customized process solutions.

Efficiency Revolution: How Does Five-Axis Machining Shorten Production Cycles By 30%?

Improving 5-axis machining efficiency in the fierce competition within the manufacturing industry is actually enhancing the core competitiveness of an enterprise. The shortening of a production cycle by 30% is not an accident; instead, it is the inevitable result of the substantial transformation due to 5-axis technology on conventional machining processes. Its core advantages are mainly reflected in 3 key aspects:

Avoiding Duplicate Clamping and Saving Auxiliary Time

During conventional machining, complicated parts need to be disassembled, assembled, and aligned repeatedly. This not only leads to datum conversion errors but also wastes much time by non-cutting. Continuous 5-Axis CNC machiningcan totally avoid the repeated positioning and adjustment of the tool through "one clamping, completing machining of 5 surfaces." About 25% of the total processing time can be saved in this way, while eliminating rework caused by repeatedly clamping.

Short cutting edges have high rigidity and an improvement in cutting stability

In the case of deep cavities and inclined walls, 3-axis machine tools need long cutting edges that easily give rise to vibration, forcing a reduction in cutting parameters. By adjusting the tool axis angle, 5-axis technology will make even short toolholders efficiently carry out deep cavity machining, increasing the rigidity of the tool by more than 50%, thus enabling feed rates and depths of cut to be increased by 20-30%, therefore extending tool life and reducing tool change frequency.

Dynamic optimization of the cutting conditions for optimum material removal

This 5-axis linkage controls the tool tilt in surface machining, which enables the tip of the tool to have an ideal cutting speed and avoid "zero-speed" cutting at the center of a ball end mill. Not only does this increase effective cutting efficiency by more than 35%, but it also assures even chip load for the maximum possible material removal.

Advantages of multi-axis machining far exceed the simple gain in speed; this is a systemic revolution in efficiency because it integrates and optimizes processes. By avoiding pauses for clamping, improving the stability of cutting, and optimizing the parameters of machining, it turns non-value-adding time into effective cutting time, hence giving a qualitative leap in production efficiency.

Figure 2: Multi-axis machining center coordinate system diagram by LS Manufacturing

Main Applications Of Simultaneous 5-Axis - Which Industries Cannot Do Without It?

5-axis machining application is widely regarded as the cornerstone of technological breakthroughs and product innovation in high-end manufacturing today. As one of the core technologies of LS manufacturing industry solution, with decades of experience in serving top clients in every respective industry, we have come to understand how 5-axis technology solves core manufacturing challenges in certain fields. The following are its indispensable key application scenarios:

Aerospace

Parts in this field very often are made from difficult-to-machine materials and have extremely complex spatial surfaces. For instance, other than the high demands on the aerodynamic shape of engine impellers, there are also extremely strict dynamic balancing conditions to be satisfied. 5-axis machining ensures that all surface and flow channel machining can be highly precisely completed in just one operation, which has insured efficient and stable airflow, guaranteeing performance and safety right from the very source of manufacturing itself.

Medical Devices

Through the use of implants like artificial joints and bone plates, the degree with which they fit into the human skeleton will have great influence on the effect of surgery. 5-axis machining can shape an implant to have a perfect organic surface and microporous structure, offering the best osseointegration with a mirror-like surface finish to minimize tissue friction and rejection reactions.

Precision Molds and the Automotive Industry

Cooling efficiency has a direct bearing on the production cycle time of large injection molds, like automotive hoods, in addition to product quality. Applying 5-axis technology allows milling in one operation of conformal cooling channels to the product surface, increasing cooling efficiency by over 30% compared with conventional methods of drilling and splicing. This greatly shortens the injection molding cycle and reduces product deformation.

From high-performance aerospace components and life-saving medical implants to precision molds for improved efficiency, LS manufacturing industry solution embraces this technology in providing integrated high-end manufacturing support right from design to molding, thus cementing the company's position as an indispensable technology partner to customers spanning many industries.

Figure 3: Sophisticated parts embodying advanced 5-axis machining by LS Manufacturing

Overcoming Programming Challenges: How Does LS Manufacturing Conquer 5-Axis CNC Programming?

In particular, the complexity of 5-axis CNC programming, especially toolpath planning, collision avoidance, and attitude optimization, is regarded as the biggest obstacle to applying 5-axis technology. It is exactly this core value of LS Manufacturing solutions-to turn challenging programming into reliable manufacturing advantages for you:

Advanced CAM Software and Intelligent Programming Strategies

We operate an industry-leading CAM software platform in which the intelligent algorithms automatically calculate the best tool axis, balancing the efficiency of the cut with the characteristics of the machine tool motion. Using a library of parametric templates, programming engineers rapidly produce efficient and safe toolpaths. This increases programming efficiency by over 40% for complicated surfaces.

Introduction Powered by the practical experience of a senior engineering team

With over a decade of collective professional experience, our team of programmers boasts extensive knowledge and competence in material properties, cutting mechanics, and machine tool performance. It is not just a question of writing the code but applying practical knowledge, too, in how to program for optimization, such as anti-vibration toolpath design for thin-walled parts or customization of the layered cutting strategy for high-strength alloys to ensure successful first-article machining.

100% Collision Protection through Full-Process Virtual Simulation

Full-process simulation is enforced with the help of a virtual machining system before the deployment of the program to production. The system accurately reproduces the structure of the machine tool, tool holders, fixture, and blanks to dynamically detect the interference risk between all moving parts. Such interference or on-site collision can be completely avoided to provide ultimate assurance for machining reliability.

Based on the triple guarantee of "intelligent software + senior experts + virtual verification," not only have the 5-axis CNC programming challenges been overcome, but the entire programming process has been turned into predictable and controllable standardized workflow, offering extremely high machining reliability and production efficiency to customers.

Cornerstone Of Precision: How Does LS Manufacturing's 5-Axis Machine Tool Uphold the Micron-Level Promise?

While achieving micron-level machining accuracy requires much more than just adding rotary axes to the machine, its core is essentially a systematic engineering approach that needs to permeate every aspect of equipment design, control, and compensation. The following are the key technological foundations on which the LS Manufacturing 5-axis machine tools ensure equipment stability:

| Technical Aspects |

Implementation Methods and Value |

| Mechanical Foundation | Based on a high-rigidity mineral casting bed to remove the source of cutting vibration; hence, ensuring dynamic stability during machining. |

| Feedback System | Equipped with a fully closed-loop optical encoder directly reading the table position, it avoids transmission errors, achieving high positioning accuracy at the nanometer level. |

| Thermal Compensation Technology |

The intelligent thermal deformation compensation system detects and calculates the thermal drift caused by the environment and the machining process in real time and performs real-time compensation to ensure accuracy throughout the day. |

| In-machine measurement | Equipped with an automatic tool measuring and workpiece probe, it automatically compensates for tool wear and clamping deviations to guarantee consistency in mass production. |

The commitment to precision in LS Manufacturing 5-axis machine tools is brought about by a complete chain of technological means, from mechanical to intelligent compensation. While this ensured the perfection of the first part, through equipment stability and closed-loop control, the 1000th part maintained the same micron-level machining accuracy as the first, providing customers with sustainable manufacturing reliability.

Figure 4: Dynamics of 5-axis versus indexed 3+2 machining by LS Manufacturing

10-Day Delivery: How 5-Axis Machining Resolved The Turbine Housing Crisis?

The following LS Manufacturing successful case perfectly highlights how advanced technology can be transformed into a decisive market competitiveness. A leading automotive supplier was in dire straits because of a turbine housing project.

Customer Dilemma

The customer had to cope with a turbine housing structure that imposed very high demands on the dimensional and positional tolerances of its internal flow channels and mounting surfaces. Multi-stage machining on conventional 3-axis machine tools caused not just a four-week cycle time but also serious cumulative errors due to multiple clamping operations, which resulted in an extremely low product yield and an enormous risk of project default.

LS Manufacturing Solution

Our simultaneous 5-axis machining technology has become the key to breaking the deadlock. In 48 hours, the process team completed the design and programming of special tooling. LS Manufacturing 5-axis could finish all the complex internal cavities, inclined holes, and curved surfaces within just one clamping, wholly avoiding repetitive positioning errors. Meanwhile, the online measurement system enables real-time compensation in the process of machining, ensuring a closed-loop accuracy system.

Results and Value

The project was finally delivered in 10 days with consistently controlled dimensions within ±0.01mm. This helped our client avoid any kind of penalty for a breach of contract and reduced their total cost by 15%. Such efficient crisis resolution earned long-term recognition for the client as a "high-quality supplier" by the OEM.

In a word, the key to such success lies in the fact that 5-axis machining technology has been transformed from a simple machining tool into a systematic crisis solution covering process planning, workflow optimization, and quality control. It can be said that in the high-end manufacturing field, the core value of successful cases from us lies in transforming technological advantages into tangible market advantages for clients.

Free Evaluation: Which 5-Axis Strategy Best Suits Your Application?

Choosing the optimal machining strategy for your project is the most important first step in making the project both technically feasible and cost-effective. We thus recommend a quick self-assessment based on the following core dimensions that will initially help you determine the technical requirements of your project.

Part Geometric Complexity: Does it possess complex curved surfaces or deep cavity structures?

If your parts have complex free-form surfaces, deep cavities, or negative angles, together with machining features not readily accessible directly, that is generally a strong indication that 5-axis machining is called for. Simple polyhedral structures may be more suited to efficient 3+2 axis positioning machining.

Production lot size and flexibility needs: Small lot, multiple varieties or mass production?

5-axis machining offers great flexibility for projects with small batches, many varieties, or in the R&D and prototyping phases by "clamping once" to achieve rapid response to design changes. If the batches of parts are large with fixed structures, the comprehensive assessment of efficiency improvements that 5-axis machining can bring should be evaluated against the cost advantages of 3+2 axis machining.

Accuracy/Quality Requirements: Must the part be manufactured to tight geometric tolerances?

With high requirements for geometric tolerances, such as hole position and surface profile accuracy, 5-axis machining with one-time clamping can fundamentally avoid the cumulative errors brought about by multiple clampings and provide a technical guarantee for ultra-high precision and batch stability.

The above checklist is intended to give some starting ideas for a decision. We invite you to take advantage of our free assessment service. Experts at LS Manufacturing Consulting will work together with you to deeply explore your needs and make objective, economical, and reliable process route suggestions that ensure a clear return on investment.

Figure 5: Schematic of tool path planning for multi-axis machining by LS Manufacturing

FAQs

1. Is 5-axis machining only for mass production?

That is a general misunderstanding. For such complicated single-piece or small-batch prototypes, 5-axis technology can save much time in specialized tooling and repeated debugging by completing all the machining in one setup. Thus, its overall cost and delivery speed are often better compared to the conventional multi-process method. Therefore, it is especially suitable for R&D and high-end customization.

2. Is 5-axis programming leading to project preparation time being too long?

No. With the help of a standardized process database and experience of senior engineers, programming efficiency is raised by more than 50%. We pursue "doing it right the first time", using virtual simulation to make sure that programming efficiency and reliability really shorten the total time from drawing to finished product.

3. In comparison with 3+2 axes, where is the precision advantage of 5-axis machining?

Dynamic precision and overall consistency are the keys. While 3+2 axes can provide high precision in a single pose, multiple setups present cumulative errors. 5-axis machining, with a single setup completely eliminating datum conversion, can thus obviously ensure higher shape accuracy and surface quality consistency, especially in the machining of complex curved surfaces.

4. What size workpieces can your equipment handle?

Our 5-axis machine tool series is varied, with a size range from 500mm to over 2000mm and a load capacity of up to several tons. Please provide the approximate size of the workpiece. We'll do the actual matching of equipment resources in order to make sure of the feasibility of the machining.

5. Is 5-axis machining more expensive than 3-axis machining?

The hourly rate might sound high, but the overall often comes out to be lower. The process of 5-axis machining greatly reduces the total cost and cycle time by minimizing clamping, tooling, secondary handling, and scrap rates. We will provide tailored solutions to help you reach an optimal balance between budget and efficiency.

6. Do you offer any surface treatment after 5-axis machining?

Yes, we offer a one-stop post-processing service including sandblast, anodizing, spray, and precision polishing to ensure a smooth transition from machining to surface treatment, consistency in final quality, and manage costs for you.

7. How do you ensure tool life during 5-axis machining?

Optimizing the parameters of the cut, smoothing of the toolpath, and on-machine system monitoring allow us to intelligently control the load and temperature of the cut. This methodology will extend tool life by more than 20%, provide machining stability, and give you in-depth control over consumable costs.

8. How to get a 5-axis machining quote from LS Manufacturing?

You only need to provide a 3D model and other technical requirements, such as material, batch size, and precision. We can ensure a detailed solution comprising process analysis, quotation, and delivery time within 24 hours to help you start your project efficiently and transparently.

Summary

5-axis machining is no longer an expensive "showpiece"; it's a strategic investment in mastering the task of handling complex parts and strengthening supply chain resilience. It represents a leap in quality from "being able to machine" to "precision machining" and "superior machining."

Don't let machining capability constrain your design imagination and responsiveness to the market. Start now to have your personalized value analysis. Contact us and upload your part drawings now to get a free manufacturability analysis report from LS Manufacturing. Further, our experts will show you the way to the optimal path of machining with potential cost optimization within 24 hours.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .