When product designs must include multiple material characteristics--e.g., applying a soft-touch finish to a handle or embedding a metal skeleton within a plastic part--overmolding and insert molding are the optimum process choices. But there is a specific technical procedure and application scenario for each, and this choice most immediately impacts product performance and cost structure.

This guide extensively details the core differences, advantages, and shared application areas of these two molding techniques so that you are able to make an informed choice about your individual needs. LS Manufacturing provides multi-material composite injection molding with extensive capabilities in cutting-edge sectors like medical devices. We provide end-to-end solutions from material compatibility testing and mold development to optimal production.

For further evaluation after reading this guide, please upload your product concept or drawings. Our technical team will provide a free process feasibility analysis and preliminary quote. To save you time, here’s a quick overview of the core conclusions.

Core Quick Reference: Overmolding vs. Insert Molding

| Comparison Dimensions | Overmolding | Insert Molding |

| Core Process | Infusing a second material onto a base material (e.g., plastic, metal) to develop a multi-layer composite shape. | A preformed insert (e.g., metal part) is placed in the mold, and plastic is infused to encapsulate and hold its position. |

| Material Combinations | Plastic + Plastic, Plastic + Rubber | Plastic + Metal, Plastic + Ceramics, Circuits, etc. |

| Major Benefits | Increased comfort (soft feel), sealing, shock absorbing, appearance, and color variation. | Enables higher-order functions, enhances structure strength, sustains greater loads, and increases service life. |

| Typical Applications | Soft rubber handle for razor/toothbrush, non-slip handles for tools, seals for electronic equipment. | Metal-threaded plastic housings, plastic encapsulation of metal blades in medical instruments, and metal insert nuts for motor vehicles. |

| Design Complexity | Concerned with bonding of the material interface and looks. | Concerned with precise positioning of the insert inside the mold and encasement of the plastic. |

| Relative Cost | The processes and molds may be more complex, but secondary assembly cost is reduced. | Inserts themselves are costly and may require pre-placement operations, but they offer high levels of overall functional integration. |

The process that you choose essentially depends on your product's fundamental needs:

- If your goal is enhancing product performance and customer satisfaction, such as softness, sealing, or vibration damping, overmolding would be a preferable method.

- If your goal is to create complex mechanical or electrical functionality, such as embedding metal threads, bearings, or wiring into a plastic piece, insert molding would be preferable.

The ultimate decision needs to be made after a complete review of function, volume, cost, and supply chain factors. LS Manufacturing has extensive experience in both processes and can provide professional guidance and feasibility study from the design stage.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

LS Manufacturing has years of history in multi-material injection molding. We are not just theorists; we are practitioners who encounter difficult molding issues every day. In insert molding, we helped a medical device customer successfully integrate a threaded metal insert, a core product subject to repeated torque, into a precision plastic housing.

The project's challenge is that the plastic and metal must never come loose at high stress and that flash is to be avoided. With our patent-pending mold positioning and temperature control technologies, we can provide flawless performance throughout millions of cycles and pass stringent ISO 10993 biocompatibility testing.

In overmolding, we have created solutions for a number of professional tool manufacturers that deliver tough structure with superior grip. For example, a high-end screwdriver handle application required molecular adhesion between tough PP reinforcement and soft TPU rubber to prevent delamination with repeated use.

LS Manufacturing's materials development group screened and optimized the best compatible TPU material from hundreds of grades. Through the use of a specially created mold flow layout, we were able to resolve the bond line strength issue in its entirety, enabling the product to pass blind user feel testing and durability testing successfully.

These have taught LS Manufacturing that behind every successful product there's almost fanatical management of material properties, mold precision, and process parameters. It is this hands-on problem-solving experience that motivates our good advice.

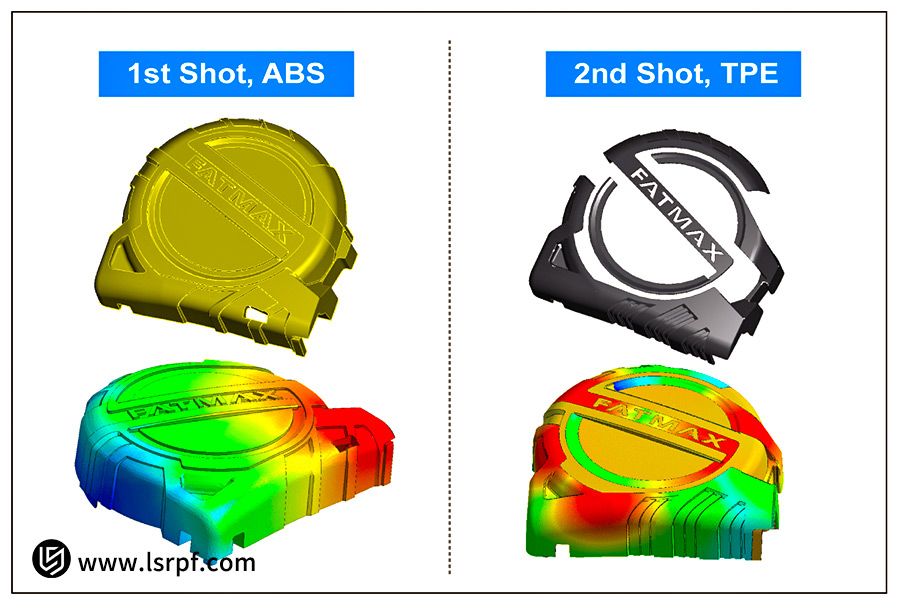

What Is Overmolding? How Does It Enhance Product Value By Combining Multiple Plastics?

Overmolding is an advanced multi-material plastic molding process. At its core is the close bonding of one layer of elastomeric material (such as TPU, TPE, or silicone) on top of a pre-existing base material (typically a rigid plastic like ABS or PC) through secondary injection molding. This, often referred to as two-shot injection molding, is a key technology in achieving multifunctional, integrated products. How does it generate significant added value to products? This is mainly expressed in the following key points:

1. Enhanced User Experience and Functionality:

By encasing the grip area with a soft elastomer, it significantly enhances comfort and slip resistance, making it highly appropriate for tool handles, electronic device housings, and medical instruments. The elastomer coating also provides enhanced shock absorption and sealing, which protects sensitive inner components.

2. Enhanced Product Durability and Integration:

The strong bond between the two materials literally precludes component wear, loosening, and even accidental dropping. From the manufacturing aspect, overmolding takes multiple assembly steps and integrates them into a single molding process, eliminating the need for glue or mechanical fasteners. Not only does it simplify the manufacturing process, but also it increases product integrity and reliability.

3. Strong Aesthetic Expression:

This process provides designers with plenty of creative latitude, enabling them to integrate various colors, textures and soft and hard materials on the same component without any difficulty, which eradicates post-production painting to produce products that possess excellent appearance and highly recognizable brands.

More than a simple manufacturing operation, overmolding is a strategic choice that increases a product's inherent competitiveness and gives it more value in the marketplace through materials science.

What Are The Unique Advantages Of Insert Molding In Integrating Metal And Plastic?

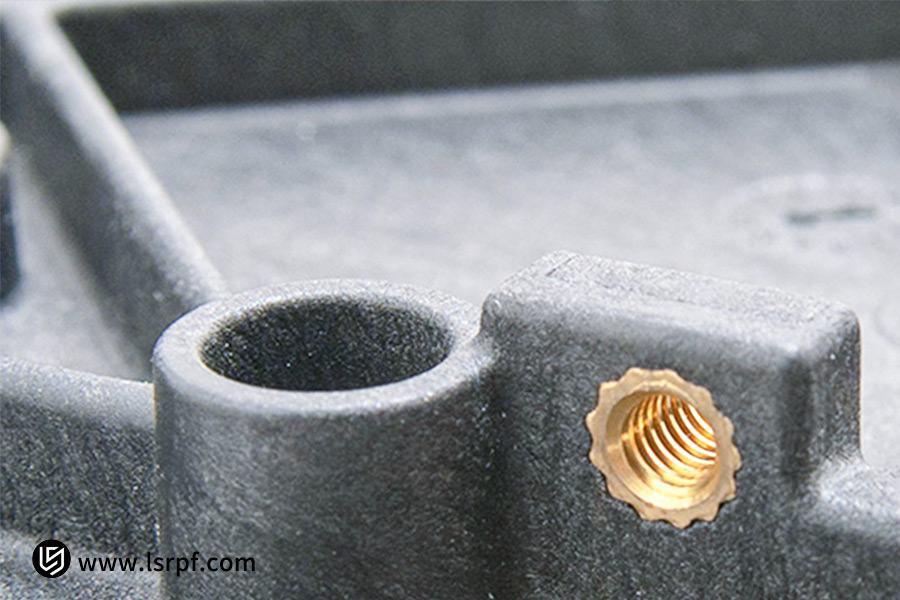

Insert molding is a precise injection molding process. Its value lies in the precise placement of a pre-fabricated metal piece (e.g., threaded insert, blade, electrode, or connector) inside the mold cavity. Molten plastic is then injected into the mold. Upon cooling, the metal insert is securely embedded in the plastic matrix to form a finished component. The reason this process has gained popularity is that it has some new advantages:

1. Significantly Reduced Subsequent Assembly Steps:

The insert molding process replaces various independent assembly steps with a single injection molding operation. Previously, the plastic part was produced first and then joined to the metal part through press-fitting, screwing, or welding. Currently, all these steps are replaced by a single step of molding, significantly reducing the manufacturing processes and labor and time expenses.

2. Creating High-Strength, High-Function Composite Structures:

The plastic insert can wrap around the metal insert tightly when cooled and contracted while creating a mechanical interlock. Combined, they create composite structures that are significantly stronger and more resilient than single plastic components. A plastic housing with durable metal threads, for example, offers greater torsion and pullout resistance, effectively eradicating problems such as thread stripping.

3. Improving Production Efficiency and Connection Reliability:

When compared to post-assembly processes involving gluing or screwing, insert molding creates metal-plastic joints with unmatched consistency and reliability. It virtually eliminates failure possibilities due to the aging of glue or loosening of screws, which makes it particularly well suited for mass production in an automated process. It creates uniform product quality and yet attains optimal production efficiency.

For applications in which the utilization of the strength and conductivity of metal and the lightness and complex shapes of plastic is contemplated, selecting a mature insert molding factory is most critical to achieving the highest product performance and cost-effectiveness.

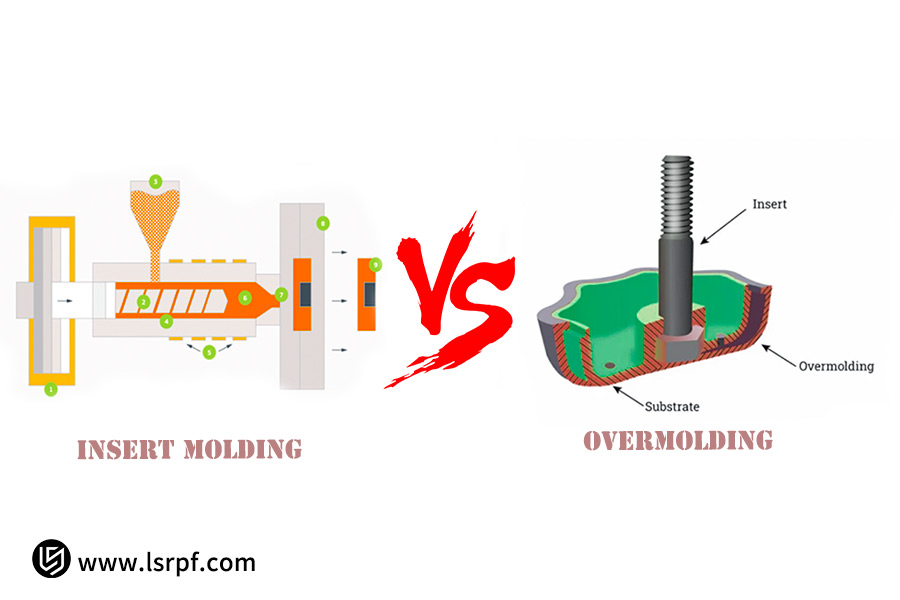

What Is The Core Difference Between Overmolding And Insert Molding?

The key distinction between overmolding and insert molding can be reduced quite simply by reference to the side-by-side comparison in the following table:

| Comparison Dimensions | Overmolding | Insert Molding |

| Core Objectives | Enhance sensory character and user experience | Enable advanced functional and structural integration |

| Substrate/Insert | Typically a plastic or metal substrate | Preformed metal components (e.g., screws, bushings, electrodes) |

| Process Steps | Typically a two-step process: first, shape the substrate and then over-mold with an elastomer. | One-step process: put the metal part into the mold and over-mold in one stroke. |

| Main Applications | Tool handles, waterproof seals, touch buttons | Metal-threaded enclosures, structural reinforcement, and electrical contacts |

The most significant differences between overmolding and insert molding are:

- Overmolding is "plastic plus plastic" (hard plastic + soft rubber), aimed at enhancing product feel, look, and human-machine interface.

- Insert molding is actually the marriage of "metal and plastic," designed to insert a "skeleton" or "viscra" into a plastic component to give mechanical integrity or electrical function that it cannot provide on its own.

What Specific Product Goals Are Typically Achieved When Choosing Overmolding?

Businesses choose overmolding procedures not just for the process itself but to achieve a variety of well-established product and market objectives. The process in particular addresses a variety of crucial product design challenges by joining a hard substrate to a soft elastomer in a way that eliminates seams. Interestingly, overmolding is often chosen to achieve the following simple objectives:

1. Creating an exceptional grip and a safe, non-slip finish:

- Applications: Power tool handles, domestic tools, and garden appliances.

- Target Value: Adding a soft rubber cover to a hard handle effectively increases grip comfort and stability, eliminates fatigue during prolonged use, and effectively prevents accidents caused by hand slipping, enhancing product safety and professionalism immediately.

2. Achieving a reliable seal and effective shock absorption:

- Applications: Handles of electric toothbrushes, razors, and cases of outdoor communication devices.

- Target Value: Soft rubber elasticity allows effective seals at component joints to be realized because of the prevention, in large quantity, of dust and moisture, and extension of product lifespan. Operating vibration and impact energy attenuation are also minimized through soft rubber coating, which shields internal precision components and reduces device noise.

3. Improving the safety and user-friendly experience of medical products:

- Applications: Enclosures of diagnostic equipment, home care devices, and surgical instrument handles.

- Target Value: Not only does medical device overmolding produce ergonomic, non-slip grips that reduce operator fatigue, but its ease of use and easy-clean features also meet stringent hygiene needs. Aside from this, the soft touch can also reduce patient stress when undergoing treatment, significantly reducing stress, making the product more user-friendly.

4. Enhancing Product Aesthetics and Brand Recognition:

- Applications: Wearables, personal care products, and consumer electronics enclosures.

- Target Value: Depending on application of differently colored or textured soft rubber to target areas of the product, a two-tone appearance, brand recognition, or functional difference can be created, visually and tactilely distinguishing the product for enhanced marketability.

Whenever your primary goal for your product is user comfort, functional protection, meeting exact industry standards, or creating differentiated looks, choosing LS Manufacturing's skilled overmolding solutions is the best means of attaining those values and creating product competitiveness.

In What Situations Is Insert Molding The Optimal Solution?

When the fundamental requirements of a product shift from appearance and feel to in-built structural strength and functional integration, insert molding becomes a preferable one-stop injection molding option. It confirms its inimitable strengths in the following most critical scenarios:

1. Requirement for high-strength connections and durable threads:

- Typical applications: Plastic connectors with metal threads, sensor housing in automotive engine compartments, and interface components requiring frequent plugging and unplugging.

- Solution: Inserting brass or stainless steel inserts into the plastic directly, the resulting threaded connection is much stronger and wear-resistant than plastic threads. It will have greater torque capacity and will withstand repeated assembly and disassembly, virtually never stripping or cracking threads, and will make long-term, consistent connections.

2. Need to integrate core functional components:

- Typical applications: Surgical tools (embedding metal blades, electrodes, etc. into plastic grips in one operation), metal charging contacts or sensor probes for application in intelligent wearable devices.

- Solution: The insert molding process perfectly encases precise metal functional components in plastic and offers a smooth, reliable connection. Not only does it eliminate gaps with traditional assembly, where cleaning and sterilizing can be simpler, but also ensures stable and precise electrical connections, which contribute significantly to product function and reliability.

3. Need for lightweight yet strong composite structural components:

- Typical applications: Post-mold assembly of plastic components and metal frames in thin-gauge automotive components and transmission parts.

- Solution: By placing metal elements at areas of highest stress, the process allows for the final product to retain the thin-walled and complex styling capability of plastic with local strength and load-carrying capacity equal to that of metal. This is a highly effective way of achieving structural optimization.

If your project involves significant mechanical joining, precise functional component assembly, or has extremely high requirements for structural integrity, choosing an insert molding supplier with experienced professionals is equivalent to choosing an effective, efficient, and cost-saving one-stop injection molding service.

How LS Manufacturing Reduced Assembly Costs For A Medical Client By 30% Through Insert Molding

In manufacturing medical devices that require extremely high accuracy, traditional assembly processes typically encounter both efficiency and reliability issues. The example of an LS Manufacturing injection molding below shows how we assisted a biopsy needle manufacturer in adopting a revolutionary approach with cutting-edge insert molding technology.

1. Customer Pain Point:

The customer's primary process of the one-time use biopsy needles is metal barrel and plastic handle assembly. The existing process involved separately injection molding the handle and manually applying an adhesive to bond them together. This process was not only time-consuming and costly, but also included risks of inconsistent bond strength and yield instability. Of most concern, however, the adhesive could leave chemical residues, which compromised the product's biocompatibility certification—a critical injection molding defect in medical devices that directly contact human tissue.

2. LS Manufacturing Solution:

To fulfill this requirement, the manufacturing department of LS Manufactuirng developed an entire insert molding system. We developed a high-accuracy mold and auto-loader system specifically to place each thin metal needle into the mold with micron-level precision. Following this, medical-grade PPSU plastic is injection-coated directly onto the needle tip in one operation in a cleanroom, creating a structurally integrated handle piece with little to no adhesive used.

3. Results and Value:

The use of this insert molding solution has yielded the customer multi-faceted value improvements:

- Cost Savings: The bonding process, and its associated labor and consumables expense, have been completely eliminated, significantly reducing overall cost of assembly by 30%.

- Efficiency Improvements: Manufacturing cycle times have been reduced by 40%, significantly enhancing manufacturing capacity.

- Leaps in Quality: The product has almost 100% consistency, and the handle-barrel bond is exceeds specifications, which will not detach and attains strict medical requirements of biocompatibility and sterility.

The case shows how a leading-edge insert molding solution can bring cost savings, efficiency improvement, and quality improvement simultaneously, particularly in injection molding of medical devices at high grade.

What Are The Differences In Cost And Cycle Time Between Overmolding And Insert Molding?

Cost and cycle time are two of the principal considerations when selecting a process. Due to their diversified technical nature, there are significant differences between overmolding and insert molding regarding cost structure and manufacturing cycle.

1. Cost Structure Analysis:

- Overmolding: Costs are primarily in materials and molds. Molds are usually more complicated (e.g., rotational or co-injection systems). They also use more expensive specialty elastomers (TPE/TPU). But with a single-step molding process, it avoids secondary processing costs such as two-color paint, assembly, or silicone encapsulation.

- Insert molding: The principal expenses are in the metal insert itself and automated integration. Acquisition price and precision requirements for the insert are significant expenses, and automated equipment (robots) also must be provided for proper placement. Its primary benefit lies in replacing the entire sequence of subsequent operations such as press-fitting, screw fitting, and welding, which entail colossal labor and time savings.

2. Impact on Production Cycle Time:

- Overmolding: The overmolding cycle time is affected by the process of multi-material injection molding, and thus the individual cycle times will be slightly longer. However, with the integration of multiple steps of production, overall cycle time from raw material to final product is significantly reduced.

- Insert molding: Insert molding's effectiveness in a cycle depends on the level of insert placement automation. When once optimized, its "one-step molding" feature can significantly enhance the supply chain and manufacturing process to support quick, high-volume production.

While initial mold investment and per-part material cost for both processes can be higher than traditional injection molding, they both decrease overall production cost and time-to-market substantially by reducing or eliminating secondary processing and assembly.

If you have a specific project, the best method of obtaining a quotation is to provide your specifications. LS Manufacturing will provide you with an accurate process and cost simulation review.

Why Choose LS Manufacturing As Your Overmolding/Insert Molding Partner?

In today's competitive marketplace, a solid manufacturing partner is the key to product success. By choosing to use LS Manufacturing, you gain more than just a supplier; you also gain a technical partner who is extremely involved and committed to making your project a success. Being an experienced insert molding manufacturer and overmolding supplier, we offer the following core values:

1. Mature Experience, High-Demand Markets:

LS Manufacturing has mature experience in injection molding for precision electronics and medical devices. We have keen insight into the stringent demands for product consistency, biocompatibility, and reliability in these markets and can hence anticipate and preclude potential risks.

2. Technical Expertise, Overcoming Core Challenges:

We not only make it, but also perfect the science of it. From material compatibility analysis and mold flow design to process parameter optimization, LS Manufacturing's team of engineers is committed to solving critical issues like adhesion and internal stress in multi-material integration, such that superior molding quality is ensured.

3. One-Stop Injection Molding Solutions, Seamless Integration:

LS Manufacturing provides complete services, from design and manufacturing (DFM) and precision mold development to mass production and inspection. Its comprehensive approach ensures smooth and efficient project implementation, reducing administration costs and accelerating time to market.

4. Rigorous Quality Commitment, Delivering Reliable Products:

LS Manufacturing has put in place an extensive quality control program that monitors the entire process, right from raw material incoming inspection to shipped products. We ensure that every product we send out meets your high-quality requirements and specifications with consistent performance.

LS Manufacturing is a technology-based, one-stop injection molding solution provider that specializes in quality. Allow us to transform your complex designs into competitive, high-quality products.

FAQs

1. Can the two processes be combined?

Absolutely. LS Manufacturing has bucked the trend of insert molding and overmolding and evolved an in-house "insert + overmolding" hybrid process. For example, in the case of surgical instrument manufacturing, we initially attach the metal blade to the plastic substrate through insert molding, then overmold the handle using medical-grade soft rubber. The process ensures structural integrity of the core functional part while ensuring great handling, best balancing functionality and convenience, and completely demonstrating our expertise in complex injection molding.

2. What is the minimum order quantity (MOQ)?

LS Manufacturing is committed to providing customers with flexible manufacturing options. Our policy for MOQ is based upon product complexity and mold investment, allowing us to support startup small-batch trial orders as well as high-volume production for established programs. Whether it's a 50-piece proof test or a steady production run of 500,000 pieces, we can plan the overall production so that our customers receive the most cost-effective order option at every stage of development from pilot manufacturing through volume production.

3. What types of plastics and metals do you use?

LS Manufacturing has a good history of engineering material applications, which include engineering plastics such as ABS, PC, Nylon, and PEEK, and elastomers such as TPE, TPU, and silicone. For metal inserts, we can process various types of materials, e.g., stainless steel, copper alloy, and aluminum alloy. Furthermore, we are able to recommend the most suitable material combination based on your product's functional needs (e.g., chemical resistance, impact resistance, and biocompatibility).

4. How long does it take from design to prototype?

The typical prototype lead time is 3-5 weeks. This includes critical design reviews, mold fabrication, mold trials, and sampling. LS Manufacturing uses efficient project management and concurrent engineering to ensure timely completion of each process. On high-priority projects, we also offer expedited services to maintain delivery time to a minimum while ensuring quality, allowing customers to quickly validate product designs.

Summary

Insert molding and overmolding, being inherent operations in modern-day plastics processing, hold unique importance in enabling human-machine interface and structural integration, respectively. The choice of a suitable process, not only influencing the product performance, is also intimately related to the cost of production and competitiveness in the market.

Whether insert molding for structural integrity or overmolding for comfortable grip, the concept is to bring more added value to products by leading-edge integration of material and process. Contact LS Manufacturing and upload your design drawings now and get an instant overmolding quote ( overmolding price), let LS Manufacturing be your strong backing in pursuit of ultimate overmolding precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.