Custom CNC machining services offered address the main challenges associated with the precise manufacturing of metal parts competently. At the current review, the first time yield in the production is estimated at 85-90%. This negatively impacts innovation for the companies because the cycle for product delivery is positioned at 4-6 weeks.

The services offered by us, through our CNC machining, focus on the root cause, i.e., dependency on expertise and not a process-oriented approach. In addition, having a process-oriented approach to quality control, we at URBI can provide accuracy in manufacturing, giving rise to the attainment of 99.5% product qualification, reducing the time value by 1-2 weeks, and a 30% cost reduction.

CNC Machining Services: At A Glance

| Section | Key Points |

| Core Advantages | High precision, repeatability, and material versatility. Ideal for complex, tight-tolerance metal parts. |

| Technology & Capability | Well-equipped multi-axis CNC machines, advanced CAD/CAM programming, and availability of in-house tools for maximizing speed and accuracy. |

| Quality Assurance System | Full processing control based on SPC, Automatic Inspection with CMM machines, First Article Inspection. |

| Process & Efficiency | Scientific analysis for DFM, optimal machinability parameters, lean process flow for maximum process efficiency, and shorter lead times. |

| Cost Management | Transparent costing, process analysis for the elimination of waste, value engineering for lower component costs. |

The usual difficulties faced in the production process are yield, lead time, and cost. The difficulties in production are overcome by our production of the CNC machining services, as the quality will be of 99.5% and the turning time will be 1-2 weeks, saving a production cost of 30% because of the accuracy done at a high speed.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The reason why this guide is trustworthy is the fact that it comes from our overall body of knowledge in CNC machining services. We have employees working in the shop, battling problems such as machining strong alloys on a daily basis. The information we are able to impart to the reader is in no way theoretical; quite simply, it is expertise that we have gleaned to produce custom parts.

We have direct experience in key sectors. We machine parts where failure is not an option, to strict standards such as ISO 13485 for medical devices. This battle-hardened process optimization, according to the best practices for the Society of Manufacturing Engineers (SME), is what we bring to the table for every project, whether aerospace engine parts, medical tools, and so forth.

Every suggestion shown on this page has been forged from successful practice. The vital ways of satisfactory machining of refractory metals, the ways essential in making errors not costly have been determined and this booklet has been prepared in the light of expert and learned know-how.

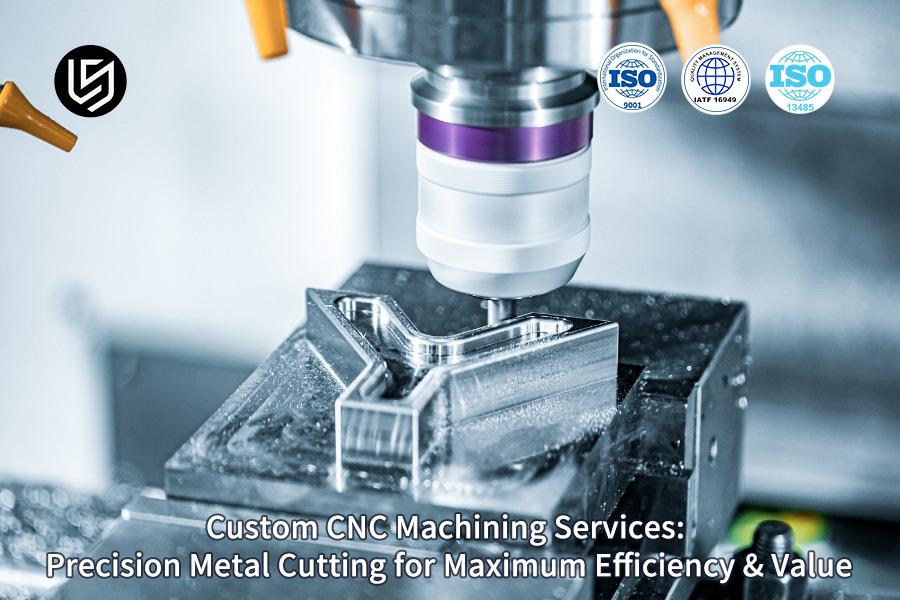

Figure 1: Requesting quotations for precision metal drilling via CNC services by LS Manufacturing

How Can Customized CNC Machining Achieve 30% Cost-Efficiency Through Process Optimization?

Substantial cost reduction in custom CNC machining can only be achieved if innovation is introduced in this process too. The present document will identify the process that is being used in this particular case to enrich this process through ironing out technological-procedural issues, hence bringing maximum benefit to the consumers directly. The process segregates overall costs into three interlocking pillars:

Optimizing Tool Paths to Eliminate Non-Cut Time

One of the important factors causing waste in our case is the unnecessary motion of the tools. The software we are using in our project for CAM allows us the benefit of optimizing the shape of the parts, thus eliminating air cuts and rapid motions. During the optimization of a complex aluminum housing, we used tool paths having optimized parameters of rest machining and point to point motions, through which we were able to minimize non-cutting tool motion by 40%.

Implementing High-Performance Cutting Tools and Parameters

In the first place, despite incurring additional expenses for the conventional parameters, we have comprehensively tested different materials in such a way that the tools and parameters can be optimized. In machining 316 SS, for that matter, with the change over to other tools such as carbide tools, it made it optimal in the sense that the speed of the cutting tool is increased by 35% without requiring the life of the tools to change.

Leveraging Intelligent Scheduling for Maximum Asset Utilization

Downtime of equipment is an important cost driver. The smart order processing software, based on equipment status, processes the orders. The software further breaks similar custom CNC machining orders into batches, verifies no bottleneck existed, and finally changed equipment in software. This has increased our equipment utilization percentage from 65% to 85% as it does the following.

This framework demonstrates that a strategic, data-driven overhaul of the machining process is essential for true cost leadership. The proven savings of 28-32% have not been determined through generic capabilities but through the solution of particular and interrelated technological challenges in the area of tool path optimization, cutter dynamics, and production flow. In order for us to provide you with a full estimate of CNC machining quote taking into consideration the above-mentioned capabilities in CNC machining services, our engineers will analyze your project.

How To Ensure Micron-Level Precision Stability In CNC Machining?

CNC machining is a process that requires a whole range of activities for the process to achieve precision at the micron level. The process for high-precision CNC machining has been designed in a way that involves controlled environments, high levels of metrology, and feedback included in the process to achieve precision at the micron level for the following purposes:

Environmental Stability Control

- Constant Temperature Workshop: This is maintained at a constant 20±1°C. This is vital because heat distortions can result due to temperature variations, which have significant impact on the correctness of the results being attained while doing precision metal cutting.

- Thermal Management Systems: Employ HVAC systems along with insulation to cause uniform temperature distribution within the area, with the intent of suppressing machine and material drift.

Precision Calibration and Verification:

- Laser Interferometer Calibration: Ensures positioning accuracy within ±0.003mm through regular machine tool calibration, ensuring that the CNC machining parts are repeatable.

- Scheduled Calibration Cycles: Implement automated checks so that the precision standard of the long-term is upheld.

Dynamic Accuracy Monitoring

- Ballbar Testing: Capabilities include dynamic error measurement and correction to ≤0.008mm, and real-time optimization of machine geometry.

- Performance Analytics: It checks for trends in the data that signify it is time to make the move in terms of avoiding inconsistency.

Closed-Loop Machining Process

- In-Process Measurement: Immerses the parts in the machine in order to measure their dimensions.

- Statistical Process Control (SPC): It is triggered if there are more than 1.67 CPK for critical dimensions. It helps to ensure that there is consistency in precision CNC machining for production.

This can be attributed to the fact that the above framework emphasizes our technical competence in precision CNC machining because of its close-tolerance environment, calibration, and closed-loop control for micron accuracy in precision metal cutting services. Yes, we are the best because we compare favorably with the rest because we prefer error prevention over corrections because we are data-optimum.

What Are Key Technical Sspects Of Metal CNC Machining For Diverse Materials?

Achieving optimal results in metal CNC machining requires material-specific strategies, as generic parameters lead to reduced tool life and poor surface finish. This document details key technical parameters for common alloys, derived from empirical process databases, to ensure efficiency and part quality in high-value CNC cutting services.

| Material | Critical Focus | Recommended Parameters / Strategy | Technical Outcome |

| Aluminum Alloys | Effective CHIP removal and cooling in order to prevent CHIP adhesion. | Spindle Speed: 3000-5000 rpm; Feed per Tooth: 0.1-0.3mm. | Maximizes material removal rate while maintaining superior surface finish. |

| Stainless Steel | Controlling the forces of cutting and work hardening. | Use lower speed (800-1200 rpm) with higher feed (0.15-0.25mm/tooth). | Effectively breaks chips, mitigates heat buildup in the cut zone, and extends tool life. |

| Titanium Alloys | The management of high temperatures in the cutting area in order to prevent the tools from failing. | The use of a coated tools technique that entails high-pressure coolant and lower cutting speeds. | This controlled thermal strategy can double tool life compared to industry averages for precision CNC machining. |

Precision CNC machining can also have data-driven approaches for two or more types of material. Taking into account the above list or at least with the parameters discussed, there can be a synthesis made in order to form a competitive approach in dealing with the demands of the product designers seeking verified ways for the utilization of the CNC cutting services based on the material.

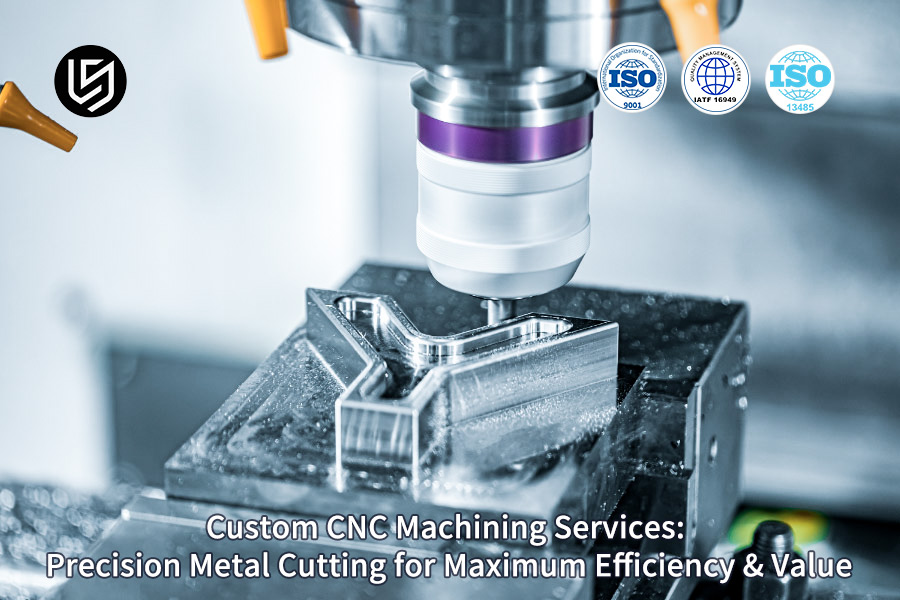

Figure 2: Industrial custom metal part production using CNC machining services by LS Manufacturing

How Can Cost Optimization Be Achieved For CNC Machined Parts Through Scientific DFM Analysis?

It should be pointed out that the process of cost optimization begins in the manufacturing sector at the design stage. In this area, there is a Systematic Design for Manufacturability commonly referred to as DFM analysis that eliminates the inefficiency in the manufacture process prior to the actual production of parts for the purpose of optimizing costs using approaches such as:

Topology-Driven Material Optimization

We are using CAE simulation in the visualization of the stress pattern in CNC machining parts. This ensures that the non-critical values of wall thickness are minimized and unnecessary material is eliminated in an effort to achieve an average material reduction of 15-25% without affecting the integrity of the CNC machining parts.

Design-for-Production Feature Standardization

Special tooling is considered as one of the major cost drivers in performing the custom CNC machining services. The DFM tool analysis conducted within our company evaluates the geometry of the parts in an effort to standardize geometric characteristics such as corner radii, hole diameters, and pocket dimensions. Through standardization, we will attain reduced variability in part geometry and hence lower the need for special tools and thus reduce the costs associated with small batch production.

Proactive Manufacturability Validation

Beyond geometry, we simulate the CNC machining process itself. This virtual run identifies potential issues like tool deflection, chatter, or inaccessible geometries that could cause scrap. Resolving these virtually ensures the first article is right, securing project timelines and protecting margins for our CNC machining services.

This human-designed optimized DFM process will allow the basic checkbox design review we have accomplished to move into a domain where we can start with a tough design concept and manufacture it into a functional asset. This puts our company ahead in terms of know-how and represents a truly humbling degree of competitive advantage with regard to predictability and reliability for complex production in the market of production and manufacture.

How To Select A Reliable CNC Machining Supplier To Ensure Project Success?

Selection of the right CNC machining company could be a major technological business decision, as it has implications for cost, time, as well as the outcome of the project. The key for success is not dependent on equipment, but rather upon the process that is systemically oriented towards quality, processes, and traceability. The above is followed by a discussion on the technological rationale underpinning assessment.

Certified Quality Management System Architecture

- Foundation: ISO 9001 Certification: The ISO 9001 Certification ensures all procedures required for the consistent execution of processes for all types of CNC machining services.

- Implementation: Documented Work Instructions & SOPs: This will work towards making sure that all the operational steps involved in the programming to the inspection are carried out under a set standard.

Advanced Metrology and Process Verification

- First-Article Validation: Uses CMMs (accuracy ±0.002mm) and surface roughness testers for a complete validation of a first article against a 3D model before proceeding with actual manufacturing.

- In-Process Inspection: It involves the implementation of scheduled in-process inspections with the aid of calibrated measuring instruments with the aim of correcting deviations in a real-time manner and in respect to the precision CNC machining processes.

Full-Process Traceability and Data Integrity

- Material to Part Tracking: This allows it to keep an electronic and physical record of lots from approved material through finished parts after each machining and inspection procedure, so as to easily track defects.

- Inspection Data Record: It helps to record the entire set of inspection results completed as well as the entire set of quality data relating to the production order, to provide auditable evidence of conformity.

A quality CNC machining company will never be defined by its equipment but rather its products, and we are always striving to go beyond the limits of quality conformation at a level well above 99.5%. The focus that we are bringing regarding the adoption of traceable processes will result in traceable to and traceable within the process capabilities to levels.

Figure 3: Precision industrial part fabrication through CNC cutting and machining by LS Manufacturing

How To Control Deformation In Precision Metal Cutting Of Thin-Walled Parts?

Precision metal cutting services in relation to machining thin-wall components are one of the most difficult operations when it comes to controlling the distortion. Overcoming the forces in relation to maintaining size when it comes to advanced CNC cutting services is covered in this report.

| Technical Focus | Implementation Method | Quantified Outcome |

| Process Strategy | Perform symmetrical machining processes to offset the effect of the internal stresses. | Stress control in redistribution to avoid net distortion. |

| Parameter Optimization | High spindle rates, lower and stable feeds, and small radial cutting depths can reduce the forces and heat generation. | It reduces the load driving cause for thermal and mechanic distortions. |

| Workholding & Fixturing | Designing custom fixtures that provide maximum support to weak areas using conformal or vacuum clamping, avoiding over-constraint. | Secures the part dynamically without introducing external clamping stresses during metal CNC machining. |

| Material-Specific Results | Applying the above protocol, with tailored toolpaths and coolant strategies for different alloys. | Achieves ≤0.05mm deformation for Aluminum (0.5mm wall) and ≤0.08mm for Stainless Steel thin-wall parts. |

Effective distortion control requires a pre-emptive, multi-axis strategy balancing force, heat, and stress. The actionable protocols detailed—symmetrical toolpaths, force-minimizing parameters, and stress-neutral fixturing—provide a proven framework for successful precision metal cutting of thin-wall components. This data-driven approach is essential for high-value applications where geometric integrity is non-negotiable.

What Are The Components And Optimization Strategies For CNC Machining Quotes?

All good projects rest upon, in short, a no-nonsense and fully optimized CNC machining quote; conventional quotes cloud the underlying drivers of cost. The following paper will attempt to analyze the total cost in the relevant technological and operational views, thus laying a good foundation for optimizing such cost in CNC machining services.

Transparent Cost Decomposition and Analysis

A scientific CNC machining quote will have concrete roots based on material cost (30-50%), machine shop man hours (25-40%), tool usage cost (10-20%), and other costs. Our CNC machining quote will identify the details of the costs and thus in this manner, a price quote will not only be a price; it can instead become a guideline for a decision-making process of a custom CNC machining project that you may be embarking on.

Strategic Material and Design Optimization

Materials cost gets the highest priority. After that, there is dfm consultation for materials. The geometry of the part is evaluated to provide the best size of material stock, in terms of grades for performance specs, which would impact the cost bucket for the materials directly in the range of 30% to 50%.

Machine Time and Tooling Consumption Efficiency

We can lower the cost of machine time spent per our components by a percentage of 25-40% using advanced CAM programming that yields high-efficiency toolpaths and optimal speeds and feeds. On the other hand, we must optimize the cost of tooling at a percentage of 10-20% based on durable tool geometry and tool life tracking.

The correct cost optimization is gained from the forensic/technical pass within each cost category, not from arbitrary discounting. Thus, through the break-down in the quote process and the execution strategy within material use, programming efficacy, and tool management, we achieve stepwise reduction within the total cost of 25% to 35%. This ensures optimal value creation for technically complex, precision-oriented CNC machining services.

How Can High-Volume CNC Machining Achieve Efficiency Breakthroughs Through Automation?

In mass production, the key to success in terms of efficiency involves the transition between manual control and the goal of integrated automation. Regarding the aforementioned process within the document above, there is a step-by-step approach towards the implementation of the use of robotics and data analytics in the integration of optimal production into CNC machining services.

Integrated Automated Manufacturing Cell

- Robotic Material Handling: Tilization of 6-axis robots for automated loading and unloading of raw blanks and CNC machining parts for true 24/7 lights-out manufacturing.

- Synchronized Production Flow: This entails optimizing conveyors and pallets in such a way that there is no machine time spent waiting for operator action.

Tooling and Process Monitoring System

- Predictive Tool Management: Implementing in-process sensors for tool wear and spindle load, which automatically triggers tool changeovers or notifications before tool failure, which is especially important for precision CNC machining quality.

- Condition-Based Maintenance: Leveraging system data to schedule maintenance activities according to actual running time and operational capacity to avoid downtime.

Data-Driven Process Optimization

- Overall Equipment Effectiveness (OEE) Analytics: Real-time analysis of the availability, performance, and quality rate parameters for optimal strategies toward the removal of deficiencies in enhancing the measures of OEE over 85%.

- Closed-Loop Quality Feedback: This is achieved by connecting the data produced in the processing stage back to the machine controller for the purpose of self-correction of the offset to allow for standard quality in the chain of the production process.

This automation platform is far more than substitution. By using our implementation of robotic work cells, predictive tool management systems, and real-time OEE optimization systems, we can ensure better reliability in high-volume production. It has already been verified that this is much better and provides a cost saving of 40% for each piece produced. This is the ultimate way of having high-volume CNC machining services with high reliability demands.

Figure 4: Custom machining and precision cutting services via CNC by LS Manufacturing

LS Manufacturing New Energy Vehicle Industry: Precision Machining Project For Motor Housings

As optimizing performances is necessary in the electric vehicle market, the related performances in the powertrain components can be recognized as one of the most prominent considerations. The following case study will explore how the considerations in the manufacturing task related to the precision machining of the motor housing in the drive unit of the new energy vehicle were addressed at LS Manufacturing:

Client Challenge

The customer was facing production problems with the aluminum (A356-T6) engine housing component in their motor. The traditional machining process performed by 3 axes was causing defects in the cooled channels and inaccuracies in size, which was giving the customer not better than an 88% first article yield in one cycle and taking a cycle time of 5 days.

LS Manufacturing Solution

We adopted an integrated 5-axis precision CNC machining method. Here, to take advantage of simultaneous 5-axis CNC machining, we could optimize complicated helical cooling channel tool paths to achieve optimal surface finish. Together with high-speed machining conditions, in-process probing for automatic tool offset correction allowed us to verify accurate and tolerance-sensitive geometry, which was highly significant regarding thermal and assembly problems.

Results and Value

The last step of component validation proved that the first-pass yield reached 99.8%, with a 25% improvement in heat dissipation performance. Machining time has also been reduced to up to 2 days. This has contributed to an increase in the client's prototyping cycle by 60%, while at the same time reducing costs by over 1.2 million RMB annually.

This project confirms our capability in overcoming difficult-manufacturing tasks with a higher stake through innovative processes. By combining the capabilities of 5-axis machining with in-process metrology solutions, we manufacture not just a part but also optimize its performance, together with the certainty of certainty within a time box for mission-critical industries like electric mobility.

Future Development Trends And Innovation Directions Of CNC Machining Technology

The future of competitiveness in manufacturers will be realized in moving beyond responsive and operator-driven processes. The future of CNC machining services will be realized in moving along the lines of responsive processes in the following way: The next evolution of CNC machining solutions will be realized in moving along the lines of responsive processes in the following way:

Self-Optimizing Machining Through Adaptive Control

Unpredictable tool wear and material characteristics are presently major issues linked to precision CNC machining. For this reason, we suggest an adaptive method for utilizing sensors for spindle power and vibration to control variations in feed speed and rotational speed. Our proposed method is a direct remedy for variations in performance because it ensures that tolerance level and surface qualities are kept constant and cannot permit machines to fail nor are they impacted by difficult alloys.

First-Time-Right Guarantee via Digital Twin Simulation

It would not have been possible to consider trial-and-error processes for addressing complex custom CNC machining with lower production volumes. In essence, what is happening here is that we are using what we call a high-fidelity digital twin, and by this we mean simulation of the machine, tool, and fixture. What happens in essence is we simulate every process relative to collision and deformation detection, as well as tool path optimization for reduced stress to ensure First Article success with greatly reduced lead times.

AI-Driven Process Synthesis and IoT-Based Predictive Oversight

Systems are under development that will have the capability to benefit from the geometry and materials that the components will provide for the automatic generation of G-code. This will result in the programming steps of the components being radically reduced. In addition to the above, a smart IoT system will have the capability to merge information provided by the machine controllers as well as information provided by the sensors.

The path of growth in this regard will be: formation of self-regulating and self-correcting systems in production, which will also cover adaptive control in real-time instability rejection, digital twin in manufacturability, and use of AI in intelligent synthesis in order to enhance services involved in the CNC machining services under the predictable science of the intelligent art of advanced production.

FAQs

1. What is the minimum tolerance in CNC machining processes?

CNC machining has allowed it to achieve machining accuracy of ±0.005mm tolerance or even more precise-for special demands of ±0.002mm.

2. What is the cost difference for machining between aluminum alloys and stainless steel?

Cost for machining stainless steel is 40-60% higher than for aluminum alloys. The reason can be attributed to heavy wear and tear of tools, and less efficient machining. The cost for machining will depend upon the complexity involved.

3. How can the cost of small batch machining be controlled?

With standardized process, combined fixtures, and material usage optimization, small-batch machining capacity can decrease machinating cost by 25 to 35% and improve lead time by 40%.

4. What makes for consistent quality in batch machining?

By incorporating process control through SPC analysis with critical dimension CPK >=1.67 and frequent equipment calibration, LS Manufacturing is able to ensure that it has a pass rate of over 99.5% for batch production.

5. What special equipment is required in machining complex parts?

These critical machine tools would comprise 5-axis CNC machining centers, mill-turning machine centers, and online measurement systems. These machine tools would be required to ensure multifunctional machining in one operation for complex parts.

6. What grades of surface roughness can be achieved by CNC machining?

Comparative to other machining methods, for conventional machining, a value of Ra1.6μm can be achieved, while for finishing and mirror finishing, a value of Ra0.8μm and Ra0.2μm can be achieved,

7. What should I do in order to get a good CNC machining price quote?

Kindly include 3D drawings, specifications for materials, specifications for accuracy, and the quantity of the batch order. Quotation details including process descriptions will follow within 2 hours.

8. In what time can the fastest delivery be arranged for urgent orders?

Urgent samples require 24-48 hours, small batches require 3-5 days. LS Manufacturing has established an appropriate communication channel in the accomplishment of projects.

Summary

Through scientific process optimization and quality control, high efficiency, low cost, and high quality can be ensured in CNC machining. LS Manufacturing, a company with a strong technical system and rich practical project experience, can provide its customers with high-quality machining services.

If you would like to have a customized CNC machining solution or would like to have a free process analysis, you can get in touch with the technical team at LS Manufacturing. By uploading your part drawings, you can get a quick and accurate quote, as well as engineering consulting, related to your application.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.