5-axis CNC machining for aerospace, medical instruments, and high-quality machinery that solve problems when engineers are dealing with complexities related to the job on curved surfaces, multi-angle machining, and many configurations in 3-axis machining, which result in errors being cumulatively added, and when engineers decide to work on it manually, there are no guarantees for accuracy and efficiency as in mass production.

The fundamentals of these technologies emerged from the limited degree of freedom in the conventional approaches that simply could not, in one system, perform the accurate processing of complex shapes. As will soon be apparent in the context of this guide, the 5-axis CNC machining technology introduced an innovation in the manufacture of complex components with the inclusion of the control of the tool orientation in two rotary axes.

Quick-Reference Guide: 5-Axis CNC Machining For Aerospace

|

Section |

Key Topic |

Core Points |

|

Introduction |

The Challenge & Solution |

Pain: Complex geometries with tight tolerancing and low yields associated with 3-axis cutting heads. Solution: 5-axis enables single-setup, full contour machining. |

|

How It Works |

Axis & Motion |

Linear axes (X, Y, Z), orRotational axes (A, B, or C).Axes of motion enable movement of the cutting tool towards the workpiece in various directions. |

|

Key Benefits |

Advantages |

1. Accuracy: One-time setup, no cumulative error. 2. Complexity: Produces complex shapes. 3. Productivity: Faster, fewer operations. 4. Surface Finish: Improved finishing, optimal tool orientation. |

|

Aerospace Applications |

Use Cases |

Structural components, engine parts (blisks, IGVs), prototypes, tooling. Lightweight, strong, complex parts. |

|

LS Manufacturing Edge |

Capabilities |

Advanced machinery, expert CAM programming, rigorous quality control, industry-specific expertise. |

|

Implementation Guide |

Considerations |

Part Design-DFAM, CAM Programming, Machine Selection, Post-processing, Quality Control 5-axis CNC machining for aerospace. |

5-axis CNC machining for aerospace is revolutionizing manufacturing, addressing core challenges of complexity, precision, and efficiency. For aerospace engineers, collaborating with partners like LS Manufacturing, which holds AS9100 CNC machining certification, on 5-axis technology is crucial for achieving innovative designs, meeting stringent tolerances, and optimizing the entire manufacturing process from prototype to high-performance end-parts.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Trust this guide, as it is written in the cutting-edge world of aerospace production. The truth is, our team is faced every day with precision aerospace parts, such as turbine blades and aircraft structural components, where the micron-level tolerancing requirements of the 5-axis paths are not optional but absolutely necessary for CNC machining for aircraft parts safety and reliability. The information dispensed within is not merely theory; it has been the direct experience of how the challenges of aerospace tolerancing requirements and materials have been overcome.

Our strengths are based on a record of success in providing critical components for mission-critical applications. In this, we strictly follow the quality management principles as outlined in ISO 13485 for Medical Devices and extend this high degree of process control into our production for aerospace applications. Moreover, our emphasis on quality includes best practices drawn from recognized authorities such as the National Association for Surface Finishing (NASF) for optimal surface integrity and life for our high-performance products.

This guide provides down-to-earth and battle-proven advice. We take experience and knowledge gained from working on complex tasks such as optimal speeds and feeds for working with titanium material to ensuring thin-walled stability during dynamic 5-axis milling and turn that into useful knowledge. Each piece of advice is aimed at helping you deal better with the challenges of aerospace machining.

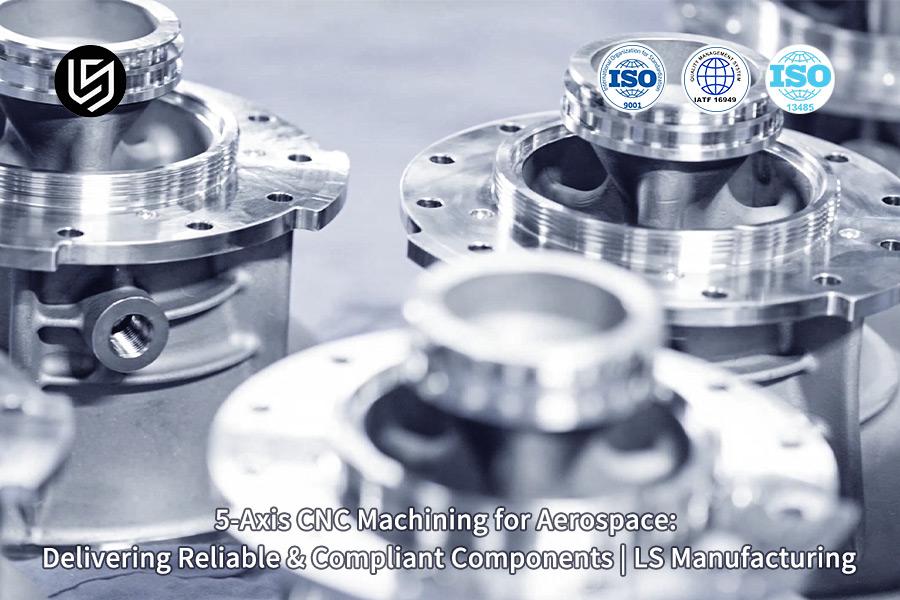

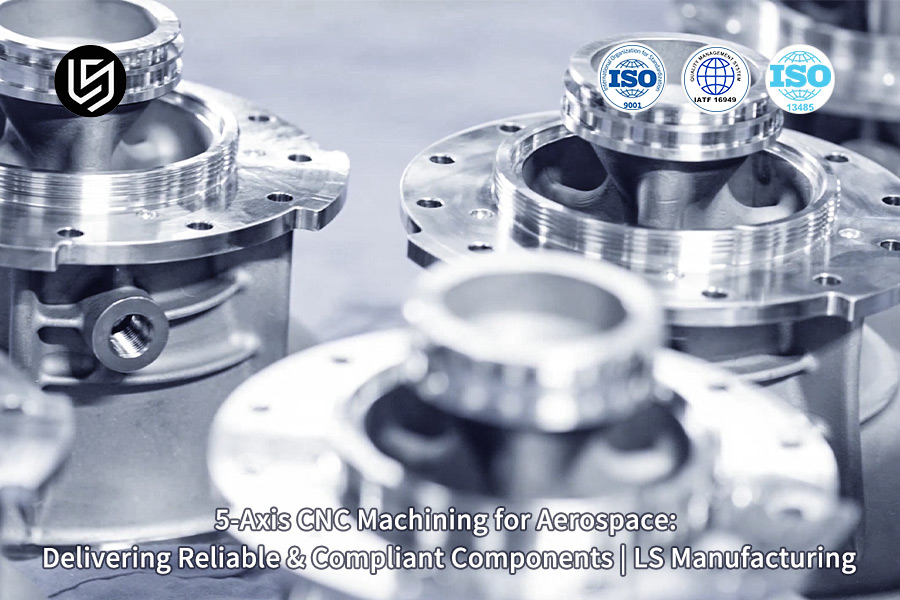

Figure 1: Precision manufacturing of large aviation components by LS Manufacturing

How Does A 5-Axis CNC Machine Tool Achieve Complex Machining Through Two Rotary Axes?

Due to the shapes used in the product, there are certain limitations of the use of a 3-axis CNC machine. This is owing to the flexibility offered by the other two axes, which provide for the position of the cutter. This is not possible in a CNC machine. This advancement, being the most elementary, enables the person using the machine to generate contours and angles in one and the same machining; this removes a major problem pertaining to the shapes used in making complex aerospace components. This is a description of the process, as explained in a diagram:

Enhanced Machine Configurations and Axis Composition:

5-axis CNC machines are typically built in configurations like a trunnion-style (where the rotary axes are on the table) or a swivel-head style (where the rotary axes are on the spindle). The core principle involves the 3 standard linear axes (X, Y, Z) for movement, combined with two rotary axes. Common pairings are the A-axis (rotating around X) and C-axis (rotating around Z), or B and C. This combination is the foundation of how 5-axis CNC machining enables complex manufacturing by providing the necessary degrees of freedom.

Tool Orientation Optimization for Optimal Cutting Dynamics

This will entail the orientation of the tool with the use of two rotational axes, which will be responsible for the positioning of the tool in relation to the cutting surface. With this, the positioning of the tool in the optimal position for cutting will be realized, with even more possibilities of rotating the tool with the aim of ensuring optimal cutting conditions. This is an integral part of consideration when focusing on the 5-axis CNC machining, particularly in relation to the optimal cutting of the deep cavities as well as the optimal evacuation of the chips.

Machining Complex Features in One Machining Cycle

With the emergence of the dynamic orientation of machining tools, machined components will soon have a work piece easily accessible in all directions. With the help of this technology, machined complex features in an aerospace turbined airframe structure with necessary passages inside an aerospace turbined airframe with machined complex features in one machining cycle will soon become a simple process. Machining the advance 5-axis CNC machine parts aerospace turbined airframes will soon become a necessity.

Efficiency and Precision Features

These machines run smoothly because of the continuous 5-axis machining. This results in faster processing and a smoother finish on the final surface obtained. Furthermore, due to the single setup processing obtained from the machines above, the entire processing task is not influenced by the standard tolerance that results from the distance required in the processing of multiple destinations. This results in the final output displaying greater geometrical precision in the entire process. The efficiency and precision brought into the 5-axis CNC machining services system make this process revolutionary.

In fact, the combination of these two rotary axes and 3 linear axes provides so much liberty of movement to the cutting tool that never before has been attained. It led to the optimal orientation and positioning of the cutting tool and stepped and continuous processing in various directions and thus solved the problem relating to designing shapes having accuracy in one pass.

Compared To 3-Axis Machining, What Disruptive Advantages Can 5-Axis Technology Bring?

3-axis machining proves to be a linear process, a bottleneck process, whilenecessarily a process of machining curves. Even if two rotary axes are mergedtogether, as seen in a 5-axis machining process, it is not an easy conversionbut a paradigm shift in itself because, with that, a new dimension of flexibilityis added, and a new world full of possibilities is unfurled. The benefits thatprov emerged because of the emergence of 5-axis technology in machining aregiven below:

|

Advantage |

Key Impact |

|

Single Setup Complete Machining |

It eliminated several part reposition movements. This significantly reduced overall positioning errors and non-value added time for a large number. This enhanced overall quality. |

|

Functioning with Smaller, Stiffer Tools |

It helps in optimizing the orientation of the tool and hence the use of small tools and therefore stiffness and smooth finish and accuracy. |

|

Optimized and Reduced Tool Paths |

Enables the shortest possible path of movement for the tool. Suppresses non-productive repositioning cuts involving multiple axes. |

|

Machining Capability of Complex Geometries |

It helps in machining complex shapes such as undercuts, deep cavities, and surfaces containing organic compounds in a single machining process which cannot be performed in 3-axis machining. |

|

Enhanced Accuracy and Reproducibility |

Since this process is executed in a single system, there is less use of human intervention, which might have some inaccuracy. As a result, optimal corresponding tolerance values will become possible. |

In summary, the advantages of 5-axis CNC parts are transformative. From enabling complex manufacturing with 5-axis CNC of once-unthinkable geometries to guaranteeing unparalleled precision, the technology delivers a decisive competitive edge. This makes 5-axis CNC machining the indispensable solution for producing high-value, high-complexity components with optimal efficiency and reliability.

Which Types Of Parts Must Be Machined Using 5-Axis CNC Machining?

The 5-axis CNC machining center possesses the capability to locate the cutter in any desired fashion; this could often prove to be a common requirement in a certain situation that demands the machining of a certain complex shape that demands undercuts and surfaces. The parts that are machined by 5-axis CNC are:

|

Part Type |

Reason for equirement |

|

Blisks, Impellers & Turbine Blades |

High-order aerodynamic airfoils with high packing density and complex surfaces maintaining constant multi-axis orientations |

|

Complex Aerospace Structural Components |

Highly complex structural geometries that maintain deep pockets, complex rib geometries, and complex mounting points that are inaccessible for 3-axis machining. |

|

Medical Implants (Joints, Spinal Cages) |

Require precise, biocompatible organic contours that perfectly match human anatomy, often machined from difficult materials like titanium. |

|

High-Precision Molds & Dies |

The complex 3D geometrical patterns, corners, and textures that could not be indirectly machined would have to be produced in this area. |

|

Multi-Sided Parts with Compound Features |

The machining of 5 or more sides of an object for holes, slots, and angles found in shapes. |

In all, 5-axis CNC machined parts fall into the class of "mission-critical" parts, and with the level of quality and accuracy, their integrity assumes precedence by way of priority. Be it the complex manufacturing with 5-axis CNC through to 5-axis CNC milled parts, this is indeed a critical path for complex designs functionality.

Figure 2: Precision 5-axis CNC milling for critical aerospace aluminum components by LS Manufacturing

How Do You Determine If Your Project Requires Investment In 5-Axis CNC Machining?

Decisions related to 5-axis machining, other than part complication issues, are strategy-related and embed other requirements of the project. In this particular scenario, having a proper structured approach is very much essential. In this context, there are critical factors discussed below that will help you choose a strategy for manufacture in project implementation.

Part Geometry and Complexity

The primary indicator is geometric necessity. Does your design feature deep cavities, undercuts, compound angles, or complex 3D contoured surfaces like organic shapes or turbine blades? If these features would require multiple, complex fixtures and setups on a 3-axis machine, then 5-axis CNC machining becomes essential. It enables single-setup fabrication, turning a multi-step, error-prone process into a streamlined operation, which is the core advantage of advanced manufacturing.

Precision and Tolerance Specifications

If there are specifications regarding the tolerance amount and the piece that is being manufactured is not positioned on parallel surfaces, then the total amount of the positioning error that is involved because of the 3-axis procedure on the CNC machine is not acceptable, but for the 5-axis CNC parts process, the positioning of the part is accomplished by the machine itself within one fixture, meaning that the positioning procedure is without any amount of error and is precise.

Cost of Production vs Total Cost Comparison

The hourly cost, of course, should not and must not be evaluated solely for comparison's sake either. In prototypes, low-series, and medium-series production, the advantage of single-setting machining could very well counterbalance the slightly higher costs of CNC machining centers. The Total Cost of Ownership of other costs, however, will very likely indicate how 5-axis CNC machining is faster and less expensive for appropriate products.

Materials and Secondary Processing Effect

Evaluate their effects. In fact, the finish that can be achieved with the help of one machined part method will not only be fast, but also precise, without necessarily having to resort to a secondary processing method in order to achieve this result. It should be noted, though, that it is actually the benefit that comes with employing the best point in the tool within a 5-axis machine that will significantly affect tough materials such as Titanium and Inconel instead. It therefore will provide a sufficient reason in terms of cost that will be incurred over its entire lifespan as a tool.

This article on 5-axis CNC parts guide highlights the importance of interaction with the competent person from LS Manufacturing 5-axis machining due to the fact that in instances involving the need for complex designs and the meeting of specific requirements and achievements in this regard, interaction is not extra business cost, but business investment.

Figure 3: Precision multi-axis CNC milling for aircraft structural parts by LS Manufacturing

Case Study Of 5-Axis Machining Of Aero Engine Bladed Disks: How LS Manufacturing Overcomes The Problem Of Thin-Walled Blade Deformation

Blisk production activity is the very meaning of complex manufacturing with 5-axis CNC technology. Precision here is generally analogous to quality. We shall move on to the next stage of pinpointing the challenging task and technology used in our firm that reflects the implementation of the most recent technological innovation applied to deal with the challenging production task.

Client Challenge

The challenge that was posed by the client's problem was connected with the machining of the high-temperature blisk made from high-temperature alloys by the prime aerospace client of the firm. The challenge posed by the thin-bladed maching of the blisk with the cantilever configuration and the small inter-blade gaps was basically the vibration and chatter that were generated from the conventional maching carried out on the 3 axes. This is because the challenge posed by the maching was the blading distortion and thinning-out that was carried out within the overall yield of 60%, which was basically defective output because the integrity of the primes' aerospace client was at stake.

LS Manufacturing Solution

To overcome this problem, the team involved in the development of the LS Manufacturing 5-axis machining decided to implement the 3-track solution in the machining process through the use of the high-precision 5-axis simultaneous machining center. The concerned CAM software demonstrated the use of optimal constant tool path movements with the optimal cutting engagement angle of a fixed value to overcome the problem of the higher value of the radial cutting force involved in the machining process.

Results and Value

It was a highly transformative activity. The tolerance on the blade profile remained constant at 0.05mm, and the rate of increase in the part yield had a staggering increase from less than 60% to 98%. Also, the total machined cycle time had a 20% reduction due to the optimized process. It remained an extremely success-enabling activity regarding the successful fulfillment of the highly important ordered 5-axis CNC machine parts, resulting in the highly value-satisfying outcome for the next generation engine development project of the concerned client.

This is a classic instance of technical issues being used as a means to create more critical manufactured output. Another important consideration, which one must never forget, is that in highly demanding areas of application, it is impossible to uncouple knowledge of the domain of application from world-class technology that is highly complex-as in the case of LS Manufacturing aerospace.

Manufacturing bottleneck with your complicated part? Need expertise in 5-axis machining? Consult LS Manufacturing today!

What Core Capabilities Should Be Emphasized When Selecting A 5-Axis CNC Machining Service Provider?

Choosing the right 5-axis CNC machining service provider is a critical decision that directly impacts the success of your high-complexity project. Capability in 5-axis CNC machining service provision is pegged on more than just the ownership of advanced machines; it is defined by the complete integration of technology, skills, and tight process control when executed in practice. This 5-axis CNC parts guide outlines the key competencies to review, which ensure your partner is in a position to transform complex designs into flawless and functional parts. Core competencies to focus on while evaluating suppliers:

- Advanced Equipment and Technical Precision: Its portfolio includes 5-axis equipment with brand and model, number, but above all demonstrated positioning accuracy and repeatability. Only the best high-performance well-cared-for machines from top manufacturers will meet such demands necessary to achieve tight tolerances for state-of-the-art 5-axis CNC machine parts and quality production consistency.

- Experienced in Programming and Simulation: While discussing this aspect, it is important to mention that the programming skill is something, which enhances its machining capacity. Thus, it can be stated that in the domain of CAM programming, it requires highly skilled personnel. Using these skills, they will be able to simulate a complex path of machining. The 5-axis machining requires simulation software to be successful in producing its first parts.

- Documented Process Experience and Material Knowledge: What works in theory needs to be shown in practice. Scrutinize documented experience of a provider in working with parts of similar geometric complexity and, importantly, in your required specific materials like aerospace aluminum, titanium, or Inconel. Past performance generally serves as the best predictor of how well a team will overcome the peculiar obstacles of 5-axis CNC machining, from tool selection to optimization of the cutting parameters.

- Metrology and Quality Assurance: Since the parts would be of finite tolerance, the size of the components would also need to be of finite tolerance. This would give rise to the requirement for a closed-loop system. The components would then require an on-machine probing, laser tool-setter, and CMM inspection to make sure that the component acquires the needed tolerance information.

In coming up with a conclusion to choose a 5-axis CNC machining service provider, it is not a very easy job to evaluate the technology environment, knowledge, and passion for quality. The 3 make up the best use of a machine for the production of products. Taking into consideration all the initiatives where success cannot ever be a matter for jeopardization, to partner with a technology guru, like LS Manufacturing 5-axis machining, is to have the potential to experience success even in the process of concepts creation based on the final product.

Is The Cost Of 5-Axis CNC Machining Worthwhile? How To Analyze Its True Return On Investment?

The perception of 5-axis CNC machining cost is often limited to its initial higher hourly rate compared to 3-axis. A true assessment, however, requires a holistic view that looks beyond this single metric. The value proposition lies in its ability to streamline the entire manufacturing workflow, often delivering a superior overall return on investment (ROI) for suitable projects, as this ultimate guide to 5-axis CNC parts explains. Here is a framework for analyzing the true ROI of 5-axis technology:

- Direct Cost Savings from Process Consolidation: The most immediate financial benefit stems from dramatic process consolidation. By completing parts in a single setup, it eliminates the costs of multiple fixtures, reduces machine and labor hours dedicated to repositioning, and slashes related programming and setup time. This direct efficiency gain often offsets the higher per-hour rate, making the total part cost competitive or even lower.

- Quality and Yield Impact on Overall Expense: Improved quality is a direct cost saver. Single-setup machining drastically reduces cumulative tolerancing errors, directly lowering scrap and rework rates. The enhanced precision and surface finish also frequently reduce or eliminate the need for expensive secondary finishing operations. This boost in first-pass yield is a critical component of the advantages of 5-axis CNC parts that directly improves the bottom line.

- Accelerated Time-to-Market Value: 5-axis machining significantly compresses the production timeline. Faster turnaround from design to finished part accelerates product development cycles, gets products to market sooner, and improves responsiveness. This time value, including reduced work-in-process inventory, represents a substantial but often overlooked financial advantage that enhances the overall investment return.

- Innovation Enablement and Product Performance: Cost-benefit can also be applied in other areas related to accounting. 5-axis technology has been used within the production of the final product that is lightweight and stronger than before. This final product cannot be produced through the production processes. This results in the fact that cost-benefit cannot act as a cost of production.

Therefore, there could not but be an assumption that for a proper ROI procurement of a 5-axis CNC machining, there must be a consideration of a comprehensive ROI analysis. This means that generally, there must be an investment in efficiency and innovation and quality of the product. For consideration of all benefits of fully integrated processing and enhanced production at greatly minimized production time and optimized products, there could be an assumption of highly economical behavior if it is a highly economical approach that prefers a 5-axis CNC machine for preference.

Figure 4: A fabrication process for ultra-precise components in aerospace by LS manufacturing

What Is The Typical Process For A 5-Axis Machining Project In Collaboration With LS Manufacturing?

The mere initiation of the process concerning the 5-axis CNC machining would be necessarily related to huge open collaboration for the successful processing of a successful task of this undertaking. Regarding the case of LS Manufacturing in this analysis, a collaboration process, together with the phase gate process, in relation to our experience amounting to the volumes within your part of the conceptual undertaking down to implementation, would be determined to include. The description above would be used in an attempt to justify that the collaboration process would involve:

- Initial Consultation & Data Review: The successful projects are followed by the kick-off process of technical communication in detail. We stress significantly on the process of understanding your performance requirements, material requirements, as well as your tolerance requirements in our process. This is probably the point where you will send us your CAD drawings; it is here that our engineers start the initial feasibility consultation process, and we initiate our 5-axis CNC collaboration process.

- DFAM & Process Planning: This critical phase unlocks value. Our engineers provide a complimentary DFM analysis, suggesting optimizations for manufacturability, strength, and cost-effectiveness specific to 5-axis machining. We then develop and present a detailed manufacturing process plan, including fixture strategy, tooling selection, and a preliminary timeline, forming the blueprint for production.

- Programming, Simulation, and Approval: Accuracy starts where we, as a business organization, begin our process of programming and simulation on the computer screen. For our CAD/CAM software, skilled programmers have been developed to work for us in the optimization of our path motion with no collision. Our state-of-the-art software will be able to simulate the process of cutting for the metal materials we will be producing; thus, we were able to view the entire process even before developing the first product made of metal leading to the entire process for LS Manufacturing 5-axis machining.

- First-Article Production & Inspection: From Digital to Physical with Accuracy As such, this entails the production of the first article according to the exacting process, where the first article is machined based on these requirements. Afterwards, the first article goes through an elaborate inspection by CMM and other metrology devices. The data collated from this shall be compiled and put down in the first article Inspection Report, to which the same shall be presented before you for your perusal and ratification for purposes of transparency and to ensure that all requirements have been compiled.

- Full Production & Quality Assurance: This is where the full production is accepted and production of your order is actually begun. In our company, quality assurance would be performed right alongside manufacturing, but would not include any acceptance testing following the completion of the product. This would be achieved through the statistical process control at the production floor and at our end for inspection guarantee, respectively.

- Delivery & Post-Production Support: At the end, we would like to complete our list by concluding the delivery and post-production support service. Not only are we capable enough of taking care of the delivery part on your side so that it will be safe on your side, but we would also assist you in taking care of any paperwork on your side regarding your parts, other than helping you out if you are in some situation that may arise on your side regarding the assembly and product chunks.

In summary, partnering with LS Manufacturing 5-axis machining means engaging in a disciplined, collaborative, and transparent workflow designed for certainty. This proven 5-axis CNC collaboration process, as detailed in this ultimate guide to 5-axis CNC parts, transforms complex manufacturing challenges into reliable, high-performance outcomes, project after project.

FAQs

1. What is the Highest Precision Achievable with 5-Axis Machining?

In the best case, the 5-axis computer numerically controlled machine from our firm is able to position an object to within ±0.01mm or even less. This form of positioning precision can actually be realized; this will depend on the size and material, as well as rigidity, of the object.

2. What is the Minimum Order Quantity (MOQ) for 5-Axis Machining?

We also have flexible MOQ requirements, ranging from one-shot prototypes to large batch orders. Whether it be R&D validation samples or large product orders, we are able to meet your needs whatever point your project is at.

3. How Long Does It Take to Receive a Quote After Submitting Drawings?

Basically, under normal conditions, if we had to make the quote for your query for the production of these complex 5-axis parts in question, it would take us 1-2 days to process the quotation. Besides this, this process would also be incorporated within the quotation for easier collection of information on the project.

4. Do You Offer In-Process Measurement and Compensation During Machining?

Yes, yes, indeed. For instance, the 5-axis machines will have Renishaw probesystems integrated. Therefore, calculations pertaining to sizes needed during the processes will be possible. The cutting tool used during the processes will also be able to be compensated.

5. Does My Design File Need Special Preparation for 5-Axis Machining?

Just provide us with the complete model, in 3D format, which is a STEP file, and we would do everything else. This is because our process engineers are doing all DFM analysis and 5-axis operations themselves. And that would be pretty much the way we would optimize your model.

6. Is 5-Axis Machining Suitable for All Types of Materials?

The machining services we can provide include different materials and alloys, such as aluminum alloy, high-temperature alloy, titanium alloy, stainless steel, and engineering plastic. We will be pleased to recommend the type of material and corresponding process which will be applicable for your specified requirements.

7. How Do You Ensure Surface Quality for Complex Curved Parts?

This has been achieved with a view to get a finish on the surface for all possible geometries of the curve with regard to the processing of the value of the optimal cutting parameter and the value of cutter step-over and step-down.

8. How Can New Customers Start Their First 5-Axis Machining Project?

As regards your case, all you have to do is contact us from our website or from our numbers. Subsequent to this, our project engineers will take care of all the proceedings right from answering queries pertaining to the technology to placing orders for the projects from your CAD files.

Summary

It is not only that the 5-axis CNC machining are now the only possible advanced solution, but even the only feasible solution that can be worked out in order to address the complicated tasks of precision machine work.

Days of complexity delaying production are behind us! Only think about the number of chances that are going to be presented in front of you the moment you are able to avail the chance of getting associated with the LS Manufacturing experts of 5-axis machining and resolve your problems related to the production. It is really simple. You just have to press the 'Get Free 5-Axis Machining Technical Solution Consultation' above, and we will check out its techno-feasibility, free of cost, and develop your inventions.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.