CNC machining service will have some problems when drilling holes, which might include the inability to accurately determine the opening with a precision level of ±0.02mm and high surface roughness with values of Ra 1.6μm. These stated conditions will be linked to the utilization of generalized reamers, which will not be appropriate for the material properties and technology used.

The key component in arriving at a solution for us is to verify that we possess a correct customization of the reamer design as much as feasible for us. It will help us achieve the machining of exact dimensions with accuracy of ±0.005mm with a surface finish of Ra 0.4µm.

CNC Machining Services: Precision Hole Machining Overview

| Section | Summary |

| The Problem | Manufacturers face issues like inaccurate holes, rough finishes, and high costs when using standard reamers on special materials. |

| The Core Reason | Such difficulties are caused due to the innate incompatibility of general-purpose tools and the specifications of the applications associated with the tools. |

| Our Approach | The customer specific reamer designs come out of successful projects on a wide range of machining processes for some customers. |

| The Result | Customization enables exceptional precision of ±0.005mm and superior surface quality of Ra 0.4μm. |

We offer a solution to one of the most pressing problems that come with precision hole cutting by supplying custom-designed reamers instead of poor-quality standard reamers. Hence, our solution is a straight answer to a poor degree of accuracy with cutting, poor surface finish of a cut hole, and poor durability of tools.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Precision machining will and ought to have an experience that goes beyond knowledge. It is because of our over 15-year experience at our workshop, combating difficult alloys and tolerances, that our advice and guidance have come about. At our workshop, we also conform to rules and regulations provided by organizations such as the Occupational Safety and Health Administration (OSHA) with regard to safety and use the best current practice that meets or exceeds standards followed by organizations such as 3D Systems.

The capabilities of our team have been proven in critical application fields. We have produced parts where the drill hole tolerance becomes critical, like in the assembling of aero-mechanical parts or critical medical implants. Here, thousands of tough project work have been done to arrive at solutions based on the tool capabilities, materials, etc.

The tips provided in this guide pack all the tough-learned lessons from our experience in the following tips so that you can avoid goofing up while also achieving quality outputs. Trust us; all the following tips have been tested every day by us in our real-life experience.

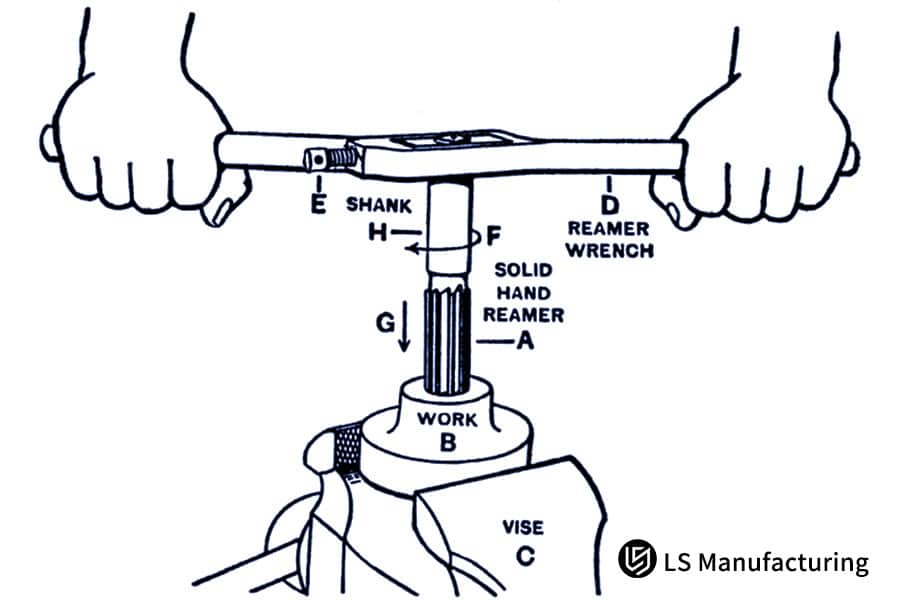

Figure 1: Precision CNC hole finishing utilizing specialized reaming tools by LS Manufacturing

What Are The Advantages Of Custom Reamers Compared To Standard Reamers?

Standard reamers are likely to fail when there are specific material requirements and tolerance levels. This causes wear and tear. The problem is solved by custom reamer tools because such tools make the tool itself a variable for precision hole finishing:

1. Material-Specific Geometry Optimization

It is evident that a common geometric system is not being used. On hard steel, a very low angle of 6-8° is required for the regulation of cutting forces, whereas for aluminum, an angle of 10-12° with a polished surface on the flute prevents the binding of chips to the cutting tool surface. In fact, for the purpose of only satisfying a cutting force, a much smoother cut is required, thereby enabling a surface finish with an Ra value of 0.4um that is impossible with standard tooling.

Engineered for Dimensional Integrity and Stability

The nominal tolerance allowed in a standard tool is a gamble. Each of us has amended our custom reamer tools to take into account the average value of your hole tolerance range, taking into account machine deflection and growth. This foresighted move, alongside our controlled deviation range width of 0.1-0.15mm, allows us to supply your bores with diameters that fall within a tolerance range of ±0.003mm.

Design for Predictable Longevity in Production

The point has come where the focus must shift from cost to cost per hole. We must systematically attack the problem of hole-making tool failures, increase the life of the hole-making tool up to 3 times, and reduce hole making, which is a burdening maintenance activity in the volume CNC machining services, to a predictable, higher uptime procedure through optimal lead angles (15°-45°), depending on the ratios of depth and hole diameters, and customized hole-making coatings.

The significance of this guide is that it gives a methodology applicable and shows ways and means of solving a machining limitation. The significance derived or created here is based on its value related to giving ways and means of realizing a specific configuration in view of geometric parameters and manufacturing tolerances.

How To Select The Optimal Reamer Type And Geometric Parameters Based On Material Properties?

The key technical factor affected by the correct reamer tool types and geometry is the quality of the holes produced, the life of the reamer, and the associated costs of the process. The wrong choice of reamer causes the reamer to wear out very quickly, produces poor surface finish quality holes, or produces holes in the form of scrap materials. The technical note would discuss how to choose reamers by matching the parameters of the reamer with the machining difficulties presented by the different materials of the workpieces:

| Material Group | Primary Challenge | Recommended Reamer & Coating | Key Geometry & Parameter Focus | Achievable Outcome |

| Stainless Steels | High-working hardness, shearing force, overheating. | Cobalt HSS with hardness-enhanced TiAlN coating. | Positive angle of 6° - 8°. Low speed: feed rate of up to 15 m/min. | Controls heat and deformation, enabling consistent high-precision reaming and extended life. |

| Aluminum Alloys | High material adhesion (BUE), hard surface finish required. | Solid PCD (Polycrystalline Diamond) tip. | Sharp and positive rake angle (10°–12°); high speed (~80 m/min); polished flute. | Eliminates built-up edge, achieving superior finish (Ra <0.4μm) and extreme longevity. |

| Composites/FRP | Abrasive wear, delamination, fiber pull-out. | Micro-grain carbide with fine-grade diamond coating. | Strong cutting edge, negative or neutral rake angle, and unique chip flute design. | Mitigates abrasion and shear forces, protecting hole integrity and ensuring 5000+ hole life. |

This systematic selection is key to high-precision reaming. Match the tool to counteract the material's primary failure mode. This data-driven method controls hole variation within 0.002mm and optimizes cost, providing a definitive how to choose reamers guide for competitive, high-value applications.

Figure 2: Configuring a CNC reamer for precise finishing of holes by LS Manufacturing

How To Ensure Stable Hole Diameter Accuracy And Surface Quality During CNC Reaming?

The end reproducible high-precision reaming means having a machine that provides repeatable results as well as sufficient attention to the overall process to achieve a repeatable process. The key to this is to offset factors that affect the hole making process, such as thermal variation, tool wear, and removal of chips:

Environmental and Thermal Stability Control

- Uncontrolled ambient temperature is a main contributor to the dimensional drift.

- In our laboratory, a temperature-controlled processing workshop is maintained at 20±1°C to reduce the expansion/contraction of the machine tool, workpiece, and cutting tool due to temperature.

- Such basic system stability eliminates one of the greatest variables, as these coordinates are directly related to the machined result, which is a key factor in maintaining tolerances at ±0.005mm.

Real-Time Process Monitoring and Compensation

- This causes inconsistency in the case of passive machining. We implement in-process metrology for active control.

- Predictable tool wear trends are identified on the basis of in-process gauging or tool presetter data.

- It will automatically apply these micro-changes to the tool path/offsets, compensating for the wear well before parts go out of tolerance, ensuring that long-term Cpk values are better than 1.67.

Optimized Chip Evacuation and Surface Finishing

- Chips that are drawn across the surface of the bore are the chief cause of poor surface finish. In particular, the design of the cutting fluid delivery system is based on overcoming this problem.

- Minimum Quantity Lubrication (MQL) applied with a exactly measured flow rate (e.g. 50 ml/min) delivers lubrication directly to the cutting edge.

- This simultaneously provides an effective lubricating ability that reduces friction and temperature while, at the same time, keeping fluid volumes low, thus avoiding re-contacting of the machined surface, which plays an important role in ensuring a constant surface Ra 4µm.

In this technical note, the procedure explained is this: a closed-loop system that performs control of environment, compensation, and lubrication. It provides a replicable methodology for transforming the CNC reaming process from a variable finishing step into a predictable, high-reliability operation capable of sustained precision hole finishing in demanding production environments.

Comparative Analysis Of Feasibility Of Hole Finishing Processes?

The identification of the most preferred hole finishing techniques necessarily involves considerations of precision, throughput rates, and costs. The following section will compare and contrast the processes of reaming, honing, and lapping based on actual production data and will serve as a guide for costing considerations:

| Process | Typical Tolerance (ISO) | Relative Efficiency | Relative Cost per Hole (Index) | Best Application Context |

| Reaming | IT6-IT7 (Highest) | High | Medium | CNC machining services for through/blind holes requiring high positional accuracy and finish in a single setup. |

| Honing | IT7-IT8 | Medium (3-5 holes/min) | High | Achieving fine surface finish and exact bore geometry on hardened materials or correcting form errors. |

| Lapping | IT5-IT6 | Very Low | Low (e.g., ¥0.5/hole) | Achieving ultra-fine surface finish on small, hardened parts where stock removal is minimal. |

The most cost-effective reaming has to satisfy all of these constraints. In a Φ10H7 hole, maximal benefit relative to cost constraints for a custom reamer compared to honing and lapping operations is provided by an optimized reamer. The recommendation is as follows: Choose based on where single-setup accuracy, correction of form error, surface finish of hardened material are of most concern: Reaming, honing, lapping.

How Can Tool Geometry Optimization Address Machining Challenges For Specific Materials?

The difficulty is when traditional tool geometry does not work well with advanced materials, work hardening, delamination, or chatter makes the quality for parts poor. The answer is to intentionally design the shape of the tool to compensate for the particular failure mode of the material, turning the task that is causing you difficulty into a perfected process. This is the essence of knowing how to choose reamers effectively for demanding applications:

Preventing Work Hardening in Heat-Resistant Alloys

- A work-hardening material like Inconel hardens quickly at excessive pressure coupled with high temperatures from a standard tool.

- We employ a very positive rake angle; for instance, 15° offers thinner undeformed chips, which reduces cutting forces to a great extent.

- Together with its smooth surface and optimized coating, the geometry seamlessly shear the material without any deformation, ensuring that the material is not hardened and is stable for precision hole finishing with IT6 tolerance.

Eliminating Delamination in Composite Materials

- Due to its multi-layered structure, it is prone to splintering and fiber pull-out during poor cutting performance.

- The blade employs an extremely acute cutting edge with a purified edge and land.

- In this way, there is scissors movement, not tearing, creating a neat cut edge that is burr free on the bore, which makes it a bore edge of high quality.

Dampening Chatter in Thin-Walled Components

- These thin sections cause vibrations during machining, hence poor surface finishes, along with elliptical and enlarged holes.

- In our custom reamer tools, variable pitch/helix has been employed to negate these resonating vibrations to some extent.

- Such a design affects the resonant frequency distribution, and thereby, resonant frequency damping occurs due to chatter vibration. Stable machining, a higher removal rate, and an IT6 accuracy level can also be achieved.

The presented work provides a method for the solution of specific complex problems. It illustrates that a good result for hard materials consists not in a higher standard solution but in a correct definition of geometry in custom reamer tools.

Figure 3: Finishing holes manually using a reaming tool on a workpiece by LS Manufacturing

What Special Process Control Measures Are Required For High-Precision Reaming?

High-precision reaming operations on critical components are done inside a climatic chamber. The temperature is held constant at a fixed value of 20°C ±0.5°C, and the humidity levels are also held constant at a fixed value because of thermal expansion effects on machine tools and components, and also on other measurement equipment required for such a process to happen. The major factor contributing to part variation differences is eliminated through this method.

Environmental Stability as the Foundation

All precision hole finishing processes for critical components take place in an environmentally controlled enclosure. The temperature in this enclosure is held constant at 20°C± 0.5°C, with controlled humidity to counter temperature growth in machine tools, workpieces, and measurement equipment. In this way, an important source of dimensional error, which results in variations in measurements from part to part, is eliminated.

Real-Time Compensation via In-Process Metrology

We utilize closed loop feedback systems where the touch trigger probe or laser micrometer makes a measurement of the borehole directly after completion of the reaming cycle. The results are then fed back into the machine control where an automatic tool offset is implemented. The quick action taken as part of our CNC machining services prevents an out-of-spec part from occurring as it maintains spec within the hole tolerance window.

Tool Life and Performance Management

Each custom reamer tool offer traceability from first use through their tool management system. The tool management system keeps track of the number of holes that were drilled with each tool as well as their cuts and tests. The record created from information allows for future tool changeovers based upon actual rather than best estimate of optimal use and delivery before tool failure based upon forecast.

Such control and high-precision reaming reflect the capability of maintaining the accuracy below the sub-micron level on a designed, not an aberrational, basis. The basis for our competitiveness begins with our strategy of balancing the importance of environmental control, in-process inspection, and the use of knowledge in our CNC machining services of mitigating the effect of mass precision hole finishing.

How Can The Cost-Effectiveness Of Custom-Made Reamers Be Quantitatively Evaluated?

In this connection, in order to judge correctly the return on Investment for these custom tools, it has become necessary to move away from Investment to total cost of usage. As part of this presentation on a methodology for identifying an cost-effective reaming, the economics for custom reamer tools for handling particular production difficulties would be established:

Problem Diagnosis and Baseline Establishment

The process begins with a forensic analysis of the existing drilling/reaming operation. We measure not just final hole diameter and surface finish, but also tool wear progression, cycle time, and the hidden costs of downtime and scrap. For a client producing hydraulic valve bodies, the baseline revealed a standard reamer lasted only 3,000 holes before exceeding a 5µm tolerance, causing a 2% scrap rate and frequent stoppages.

Custom Tool Design for Targeted Performance

Based on diagnostic data, the tool is engineered for the specific application. This involves selecting a substrate (e.g., micro-grain carbide), optimizing flute geometry for chip evacuation, and applying a proprietary wear-resistant coating. For the valve body case, we specified a polished flute design and an AlTiN coating, which directly targeted the abrasive wear and built-up edge identified as the primary failure modes.

Precision Manufacturing and Validation

This design is actualized through our in-house CNC machining services to make sure the tool geometry perfectly matches the CAD model. Every tool goes under severe inspection on CMMs to confirm critical dimensions like flute concentricity and edge preparation. This ensures that the performance designed is built into the physical tool before it is field tested.

ROI Modeling and Lifecycle Cost Analysis

We perform a controlled production trial with the custom tool, gathering empirical performance data to feed a financial model that will compare the total cost per hole. In that instance, life for the custom reamer increased to 10,000 holes, scrap fell to 0.1%, and cycle time improved 15%. The model quantified a 40% lower cost-per-hole and proved payback in less than 2 months at 10,000 holes/month volume.

This report describes a complex and technical process for identifying cost-effective reaming from root cause analysis through to economically proven payback. This report will show that an economically viable benefit of custom reamer tools is not mere hypothesis or mere speculation, but is instead an analytically based result of certain engineering and precision manufacturing parameters. That is our distinction with this empirical and data-proven methodological approach to address specific cost-per-hole concerns and problems with your current CNC machining services.

Figure 4: Selecting reamers for high-precision CNC machining operations by LS Manufacturing

How To Evaluate A CNC Machining Supplier's Precision Hole Machining Capabilities?

Evaluating a CNC machining supplier's capability for precision hole finishing hinges on ensuring dimensional accuracy and process reliability. LS Manufacturing, with its CNAS-accredited lab and end-to-end tool management, provides solutions that directly address precision control and efficiency challenges:

Precision Inspection and Verification Capability

- A CNAS-accredited inspection center provides authoritative reports for hole diameter accuracy of ±0.001mm, verifying quality in real-time.

- High tech metrology equipment is also being used to track the data of the holes in order to obtain immediate feedback in case of deviation from the designed specifications.

- This goes a long way in ensuring that there is little human error involved and that accuracy can be guaranteed as measurable results are derived.

Cutting Tool Fabrication and Performance Optimization

- Custom reamers, produced using highly developed 5-axis tool grinding machines, provide geometric accuracy for productive high-precision reaming.

- The use of a proprietary tool life management system gives owners the tool calibration and maintenance capability, thereby increasing tool life.

- The parameters of this tool may be optimized for specific materials with improved wear resistance and consistency of hole finishing. The variable conditions include temperature.

End-to-End Service and Process Integration

- We provide comprehensive CNC machining services, covering tool customization, process setup, machining, and final inspection.

- Custom CNC machining solutions integrate intelligent parameter optimization to achieve efficient and reliable precision hole finishing.

- Continuous process refinement reduces scrap rates and lead times, lowering overall cost and boosting client competitiveness.

In summary, LS Manufacturing excels in CNC machining services by delivering high-precision reaming and precision hole finishing through certified inspection, advanced tool grinding, and end-to-end management. The emphasis on practicality is useful for ensuring the customers of the accuracy of the holes they receive and therefore displays expertise.

LS Manufacturing Medical Device Industry: Precision Hole Machining Project For Joint Implants

Client Challenge

In a medical devices manufacturing company, the firm struggled seriously for the production of locating holes with the value of Φ8H6 on the Femoral part, which consists of a Cobalt-Chromium-Molybdenum Alloy. Thus, as a consequence, the reamer worked well for the production of locating holes only up to a maximum of 200 holes, seriously affecting the production procedure. The variation produced for the hole diameter surpassed the limitites by 0.015mm, and the surface roughness was seriously affected with Ra1.2μm.

LS Manufacturing Solution

The proposed solution required the employment of a designed superfine grain carbide reamer with optimal geometric characteristics: the rake angle of 8°, tolerance of 0.08mm, and so on. The reamer employs the optimal cutting tool with the optimal special PVD-AlTiN coating layer on the cutting tool. In machining, the optimal speed of 20 m/min and optimal feed of 0.05mm/r were used.

Results and Value

The result was nothing short of dramatic. Thus, tooling life improved by 650% from 1,500 holes, and dimensional accuracy was maintained to a very stringent tolerance of ±0.003 mm, and surface finish improved greatly to Ra 0.4 microns. These improvements in process capability have enabled the client’s product quality qualification rate to be at 99.9% and have allowed annual tooling savings of $11,000, which are exceptional for production efficiency and cost of ownership.

The importance of this LS Manufacturing case lies in proving that even complex metal machining tasks can be effectively addressed by professionals. The correct and accurate solution provided ensures manufacturing excellence for us and makes us an authoritative partner in carrying out complex manufacturing operations.

Struggling with cobalt-chromium alloys? Let's explore precision solutions for superior hole quality and tool life.

Future Development Trends And Innovation Directions In Precision Hole Machining Technology

Future upgrades in precision hole machining must overcome the important task of achieving accuracy within microns at high speeds, from traditional static machining to the setting up of intelligent adaptive machining systems. LS Manufacturing's R&D efforts are pertinent to overcoming the problem of:

Intelligent Tooling with Predictive Maintenance

From a reactive and maintenance state, along with our custom-made reamers containing an RFID/NFC chip, this solution transitions us into the predictive state. The analysis for the life span and usage data for our tools happens in real-time directly from the machine. The solution relies on the historical analysis of high-precision reaming and then predicts the point where tools must be changed.

Closed-Loop, Adaptive Machining Systems

We remove scrap due to tool wear or thermal drift by incorporating in-process probing with a closed-loop system. After each bore is machined, it is measured by an inline probe for actual diameter. The algorithm calculates compensation values based on measurement data. The system’s algorithm then calculates the necessary compensation and automatically updates the tool offset for the next part, ensuring consistent precision hole finishing without manual intervention.

Advanced Process Development for Next-Generation Materials

In terms of hard-to-cut alloys, we are at the forefront in researching the application of ultrasonic-assisted reaming. In this technique, a high-frequency vibration is incorporated with the cutter. Consequently, the force of cutting as well as the generated heat during cutting are significantly reduced. Therefore, it is achievable to go beyond what is possible in CNC machining services.

LS Manufacturing advances the art of precision hole finishing with our intelligent, closed-loop systems in these areas. We provide effective solutions to some of the critical issues associated with tool wear and variations in our process using sensor technology. The applications in our precision reaming service pertains to high-precision reaming.

FAQs

1. What are the advantages of special reamers besides the usual advantages of conventional reamers?

The optimized geometric parameters enable the customized reamer to precisely meet the working condition. Thus, there will be a massive improvement in terms of the longevity and accuracy of machining and the surface finish even for production machining.

2. How to select the most suitable reamer type based on the processing material?

The quality of material with respect to hardness and strength should also be taken into account. Cobalt high-speed steel should be preferred for cutting stainless steel, and the application of PCD material will be most ideal for cutting aluminum alloys, and diamond coating will be most ideal for cutting composite material. The process will require the determination of the best parameter during the cutting test.

3. How to ensure the stability of hole diameter accuracy during CNC reaming?

In systematic processing, it is required to implement environment control with regards to temperature constancy, online measurement of dimensions, and online compensation for tool wear so that the diameter of holes can be controlled at the micron level through mass production.

4. How to quantitatively evaluate the cost-effectiveness of custom reamers?

Even in this process, there would be an increase in costs, although visible economic advantages exist for values over 5000 holes, relating to increases in efficiency. A full study for return on investment needs to be developed.

5. What special process assurance conditions are needed for high-precision reaming?

A constant temperature environment, humidity, a high precision online measurement system, a tool management system are requirements for a machining operation to have accuracy and stability. These requirements are equivalent to the demands required for quality in high-end manufacturing.

6. How to determine if a reamer needs resharpening or replacement?

Because if the deviation in the hole’s diameter exceeds 30% of the tolerance range or in case the roughness of the surface deteriorates and the cutting force increases, appropriate action must be taken without delay. Regular checks can also avoid the occurrence of massive quality problems by observing the status of the cutting edge.

7. What are the key points to pay attention to when reaming special materials?

The difficult-to-cut materials need optimized geometric parameters along with optimized cutting parameters. The high temperature alloys need high rake angle to avoid work hardening. The composite material has a special requirement to avoid delamination defect in it.

8. How to obtain professional reamer customization solutions and accurate quotations?

In this context, specialist suppliers can use specific information related to workpiece material, hole diameters’ accuracy, and production requirements to fulfill technical requirements and delivery times of no more than 4 hours.

Summary

By carrying out scientific selection of the reamer and the machining process, it is possible for enterprises to optimize the machining quality of holes and the life of the reamer, ensuring that the machining accuracy and economy reach the optimum state. From the point of customization experience and technical system, LS Manufacturing can be a credible supplier of hole machining services.

If you would like a custom-made solution for your reamer process or would like a free process analysis, you can contact our technical team at LS Manufacturing. All we would need is information about your machining need, and we will furnish you with expert machining solutions, including free quotes.

Upgrade your hole machining quality; custom reamers will help you achieve ±0.005mm accuracy.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.