Metal rapid prototyping directly tackles the core pain points of conventional manufacturing, such as the long cycles and high costs of processes like mold making and casting. It overcomes the material waste and design limitations of subtractive manufacturing, as well as the high initial investment and inflexibility of conventional molds, meeting the market's need for rapid iteration.

LS Manufacturing's technology not only quickly produces high-performance functional parts but also provides end-to-end solutions from prototyping to mass production via rapid tooling and small-batch molding. So, how exactly does this technology create value for your business? To save you time, here is a brief overview of the key findings.

Metal Rapid Prototyping Full Text Quick Reference Table

| Module Title | Core Content |

| Technical Essence | An additive manufacturing technology that directly manufactures metal parts by layer-by-layer deposition of materials based on 3D digital models. |

| Core Principle | Utilizing laser/electron beams as an energy source, it selectively melts layers of metal powder, accumulating them layer by layer to form dense parts. |

| Core Value | Enables complex internal cavities, lattice structures, and other topologically optimized structures that are impossible with conventional machining, unleashing design potential. |

| Time Advantage | Eliminates the mold-making process, enabling rapid conversion from design to part, shortening the development cycle from months to days. |

| Cost Advantage | No mold costs, relatively fixed unit cost, particularly suitable for economical production of small batches of highly complex parts. |

| The main applications | Direct manufacturing of functional prototypes, customized end components, lightweight structural parts, and conformal cooling molds. |

| Technology Extension |

It effectively bridges the gap in prototyping and mass production needs through rapid prototyping, such as injection molds and die-casting molds. |

| Applies to | Applies best when the geometry of the parts is complicated, the construction must be lightweight, or there are small batches or tight delivery deadlines. |

The core competence of metal rapid prototyping is digitally driven manufacturing agility. Free from the conventional mold constraint, it greatly improves not only the development speed of the product but also fundamentally unlocks the ceiling of design innovation. This technology represents an important strategic tool through which modern enterprises can face rapidly changing markets and realize product differentiation with rapid iteration.

Figure 1: Rapid Aluminum Prototyping via Metal 3D Printing by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Why are we confident in this guide in the information explosion era? Because we firmly believe that real knowledge does not come from theoretical discussion; it comes from repeated practice at the production line. All insight from this article is from the LS Manufacturing team's long-term and deep cultivation in high-end manufacturing fields. We are committed to transforming the most valuable practical experience into your competitive advantage.

Within the last decade, we have completed over 50,000 custom projects. Each challenge brought us deeper into understanding how to choose the optimal laser scanning strategy for different metal powders, how to effectively control residual stress during printing, and how to find a balance of accuracy, strength, and efficiency by means of parameter optimization.

This course will share this kind of practical wisdom condensed from countless successes and early lessons. The pits we have gone through are for you to avoid; the methods summarized have been repeatedly verified in actual production and strict quality control. So please rest assured that the content herein is the core knowledge that we believe in and use at work daily, in the hope that it will help you make accurate decisions.

How Does Metal Rapid Prototyping Redefine Part Manufacturing Processes?

What is metal rapid prototyping? The basic principle underlying metal rapid prototyping is based on a fundamental paradigm shift-from a subtractive to an additive process. More precisely, such a redefinition materializes through three basic changes:

1. Rapid Process Compression:

In metal rapid prototyping techniques, the concept of direct "from digital model to physical part" manufacture has been implemented. One can initialize the manufacturing process simply by importing 3D CAD data into the equipment. Without the need for mold making and preparation of specialized tooling, processes that may have taken a number of weeks or even months get compressed into days, which means a jump in the pace of product development.

2. Design-Driven Manufacturing Freedom:

Conventional processes such as machining and casting are bound by the rules for tool accessibility, draft angles, and so on. Such rules make the designs compromise in the best way for the manufacturing capabilities. In the case of metal rapid prototyping, no matter how complicated an internal conformal cooling channel, a lightweight structure with lattices, or molding components of a complicated one-piece, so long as it can be designed on a computer, it can be directly manufactured.

3. Restructuring the Cost Logic:

Conventional manufacturing has shown that part complexity is directly proportional to the difficulty and cost of processing. In Rapid Metal Prototyping, cost is dependent upon material usage and printing time with little dependence on geometric complexity. In this way, constructing parts of complex functionality, such as lightweight structures and integrated internal flow channels, is no longer prohibitively expensive and provides an economically viable path for product functional innovation.

In other words, digital additive manufacturing technology enables the implementation of rapid metal prototyping. It changes the axis of manufacturing from "mold/tool" centric to "data" centric. Thus, it achieves a breakthrough in terms of speed, freedom, and economy. New product development becomes a norm characterized by rapid iteration, on-demand production, and functional optimization.

What Are The Characteristics Of Mainstream Metal 3D Printing Technologies?

There are subtle differences between the various technologies used in metal 3D printing services, and understanding these differences is crucial for the performance and cost of the final part. This article will compare two mainstream technologies: Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). We will demonstrate our expertise in selecting the appropriate process based on our clients' needs.

| Comparison Dimensions | Selective Laser Melting (SLM) | Direct Metal Laser Sintering (DMLS) |

| Working Principle | The working principle is to fully melt and solidify metal powder using a high-energy laser, thereby achieving metallurgical bonding. | The laser heats up the metal powder to the sintered state, where at the molecular level, particles melt together. |

| Density | This allows the manufacturing of parts with near 100% density whose mechanical properties are similar to those obtained by forging. |

Parts could have internally micropores, giving a slight reduction in density; yet, it meets most of the industrial requirements. |

| Applicable Materials | Especially suitable for treating pure metals or alloys containing only one active metal component, such as titanium and aluminum alloys. | Appropriate for sintering pre-alloyed powders and may be used to process mixtures of multiple metals. |

| Features | Realize ultra-high strength and density of parts; produce functional components. | The internal stress is small during forming, which is beneficial for preparing thin-walled parts with complicated shapes. |

| Typical Applications | Aerospace structural parts, medical implants, high-pressure fluid, etc. |

Lightweight structures with complicated internal cavities; customized fixtures; low-volume spare parts, etc. |

Although both selective laser melting (SLM) and direct laser sintering (DMLS) are powder bed melting technologies, SLM offers higher density and mechanical properties for manufacturing load-bearing end-use parts, making it particularly suitable for applications with extremely high performance requirements. DMLS, on the other hand, is more flexible in handling complex geometries, using different materials, and controlling internal stresses.

Figure 2: Operation of an advanced metal 3D printing system by LS Manufacturing

What Are The Disruptive Advantages Of Choosing Rapid Metal Prototyping?

| Advantage Dimensions | Metal Rapid Prototyping | Conventional Machining |

| Production Speed | Direct digital prototyping produces the first part in days, eliminating programming and fixtures. | Conventional prototyping involves extensive preliminary work like programming and tooling, taking several weeks. |

| Design Freedom | It enables "design as manufacturing" to create complex lattices, internal channels, and arbitrary geometries. | Tool accessibility limitations prevent machining of enclosed cavities and complex surfaces. |

| Cost Structure | Allows "on-demand manufacturing" without mold costs; hence, material use is high. | Small-lot production is inefficient for conventional methods due to high mold and material waste costs per piece. |

| Integration Level | It supports integrated molding, producing parts in one piece to reduce assembly steps and improve structural strength. | Conventional separate processing and assembly is cumbersome and can introduce weak points at connections. |

| Material Usage | As an additive process, it targets and melts only the required metal powder, enabling near 100% material utilization. | Subtractive manufacturing's defining characteristic is material removal, leading to significantly higher waste and lower utilization. |

In a nutshell, the benefit of metal prototyping is that it overcomes the conventional manufacturing logic of "molds" and "tools" and builds a production model with "3D data" at its core. It has achieved not only the leap in speed from weeks to days but also made small-batch, customized production of complex functional parts economically valid through releasing design freedom and restructuring cost-effectiveness.

How Might The Value Of Metal Rapid Prototyping Be Increased By Integration With Conventional Manufacturing?

At a fundamental level, metal rapid prototyping depends on a collaborative approach, not a replacement approach, and rapid tooling offers a significant bridge toward that. Such a combination of technologies creates important value in particular within the areas:

1. Rapid tooling manufacturing cycle:

Conventional mold steel CNC machining generally takes weeks, while the use of metal 3D printing technology can manufacture mold inserts with intricate, conformal cooling channels directly. This rapid tooling cuts the time to make molds from weeks to days and can further optimize injection molding cycle time by means of improved cooling efficiency.

2. Reduces the cost of small-batch production:

Because of the high cost, it is uneconomical to make openings in a conventional steel mold for small lots ranging from hundreds to several thousand aluminum prototyping or other materials. Rapid prototyping, with material such as mold steel or high-performance alloys, is an economical alternative that bridges perfectly between prototyping and mass production.

3. Improving End-Part Quality:

Contrary to conventionally drilled cooling channels, the conformal cooling channels from 3D printing dissipate heat much more evenly and efficiently. This would greatly reduce injection molding cycles, but most importantly, it effectively reduces warpage of parts and hence improves dimensional stability and surface quality considerably in mass production.

This innovative application of rapid prototyping retains the high efficiency and low cost from conventional mass manufacturing while introducing agility and design freedom from rapid prototyping. This hybrid manufacturing model integrates both physical and digital technologies, showcasing the best practice route for companies in how they can balance speed and cost in a variety of product iteration, market testing, and small-batch customized production scenarios.

Figure 3: Rapid tooling enabling functional metal prototype components by LS Manufacturing

To What Kinds Of Industries And Products Does The Technology For Rapid Metal Prototyping Apply Most?

Taking aerospace design as an example, it could mean redesigning an engine fuel nozzle from many dozens of parts down to a single piece to make it stronger and more fuel-efficient. This is exactly where metal rapid prototyping plays an important core value, demonstrating the profound applications of metal rapid prototyping in changing the manufacturing paradigm across a number of very high-end industries.

- Aerospace: It produces complex internal flow channel-supported titanium alloy parts, ultra-lightweight lattice structure parts, and high-temperature alloy turbine blades to reduce weight and enhance efficiency.

- Medical Devices: Patient-specific high-matching-to-anatomy porous surface titanium alloy acetabular cups with personalized surgical guides will be developed, which may promote precision medicine.

- Automotive Industry: Use rapid prototyping to test prototypes in aluminum alloy; make lightweight manifolds for small batches of high-performance race cars, with fast iteration in R&D.

- Industrial Manufacturing: Such manufacturing can print high-efficiency injection mold inserts with built-in conformal cooling channels to improve production line efficiency and be used for printing high-strength customized composite carbon fiber fixtures.

In a nutshell, with the maturation of technology, the application scope for rapid metal prototyping has continued to expand. Several characteristics are shared across application scenarios: extremely high requirements related to geometric complexity, lightweight design, personalization, or speed to market.

What Key Technologies And Materials Need To Be Considered To Achieve High-Quality Metal Forming?

In LS Manufacturing, we well realize that great part quality does not depend on just the printer; it is an engineering process which is systemic throughout the process. Final quality in metal 3D printing services depends on three critical elements of such a process, which must be accurately controlled:

1. Material Basis:

The quality of forming is first based on the quality of the powder. Materials are strictly screened for sphericity, particle size distribution, and flowability, ensuring high powder purity and good spreadability. The former is a prerequisite that guarantees uniform thickness of the printed layer, preventing defects such as porosity and inclusions.

2. Core Process:

Laser power, scanning speed, layer thickness, and optimized scanning strategies such as island scanning become the decisive parameters inside the printing chamber that determine stability within the molten pool and, hence, the density of the part being formed. Precise setting of these parameters will ensure effective control of residual stresses, preventing deformation or cracking of parts, and is key to attaining near-forging mechanical properties.

3. Performance Assurance:

Printing itself is just the "blank." Subsequent heat treatment for purposes such as stress relief and grain structure optimization, wire cutting to separate it from the substrate, removal of supports, surface finishing including sand blasting and polishing determine dimensional accuracy and surface quality and, ultimately, service performance of the part.

In a nutshell, high-quality LS Manufacturing metal prototyping represents technology deeply integrated with superior materials, precision processes, and professional post-processing knowledge. Our metal 3D printing service provides not only printing equipment but also a proven, stable, reliable end-to-end quality assurance system to ensure every delivered part meets stringent industrial application standards.

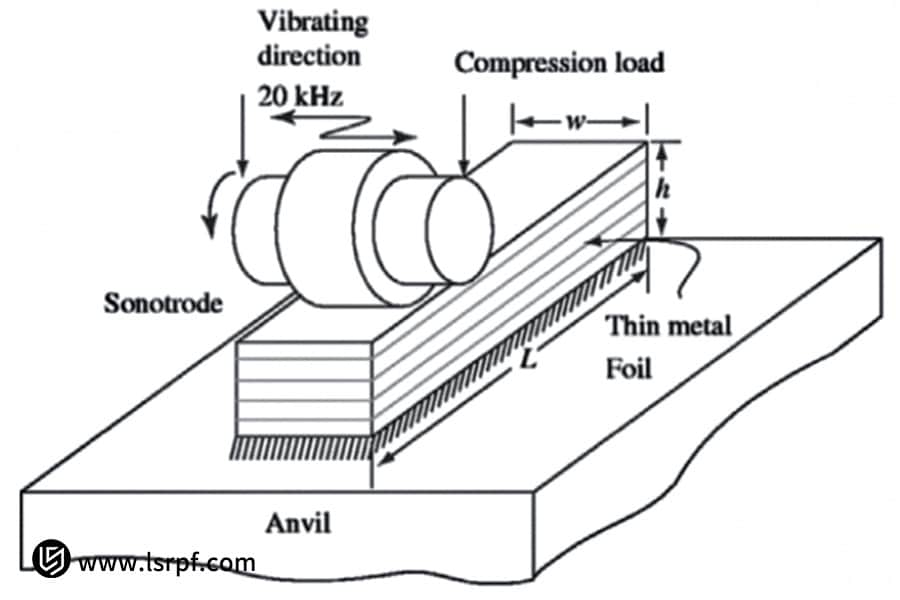

Figure 4: Technical diagram of the ultrasonic consolidation additive process by LS Manufacturing

How Does LS Manufacturing Utilize Rapid Metal Prototyping To Address Customer Bottlenecks?

Our value consists of translating advanced technology into concrete customer competitiveness. The case study below puts across how the metal-forming capability of LS Manufacturing metal prototyping helped its client to overcome a very critical challenge.

1. Client Challenge:

The leading analytical instrument manufacturer wanted an advanced, oddly-shaped heat-dissipation channel formed integrally within the core sensor housing for its next-generation product. Conventional CNC milling technology could not finish internal cavity milling as a whole, while conventional mold casting came with mold costs above 200,000 RMB and a delivery cycle of up to 8 weeks, severely postponing product launch.

2. LS Manufacturing Solution:

Our company addressed the challenge with a professional solution by means of rapid metal prototyping. We used SLM technology and printed a fully functional part in one operation with high thermal conductivity aluminum alloy within 5 days. In this process, the complex internal flow channel that could not be realized by conventional processing was perfectly accomplished. It also finished the heat treatment and precision machining of key components.

3. Results and Value:

Ready-to-assemble end parts were delivered to the client in less than two weeks, saving more than 85% of the original costs associated with conventional solutions. More importantly, the product was launched two months ahead of schedule, which helped the client promptly establish a leading industry advantage and secure valuable business opportunities.

Using our metal rapid prototyping solutions, we free our customers from the "design constrained by manufacturing" dilemma, directly meeting their core demands of speed, cost, and complexity, turning their technological bottleneck into a formidable competitive edge in the marketplace.

After Prototyping, How To Economically And Efficiently Transition To Small-Batch Production?

This is the most crucial step in the successful commercialization of a product. Our integrated manufacturing solution connects prototyping and market launch and is specifically directed at the precise application of rapid prototyping technology. We ensure continuity and economy through the following three stages:

1. Functional Validation and Design Optimization:

First, we use metal 3D printing services for fast manufacturing of functional prototypes. We comprehensively test performance, assembly, and market feedback. During this stage, low-cost and fast design iterations make sure the product design is fully matured.

2. Rapid Prototyping and Market Testing:

Instead of using expensive steel mass production molds after design freeze, rapid tooling are used for trial production, such as aluminum molds or 3D-printed soft steel molds. This produces hundreds to thousands of mass-production-quality parts at an extremely low cost in a very short cycle, usually only 1-2 weeks, for marketing, early user feedback, or small-batch sales.

3. Smooth Scale-Up to Mass Production:

This will enable clients to make zero-risk decisions with respect to market demand and the production processes validated during the pilot production phase: invest confidently in long-life steel molds for large-scale production or, if demand remains stable at small to medium batches, continue with LS Manufacturing Metal Prototyping or move to solutions such as rapid casting, reaching highly flexible production.

In other words, by combining rapid prototyping with rapid die-cutting technology, we get customers out of the classic dilemma: "high risk with large molds and inability to mass-produce without molds." Based on this model of "small steps, quick progress instead of huge gambles," financial and market risks will be drastically cut down for both startups and iterative products, which means you will transform your idea into a product with the least initial investment and grasp market opportunities firmly.

How To Choose A Reliable Metal Rapid Prototyping Service Partner?

When you decide to tap the competencies of a metal 3D printing service bureau to accelerate innovation, the selection of the right partner will be at least as important as technology selection. A truly valued supplier should be able to promise value creation at more points than just "printing." To this end, we want to propose that your evaluation be based on the following key dimensions emphasized by LS Manufacturing metal prototyping:

- Technology Platform: Advancement and Stability: A partner should have industrially advanced printing equipment that is well-kept. This is very important in making sure of part accuracy, consistency, and repeatability-not just an ability to "print."

- Material Science and Process Certification System: A wide and qualified material library of, amongst others, titanium alloys, high-temperature nickel-based alloys, mold steels, together with deep knowledge of the properties of these materials, is crucial for ensuring those parts will meet end-use functional requirements.

- Technical Team Experience and Capabilities in Positive Design Support: A good partner should be one with a team of experienced application engineers who can solve not only technical problems in printing but also intervene in the design phase, such as advising how to include lightweighting and topology optimization, adding supports with the aim of maximizing the value of the technology.

- Full-service post-processing and a strict quality control system: The integrated post-processing workflow includes wire cutting, heat treatment, and precision machining. Quality control regarding dimensional inspection and mechanical property testing is done right through to the end. Even internal defect CT scans are performed to ensure that qualified industrial-grade products are delivered.

In brief, true metal 3D printing service is systematic project work. The core competitiveness of LS Manufacturing metal prototyping encompasses the effective integration of state-of-the-art equipment with mature material processing by a richly experienced team and a rigorous quality management system. We are committed to helping you unleash your design potential, reduce project risks, and ensuring every innovative idea you have is efficiently and reliably turned into a high-quality end product.

Figure 5: Precision metal parts via rapid prototyping and 3D printing by LS Manufacturing

FAQs

1. How strong are 3D printed metal parts?

With the development of optimized printing processes and post-processing, such as HIP, their internal structure is dense, while mechanical properties, such as strength and fatigue life, can be improved to a level not only comparable but even better than that reached by conventional forging, fully meeting application requirements for high-end fields like aerospace and medical devices.

2. What is the common delivery cycle in rapid metal prototyping?

In general, the delivery cycle from confirmation to actual shipment is within 3 to 7 business days for common small to medium-sized parts. The exact time depends on the size of the part, the batch size, and the post-processing complexity required like heat treatment and finishing.

3. Is this technology suitable for large part manufacturing?

Large-scale forming equipment is available. Backed by an engineering department, professional modular design and reliable connection solutions will be provided to guarantee the best manufacturing efficiency and cost control while meeting required performance.

4. What surface finish does metal 3D printing provide?

The general surface roughness for an as-printed part is about 10 to 20 micrometers. We offer a wide range of post-processing techniques-from standard sandblasting to precision CNC machining to achieve different finish levels according to your needs in either assembly or appearance.

5. Among rapid metal prototyping and CNC machining, which one is less expensive?

In general, except for parts in some very simple geometries, CNC machining will be less expensive. Still, when those parts start having internal flow channels, lightweight lattices, or turn into one-piece molding, the advantages are huge in terms of overall cost and speed of metal rapid prototyping since metal rapid prototyping eliminates mold and assembly costs.

6. For mainstream 3D design software, what format do you support?

We support all the commonly used neutral formats including but not limited to STEP, IGS, and X_T, among others, and also native software formats like SLDPRT. This will make your design data directly integrated into our manufacturing system for your design intent to be realized with accuracy.

7. Do you provide design optimization services?

Yes, we provide professional DFAM consulting, including lightweight topology optimization and support structure optimization, done by our engineering team that can redesign your parts to make full use of rapid prototyping.

8. How to get a detailed quotation for my part?

Just attach your 3D model file format, like STEP/STL, etc., with some short technical requirements through our website or email, and in less than 24 hours, we will analyze the data to give you a clear, transparent, detailed quotation, and preliminary process plan by our expert team.

Summary

Much more than just the technology of manufacturing, it represents a revolutionary further step in how products have been developed. Not only offering unparalleled speed, freedom, and flexibility, but it also acts as one of the central engines driving innovation. For rapid metal manufacturing, LS Manufacturing is your go-to partner, powered by top-of-the-line equipment and our team of experienced engineers.

We will be glad to get your 3D designs today for a free professional review and competitive quote for your project! Contact us and allow us to support your creativity with state-of-the-art technology.

📞Phone: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website: https://lsrpf.com/

Disclaimer

The content on this page is for informational purposes only. LS Manufacturing makes no representations or warranties, express or implied, regarding the accuracy, completeness, or validity of the information. It should not be inferred that third-party suppliers or manufacturers will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type, or processes through the LS Manufacturing network. The buyer is solely responsible for this information. For parts quotations, please specify the exact requirements for these parts. Please contact us for more information .

LS Manufacturing Team

LS Manufacturing is an industry-leading company specializing in customized manufacturing solutions. With over 20 years of experience serving more than 5,000 clients, we focus on high-precision CNC machining , sheet metal fabrication , 3D printing , injection molding , metal stamping , and other one-stop manufacturing services.

Our factory boasts over 100 state-of-the-art five-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient, and high-quality manufacturing solutions to customers in over 150 countries and regions worldwide. Whether it's small-batch production or mass customization, we can meet your needs within 24 hours. Choosing LS Manufacturing means choosing efficiency, quality, and professionalism.

For more information, please visit our website: www.lsrpf.com .