The metallic lustre never fades, but the cost is out of reach. Luxury architectural facades are the preference of a revolution in materials science. In contemporary architecture competitions, anodized aluminium is rapidly becoming the signature material for luxury facades. From the US Olympic Museum to the Guangdong Science and Technology Museum, from the Hainan History Museum to the Dalian International Convention Center, landmark buildings around the world have chosen this material, with its long-lasting metallic sheen, as their "cladding." Yet when architects and buyers first spot quotes, they are typically shocked by prices a number of or even ten times higher than ordinary spray-coated aluminum. Why would a curtain wall be such a large investment? Is value or uncontrolled costs driving it? In this article, we'll deconstruct the factors which influence the exorbitant cost of anodized aluminum, detailing why it's up to ten times higher than spray-coated aluminum. We hope you enjoy this guide!

Quick Reference: Pick Your Tap at a Glance

| Price Influencing Factors | Special Performance |

| Raw Material Cost | Import aluminum alloy substrate, imported bauxite with volatile prices |

| Process Complexity | Electrolytic oxidation process, various sensitive steps, high energy usage |

| Technical Requirement | Stringent parameter control and experienced labor |

| Production Cycle | 2-3 times longer process time in comparison to standard spray coating |

| Performance Advantages | 50-year maintenance-free life, excellent color stability, long-term cost-effectiveness |

| Sustainability | 100% recyclable, green building certified, environmentally friendly |

Why Trust This Guide? Practical Experience from LS Experts

At LS, we are not just an anodized aluminum supplier but a technological disruptor too. We have witnessed in the past fifteen years the journey from relying on imported anodized plates and paying a ten times price premium to developing independently and shattering price monopolies. We understand best: anodizing's value proposition is so much more than a cost-add and cost-subtract.

We helped an energy vehicle company break through cost constraints before. When others were trapped in a 65% yield rate due to electrical breakdown of thin plates, our nanoscale gradient pore sealing process optimized the oxidation pass rate of 0.8mm battery cases to 92%, reducing the cost per square meter by 37%.

If you need product consultation for anodized aluminum, choosing LS is choosing a partner who fully understands you and can efficiently and productively actualize your design dream.

What is Aluminum Anodizing? Understanding Anodized Aluminum

Anodized Aluminum

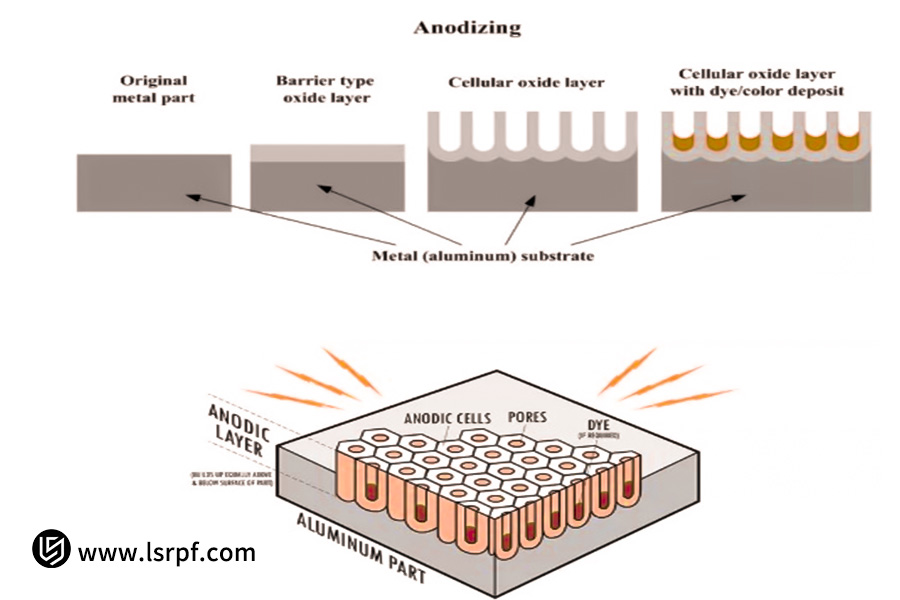

Anodizing of aluminum is an electrochemical process that wears a resistant oxide coating onto the surface of aluminum. Anodizing of aluminum parts makes it strong, corrosion-resistant, wear-resistant, and attractive. Anodizing of aluminum parts is a specialty finishing operation. It differs from other materials in that it constructs a protective layer onto the material during the machining process.

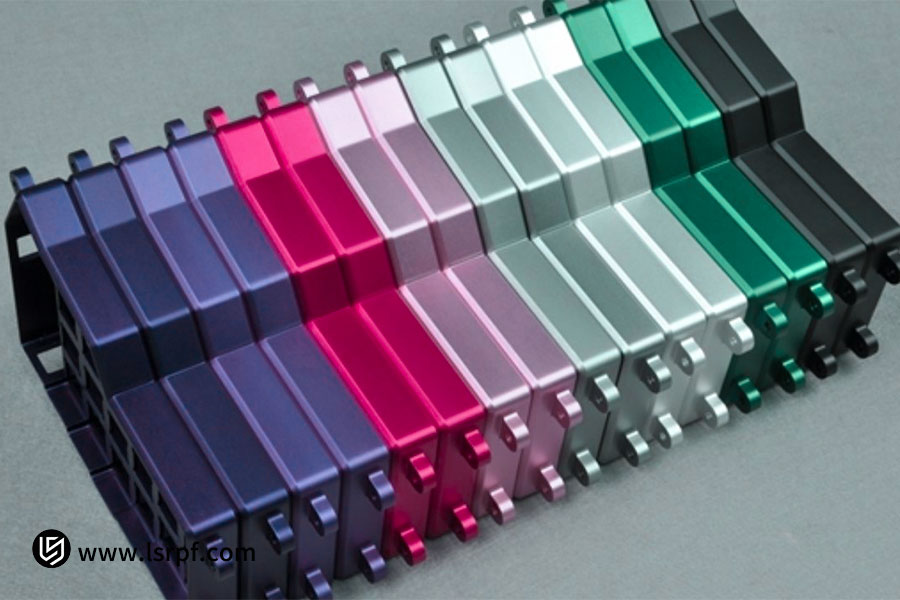

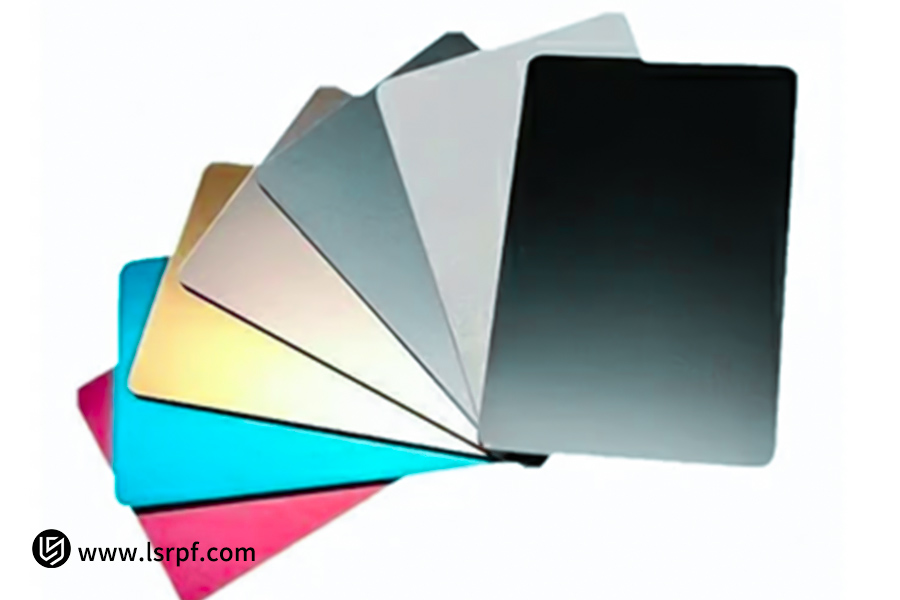

Anodized aluminum surfaces are extremely scratch- and wear-resistant. The target layer can be dyed into various color hues. It is therefore protective as well as aesthetic. Anodizing has extensive use in aircraft, automotive, and manufacturing industries, where the surface strength and appearance are of utmost importance.

Types of Anodizing Processes

There are three types of anodizing processes for aluminum parts. Each provides different degrees of coating, depending on the electrodes, electrolyte, and electrical power used.

Type Ⅰ aluminum anodizing is also known as "light" type. In this type, the aluminum part is immersed in a bath of chromic acid, with the part being the anode.

An electric current is passed through the chromic acid, and positively charged aluminum particles are removed from the surface. The stripped particles leave behind microscopic grooves, which, when oxidized, give rise to an oxide layer. Type Ⅰ anodized aluminum parts possess enhanced heat resistance and corrosion resistance than unoxidized aluminum.

Type Ⅱ components are made the same way as Type Ⅰ. The only difference is that sulfuric acid is used in place of chromic acid, and because it is stronger, it produces deeper grooves and a thicker oxide. Type Ⅱ aluminum parts hold paint better because they are deep and easy to fill.

Type Ⅲ

This involves the use of higher voltage and a strong acid (sulfuric acid). It is also known as hard anodizing and is ideal for the manufacture of heavy-duty wear-resistant parts.

Is "10x" exaggeration or fact? Demystifying Perceptions

Sharp Material and Processing Cost Increases

Anodized aluminum price 10 times more because the anodizing process increases material and processing costs. The reasons are:

Anodizing Process: Anodizing forms a layer of aluminum oxide over the surface of the aluminum. It requires special electrolytes, currents, and conditions, which also contributes to material and production costs.

Material Cost: Anodizing requires high-purity aluminum, which is generally more expensive than normal aluminum.

Processing Cost: Anodizing requires additional steps and equipment, which also contributes to production costs. Specifically, the cost of anodized aluminum is affected by the following factors:

Oxide film thickness: The thicker the film, the more costly.

Color: Special colors or tones of anodizing may entail additional processing, which will affect the cost.

Aluminum grade: Different grades of aluminum have different prices.

Fabricator: Different fabricators will also price differently.

In short, anodized aluminum is costly due to the fact that its manufacturing process is complicated and needs some materials.

High-end Applications

Due to its high performance, anodized aluminum is used in many high-end products and applications, thus the corresponding increase in its price. Let us look at some of its applications so you can have a definite idea of why it is expensive.

A few of the end products that use anodized aluminum include: building exteriors, such as storefronts, curtain walls, and roof systems; consumer appliances, such as refrigerators, dryers, coffee makers, stoves, televisions, and microwave ovens; building vents, awnings, dust covers, light fixtures, storm doors, window frames, mailboxes, bathroom accessories, patio covers, and wall switch panels. Display cases, pans, coolers, and grills for the food industry. Home and office desks, beds, file cabinets, and storage units. Boats, golf carts, and camping or fishing equipment for the recreational market. Motor vehicle parts numbering in the thousands, such as trim, wheel covers, control panels, and nameplates. Exterior panels for aerospace vehicles, clocks and electronics, fire extinguishers, photographic equipment, solar panels, telephones, picture frames, and bathroom accessories. Interior trim and decoration.

Value Perspective: Expensive, But Why Pay for It?

Among many surface treatments given to products, especially aluminum, anodizing is one of them. Being as costly as it is, why would anyone invest in it? The reason is that anodized aluminum provides great advantages. So, why is anodized aluminum superior to other treatments, e.g., painting? Below, we'll briefly examine the value proposition and present a series of reasons why you should utilize this technology.

Durability

The anodizing process builds up aluminum oxide, which is well-known for its hardness. Oxide is harder than the underlying metal, and when we anodize a component, we're increasing the surface area of the oxide layer. So we're making the component's surface even harder. With Type 3 anodizing, up to the level of some metal-cutting tool steels. Plus, this durable finish requires very minimal maintenance.

Chemical Resistance

The aluminum surface becomes chemically resistant when coated. This is because the coating stabilizes the surface, making it inert to chemicals. The oxide will not react, even with high temperatures.

Paint Retention

Anodizing aluminum parts makes them non-peeling. This is because the pores retain the anodized color. As it is, normal mechanical action, such as peeling, will not scrape off the color.

Environmentally Friendly

Anodizing is an environment-friendly process as its byproducts are not toxic. This makes it stand out from other technologies that are utilized within the industry.

Adhesive Options

Anodized surfaces can have adhesives, which allow you to bond different aluminum parts together.

Aesthetics

Anodizing is a great surface treatment for aluminum parts for aesthetic reasons. It provides a fine and unique finish that adds value to any application.

Transaction Perspective: Procurement and Supply Considerations

A tenfold surge in the prices of anodised aluminium is a compact summary of the deep-seated contradictions within the supply chain.

Supply

From a supply point of view, the phenomenon of technological scarcity poses a basic challenge: fabrication of high-purity aluminum substrates is expensive owing to the varying costs involved with these substrates, an energy constraint arising from 18 particular fabrication steps, and yield losses due to electrical defects in ultra-thin plates. In addition, the traditionally constrained supply has been redirected to more profitable markets, including medical electronics, that forces products such as architectural curtain walls to compete mainly on high pricing.

Procurement

Risk distribution in the procurement process intensifies price volatility: the need for minimum order volumes for artist color modulation places the cost of customizability on lower-order tiers, while the likelihood of claims from defective coatings results in higher warranty expenses. In addition, the opacity in cost structures—highlighted by uneven transparency of substrate, processing, and certification costs—reduces buyers' bargaining leverage. As such, buyers are forced not only to absorb the cost of raw materials but also to pay an "insurance premium" for the uncertainties of the supply chain.

The answer lies in the evolutionary fit of the partnership model; suppliers can lower marginal costs through process standardization (e.g., standardizing colors of inventories and using narrow-width lines), and buyers must break out of the zero-sum mentality through joint purchasing and mutually held risk. If both parties evolve beyond cost competition to value synergism, then the "tenfold price premium" should eventually be offset by technological advances and increases in supply chain efficiency.

Six Major Factors That Make Anodized Aluminum "10 Times More Expensive"

For the best surface finish on aluminum parts, most people will opt for anodizing instead of painting. Easy as the choice may be, it is all contingent on the cost of anodizing the chosen aluminum part. The following are six key determinants of the "ten times more expensive" cost of anodizing for aluminum parts.

Part Size and Quantity

It is harder to achieve a uniform oxide layer on bigger parts since they have more surface area, which requires more material, machining equipment, and precise process control, all of which translate to higher costs.

In addition, larger part volumes increase the overall labor and time required upfront. However, larger volumes typically experience economies of scale, as fixed setup costs are spread across more parts and batch processing increases efficiency. This produces lower per-unit costs for large orders. For example, products like camera adapters or small electronic brackets can be as little as $2 per part when volumes exceed 200.

High Material Costs

Different aluminum alloys, such as 6061, 5056, and 2024, can also vary in price.

Coating Thickness

Coating thickness is the thickness of the oxide coating on the surface of the aluminum part. It's the primary factor in determining how much anodizing to apply to aluminum parts. A minimum thickness is the least expensive. Coating thickness does not have as big an effect on the price of anodizing aluminum parts as most individuals believe. Most people expect that heavier coatings cost more. However, the thinner or narrower the coating range, the more costly. For example, a +/- .001" coating is cheaper than a +/- .0001" coating. This is because it is easier to maintain a thicker oxide layer than a thinner layer. This type of control requires experience and expertise, and it translates directly into higher anodizing cost.

Types of Anodizing Processes

Under Types of Anodizing Processes for Aluminum Parts, we discussed three possible types of surface treatment. The choice of any one of these three types is a significant consideration in the cost of anodizing aluminum parts.

Different anodizing processes have different costs:

| Sulfuric acid anodizing (Type II) | Typically costs $20.00 to $1,000 per 4.00 square feet. This type is widely used for general-purpose applications. |

| Chromic Acid Anodizing (Type I) | It costs on average between $0.70 and $3.00 per square foot. It is applied primarily where thin thickness and superior corrosion resistance are necessary. |

| Hard Anodizing (Type III) | Due to the thick coating and expensive tooling and materials, it is more expensive, costing between $1.50 and $5.00 per square foot. |

Of the three types, Type 1 anodizing is the least expensive. This is because materials used, such as chromic acid, are inexpensive and require less energy. Anodizing aluminum parts using the Type 3 process is more expensive since it involves the use of expensive materials. For example, sulfuric acid is used in place of chromic acid, and there is higher energy consumption. In most cases, the higher the type, the more it costs to anodize aluminum parts.

Racking

Racking is a necessary process that allows work to be transferred from one process step to another. It is also necessary because it guarantees a safe electrical contact. Racking can be in different forms, such as welding racking, clamp racking, and bolt racking. It is a process critical to quality and has a major contribution to the cost of anodizing. If no method is specified, the manufacturers will use the least expensive method to achieve the optimum yield at the lowest cost. Racks also impact how many parts you can process at the same time, which can add costs.

Additional Services

As a customer, if you require additional processes to make the process more efficient, you'll need to pay more. Costs may vary based on location and provider. Large volumes of work completed in a short period of time can cost more. The same applies when aesthetics are a major goal for such a product. Planning to cap or fill holes is additional services and a higher cost.

LS's Value Proposition: Finding the Optimal Solution Amidst Expensive Costs

We are confronting the inherent high cost of anodized aluminum—not just a premium, but a separation of technological scarcity, long-term value, and short-term investment. LS's solution is:

Leveraging technological innovation to break through this "false premium": With pulsed intelligent oxidation technology, we reduce film uniformity error to one third of industry average, avoiding the unseen costs of color mismatching scrap;

Leveraging design intelligence to break through customization confines: 12 standard color palettes and modular gradient solutions make artistic expression and scale economics coexist; Riding supply chain resilience to hedge against uncertainty: Direct procurement of aluminum ore with long-term contracts commits raw material risks, and regional collaborative bases eliminate delivery congestions.

We don't offer cheap alternatives; we ensure that each investment in high-quality materials truly works: While you pay the initial cost of maintenance-free operation for 50 years, LS is saving you the cost of refurbishment in the next 30 years with self-cleaning anodized film technology.

LS Precision Manufacturing: Your Partner in Making Anodizing More Cost-Effective and Production More Efficient

We go beyond being a supplier to become an ally in technological innovation and risk-sharing. Process Empowerment: We transfer genes of precision manufacturing, extending automotive-grade ±0.02mm control precision to oxidation tanks, achieving over 99% yield of thin plates.

Risk Reconstruction: Our company introduced a better, industry-leading guarantee against salt spray and instituted a buyback program for used plates, maximizing their residual value to give funds to undertake new projects.

Contextualized Solutions: LS offers integrated solutions to a variety of financial issues, from expedited transport customized to suit the needs of today's consumer to innovative breakthroughs in micro-arc energy efficiency to be used specifically in medical computed tomography gantries.

Choosing LS LS means reframing "expensive" into three promises:

Cost Transparency: Examining the typically hidden cost of substrates, processing, and certification;

Risk management is achieved through employing long-term contracts based on fixed pricing models;

Value creation happens when reoxidation of recycled material drives the circular economy;

Our approach does not shift costs; instead, it seeks to develop a feasible plan for big implementation.

FAQs

1. Is the price difference between regular aluminum and anodized aluminum worth the investment?

Absolutely. If your product needs durability, aesthetics, and performance, anodized aluminum is most definitely worth the investment. Its looks and corrosion resistance have led it to become a force material in most premium industries.

2. What is the production cycle for anodized aluminum?

The process is determined by the particular processing requirements, but it's longer than regular aluminum, typically several hours to several days, depending on the project size.

3. Does the anodized aluminum color treatment affect the cost?

Yes, anodized aluminum color treatment increases the cost. Different colors and decoration effects require different electrolytic and post-processing treatments, which are added to the overall cost.

4. In which industries is anodized aluminum used?

Anodized aluminum finds wide usage in construction, automotive, aerospace, electronic equipment enclosures, home appliances, and food industries, especially where corrosion resistance, friction resistance, and a good appearance are required. It is used widely.

Summary

The contention that anodized aluminum is ten times more expensive than spray-coated aluminum is neither baseless nor a premium. This tenfold greater expense is the unavoidable result of such aspects as cost, process complexity, technical barriers to entry, production cycle, and the need for tailored ancillary services. However, the performance advantages and extended lifespan of anodized aluminum fully justify its costly price. Therefore, its costly price itself is the best affirmation of its performance and advantages.

At LS, our team of professionals will optimize and customize your product, ranging from design and production to material cost and processing and polishing. Not only will you receive the high performance of anodized aluminum, but also efficient and professional production services of high quality.

In the face of these higher challenges, LS's surface finishing service is your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized. Choosing LS is to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instant surface finishing quote (surface finishing price), let LS be your strong backing in pursuit of ultimate finishing precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com