The selection of casting process is a fundamental step in the manufacturing process of products, having a direct influence on final performance and cost of production. Various paths of processes define the significant quality characteristics of metal components, including internal density, mechanical properties, and dimensional accuracy, which have important effects on product reliability, life, and competitiveness in the market. Furthermore, the process plan is a key driver of material consumption, energy consumption, mold investment, and subsequent machining allowances and is one of the main handles for controlling overall cost. Consequently, careful process analysis and selection up front at the start of design and production are essential to technical and economic optimisation and are strategically important to a company's overall profitability. Below, we shall discuss two of the big casting processes—investment casting and sand casting—to enrich your understanding.

Investment Casting vs. Sand Casting Core Dimensions Comparison Quick Reference

| Comparison Dimensions | Investment Casting | Sand Casting |

| Precision and Quality | Extremely High • Dimensional Precision (CT7-9) • Surface Finish (Ra 1.6-6.3μm) • Almost No Draft |

Relatively Low • Broad Dimensional Tolerances (CT10-13) • Surface Roughness (Ra 12.5-50μm) • Draft Required |

| Cost Characteristics | High Unit Cost, Low Subsequent Costs • High Mold/Shell Manufacturing Costs • Suitable for Large-Scale Production to Spread Costs • Low Subsequent Machining Allowances, Incurring Savings |

Low Unit Cost, High Subsequent Costs • Very Low Mold Manufacturing Costs • Suitable for Small-Scale, Single-Part Production • High Subsequent Cleaning and Machining Allowances, Incurring High Costs |

| Applications | Complex, Precision Small and Medium-Sized Parts • Materials: Alloy Steel, Stainless Steel, etc. • Characteristics: Complex cavities, thin walls, fine patterns • Applications: Turbine rotors, medical devices, aerospace blades |

Large and medium-sized parts with uncomplicated structures • Materials: Cast aluminum, cast iron, and nearly any other metal • Features: Big frames, bases, and casings • Applications: Machine tool beds, valve and pump casings, engine blocks |

| Key Decision | Choose investment casting for lean, intricate parts, and sand casting for low-cost, large parts. |

|

Why Trust This Guide? Practical Experience from LS Experts

At LS, we understand the day-to-day frustrations of translating innovative design into reliable, precision parts. Our expertise lies in actual experience. The LS engineering team has years of real-world experience and successful cases in the field of precision investment casting. Imagine, for example, a high-pressure hydraulic valve body for a specific aircraft engine. This module has a highly complex pattern and requires highly precise internal oil circuits. Traditional casting methods offer poor yields and high levels of performance variation. LS experts employ proprietary directional solidification and control module to closely control the whole investment casting process. This not only permits the development of complex cavities in one step, but also significantly increases microstructure density and compositional uniformity, ensuring product performance exactly meets stringent aviation specifications.

Choosing LS brings much more than a single simple casting technique; it delivers an all-round, proven, and reliable approach, set by market leaders. Our imbedded "process redemption" attitude enables us to transform seemingly impossible shapes into functional products with excellent performance and low cost, effectively adding inherent core competitiveness and removing project risks. All this profound experience is the firm basis for this firm handbook.

What Is Investment Casting? Why Is It The "King of Precision Casting"?

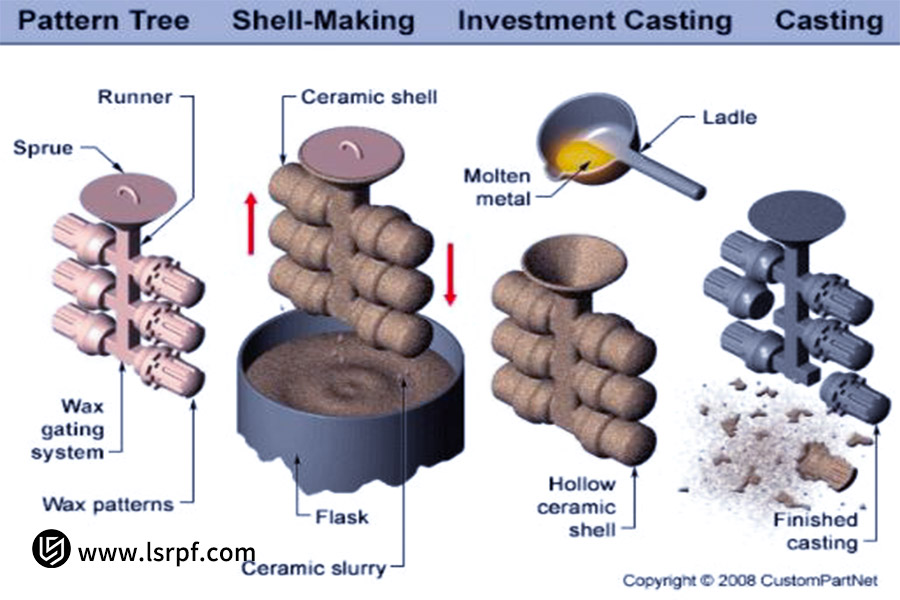

Investment casting, also known as lost wax casting, is a process that creates precision castings by building a disposable wax pattern, applying refractory layers to form the shell, and then burning out the lost wax pattern and casting molten metal. It's "The King of Precision Casting" because it is unmatched in molding ability and performance overall.

The top strengths of this process are all centered in three areas:

- It exhibits far better dimensional accuracy and excellent surface finish, enabling the production of near-net-shape parts with considerable minimization in the amount of secondary machining.

- Investment casting possesses unparalleled capacity in dealing with intricate geometries, enabling integral molding of components with extremely complex cavities, complex patterns, or extremely thin walls, a feat that is very difficult to achieve using other methods.

- It has wide material compatibility and can be used with almost all alloys, especially with excellent performance in casting high-performance stainless steel, high-temperature alloys, and other special alloys.

Investment casting has emerged as an inevitable manufacturing process for high-precision quality components, from the turbine blades of the aero-space industry to the artificial joints of the medical industry, through to complex components of equipment of high quality. It harmoniously combines complex design, high performance, and economy and thus is the "King of Precision Casting."

How Can Sand Casting Dominate The Heavy-duty Component Market At Low Prices?

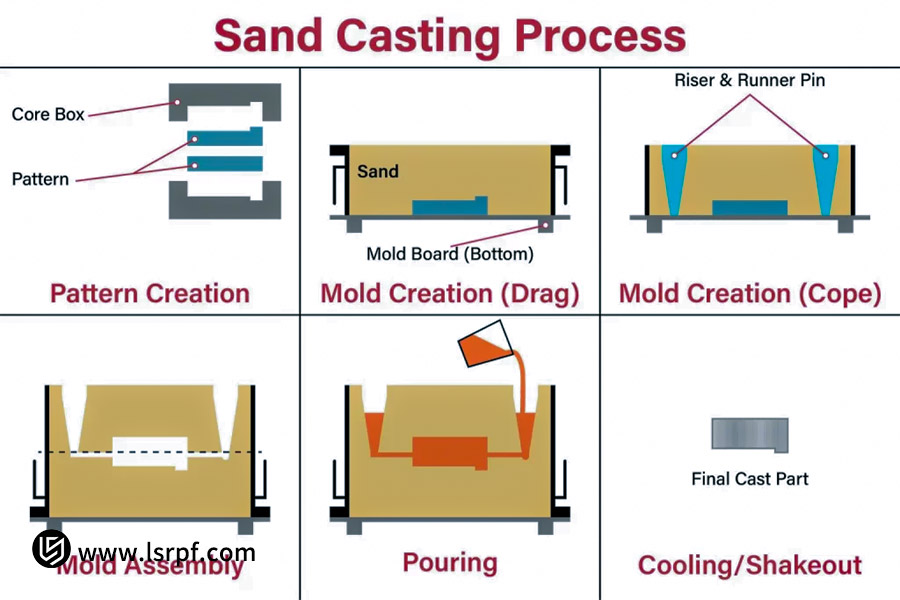

Sand casting, with its unmatchable cost advantages and excellent flexibility, is now the overwhelming favorite for heavy component manufacturing. Its position as the preferred process for heavy metal units is not due to its very high accuracy but due to its combined economical and flexible character, which precisely matches the basic requirements of the heavy component business.

This basic competitiveness is founded on three considerations:

- First, it has very low mold costs. Molds of wood or of resin are cheap and quick to produce, thus particularly suited for one-shot or small batch production, avoiding heavy initial investment.

- Second, the technique has excellent flexibility. Sand molds are virtually constrained by part size, weight, or complexity of structure, which means anything from multi-ton machine tool beds to enormous engine blocks may be molded integrally.

- Finally, sand casting has an enormous range of materials, which means everything from common cast iron and steel to other non-ferrous metals can be produced.

Sand casting is therefore an irreplaceable, inescapable production process in cost-conscious, functionality-oriented industries such as heavy machine tools, large power equipment, and excavating machinery. It delivers the capability of casting massive metal components at the lowest available cost. Such unmatched cost-effectiveness is the fundamental explanation for the fact that it has overwhelmed the heavy parts market.

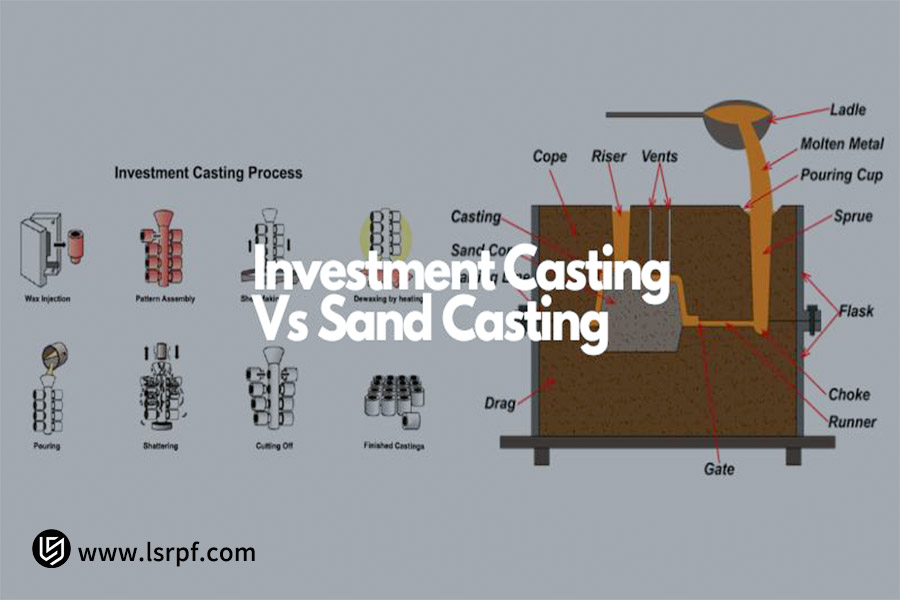

A Critical Tradeoff: A Comparison of Investment Casting with Sand Casting across Five Essential Dimensions

In critical product design and manufacturing choices, a process choice for casting is often a trade-off between efficiency, economics, and performance. As established processes, investment casting and sand casting represent two distinct technology paradigms, each prioritizing accuracy and thriftiness. Understanding their inherent differences is not winning, but indeed is all about simply matching them to the specifications of projects. The following five key differences is an attempt at showing a clear decision-making process, and helping you reach the optimal solution to this critical decision.

| Comparison Dimensions | Investment Casting | Sand Casting | Key to Winning |

| Precision and Surface Quality | • Extremely high dimensional accuracy (CT grade 7-9) • Smooth surface (Ra 1.6-6.3μm) • Near zero draft, firm outlines |

• Huge dimensional tolerances (CT grade 10-13) • Coarse finish (Ra 12.5-50μm) • Draft is required, with flash on parting line. |

Investment casting uses throwaway ceramic molds and doesn't have a parting surface, hence it's referred to as the "King of Precision Casting." |

| Cost Structure | High Unit Cost, Low Subsequent Costs • High Mold Cost: Complex design and production of metal extrusions • Low Unit Cost: Ideal for mass production to spread cost • Low Subsequent Cost: Little machining allowances, minimizing machining cost |

Low Unit Cost, High Subsequent Costs • Extremely Low Mold Cost: Inexpensive and easy to produce wood/resin molds • High Unit Cost: Ideal for single-item/small batch production • High Subsequent Cost: Heavy cleaning, polishing, and machining allowances. |

Sand casting offers unparalleled cost and speed advantages in small batch and prototype production. |

| Design Complexity | Winning • Can cast very complex parts • Ideally suited for casting complex cavities, thin walls (as low as 0.5mm), and fine details • Facilitates integral casting, reducing assembly parts |

• Structures must not be too complex • Limited by parting surfaces and draft angles • Difficult to cast complex cavities and extremely small features. |

Investment casting gives designers almost unlimited freeform shaping capability. |

| Material Adaptability | Broad • Suitable for almost all alloys, especially high-temperature alloys, stainless steel, and specialty steels. |

Very Broad • Suitable for casting almost all metals, the most common being cast iron, cast aluminum, and copper alloys. Tie. |

Both possess broad material versatility, but the economics are different depending on the behavior of material cost. |

| Production Cycle and Efficiency | Long cycle time, best suited for mass production • Lengthy mold making, shell making, dewaxing, and firing processes • Long initial preparation time but highly effective upon initiation of mass production • Low rate of production, not suitable for crisis jobs. |

Short cycle time, suitable for rapid response • Rapid mold making (a few hours/day) • Rapid mold and pouring cycles • Ideal for rapid trials and short lead-time deliveries. |

Sand casting is more flexible in delivery speed and responsiveness to design changes. |

- Briefly, the difference between investment casting and sand casting is basically a choice between the two "constant improvement" and "economic efficiency" philosophies.

- The former, with its unmatched accuracy and complex molding, is the high-end precision component's first choice;

- the latter, with its unmatched cost flexibility and heavy-duty molding, holds sway over the heavy-duty market.

- Finally, your choice should be about your product priorities: going for ultimate performance and complexity, or reconciling the economics and pace of mass production. This contrast offers a sound basis for your strategic decision.

How Complex Can Investment Casting Designs Be?

The investment casting operation, the "King of Precision Casting," has a competitive core competence in having the ability to make reality out of the very wild designers' concepts. It can penetrate nearly all the geometric limitations imposed on it by traditional manufacturing processes, and thus enjoy complete freedom to meet the final drivers of product functionality, lightweighting, and integration.

This ability to bring to life complex designs is primarily articulated in three ways:

- It makes possible one-shot molding of components with intricately detailed internal cavities, curved passages, and hidden recesses, such as the complex cooling ducts of engine turbine blades—components that cannot, or are difficult to, manufacture by other means.

- It has excellent thin-wall casting ability to cast light structures with wall thicknesses down to about 0.5 mm, conserving substantial part weight without sacrificing strength. Third, it makes possible ultimate functional integration.

- Through advanced design, complex parts that otherwise would have to be composed of many separate parts are combined into one rigid integral casting, eliminating completely the loss of strength and assembly errors associated with joints.

This is the reason why products incorporating the most sophisticated levels of industrial design expertise, from aircraft turbine blades in aviation with intricate cooling systems to porous orthopedic devices in medicine that exactly reproduce the human skeleton, all rely on investment casting technology. It is not just a molding process; it's a facilitator of disruptor innovation, completely decoupling design sophistication from the boundaries of manufacture.

LS Case Study: The Process Redemption Journey for Aviation Hydraulic Valve Bodies

Aerospace industry hydraulic valve bodies are the "hub central" of managing critical motions, and their quality directly correlates with flying safety and system performance.

Challenges encountered

An aviation hardware firm had to produce a brand-new, extremely intricate hydraulic valve body. The valve body contains a complex network of intersecting, irregular flow channels to deliver precise hydraulic control. The traditional sand cast or machine processes not only require high mold costs and long lead times, but also create numerous process holes and straight-through flow channels, resulting in massive and bulky parts. Moreover, they also suffer from significant internal fluid pressure loss and shocking energy consumption. Furthermore, expensive aerospace-grade materials are wasted in standard subtractive manufacturing, once more driving overall cost higher.

Traditional fixes

Sacrifice the design—cutting corners in the flow channel layout and applying segmented production followed by assembly at the expense of system performance and dependability; or invest significant time and capital in creating complex molds with high scrap levels. Both approaches struggle to meet the overall performance, weight, delivery cycle, and cost specifications at the same time, presenting a significant challenge to customers.

LS's innovative solution

After conducting a detailed analysis of customer pain points, the technical team developed a new combined investment casting solution with additive manufacturing (AM) as the new solution. This solution is not just a substitution of process; it's a complete redesign and reengineering of the manufacturing process.

LS' value creation

It is not just technological innovation; it's a value creation process where performance and affordability are merged. Its value is in:

- Facilitating innovative design: Breaking up the manufacturing blockages of traditional processes, allowing engineers to focus on functional realization and unlocking the unlimited potential of product design.

- Streamlining the manufacturing process: Reducing significantly new product creation and delivery cycles (from potentially weeks to months), enabling customers to seize market opportunities.

- Enhancing overall competitiveness: Enabling customers to achieve cutting-edge performance while controlling overall manufacturing costs, thereby achieving a technology lead in the market.

By achieving this technology revolution of aircraft hydraulic valve bodies, LS once again displays its comprehensive process expertise and leadership in integrating the latest technology and offers customers a new window to high-performance, efficient, and profitable production.

How Do Online Investment Casting Services Reduce Lead Times By 50%?

Online investment casting firms are using process innovation and technological innovation to cut traditional lead times of weeks by more than half. It's not only an improvement in efficiency; it's a complete overhaul from design to production. It has its center of focus centrally in eliminating mold restrictions with free data flow and maximum production control. The key to such radical reduction is contained in three basic changes:

Patternless production and digital molding

In traditional investment casting, mold creation and design take weeks. Online service providers generally use industrial-grade 3D printing machines to directly print out wax patterns. For example, LS Company imported a 3D Systems ProJet MJP 2500IC printer, capable of directly printing 100% wax casting patterns without a mold. This reduces weeks required for preparing the wax pattern to hours and allows direct incorporation into standard casting processes.

Collaboration and digital convergence

Online platforms effectively integrate systems such as CAD (computer-aided design), CAE (computer-aided engineering), and MES (manufacturing execution systems) through the creation of an integrated digital platform. Integration minimizes data silos, enabling a smooth flow from order to process instruction and tracking of data, reducing time and errors introduced by data duplication and inconsistency.

Smart Production Management and Real-Time Monitoring

The integrated MES system guarantees advanced management of the production process. Both forward and reverse scheduling modes are available in the system to optimize production scheduling. Furthermore, real-time monitoring of equipment parameters (temperature, pressure, and time) in the main processes of shell making, dewaxing, and melting enable fault warning and rapid response, ensuring effective coordination of all links and reducing waiting and downtime.

In summary, investment casting services enabled by the internet reduce lead times significantly through the elimination of mold making, connection and optimization of the digital supply chain, and smart production control. They increase production flexibility and controllability as well. This positions them to be the most appropriate for small-series, rapid-iteration production needs, allowing customers to benefit from increased market responsiveness and competitiveness.

Custom Investment Casting Manufacturing Pricing Structure Analysis

The investment casting cost is a reflection of its complex process and multiple cost drivers. Being aware of the major components of a quote is highly important. The following table describes the significant cost components in detail.

| Cost Category | Core Content | Key Influencing Factors |

| Material Costs | Metal, wax, shell refractory material (e.g., expensive zircon sand) | Part weight, material grade, number of shell layers in the mold |

| Process Costs | Process yield (casting weight/total pouring weight), energy usage, labor hours | Part structural complexity, production yield, process duration |

| Post-processing Costs | Cutting, grinding, sand cleaning, heat treatment, special testing (e.g., X-ray) | Cavity complexity, surface finish requirements, quality inspection standards |

| Administrative Amortization | Management fees, taxes, profit, scrap loss allocation | Order batch size, factory operating efficiency |

In brief, a custom investment casting quote is an integrated expression of process, material, management, and risk cost. Among these factors, process yield as a function of part design takes the center stage of cost control, and batch size of order is the optimum point of leverage to influence unit price. Therefore, optimal cost control arises from simultaneous early design with suppliers, rather than price negotiations.

3-Step Decision-Making Process: Which Process Should You Use for Your Project?

The proper choice of investment casting or sand casting is essential to optimizing product performance and minimizing cost. Don't procrastinate when faced with this decision; rather, apply this three-step process to decide on the best process route for your project.

Step 1: Evaluate Part Characteristics and Quality Requirements

The primary factors are part complexity, precision, and surface finish requirements. If your part contains intricate cavities, fine walls (less than 3mm), or requires a fine surface finish (Ra < 6.3μm), investment casting is the choice that's most clear. If, however, the structure is simple and there are loose tolerances, sand casting is more economical.

Step 2: Consider Production Scale and Economics

Batch size is the most important cost-determining factor. Sand casting has extremely low mold cost and is therefore ideal for one-piece, small-order prototypes, or mass production. Investment casting involves high initial mold investment, but each piece cost is actually spread out over lots of more units, which has a wonderful price-performance value.

Step 3: Weigh the Material and Delivery Cycle

Finally, check material compatibility (both are safe for most alloys) and shipping time. Sand casting's cycle is short and can fill an urgent requirement fast; investment casting's cycle is long, but offers an indispensable solution for complex, precise components.

In short, the key to deciding is to exactly match the "complexity, volume, and cost" triangle. Keeping in mind the rule of choosing investment molds for intricacy, small size, complex production, and high volume, and sand molds for large size, simple production, quick production, and low cost, you will make the most technologically savvy choice.

FAQs

1. What are the primary distinctions between investment casting and sand casting?

The main distinctions between investment casting and sand casting are precision, expense, and utilization. Investment casting is extremely precise and smooth and is, therefore, suitable for complicated, tiny parts, but it is also extremely costly. Sand casting is cheap and suitable for big parts, but it is also extremely imprecise and rough. Therefore, whenever you are choosing a process, you need to consider your product's particular requirements.

2. What conditions should investment casting replace sand casting?

Use investment casting if you require high accuracy, surface finish, or detailed work such as medical or artwork. Use sand casting if you require cost-effective or large pieces. For precision detail parts, use investment casting; for large pieces, use sand casting.

3. Is investment casting significantly more expensive than sand casting?

Yes, investment casting is generally several times more expensive than sand casting. This is because investment casting is complicated and requires expensive molds, so it is suitable for high-precision parts. Sand casting requires lower expenses but less accuracy and thus has a cost difference of several times. If you are not sure about the choice, please contact us at LS, where we can provide you with a free product design and selection process.

4. Can sand casting be used to produce precision stainless steel parts?

Sand casting can be employed to produce stainless steel parts, but its precision is low and surface roughness is high. It is ideal for large or non-precision parts. For precision parts, investment casting is more suitable and can maintain high detail. If your stainless steel product doesn't require high precision, sand casting can cut some cost. Otherwise, we recommend using investment casting.

Summary

Sand casting and investment casting are not matters of superiority or inferiority but technological paths taken for various product plans. With unmatched precision, intricate moldability, and smooth surface finish, investment casting has become the first choice for high-accuracy, intricate structural parts. Sand casting, with its extremely low mold cost, unparalleled dimensional flexibility, and economy, firmly holds sway over large and medium-sized simple structural components and low-batch test manufacturing. Success for your project hinges on matching these two processes to a pinpoint exactness.

Should you still not be convinced regarding your process choice, LS Group can assist you with our vast experience. We not only provide complimentary process selection analysis, but our team of experienced engineers will review your drawings, assess your requirements, and recommend the ideal technical solution to ensure success on your project. Further, to serve challenging development cycles, we can advance processing, significantly condensing production processes and allowing you to capture market share quickly. Contact LS to make your ideas a reality.

Upload your design drawings now and get an instant investment casting quote (investment casting price), let LS be your strong backing in pursuit of ultimate investment casting precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com