Rapid prototyping service In a market where speed defines success, many product teams find themselves hindered by unreliable rapid prototyping services. Common frustrations include inconsistent prototype quality, missed deadlines, and budgets that spiral out of control. More critically, subpar prototypes can lead to flawed decisions, ultimately delaying the entire product launch and eroding competitive advantage.

That will normally be because of unorganized vendor qualification and more emphasis on price factors, while less is put on expertise and quality factors. This guide is intended to define the listing criteria to help you with your specific needs and how LS Manufacturing bridges you successfully into production with better expertise on DFM analysis, excellent quality control, and smooth transition into production.

Rapid Prototyping Service Guide: Quick Reference

|

Section |

Key Content |

|

Service Core Evaluation |

Criteria: Technical Capability, Quality System, Project Support, Cost Structure. Goal: Move beyond price to assess value. |

|

Process Matching Guide |

By Need: Visual/Form: SLA, Material Jetting; Functional Test: SLS, FDM, CNC; High-Fidelity: CNC, Urethane Casting; Rule: Match process to prototype purpose. |

|

Critical Success Factors |

DFM Analysis: Essential for manufacturability; Quality Control: In-process checks & final inspection; Seamless Transition: Prototype-to-production planning. |

|

Vendor Selection Checklist |

Must-Ask: Technical portfolio & case studies; Quality certifications (e.g., ISO); Communication & reporting process; NDA/IP protection agreement. |

|

Partner Value |

Differentiator: Integrated engineering support, full-process quality management, and seamless scale-up to pilot production. |

Selecting the right rapid prototyping partner is a strategic decision critical to product success. A systematic evaluation beyond cost—focusing on technical match, robust quality systems, and engineering collaboration—is essential. The ideal partner acts as an extension of your team, ensuring high-fidelity prototypes, de-risking development, and enabling a faster, smoother journey from concept to market-ready product.

Figure 1: Visualization of a precision metal prototype fixture for assembly by LS Manufacturing

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

There are plenty of articles on rapid prototyping on the internet. Why should you read this article, then? We are practitioners and not pure theorists. Our shop floor is not a clean lab but a working area. We work with hard materials and with tight tolerance on a daily basis. We don’t ‘know’ but ‘need’ what we know. That’s what guarantees that we develop every prototype with optimal form, fit, and function.

Our skills have been developed within challenging and demanding conditions and have created rapid prototypes for aerospace assemblies, where particular dimensional specifications are absolutely necessary for safety reasons, medical device encloses requiring perfect biocompatibility, and optical components with perfect optical clarity. Within all projects, we have been applying our specific knowledge from experience based on particular demands within projects relating to optimizing 3D printing, CNC machining, and urethane casting.

We created this resource on these principles. All responses and suggestions are based on more than a decade of successful production and completion of more than 50,000 custom prototypes. We have experienced and made costly learning experiences within the first phases of projects about optimal parameters for a number of materials and factors with regards to speed, cost, and product quality. We strictly adhere to guidelines on production, as recommended by professional associations like the American Production and Inventory Control Society (APICS) and the Metal Powder Industry Federation (MPIF). We have knowledge, and it’s not based on textbook formulas.

In 2025, What Are The Six Core Dimensions To Consider When Evaluating Rapid Prototyping Service Providers?

In 2025, the right choice of a rapid prototyping service provider will decide upon the success of product development. The best rapid prototyping services differentiate themselves on six dimensions that form the comprehensive framework for how to choose a rapid prototyping service:

- Technical Breadth: A top-tier provider should offer a variety of different processes, including 3D printing, CNC machining, and vacuum casting. This would add great versatility to the service, so a method can be chosen that is best for a project based on the material, precision, and lead time needed to complete it.

- Engineering Support & DFM: Consulting engineering support-provided through free DFM analysis, for example-is a proactive part of the service. It is where potential issues are identified early on in this collaborative approach, optimizing your design for cost, performance, and manufacturability-a critical value-add when evaluating how to choose a rapid prototyping service.

- Quality Systems & Certification: Dependable suppliers have a strong quality management system, such as being ISO 9001 certified. Additionally, reliable rapid prototyping service providers should have measurement and inspection equipment in-house, such as CMMs, which enable inspection and validation of the accuracy of parts and continuous output with minimal project risk.

- Material Portfolio & Sourcing: A deep and authentic material library is important. This should include offering a wide range of certified polymers, metals, composites from reputable suppliers. This ensures that prototype properties are much closer to those of intended production materials, a vital component for the functional testing and validation stages.

- Proven Experience & Industry Expertise: Audit the partner's portfolio for relevant experience in your industry. Successful case studies with similar applications will showcase practical knowledge of specific challenges and requirements and may be a good show of confidence in their ability to deliver a suitable solution for the unique demands of your project.

- Communication & Process Clarity: Transparency in quoting, timeline, and workflow is a no-brainer. Specific communication in a clear, structured process keeps everyone in the know through regular updates to manage expectations as well as build trust, with which no collaboration can be successful with any rapid prototype manufacturing service.

The final conclusion is that performing due diligence on the providers in these six dimensions (technical breadth, engineering support, quality, materials, experience, and transparency) will clearly outline how to choose rapid prototyping service. This holistic approach ensures you are working with a capable rapid prototyping service provider who can provide high-quality prototypes with efficiency, which will ensure that the best rapid prototyping services are availed to accelerate and de-risk the product development cycle.

3D Printing, CNC Machining And Vacuum Molding: How To Make TheRight Choice Based On Project Requirements?

Below is the detailed comparative list with regards to methods that include additive and subtractive production for 2025. The 2025 rapid prototyping guide will be extremely useful for product designers and product engineers who are searching for ways and means on optimizing product production. You will be given an opportunity to choose among your three most preferred services for prototype manufacturing services, as will be discussed below. The comparative list for 3D Printing, CNC machining, and Vacuum Casting is as follows:

| Aspect | 3D Printing | CNC Machining | Vacuum Casting |

| Materials | Polymers, Resins | Metals, Plastics | Urethanes, Silicones |

| Accuracy | Good | Excellent | Good |

| Surface Finish | Layered (needs post-proc.) | Very Smooth | Smooth (depends on master) |

| Strength | Isotropy varies | Excellent, isotropic | Good, mimics production |

| Cost Profile | Low setup, medium part cost | High setup, medium/high part cost | Medium setup, very low part cost |

| Best For | Visual Prototypes, Complex Geometry | Functional Parts, High Precision | Small Batches, Appearance Models |

| Max Size (Typical) |

Medium Build Volume |

Very Large |

Limited by Silicone Mold |

Whether it will be possible to do better depends on individual project requirements, but for projects that require accuracy and project integrity with regards to functionality testing, it will be very hard to find something better than CNC machining. But projects related to rapid generation of new designs at very high speeds and generation of intricate and lighter designs cannot be matched with 3D printing. And if you want 10-50 production samples for market testing or rapid prototyping service, vacuum casting will be your cheapest option.

Figure 2: A practical handbook for mastering modern rapid prototyping by LS Manufacturing

Why Is Professional DFM Analysis The First Step To Successful Prototyping?

A common but potentially very dicey solution would be to opt directly from a CAD drawing into production. A global analysis from ‘Design for Manufacturability’ would be a very useful preventive strategy wherein one needs to very carefully make sure that any issue or solution determined with regards to manufacturability would be detected very well before any cutting has taken place and any resin packaging. It would be exactly this sort of proactive ‘heads up’ vigilance that would differentiate a successful project and an expensive tragedy and would form the cornerstone for all rapid prototyping service provider.

Proactive Cost and Time Savings

A valid DFM analysis would identify ‘hidden’ problems lurking within your designs that would have arisen as soon as they stepped into production. These would include thin walls that would have failed and creative but unnecessary undercuts causing your design to be ‘unmoldable’. These would then be remedied using costly tooling redesigns requiring heavy usage of expensive materials and causing serious project postponements. By catching these issues digitally first, the most effective rapid prototyping services prevent budget overruns and keep projects on schedule, ensuring the first physical version is right.

Optimizing for the Chosen Process

As there would be sets of ‘design rules’ for every production process. Whether it would be CNC machining and 3D printing, there would be optimized tips and suggestions made available as a result of an ‘end-to-end’ DFM review. These would include optimized draft angles for injection molded projects, some set limits with regards to ‘minimum thickness’ on some sorts of ‘castings’, and so on. These would increase chances of your initial success multi-fold.

Enhancing Prototype Function and Quality

The overall task for a prototype might be to imitate production-qualified components. A DFM analysis would be beyond general manufacturability and would also recommend enhancements pertaining to functionality and aesthetic appeal. These might be pertaining to some recommendations regarding corner filters or some tolerances on critical components. This level of analysis is a hallmark of the best rapid prototyping service, resulting in higher-fidelity prototypes that yield more valuable test data.

A Commitment to Client Success

It truly shows partnership as big as it speaks-partnership as in commitment to customer success and adoption and inclusion within DFM analysis as an added-value service. To offer some perspective on it, it would be advised that the LS Manufacturing prototyping service includes totally free DFM analysis as necessary on all projects. As big as it speaks pertaining to partnership, it speaks without going into an understanding associated with project success with projects perfectly designed from start to finish.

Finally, early-stage professional DFM analysis speaks volumes as it represents the wisest as well as successful investment on any given project within prototyping. It represents taking a very uncertain process and transforming it into a very smart as well as efficient process. By taking advantage within rapid prototyping service provider as they would be with a service provider as within LS Manufacturing prototyping, it represents giving you an advantage within your rapid prototyping competition because they will appreciate your totally free professional analysis.

Figure 3: Showcasing prototype designs for modular vehicle components by LS Manufacturing

When Obtaining A Rapid Prototyping Quote, What Details Directly Affect The Accuracy Of The Cost?

When you decide to get rapid prototype quote, the accuracy of that initial estimate is paramount. The importance becomes absolutely critical on giving prime importance within accuracy on your very first cost estimate. It would be within an unambiguous request for quotation. It would be uncorrected ambiguity on your side pertaining to interpretation, which might have some discrepancies associated with costs. Hence, it becomes imperative as in that it requires you within an expert rapid prototyping service. Below mentioned would be broken-down factors as within have a direct association with the cost as within have to be specified on selecting your own prototype manufacturing service.

| Important RFQ Component | What To Specify For Accuracy | Why Important For Cost |

| 3D File & Design |

Format (e.g., STEP, STP), Wall Thickness, Tolerances |

Defines manufacturability; complex geometry increases machining/printing time. |

| Material & Quantity | Exact material grade/name, color, and total part count. | Material unit cost varies widely; quantity impacts setup time amortization. |

| Post-Processing | Surface finish (e.g., as-built, painted, texture), assembly needs. | Each step (sanding, painting, assembly) adds significant labor and material cost. |

| Timeline | Required lead time, especially for expedited/rush orders. | Standard scheduling is most cost-effective; urgent deadlines incur premium fees. |

Briefly, the best way to get rapid prototype quote would be to include your RFQ as a project brief. By engaging every Specification from CAD terms to finish, you allow an RFQ rapid prototyping service to make manufacturability judgments with considerable ease. The result of this would be that a prototyping manufacturing service shall be capable of offering you a set price on an all-inclusive scale with no extra costs associated with unexpected problems.

Case Study on High-Strength UAV Frame Prototype Development: How LS Manufacturing Achieves a Perfect Balance Between Lightweight Design and Strength

This project epitomizes the challenge of developing a superior piece of hardware on a theoretical basis and then realizing it as an efficient working model. It calls for skills not only in fabrication but also for expertise in understanding and optimizing an article based on its usage-an attribute which should be the core prototyping manufacturing service.

Client Challenge

A drone start-up company was at an impasse. Their new conceptual design was intricate and demanding because it needed a very heavy and sturdy airframe that was still very light and capable of withstanding high stress. Though there were several vendors who could undertake the task, they could not deliver a product that would withstand testing because they didn’t have the necessary expertise and facilities to analyze and work with special materials. These vendors needed more than just a CAD file import—they needed a rapid prototyping service partner.

LS Manufacturing Solution

We began with detailed DFM analysis uniquely suited for loading paths and materials. We then optimized internal lattice and ribs for maximum stiffness with regards to weight. To achieve this, we implemented and deployed a high-performance woven pattern with vacuum resin injection. Lastly, we machined key mounting points onCNC milling. Dimensional precision here is absolute perfection. This integrated approach is the hallmark of the best rapid prototyping service.

Results and Value

The completion of projects at LS Manufacturing involving rapid prototype making services met with resounding success. It enabled a 30% weight loss and 50% relative rigidity compared with the first benchmark set forth as a challenge by our client. Moreover, it withstood all strenuous flights and stress tests with flying colors, providing hard evidence of proof for justified seed capital venture acquisition. Success factors on an LS Manufacturing prototyping project would make it feasible for our client to have immediate production on adapted designs, rescuing months worth of pokiau troubles.

A successful rapid prototyping service with optimal materials and structural advances demands very vigorous collaboration between analysis and production talent; yet again, it surpasses simple 3D rapid prototyping and CNC machining. So much would constitute a professional rapid prototype making service.

Are you looking for professional service to help with your complex rapid prototyping project? For free DFM analysis and quote, visit LS Manufacturing today.

What Are The Average Costs And Timelines For Rapid Prototyping In 2025?

A number of the sought-after answers that product innovators would want an answer to have got to be "how much?" and "how long?" While hard to put an exact figure on this, it will differ from project to project; some sense has been benchmarked within the market today. It comes from an extensive 2025 rapid prototyping guide that has lead times ranging from 1-3 days for an SLA component with minimal complexity to 3-7 days for machined components made using a CNC. Prices range from a couple of hundred dollars onwards into the thousands, depending on what level of processing it entails.

Key Cost Drivers

The final price to get a rapid prototype quote is influenced by several interlinked factors. Material is one aspect-the more expensive engineering-grade resins/metals have a considerably higher cost compared to regular plastics. The size of the piece and its complexity feature equally in growing the machine time and the volume of the piece. Procedures for post-processing, such as painting some sealants or assemblies, would add substantially to the total cost involved with any project.

Key Timeline Drivers

Lead Time: In a nutshell, it is not a question of how quickly things are fabricated. It is virtually always an accessibility problem due to service center scheduling. There can be size and orientation impacts on batch capabilities, when more than one piece is being created at one time. Far more significant, however is if the design(s) being sent from the customer are prepared and clean. The best file will speed up an entire value chain. A confused design, with multiple understandings being sent back and forth, will see extraordinary wait times.

Achieving Competitive Value

The best suppliers will try to optimize both of these factors through a combination of strategies. Investments in machines that work faster reduce lead times for production. Digital simplification in processes-from instant quoting to automated build planning-reduces paperwork. Probably the most notable, though, is the inclusion of free upfront DFM analysis prior to production to avoid those costly mistakes on the way that waste time. Hence, having inclusion for free upfront DFM analysis saves one from making costly, time-wasting production mistakes; thus, the first article was right-a fundamental value associated with professional rapid prototyping service.

The type of industry that 2025 Rapid Prototyping solutions are infinite-it is going to be concerning cost and time-having a person with this type of knowledge in a partnering relationship is going to make all the differences. We, in effect, reduce your costs and times with our optimized processes, equipment, and engineering reviews. The best scenario that could happen to your project is for you to get a rapid prototype quote, together with your complete 3D files and specifications from a reliable rapid prototyping service.

Figure 4: Featuring a professional drone prototype on its presentation stand by LS Manufacturing

How To Ensure Intellectual Property Rights And Data Security In Prototype Design?

Coming back to the innovators, a design exchange is a part that is necessary but is a reason to be concerned, in this case as well. It is a matter of equal importance that your IP is protected, as it is to develop prototypes. It’s a matter of security that a good partner is supposed to bring in; it’s your work, after all. This is one very essential part of a successful relationship with a rapid prototyping service provider.

- Foundation: Legally Binding NDA: In respect to all projects that are launched on the LS Manufacturing prototyping process, there is a full legal NDA agreement that is signed on all sides. This is a legal agreement that states the confidentiality of your own data that is going to be used, set specifically for your project only. This is what gives us a legal basis of confidentiality on your side.

- Digital Infrastructure: Turning to our digital infrastructure, yet another significant advantage has been identified. In most cases, we have computerized systems when it comes to the transfer of files. In simpler terms, this means that even the transfer of emails is going to be unavailable when it comes to the design transfer. This is because, once your documents are submitted to our special servers that are highly secured, your 3D designs are going to be secured.

- Internal Controls & Project Isolation: Our company has developed internal controls with need-to-know practices with regard to your project details, which are shared with our engineers who are working on your project. We are also providing project isolation; your client details are separated from other projects that are being processed simultaneously.

This is because the protection of your intellectual properties is now part of our business. We, at LS Manufacturing prototyping, have been in a position where we can develop a solution that protects your intellectual properties, which includes the legal aspect as well as the aspect of the Internet, with a functionality aspect. The protection of your intellectual property is now within our tight grip, and you are free to share your inventions with no reservations when presenting your advantage as a professional rapid prototyping service provider because your advantage is secured with our experts.

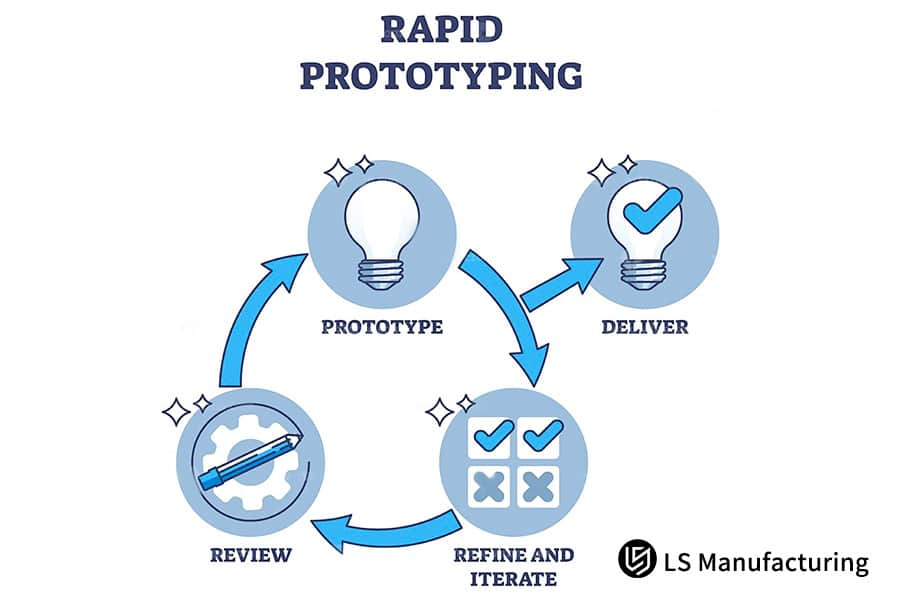

What Are The Key Steps In The Process Of Collaborating With LS Manufacturing On Rapid Prototyping Projects?

It is also highly necessary that the transparency level of the workflow is made to be extremely high, ensuring that the entire process that is necessary for the completion of a prototype is a success with no hitches. The reason why the client needs to be aware of what is going on is that it plays a vital role in ensuring that the entire process is a high degree of smoothness, timeliness, and quality that is supposed to be offered by a professional rapid prototyping service.

- Consultation, Analysis & Quotation: It ushers in a prolonged discussion of your project and a guaranteed upload of your design file. The next step is our engineers taking up an enterprise-grade and totally free DFM analysis. The DFM analysis is something on which much importance should not be given, lest the problems get defined with the help of DFM analysis for the easy optimization of your component. It lays the foundation for your quotation. It originates from proactive engineering knowledge. It is an integral service offered by LS Manufacturing prototyping.

- Approval, Production & Verification: Now that your quotes are in your hands, as is your project plan, your project is now ready to enter production. Protocase manufactures your components on the proper technology with verification stages throughout your assembly process. Then a verification check occurs before your prototypes are boxed & shipped out.

- Support & Forward Path: Completion of a project is in fact a very beginning of our tasks. We are going to support your projects as soon as we enter a post-completion stage. We WILL resolve your urgent concerns regarding your prototypes. We are going to teach professionals how to go from your level of prototypes to low volume production.

In conclusion, our rapid prototyping collaboration process is optimized with respect to comprehension, collaboration, and productivity from free DFM analysis before delivery to after delivery. Every single detail has been considered in a way that removes risks which might occur throughout the entire process, thus thereby ensuring a success of your undertaking. This end-to-end, reliable workflow exemplifies not only a superior rapid prototyping service, but also provides a clear answer for any team evaluating how to choose a rapid prototyping service based on professionalism and proven methodology.

FAQs

1. How is your free DFM analysis and quote free?

The point to be realized is that our quote service in relation to the evaluation of your DFM is free, and our service would, in fact, come with no hidden costs. This is a service that our professional service is going to undertake with the aim of helping, evaluating, and identifying the potential production risks that may prove to be in your favor with regard to saving your precious time and money.

2. How long does it take from submitting documents to getting a quotation?

We return with your submitted 3D file with requirements once we receive it, so that we return with a full detail response within business hours. The thought behind DFM Pro is that how quickly we return with your responses—that means as soon as possible—is a fundamental part in making your decisions in your projects.

3. Are there implications with regard to functionality because of design changes that are brought about because of suggestions from DFM?

It has been assumed that all proposals from DFM are to, with utmost respect, remain the same as the basic functionality, as well as your product purposes. It has been aimed that we keep in mind with respect to the functionality & feasibility cost of your product, keeping in mind that no product functionality & look requirement is to be sacrificed at any cost.

4. Are we in a position to substantiate support claims on material certifications, and are quality inspection reports available?

We are supportive of providing the 'Official Material Certificates'. On all projects, it is a basic quality check verification, plus dimensional verifications. We are capable of sending the dimensional verification reports to you, should you want verification that your prototype has met your verification standards.

5. MOQ. Is there a possibility for a single unit?

The sort of support we generally administer is in product development, unit prototypes/small batching being our specialty. We don’t set a minimum order requirement; you are free to order a single unit.

6. Would I be able to cancel my order because I don’ t like the quote?

All quotes, proposals are free to your consideration at all times during the making of your decisions, before a confirmation of your order and your payment. We are entirely free to cancel with no hesitation at all; we entirely, completely, and perfectly understand & appreciate all your decisions.

7. In what manner are highly urgent orders to be shipped?

We also maintain a special quick production system within our own organizational structure, which would be exclusively allotted to satisfy your requirement, thus helping us to quickly divert our own production resources with the intention of keeping your average turn-around times to a minimum. You can refer your urgent requirements to our customer service representatives for feasibility inquiries.

8. What procedure do new clients follow in regard to their starting prototype project?

Irrespective of the distance from your location, your satisfaction in initiating a project is extremely easy. The only condition is that you need to contact us through our website, providing your 3D files, along with your requirements. We would be in contact with your project engineer, thus helping them serve you in full because you would have accomplished all the necessary procedures, thus ensuring your first order is a success.

Summary

The choice of your service partner as a rapid prototyping service is a highly necessary part, because it is a critical component that plays a significant role in affecting the cost, time, thus the quality of your product development process. An enormously strong analysis, we put before your consideration here, a complete analysis in our theoretical modeling, knowledge, and understanding of all the final processes, association with your service partner, such as the LS Manufacturing.

We have a root base in immense expertise in variant engineering fields and notions, hence, ensuring your finale success in the project wholly secured, accepted, and guaranteed. It is now the time to take advantage of all that can be gained from the proper implementation of your service partner as a rapid prototyping service. All that is required from your side is that you need to click on the button available to your assistance, below, to acquire a “Get a Customized Rapid Prototyping Quote and DFM Analysis for 2025.”

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.