Resin molds, through their efficiency and speed, are today an indispensable tool in rapid prototyping and low-volume production. During the production process, though, common problems such as bubbles, uncured areas, and part adhesion not only have a direct impact on the quality of the finished product but can also delay project schedules and involve additional costs. To address these pain points, this article organizes workable solutions and preventative measures in a logical structure, and highlights LS Precision Manufacturing's experience with custom resin molds.

At LS Precision, our molds undergo rigorous quality control so that you do not have to worry about the usual pitfalls and can focus on product development and marketing. Supported by our sophisticated technology and abundant experience, LS Precision Manufacturing is committed to providing customers with stable and reliable custom resin mold services, turning their innovative designs into reality. To save you time, here’s a quick overview of the core conclusions.

Quick Reference Table Of Key Points Of Resin Injection Mold

| Problem Type | Key Causes | Key Solutions |

| Bubbles | Air mixed during mixing, resin viscosity, incorrect pouring technique. | Vacuum degassing, slow and gentle stirring, pour from high point in thin stream. |

| Uncured/Sticky | Incorrect mixing ratio, less stirring, low ambient temperature. | Accurately weigh, scrape bottom thoroughly and stir, ambient temperature and humidity control. |

| Stickiness | No release agent, master mold incomplete curing, master mold surface rough. | Need and use release agent accordingly, complete curing, and maintain the master mold smooth surface. |

- Material Selection: Select the type of resin based on project requirement (volume, dimensional accuracy, temperature resistance) and trial proof.

- Process Advantages: Polyurethane casting is the optimal way of achieving low-cost, short-cycle production in small lots (tens to hundreds of pieces) by using resin molds.

LS Precision Professional Value:

- Quality Assurance: Due to high-level craftsmanship and stringent quality control, flaws in the overall are practically eliminated.

- Project Efficiency: LS Precision provide end-to-end services from technical consultation and manufacture to simultaneous production for lowering delivery cycles (e.g., express delivery of 50 high-precision outer pieces in this case study).

- Core Value: Partner with a professional reseller like LS Precision Manufacturing to obtain consistent, reliable custom resin molds and have extra time for product and market development while reducing the overall project risk.

Why Trust This Guide? Practical Experience From LS Experts

The guide is based on decades of real-world experience of LS Precision Manufacturing in custom resin molds. We specialize in high-performance polyurethane casting technology and undertake mold work on smart home, medical, and precision electronics applications daily. LS Precision have a clear grasp of high specifications of mold hardness, draft angle, and dimension stability under varying application conditions.

LS Precision not only possesses a temperature- and humidity-controlled workshop to ensure a uniform curing environment, but also strictly follows over a dozen quality control procedures, from material screening and vacuum degassing to post-processing, to ensure that each mold shipped is of production-quality precision and reliability.

LS Precision had once produced a complex gear mold for a customer. Its small teeth were prone to trapping air bubbles, leading to flawed products. According to our experience, we did not simply extend the vacuum degassing time. Instead, LS Precision just reduced the initial mixing temperature of the resin to reduce the viscosity and used a staged vacuum degassing method. LS Precision thus completely eliminated all potential bubbles with high efficiency and actually increased the trial production yield rate of this mold from 65% for a customer-made mold to more than 99%.

Why Are Bubbles Constantly Forming In Your Resin Mold?

Bubbles are one of the most common and frustrating problems of resin casting. Bubbles create surface defects on the mold cavity, contributing directly to the quality of the end casting. The primary cause of bubbles stems from two main reasons: improper mixing and lack of control over the curing process.

1. Improper mixing:

Incorrect mixing is the first means of allowing air in. The A and B component epoxy resin mold material, when mixed a great deal and quickly, trap a great deal of air within the resin in the form of tiny bubbles, which cannot be removed easily by themselves.

The technical solution is to use a vacuum degassing procedure. The resin cup is quickly moved to a vacuum chamber for evacuation after mixing. The entrapped air within the resin quickly expands under negative pressure, bursting and leaving the liquid surface, thus effectively eliminating the source of bubbles. All mixed materials in LS Precision undergo this rigorous vacuum pre-treatment to ensure the optimum material condition before casting.

2. Failure to control the curing process:

Failure to control the curing process can lead to latent bubbles. The resin releases heat during the curing reaction. When the ambient temperature is not controlled, causing the reaction to be too rapid, or when too large a volume of casting is carried out at one time, heat can be generated, causing the resin viscosity to decrease instantaneously and trapping bubbles within the mold.

Pressure tank curing is the ultimate solution. The cast mold is placed in a pressure tank and is injected with high-pressure air (typically 4-6 bar). Under this high pressure, any tiny remaining bubbles are physically compressed to a size that is not visible to the naked eye, resulting in a perfect mold surface.

LS Precision not only utilizes specialized equipment at critical stages but also closely controls the temperature and humidity of the mixing and curing workshops so that every epoxy resin mold is formed in an optimal state, effectively eliminating the occurrence of bubbles and creating high-quality molds with dense internal parts and smooth cavities.

LS Precision Manufacturing is aware of the critical function of bubble control and therefore has established a standardized operating system incorporating everything from material pretreatment to environmental control of the entire process.

Resin Takes Time To Cure Or Is Sticky?

There is nothing more frustrating in moldmaking than having to work with resin that takes an eternity to cure or is sticky indefinitely. Not only is time and material lost but the entire project is derailed. These issues are not always the result of inherent resin quality issues, but rather more frequently of poor handling and environmental control.

The selection of the right and proper mold resin is the first step towards success, but even quality polyurethane casting resins cannot cure optimally if errors are made in subsequent steps. The root causes of these issues are the following three factors:

1. Improper mixing ratio:

This is the most critical error. The mix ratio of component A (resin) and component B (curing agent) for polyurethane casting resin is highly sensitive to variations in mixing ratio. Relying on visual estimation or approximate measuring with cups and spoons is prone to error. Unequal proportions directly upset the chemical balance of the curing reaction, prevent the reaction from going to completion, and result in permanent tack or softening of the resin.

2. Inadequate mixing:

Despite accurate proportions, insufficient mixing time or incorrect mixing method, i.e., neglecting to scrape the material from the sides and bottom of the cup and mix it in thoroughly, will result in areas of too much or too little curing agent. These "dead spots" of inadequate mixing are where curing failure will start, causing localized stickiness or failure to cure.

3. Improper ambient temperature and humidity:

Temperature is the "switch" that controls the curing reaction. Ambient temperatures that are too low will severely slow down the reaction rate, even cause it to "hibernate." Too high humidity, on the other hand, can cause water in the air to react with the resin components, interfering with the crosslinking process and causing surface tack or whitening.

4. How does LS Precision ensure foolproof performance?

At LS Precision Manufacturing, we completely eliminate human and environmental variables by investing in hardware and taking control of the process. We utilize fully automated mixing machines, which precisely calculate and mix the optimum mold resin at high speed, with exact mixing to the gram and thorough, even blending. Remarkably, all curing and mixing processes are done in a cleanroom under a constant temperature and humidity.

LS precisely controls the optimum curing temperature and humidity profile for each material, ensuring a stable reaction environment for your polyurethane casting resin, so that each mold achieves the optimum curing state and mechanical properties.

Mold Release Disasters: How To Avoid Sticking Between The Mold And The Master Mold Or Casting?

Perfect mold release is the last signature of successful silicone mold making, yet adhesion comes to sabotage all efforts most of the time. This not only destroys the expensive master mold but can render the whole mold unusable. The key to avoiding this "catastrophe" is to use release agents scientifically and take mold design into consideration, not intuition alone.

1. Selection and application of release agents:

Not all release agents are created equal. Different release agents of different compositions (e.g., solvent-based, semi-permanent) are required for different optimum mold resins (e.g., polyurethane, epoxy) and master/casting materials (e.g., ABS, metal, ceramic).

The LS Precision engineer selects the most suitable release agent from the empirical database based on the chemical nature of the material. When applying, the principle of "thin and even" should be observed, applying micron-level layers multiple times and allowing them to form completely, rather than a single layer. Only in this way can a complete and effective isolation barrier be achieved.

2. Mold design: draft angles are indispensable

Even with a release agent, demolding will prove to be challenging if the form of the mold itself is inherently bad. The provision of an adequate draft angle (typically ≥3°) for the master mold and mold cavity in prototyping actually reduces negative pressure and mechanical stress on demolding, eliminating the risk of tearing through "vacuum suction" and physical fracture.

At LS Precision Manufacturing, we approach demolding as a process. Not only do we match you with the optimal demolding solution, but we also provide seasoned draft angle suggestions from the very beginning of the design process.

Utilizing LS Precision's extensive material matching database and process expertise, we render your optimum mold resin precisely compatible with both the master mold and the subsequent casting material, effectively ensuring easy and flawless demolding every time.

How To Choose The "Best Mold Resin" For Your Project?

Finding the best mold resin for your application is not a question of choosing the most expensive or most versatile product, but one of precise performance matching. Different resin materials, such as epoxy mold materials, polyurethane casting resins, and silicone rubber, all have varying property profiles. The amount of replicas expected, the desired casting material, and the level of detail needed should all directly influence your choice.

1. Seeking Extreme Precision and Stability: Choosing Epoxy Mold Materials

If you need very accurate copies of parts or the master mold itself has detailed structures, epoxy molds are a great choice. Its advantages include very low cure shrinkage, very good detail reproduction, high dimensional stability, and high hardness, making it suitable for test fixtures or prototype validation. But it has some lower toughness and requires a larger draft angle and is not tear-resistant like other materials, making it more suitable for replicating plastic parts (such as polyurethane and resin) in 50 or less quantities.

2. Balancing Performance and Cost: Choosing Polyurethane Casting Resin

For most small-series production runs (50-500 pieces), polyurethane casting resin is the most economical compromise mold resin in cost vs. performance. It possesses high tear strength and toughness, which equates to a longer service life and improved demolding properties. By formulation modification, silicone resin can achieve varying hardness, from soft to hard. It is utilized for duplicating a multitude of various plastic parts, wax patterns, and even some low-melting-point alloy castings.

3. Replicate Complex Structures and Easy Demold Flexibility: Choose Silicone

If your master mold has enormous undercuts or complex undercut structures, the flexibility of silicone resin molds is the only choice. Silicone molds can be stretched and bent, allowing damage-free demolding, which cannot be achieved with rigid resins. Though ideal for replicating sculpture, jewelry, and other artwork, its wear resistance and durability are generally lower than those of polyurethane resins.

At LS Precision, our engineers will diligently learn your project requirements, from production quantity, casting material, to level of detail, to exactly match and recommend the most appropriate mold resin for optimal return on your investment.

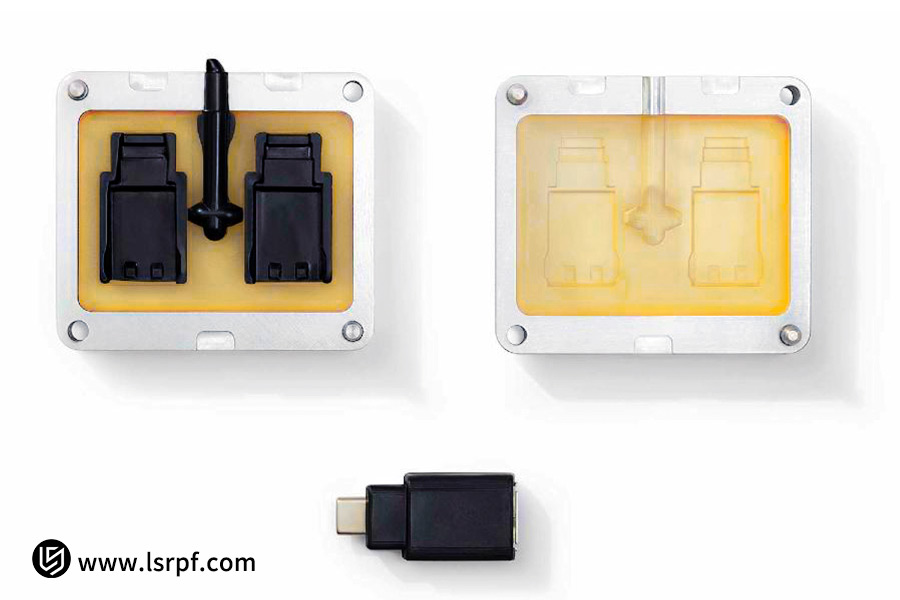

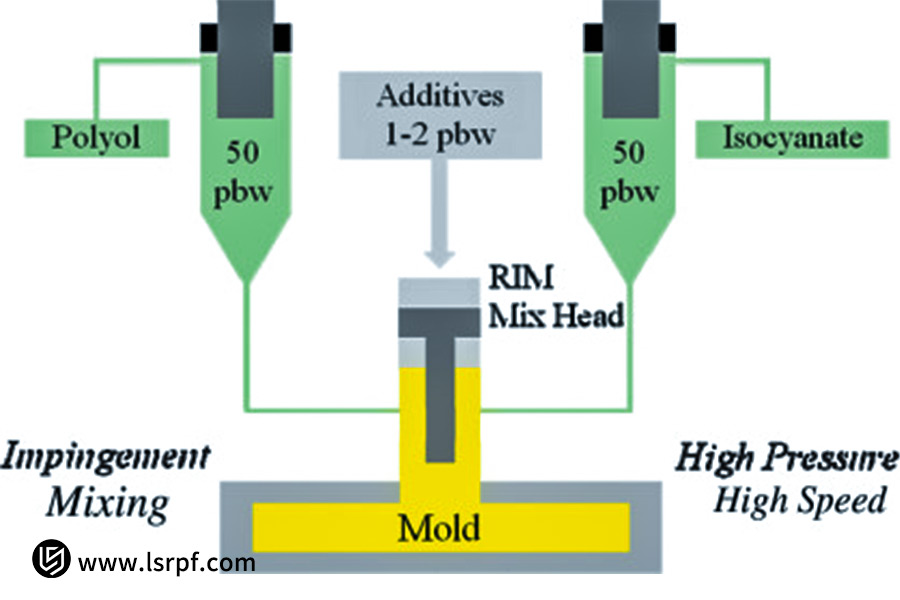

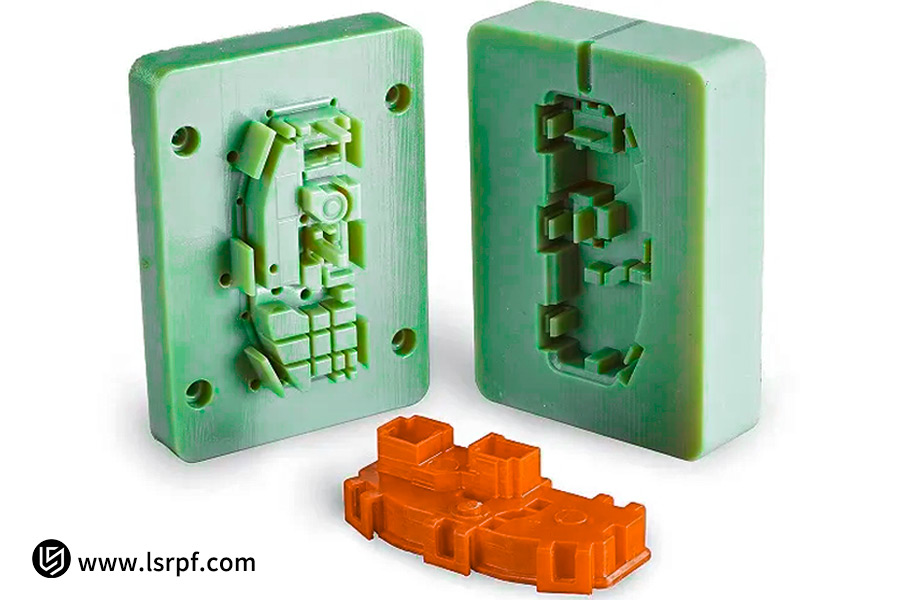

How Does Polyurethane Casting Achieve Low-Volume, Low-Cost Production?

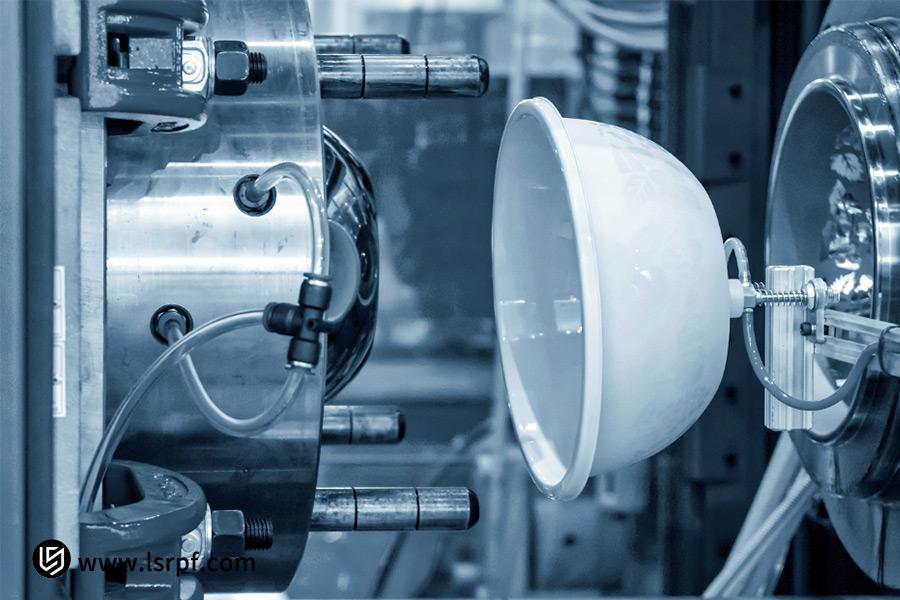

In product development, having to bear the cost and lead time of steel mold making is a tremendous burden. Urethane casting is the vital link between prototyping and production quantity, in that you can produce dozens to hundreds of functional parts with performance comparable to injection molded plastics at a fraction of the cost and speed. Its basic approach is to utilize high-precision resin silicone molds and achieve replication through the use of a vacuum casting process. This process relies primarily on the following two advantages:

1. Extremely low mold cost and extremely fast turnaround time:

Polyurethane casting eliminates the need for expensive steel molds. A soft resin silicone mold is first quickly created from your product prototype (3D printed or CNC machined). This same mold can be created in a matter of days at a cost far below that of steel molds, or even less, significantly reducing the upfront investment and risk of small-lot production.

2. Vacuum casting ensures part quality:

During the production process, the selected polyurethane casting resin is cast into the silicone mold cavity under vacuum. The vacuum effectively eliminates air bubbles, offering a dense casting free of defects. The two-component polyurethane material duplicates the mechanical and aesthetic characteristics of numerous engineering plastics (such as ABS, PP, and PC), meeting functional testing as well as market validation demands.

Polyurethane casting is the most cost-effective choice for small-series pilot production, market launch, crowdfunding shipment, or small-scale production.

How Did LS Quickly Produce 50 High-Precision Exterior Parts For A Smart Home Client?

When standing on the threshold of product launch, quickly producing a batch of high-quality prototypes for function verification and demo is a common problem for a lot of innovative businesses. This was the situation of one of our smart home clients: they had to design 50 new remote control housings on time for launch. Creating them using traditional steel mold making methods would have taken them hundreds of thousands of yuan and months of production time. This was precisely where the technology of polyurethane casting could come in.

1. Client's Dilemma:

The brand had finished designing a new remote control but time was tight before launch. They needed 50 housings that resembled and felt like the final production version for on-site functional demonstrations, media reviews, and user experience gathering. Yet producing injection molds directly for steel was not only expensive (typically over 100,000 yuan), but would take a month or two to produce, well outside their project budget and timeline.

2. LS Precision Manufacturing Solution:

Faced with the customer's urgent needs, the LS team quickly developed an efficient and reliable solution:

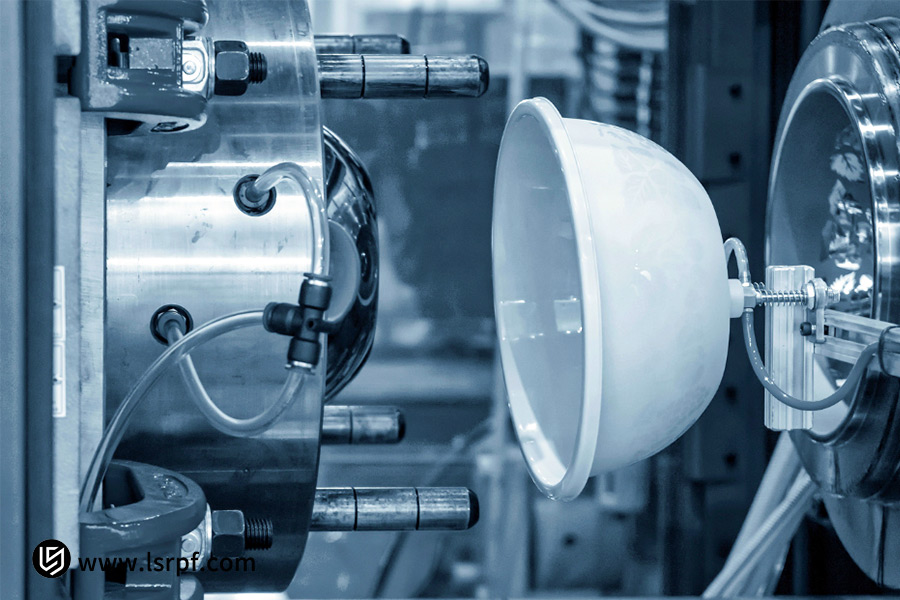

- High-Accuracy Master Mold Creation: LS Precision initially employed high-accuracy CNC equipment to create a metal master mold directly from the customer's 3D data, locking in the dimensional accuracy and surface finish of the completed part.

- Silicone Mold Optimization: LS Precision combined the optimal mold resin material to create the silicone resin mold. The material possesses a combination of high toughness, long service life, and good replication characteristics, faithfully capturing each fine texture and button detail on the remote control housing.

- Parallel Vacuum Casting Production: LS Precision utilized the prepared silicone mold to vacuum-cast polyurethane casting resin. Through preparing multiple sets of molds and producing them in parallel, we significantly shortened the production cycle for each part and achieved fast replication in small batches.

3. Results:

LS Precision managed to deliver all 50 remote control housings within a week. The parts have a smooth appearance and decent texture, which are almost identical to the final injection-molded part, fully meeting the customer's high expectation of presentation at the launch event. The total cost is only a tenth of the mold-making expenses, saving the customers a great deal of money along with valuable time, successfully aiding in getting their new products to the market.

Do you also worry about small-batch prototype price and speed? Contact LS Precision today for your rapid prototype solution!

Choosing A Professional Supplier: What Else Should You Expect Besides Mold Production?

The advantage of working with a real custom resin mold supplier goes far beyond providing a physical mold. A good supplier provides a whole technical solution and problem-free project experience. We work at LS Precision to bring your concepts from a sketch to life, making each resin casting project an efficient and high-standard finish. By dealing with LS Precision, you will have the following primary advantages:

1. Pre-emptive Design for Manufacturability (DFM):

LS Precision's engineers will also professionally check your 3D drawings prior to production and help you optimize draft angles, parting line placement, and potential sink mark threats. This avoids manufacturing risks and optimizes mold design, saving you future time and money.

2. Scientific Material Selection Guidelines:

Not all resins are appropriate for your project. Relying on our extensive material database and application expertise, LS Precision recommend the most suitable mold resin for your part's functional requirement (e.g., toughness or stiffness requirements), intended production volume, and price, so mold performance perfectly meets your project requirements.

3. Smooth trial and production service:

A turnkey, single-source capability is offered. Once the mold is completed, we can have first-article trial and production validation conducted in-house and utilize that very same mold to perform small-batch polyurethane casting. This eliminates the need for coordination with a foundry, significantly lowering the entire development cycle to final prototype.

By choosing LS Precision Manufacturing, you not only obtain a custom resin mold but also a manufacturing partner that has a stake in your project and provides end-to-end technical service.

With our end-to-end solutions from design to manufacturing, LS Precision introduce your resin casting project to the market with lower risk and shortest lead time, which allows you to reach the market faster and repeatedly.

FAQs

1. How many parts can an LS Precision resin mold typically produce?

This depends primarily on the selection of mold resin material. For example, a polyurethane resin mold of high strength will produce 200-300 pieces or more with consistency, while an epoxy resin prototyping mold is more appropriately used for production runs of 50 or fewer. Our engineers will assess your project requirements closely and suggest the optimum solution with a compromise of longevity versus economy to give maximum utilization.

2. Can I use your resin mold for injection molding?

Not at all recommended. The high temperature (typically above 200°C) and high pressure (typically above 50 tons) of the typical injection molding machine are easily capable of destroying resin molds. Our in-house resin molds are designed for low-pressure polyurethane casting. They provide excellent, low-cost bridge-of-transition-for-trials small-series production, product validation, and market validation, providing tremendous insight before ultimately investing in steel molds.

3. Do you provide a full service from mold to casting?

In fact, our strongest point is that we provide a turnkey, one-stop solution. LS Precision orchestrate the entire process, including initial mold making and design review (DFM) through ensuing small-series vacuum casting production. Not only does this prevent wasted time and administrative expense of multistep communication, but also provides continuity of quality from mold on through to finished part, giving you hassle-free access to use-ready precision parts.

4. How do I start a project and receive a quote?

The process is simple. You can simply share with us the 3D file of your product (e.g., in STP/IGS format) or a physical sample, along with your ballpark estimate of production volume requirements. Our qualified staff will quickly conduct a manufacturability check, identify optimum process and material alternative, and supply an open, detailed quote and manufacturing schedule in 24 hours.

Summary

Effective production of resin molds is an extremely advanced art that involves materials science, exacting engineering, and a lot of experience. Choosing LS Precision Manufacturing is not merely choosing a product but also reliability, efficiency, and hassle-free operation. LS Precision offer professionalism of the highest level, taking production uncertainty away from you so that you can focus without distraction on product design and market expansion.

You can provide your part details (3D drawings or samples) to us today, contact LS Precision and our team will provide you with a free technical analysis and customized solutions to create your ideas in the shortest time and lowest cost! Upload your design drawings now and get an instant plastic injection molds quote ( plastic injection molds price), let LS be your strong backing in pursuit of ultimate plastic injection molds precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS servicesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com