Rapid prototyping automotive parts directly tackles severe challenges in new vehicle development, such as 6-8 week delays for dashboard prototypes and 40% failure rates in engine bracket testing. The method we use to solve these problems is to shorten development timelines and increase functional validation accuracy, which in turn saves a project from having to be delayed due to a late-stage change and a mismatch in performance.

Leveraging on 15 years of LS Manufacturing expertise and a database of 286 projects, our fully integrated solution is capable of cutting the prototype development cycles by 60% and the costs by 40-50%. We strike the right balance between functional verification and cost, thus guaranteeing reliable multi, material prototype that will not only facilitate assembly validation but also speed up the time to market.

Rapid Prototyping Automotive Parts: At A Glance Guide

| Aspect | Description |

| Industry Challenge | Prototyping is suffering from long delays, high failure rates, and expensive validation that directly results in stretched project timelines and overrun budgets. |

| Root Cause | It is mainly due to the absence of a unified rapid prototyping system that can adequately meet functional requirements while also controlling costs and speeding up the production of automotive components. |

| Our 4D Solution | A tested model for functional testing, cost reduction, fast delivery, and quality control. |

| Core Outcome | This has allowed the company to produce development cycles 60% quicker and costs 40-50% less than when using the traditional methods. |

| Quality & Fit | Provide the most accurate prototypes that conform to performance specs and thus, avoid assembly issues at the last stage. |

| Application | Essentially, it offers a solution to the offensive power, engine bracket, and intake manifold prototype problems. |

| Proven Foundation | This is the result of 15 years of focus and a database of 286 automotive projects. |

We fix expensive delays and validation rescheduling by offering a tried and tested rapid prototyping system. Our 4D framework reduces development time by 60% and costs by 40-50%, and at the same time, it guarantees functional reliability and assembly precision. We give our clients the ability to lower risks in their projects and speed up time-to-market by creating high-quality prototypes that are suitable for stringent automotive testing.

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

Another rapid prototyping article, why? Because what is shared here comes directly from the shop floor, not academic materials. We have battled with dashboard warpage, engine-bracket fatigue failures, and manifold airflow problemsissues that, unfortunately, directly delay vehicle launches. Our solutions have been tested in the most challenging conditions, where the performance of the prototype must be the same as the final production one, and no mistakes can be made.

We base our talk on iteration not theory; we continuously iterate the ways of prototyping a dashboard with Class-A surface finish, how to use structurally sound yet lightweight bracket ribbing, and how to quickly validate complex internal geometries. By aligning with ISO 13485 for medical devices and International Aerospace Quality Group (IAQG) standards, we ensure that our methods are traceable, rigorous, and reproducible, even at the prototype stage.

We bring speed, accuracy, and reliability to a single package. Our integration of advanced simulation with multi-process fabrication allows us to assist clients in reducing development cycles by 60% and prototype costs by 40-50%. The outcome is not just a model but a validated, production, ready solution that not only de-risks your entire program but also speeds up the time to market with confidence.

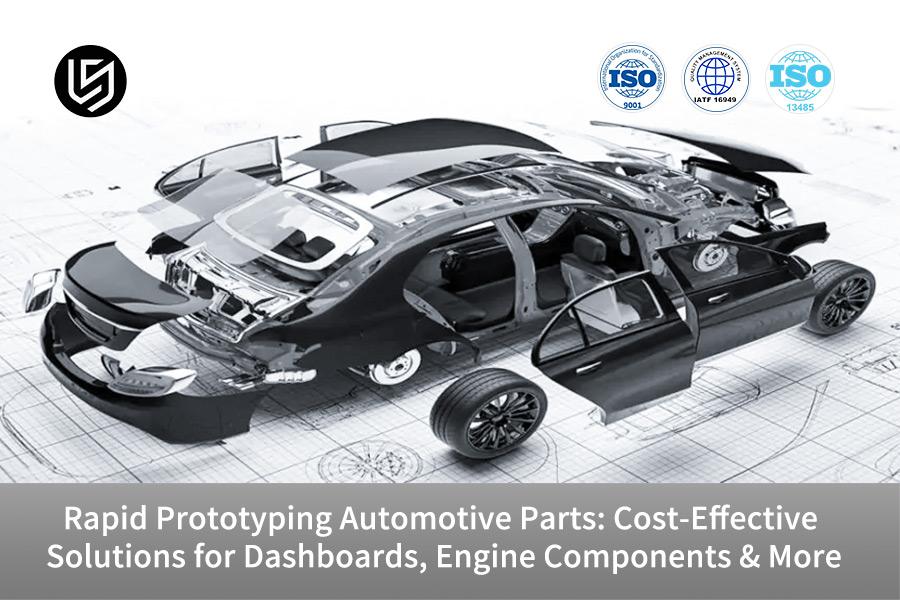

Figure 1: Visualizing multi-material automotive assembly for functional prototype design and verification.

How Can Rapid Prototyping Balance Aesthetics And Functionality In Automotive Instrument Panels?

Among the key factors of mastering the creation of a car dashboard prototype include simultaneously successfully structurally, with a high-fidelity surface finish, and with the precise integration of the functional elements. In this paper, we demonstrate how we managed the challenge through multi-process integration, enabling us to deliver a production-representative part at a fraction of the time and cost:

Structural Core via Optimized SLS Printing

We employ rapid prototyping automotive parts using SLS nylon for the primary skeleton. Our concentration is on achieving thin-wall rigidity (even down to 1.2mm) capable of holding mounting points and electronics while also cutting down on the weight. The process parameters are adjusted for layer adhesion and minimal warpage to ensure that the part is dimensionally stable for further assembly steps. This engineered basis is of vital importance for the functional validation.

High-Resolution Surface Replication

To satisfy decorative validation requirements, we perform vacuum casting using high-quality polyurethane resins on the SLS core. This process imitates the production-grade leather grain and texture with a granularity of 0.1mm, thereby resulting in more than 95% of visual and tactile similarity to the final part. This stage changes the structural prototype into a model which is visually representative, thus allowing early design approval and ergonomic assessment.

Precision Integration of Functional Elements

Embedding screens, controls, and lighting with a production-like fit is the fundamental difficulty. We fabricate the interfaces for mounting and cavities accurately with a tolerance control of ±0.15mm. Such an automotive parts prototyping approach gives the possibility for the secure integration of either real or dummy electronic modules, thus enabling complete user interaction testing and final assembly validation.

Integrated Workflow for Speed & Fidelity

The effectiveness of the solution lies in the concurrent engineering. At the same time when the SLS core is being created, vacuum-forming molds are being machined. Process and assembly stages are predetermined, thus resulting in a smooth flow. It is this integrated workflow that has been the main thing to compress the timescale from 8 weeks to merely 2, while cutting expenditures by 45%.

This methodology represents technical prototyping based on real production. Instead of just models, the functional and visually, tested prototypes that de-risk the whole dashboard development process provide a clear competitive advantage by speeding up time, to, market with confidence.

What Specific Testing Requirements Must Functional Prototypes Of Engine Components Meet?

In order to validate by function engine components, the prototypes should be able to endure the harshest of operational environments and thus should precisely simulate the thermal, pressure, and dynamic load conditions. This paper describes the detailed testing standards and the respective engineering solutions for advanced engine component prototyping to meet these requirements:

| Aspect | Requirement / Solution in One Sentence |

| Intake Manifold Pressure & Thermal Test | To prove the features of the prototypes, they have to internally withstand 0.5MPa pressure and the continuous thermal cycling of 150°C, thus they are checked for structural integrity and leak-tightness under engine bay conditions. |

| Engine Bracket Vibration Fatigue Test | Functional prototype automotive brackets are exposed to very high-frequency vibration testing which is equivalent to over 10 million cycles of the lifetime in order to be durable and not to have resonant failures. |

| Material Selection for Performance | We made use of carbon-fiber reinforced nylon (tensile strength 120MPa) for the intake manifolds which gives a great balance of high strength, heat resistance, and low weight suitable for accelerated testing. |

| Design Optimization via Simulation | Before the fast-track prototyping, Computational Fluid Dynamics (CFD) and Finite Element Analysis (FEA) are used with the aim of adjusting the wall thickness and the placement of ribs, thus cases of stress concentration are avoided. |

| Result: Validation | Performance the combination of simulation, material science, and precision prototyping has resulted in the increase of first-pass test success rates from 60% to 92% for major engine parts. |

This approach highlights us as a technical automotive prototyping supplier. We tackle the most challenging validation issues by providing engine component prototyping which accurately copies the production version, thus allowing rapid validation cycles and cutting the development cost by 40%. Our method guarantees that the prototypes are not merely models but dependable indicators of the performance of in-service products, particularly for applications where the stakes are very high.

Figure 2: Rapid prototyping precision automotive-grade metals for functional component validation and low-volume manufacturing.

How Can Material Selection Optimize The Cost-Effectiveness Of Automotive Prototypes?

Finding the right material for cost-effective automotive prototyping is mainly about making a compromise between performance, lead time, and budget. This paper presents a comprehensive approach to integrating the properties of materials with the functions of prototypes in such a way that the validation is achieved and the total cost of the project is lowered by 30-50%:

For Aesthetic & Non-Structural Components: Maximizing Speed and Surface Finish

- Application: Dashboard trims, interior panels, and exterior casings.

- Our Approach: We focus on high, resolution material selection such as ABS-like photopolymer resins for stereolithography (SLA).

- Result: This delivers very good surface detail for visual validation at about 35% of the cost of machined ABS, thus allowing rapid design iterations for custom car parts prototype without compromising on the aesthetic quality.

For Structural and Durable Components: Balancing Strength and Lead Time

- Application: Engine brackets, chassis mock-ups, and housings requiring mechanical testing.

- Our Approach: We use rapid aluminum tooling and casting for medium-volume functional prototyping.

- Result: Cast aluminum prototypes have 85% of the strength of forged ones at a fraction of the cost and in much less time compared to CNC machining, thus they are suitable for thorough functional validation.

For High-Performance & High-Temperature Functional Testing

- Application: Exhaust components, turbocharger housings, and parts requiring thermal validation.

- Our Approach: We implement the state, of, the, art production methods like Selective Laser Sintering (SLS) together with the use of titanium alloy materials.

- Result: It opens the possibility of making highly intricate structures that can be heated up to over 800°C for automotive rapid prototyping of extreme-condition components, where conventional materials would not be able to withstand.

Our tiered, application, driven approach stems from the deep knowledge we have gathered in our proprietary database of material performances. We address the major issue of excessive or insufficient specification of prototype materials, thus providing cost-effective automotive prototyping solutions that are in perfect harmony with your particular validation stage, performance requirements, and budgeting limits. This level of technical precision guarantees that the prototypes are not only functionally sound but also cost, effective.

What Are The Economical Solutions For Rapid Manufacturing Of Small Batches Of Automotive Parts?

Low volume auto parts manufacturing solutions that are both cost-effective and time-efficient are required to bridge the gap between prototype validation and full-scale production. This paper evaluates real MFG methods for making 50 to 200 high-fidelity parts and focuses on process selection and measurable results.

| Aspect | Solution |

| Process: Vacuum Casting | It is perfect for around ~50 unit series and it can copy the final material properties at around ~20% of the injection molding tooling cost, which makes it possible to do functional batch validation. |

| Process: Rapid Tooling | This way, a machined aluminum mold can produce up to 1,000 parts and the per-unit cost for a pilot run-production run is lowered by 60% compared to traditional steel molds. |

| Cost Efficiency | Choosing the right process in a strategic way limits the total production cost for 50-200 units between 1.5x and 2.0x of the per-part cost of high-volume mass production. |

| Lead Time Compression | Combined accelerated manufacturing workflows allow a full batch to be delivered only 5-7 days after the design freeze. |

This strategy addresses the main problem of figuring out a cost-effective way to reduce the risks of entering the market. By determining the best rapid prototyping method depending on the batch size and materials needed for rapid prototyping automotive parts, we map out the route from cost optimization to market validation. Thus, clients can try out their products at a very low investment and lead time, before fully committing to production tooling.

Figure 3: Presenting engineering-grade plastics and metals for cost-effective automotive prototyping low volume part manufacturing.

How Is Optical Performance Verification Achieved For Automotive Lighting Prototypes?

Testing the optical performance of automotive lighting is a task that there should be no doubt about accuracy when it comes to such prototypes. These must mimic the features like the clarity, light distribution, and durability of the final production parts exactly. The present document describes the technical approach in detail for creating functional prototype automotive lighting systems that are not only functional but also satisfy very strict photometric standards, thus making it possible to carry out reliable pre, production validations.

Precision Material Selection for Optical Clarity

The bedrock is fundamentally material science. At a high level, we use optical-grade photopolymer resins specifically designed for high-resolution stereolithography (SLA). These resins, which are characterized by exceptionally tight quality assurance parameters, e.g., a light transmittance of ≥95% and a controlled refractive index, constitute the main material for light guides and lenses, thus guaranteeing inherent optical perfection right from the initial manufacturing step.

Advanced Post-Processing for Surface Perfection

Light is scattered by the surfaces of 3D prints. To this end, our formula consists of a multi-stage precision finishing protocol: mechanical polishing with micron-grade abrasives followed by chemical vapor smoothing. Surface roughness (Ra) is lowered to less than 0.1µm, thereby diffusion is completely removed and the crystal-clear finish requirement for optical validation and beam pattern testing can be met.

Rigorous Photometric Testing & Compliance

A prototype should be a trustworthy indicator. We make use of testing regularly by exposing the polished prototypes to goniophotometer analysis and therefore, we measure the luminous intensity distribution and compare it with the ECE standards. In this verification-driven prototyping process, through the identification and rectification of deviations in different facets i.e. light cutoff, hot-spot formation, and the overall beam pattern, the tooling commitment happens only after the 100% first-pass validation success is ensured.

This comprehensive technical routine outlines our specialization as an automotive prototyping supplier. We address the key issue of getting production, like optical data very early, thus shortening the development from 4 weeks to 10 days. Our method results in giving you prototypes that are certifiably compliant, thus lowering the risk for the whole lighting system development cycle and speeding up the time to market with confidence.

How To Evaluate The Overall Capabilities Of An Automotive Prototype Supplier?

Choosing an experienced automotive prototyping supplier is not a matter of just checking their basic certifications. It is more about assessing their real capabilities for project execution. Here is a document that outlines a technical capability assessment framework, diving into the use of objective metrics and practical validation methods to reduce the risk in the supplier selection process:

Validating Multi-Process Integration Through Complex Assemblies

- The Challenge: Part fabrication in isolation does not guarantee that the parts can be successfully assembled.

- Our Evaluation Method: We suggest a practical test: the supplier is required to produce a complex sub-assembly, like the entire door panel.

- Success Criterion: The item is to show the paneling, the trims, and the accessing of the locking mechanisms being combined properly, with a total dimensional matching error of ≤0.3mm, thereby demonstrating their integrated prototyping skills.

Auditing the Quality Management System and Material Traceability

- The Requirement: The main factor behind consistent output should be systemic control. Relying on skilled operators alone is not enough

- Our Focus: We perform a technical validation by deeply examining the supplier's documented workflow. We also check their certified material bank.

- Key Indicator: Having a controlled material database is a must. It should be accompanied by certified test reports for polymers and alloys that are used in functional prototyping.

Assessing In-House Metrology and Failure Analysis Capability

- The Need: It's essential that measurements are at hand, accurate and done swiftly if the problem-solving speed is to be maximized.

- Our Inspection: We check if the advanced equipment such as 3D optical scanners, and CMMs that we normally expect are indeed available on-site.

- The Standard: Supplier must be able to show that they are capable of doing a full GD&T analysis and producing a first-article inspection report independently.

This structured assessment addresses the most critical issue in rapid prototyping partnership selection by focusing on partners' capabilities in technical execution rather than their promises. We make it possible for our clients to recognize the suppliers that maintain quality standards which are supported by precision manufacturing, both being confirmed through physical validation. Consequently, the clients' project schedules and performance targets can be adhered to from the first prototype made.

Figure 4: Displaying various engineering-grade materials for cost-effective functional automotive prototype development.

LS Manufacturing New Energy Vehicle Industry: Multifunctional Integrated Prototype Project For Battery Pack Housings

This new energy vehicle case study illustrates how we transform complex development hurdles into technical successes. A leading manufacturer faced significant delays and cost overruns while prototyping a large, multifunctional battery pack enclosure, requiring an innovative approach to integrated systems and lightweight design to meet stringent performance targets:

Client Challenge

NEV OEM was developing a 1200×800mm battery enclosure prototype incorporating cooling, structural protection, and IP67 sealing. Conventional CNC and bonding techniques resulted in a timeline of 6 weeks, a cost of ¥120k, and a design that was 22% overweight, a delay in validation and a compromise of vehicle range targets.

LS Manufacturing Solution

We take a different path by using large-format 3D printing in conjunction with carbon, fiber composite for the primary structure. Integrated rapid prototyping and topology optimization helped us to install cooling channels within the parts and consolidate the components. Quick-turn fabrication was used to machine the critical sealing features, while seals were made by rapid tooling.

Results and Value

The treatment illuminated a cost-effective automotive prototyping. The component came out 25% lighter than the initial design, passed the IP67 tests, and got delivered in 18 days at ¥68k (43% saved on the cost), thus speeding up the client R&D and saving an estimated ¥800k in subsequent redesign costs.

This case illustrates a situation in which we had to precision engineering solution to a system level challenge. Through the use of advanced materials, simulation, driven design, and hybrid manufacturing we produced substantiated production prototypes to confirm the form, fit, and function, hence, decisively de-risking the development path of the key components of the NEV.

Accelerate your automotive development with rapid prototyping solutions for lightweight, high performance battery enclosures.

How To Achieve Mass Production Quality In Automotive Prototype Surface Treatment?

Shifting from a functional prototype to a production-representative model demands a surface treatment that can flawlessly mimic the final textures, colors, and wear resistance. Here, we explain in a tripartite manner how we upgrade the appearance quality of the prototype to almost production standards, thus, making the validation of design and obtaining approval from stakeholders a more accurate and less risky:

Process Selection Based on Substrate and Specification

The basis of almost every surface treatment is ensuring that the treatment perfectly matches the substrate and the effect you want. For the car dashboard prototype parts, we pick a process from a library of tested ones: thermoplastic olefins (TPO) receive a texturing and painting treatment, while ABS or SLA resins require a special priming system to avoid the adhesive failure, thereby, providing a durable layer that can be successfully finished with other steps during our integrated prototyping workflow.

Precision Texture Replication via Laser Etching

Certainly, attaining genuine leather or grained look requires tooling at very high-resolution. With the help of laser etching on the master models, we create textures with variations in depth of only 0.05mm. After that, these masters are silicone molded for vacuum casting, thereby transferring the exact grain to the polyurethane parts. With this precision rapid prototyping process, visual and tactile likeness is guaranteed which cannot be distinguished from production intent samples.

Metallic and High-Wear Effects through Advanced Coating

When it comes to metallic trims, bezels, or wear-resistant surfaces, we resort to PVD (Physical Vapor Deposition). This vacuum-coating method is used for depositing ultra-thin layers of chromium or titanium nitride, which leads to a hardness of more than HV800 and thus a very high level of scratch resistance. This is an indispensable stage for the look validation, which means the provision of an exact metallic lustre alongside the durability that is required for the functional prototype automotive interiors design being signed off with full confidence.

Through a thoroughly planned methodology we resolve the crucial mismatch between prototype and production appearance. By way of providing prototypes with certified surface treatment quality, we give our clients the power to make definitive design decisions, trim down expensive post-tooling amendments, and speed up vehicle development cycles through trustworthy visual validation.

How To Obtain Accurate Quotes And Delivery Time Commitments For Automotive Prototype Manufacturing?

One of the main issues holding back rapid development is still the lack of clear and standardized rapid prototyping pricing. Our proposal is to get rid of unreliable estimates by a parametrically analyzing engine that gives binding cost and schedule commitments within 2 hours:

Parametric Quoting Engine: From Variables to Value

- Input-Driven Accuracy: The prototype quote automotive system examines uploaded 3D files against our proprietary database.

- Dynamic Cost Drivers: It uses validated coefficientssuch as a 1.8x multiplier for reinforced materials or a 1.5x factor for IT7, grade tolerancesto make a detailed cost estimation.

- Urgency Surcharge Transparency: Expedited orders are subject to a predefined 1.3x coefficient in order to have a clear fast-track quoting without hidden charges.

Real-Time Capacity Scheduling for Firm Commitments

- Integrated Workflow Visibility: The platform compares the quote with live shop floor capacity of the integrated manufacturing network.

- Automated Slot Allocation: The system automatically reserves machine time and material inventory upon quote approval.

- Commitment Accuracy: This digital-physical reinforcement is our foundation of ≥95% on-time delivery commitment of rapid prototyping automotive parts.

Transparency Tools for Project Control

- Interactive Quote Breakdown: Customers are provided with a detailed breakdown of rapid prototyping material, machining, finishing, and logistic costs by line item.

- Milestone Tracking: Each project is accompanied by a digital dashboard that displays real-time progress updates against the quoted timeline.

- Proactive Alert System: Any potential deviation will immediately trigger a notification along with a revised mitigation plan.

Such a data-led approach helps to overcome the major issue of project planning being a guess game. We provide a reliable, upfront cost estimation and schedule certainty, thus clients can make faster sourcing decisions, optimize their budgets, and speed up their entire development cycle while having an absolute trust in our precision scheduling.

FAQs

1. What is the shortest lead time for automotive dashboard prototypes?

LS Manufacturing simply parts: 7 days, complex dashboards with electronic components: 15 days. LS Manufacturing provides a rush service and will deliver within 5 days.

2. Are engine component prototypes fit for functional testing?

We have the capacity for high-temperature, pressure, and vibration testing, with a maximum temperature resistance of 300℃ and a pressure of 1.2 MPa, which corresponds to the verification requirements of most engine components.

3. How can the cost of a small-batch production of 50 pieces be optimized?

By employing techniques like vacuum casting and rapid tooling, we can keep the cost of small-batch production at 1.5-2 times the cost of single pieces from mass production, thus providing the most cost-efficiency.

4. How do you guarantee the performance consistency between prototypes and mass, produced parts?

The mechanical properties of the prototype parts can get to 85-95% of those of the mass, produced parts by means of material performance simulation and process parameter optimization.

5. Do you supply vehicle-level prototype assembly and verification services?

We do vehicle-level prototype assembly, the workpiece size can be up to 2000×1500mm, and we provide dimensional matching analysis reports.

6. How do you cope with manufacturing accuracy for complex curved parts?

Outfitted with a 5-axis CNC machining center and combined with 3D scanning inspection, the surface accuracy can be raised to ±0.1mm, thus meeting A-class surface requirements.

7. Do you provide material performance test reports?

As a part of our service, we provide third-party test reports, thoroughly covering mechanical properties, temperature resistance, and durability.

8. How can I get a precise quote?

Send us the 3D data and the technical requirements, and within 2 hours, we will send back a detailed quote that will also include a process analysis plan.

Summary

Rapid prototyping of automotive parts requires a comprehensive consideration of functional verification, cost control, and development speed. Through scientific process selection, material optimization, and project management, the best balance between prototype development efficiency and quality can be achieved. LS Manufacturing's professional automotive prototype service system provides customers with a full-process solution from design support to functional verification.

Upload your automotive part 3D data to immediately receive your exclusive "Rapid Prototyping Optimization Plan"! Our automotive project experts will provide you with detailed technical analysis, accurate quotes, and delivery time commitments within 4 hours. Inquire now to receive a free DFM analysis to optimize your design and accelerate project progress.

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.