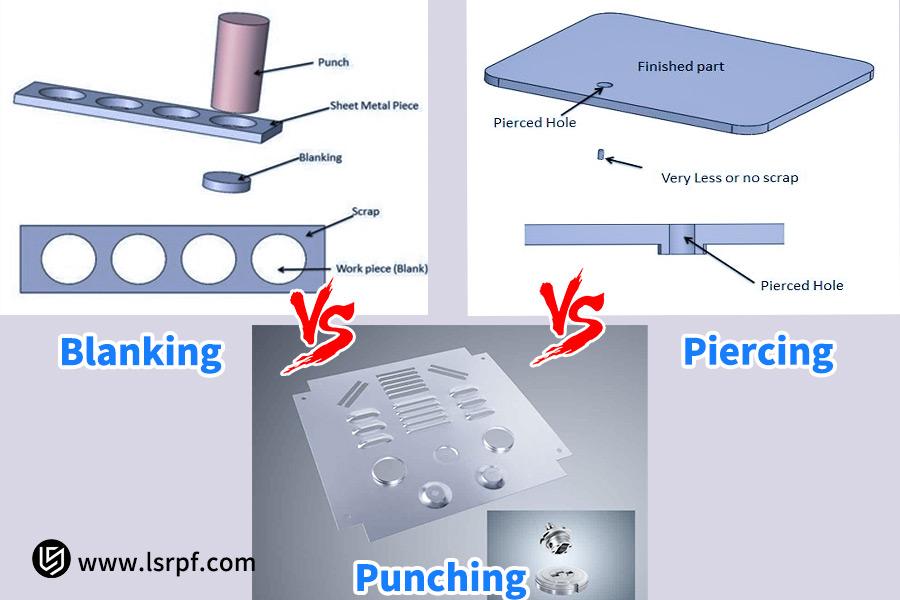

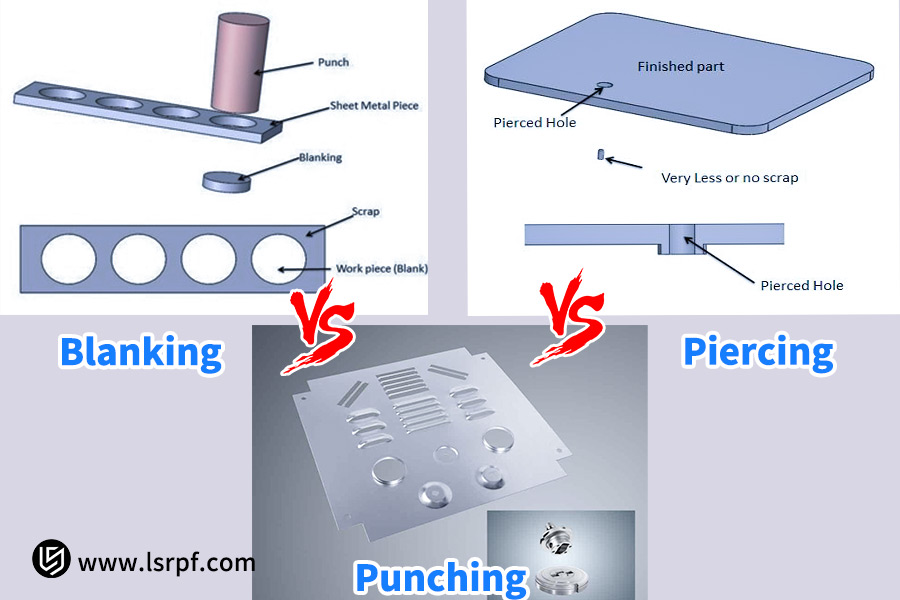

In sheet metal fabricating and stamping work, blanking, punching, and piercing are three different processes, but they are often confused due to the closeness in their operation. As a matter of fact, although the three share the common basic principle of "punching", there exist essential differences in functional purposes, application occasions, and technical details. Blanking is to obtain a complete workpiece, punching is to make holes, and perforation is more material penetration rather than shape accuracy.

Not only is mastery of their distinction the key to optimizing production efficiency, but it also directly affects product quality and cost control. In this post, we will study in detail these three processes so that you can clarify concepts, apply them accurately, and avoid process misuse and wastage of resources. To save your time, here is the summary of the major findings.

A Quick Reference Table Of the Core Differences Among Blanking vs. Punching vs. Piercing

| Characteristic | Blanking | Punching | Piercing |

| Process Purpose | Obtaining the part body | Creating a hole in the workpiece | Achieving penetration, not precise shape |

| Product | The dropped portion is the desired part | The punched portion is waste | Perforation can result in deformation or micropores in the material |

| Material Processing | Emphasis on part cross-sectional quality and dimensional accuracy | Emphasis on hole inner edge quality and dimensional accuracy | High precision and smooth cross-sections are not sought |

| Typical Applications | Manufacturing gaskets, gears, and externally contoured parts | Processing of mounting holes, locating holes, and various functional holes | Ventilation holes, drainage holes, and rough fastening holes |

| Mold Design | Based on the die dimensions, achieve a precise shape | Based on the punch dimensions, achieve a precise internal hole | Tools are typically simpler and sharper, requiring no precise clearances |

- In choosing a process, use blanking when what you are seeking is a full part;

- Punching when you are looking to create precise holes within existing parts;

- Piercing when you simply want to open up the material quickly for applications like ventilation and drainage.

Blanking and punching are precise forming operations, reverse operations (one gain, one loss). Their ultimate goal is to obtain a high-precision product or hole. Perforation is a rough penetratin operation with greater emphasis on functionality than precision.

Why Trust This Guide? Practical Experience From LS Experts

Collective decades of experience in precision metal production come with working at LS Precision. As an industry leader in solution provision, we have a full complement of advanced stamping manufacturing equipment and an R&D mold center, with emphasis on standardization of precision blanking, punching, and perforation technology innovation.

Not only are our professional personnel endowed with rigorous theory, but they also go on to provide high-precision metal parts for automotive, electronics, and medical instrument manufacturing industries at all times, rendering each inference painfully tested by industry standards.

Each process difference described in this article is rooted in our extensive practical experience. For example, we have acquired valuable practical experience in controlling blanking accuracy of core pieces in automobile seatbelt systems, maximizing the punching process of high-precision guide holes in electronic connectors, and applying micro-perforation technology to medical catheter stents.

These are real-world issues and solutions in a broad spectrum of industries so that this guide will not only provide theoretic knowledge but also practical worth to be used right away in practice in production.

Blanking: How To Get The Outline

One of many stamping operations, with a crucial influence on shaping the product as a whole, is blanking. Blanking is usually the first of all production processes, and its quality has a direct impact on the accuracy of subsequent bending, drawing, and forming processes and the quality of the end product.

1. Definition of blanking:

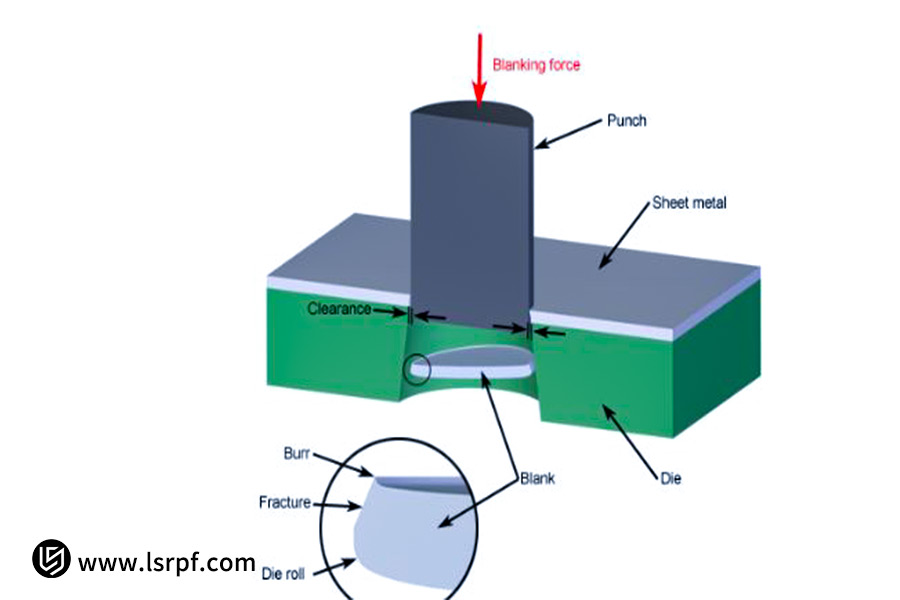

From the technical perspective, blanking is a process of cold working by which a mechanical or hydraulic press, assisted by a specifically designed blanking die, applies high pressure on a sheet metal sheet. The operation, with the accurate coordination of the punch and die of the die, shears and cuts the sheet metal along a previously determined closed boundary. The entire process is for producing a flat component or blank of specific size and shape with high efficiency and accuracy.

2. Blanking process purpose:

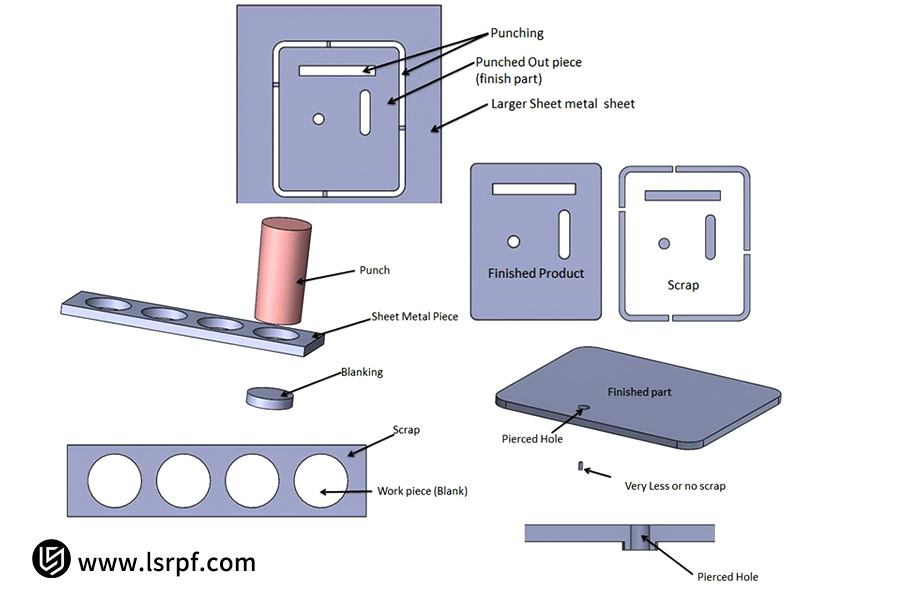

The blanking process's secret lies in its purpose: to attain the whole profile of the product. Therefore, after stamping is complete, the part falling off the die is the needed finished product, and the remaining frame (named the blank frame or skeleton) on the sheet is waste.

3. Understanding blanking process:

A typical process diagram makes the process simple to visualize: the sheet is placed into the die, where a blank holder initially presses the material to prevent displacement. The punch then descends, in synchronization with the die, to shear the material, ultimately ejecting the finished part from the die cavity.

4. Design of blanking:

The design of the blanking die is the focal point in this process, and the punch-to-die clearance is one of the important parameters:

- Too little clearance will cause secondary shearing of the cross-section and encourage die wear;

- Too much clearance will cause excessive angle collapse, burrs, and a slanted fracture band.

Correct clearance will produce a good quality, bright band (typically around one-third of the sheet thickness) on the workpiece cross-section and hence improve product quality.

5. Application of blanking:

Due to its high precision and efficiency, blanking has widespread uses. Application of blanking include, but are not limited to:

- General parts: gaskets of various specifications, retaining rings, and silicon steel sheets for electrical appliances.

- Consumer electronics: mid-plates of mobile phones, watch cases, eyeglass frames, and exterior panels of small appliances.

- Automotive industry: various high-strength steel sheet cover blanks for doors, hoods, and chassis of cars.

- Precision components: motor cores, chip lead frames, and other products with extremely stringent dimensional requirements.

Blanking is a precision separation process with the ultimate result of a high-precision, high-quality finished part. Its technological level is represented by cross-sectional quality, dimensional accuracy, and productivity, and it is a key, basic, and important processing technique in modern manufacturing.

Punching: The Process Of Creating Internal Features

After blanking the external shape of the part, adding functional internal structure becomes necessary, which is the main job of the punching process. While blanking is focused on obtaining a certain shape, punching is focused on creating precise internal details such as holes and slots.

1. Definition of punching:

Punching can be defined as a procedure for creating a hole of the necessary shape and size in already existing sheet metal, semi-products, or finished parts by applying pressure to them in order to separate them along open or closed contours with the assistance of a special punching die.

2. Punching process purpose:

The character of the punching process is explained by its purpose: to create internal features. Therefore, after punching is finished, the material that is removed and separated from the die is waste, or shavings, and the workpiece itself, or the initial sheet metal, is the desired product to be retained.

3. Punching vs. blanking:

In blanking, the "part to be punched out" is the blanking, while punching is the "part to be retained." The basic shape of a punching die is the same as a blanking die, consisting of a punch and a die. Its design, nevertheless, is intended to preserve the accuracy of hole location, size, and cross-sectional quality. Proper clearance between punch and die is also necessary to control burr size and cross-sectional quality.

4. Application of punching:

Punching is extremely versatile, and is used in nearly all sheet metal products. Application of punching include:

- Electronic and electromechanical enclosures: ventilation grilles and cooling vents on switch cabinets and computer cases.

- Mounting and functional holes: mounting screw holes, locating holes, and waist-shaped slots on most plate-like parts.

- Sieve and filter equipment: sieve plates, filter screens, and filter end caps in a variety of materials.

- Articles for daily use: stainless steel colanders, door and window hinge holes, and belt buckle pinholes.

Punching is a high-precision separation process for creating high-quality internal features in finished parts. It is the counterpart of blanking, forming the foundation of the separation operation in stamping and an important technology that is fundamental to part functionalization.

Piercing: A Special Form Of Dense Punching

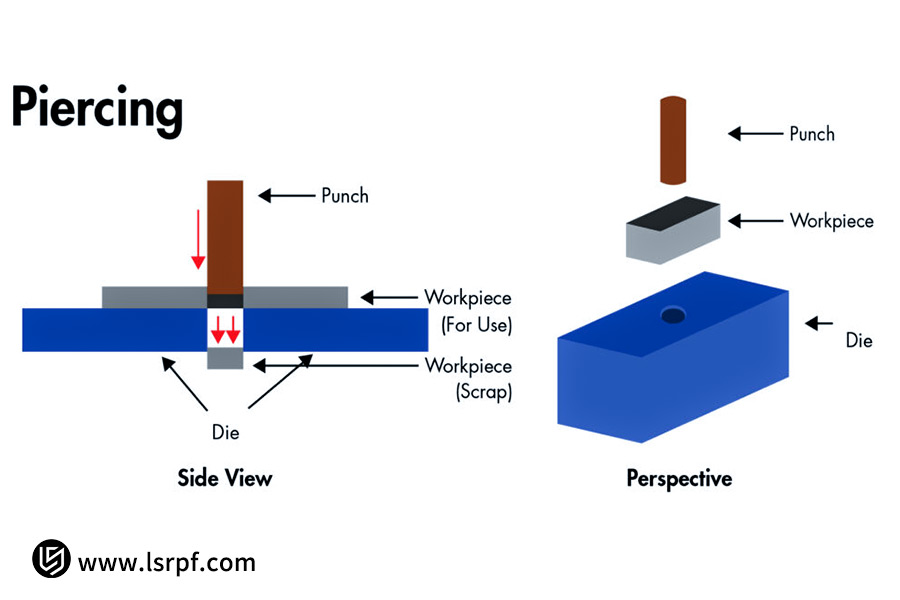

In stamping, perforation is an important operation when numerous holes at uniform intervals are to be successfully produced in a material. It is actually a specialized form of punching and a highly useful application, aimed at meeting some functional requirements.

1. Definition of piercing:

Piercing can be generally defined as a specialized punching operation that uses specialized perforating dies or machines to continuously and speedily produce a series of close-tolerance holes in a regular pattern (e.g., straight line, grid, or pre-established pattern) in a sheet or workpiece. The heart of the piercing process lies in its "dense" and "regular" character. It is not designed to make one hole or several holes, but to make a huge number of holes quickly.

2. Piercing process purpose:

The role of these special punching techniques is not the same as the role of ordinary punching. They are not always for mounting or locating, but for achieving special functions, such as ventilation and heat dissipation, filtration of liquid or gas, drainage, decoration, lightweight, and the creation of tear strips that are easily torn or deformed.

3. Special piercing die:

To achieve this type of high-efficiency, high-density punching, special piercing dies are generally used. Some examples include:

- Needle dies: These consist of a large number of minute needle-shaped punches in a regular pattern so that a single stroke of the machine generates the entire pattern.

- Step dies: These utilize one or several rows of punches. The sheet material is advanced through the machine's automatic feeding system, building up the total pattern through a number of passes of punching.

- Specialized equipment, i.e., drum punchers, employs a die mounted on a drum that rotates continuously to perforate the material, very high efficiency is attained.

Piercing is a highly efficient specialized punching operation that utilizes specialized piercing dies and equipment to rapidly produce a regular, dense pattern of holes for some specific purpose. It is an excellent operation to accomplish specialized functions such as ventilation, filtration, and decoration.

The Basic Differences Among Blanking, Punching, And Piercing

The simplest method to instantly understand the differences between blanking, punching, and piercing is to compare them using the following table:

| Characteristic | Blanking | Punching | Piercing |

| Process Purpose | Obtaining part shape | Creating internal holes | Achieving functionality (ventilation, filtration, etc.) |

| Product (Finished Product) | Punched portion | Stamped parent material | Stamped parent material (with hole array) |

| Waste | Remaining sheet metal frame | Punched chips | Punched chips (large quantities) |

| Essence | To obtain finished parts | Feature on finished products | Dense punching special shapes |

| Precision Requirements | Very high (determines the shape of the product) | High (determines the hole location and size) | Medium (sufficient to meet functional requirements) |

The above comparison clearly indicates the essential differences:

- Blanking: The purpose of blanking is to obtain the punched part itself, while sheet metal is scrap.

- Punching: The purpose of punching is to create holes in the remaining sheet material and the punched-out material is scrap.

- Piercing: It is a specialized form of punching, aims to impart a wanted function to the remaining parent material by creating a close pattern of holes. Precision accuracy is secondary, and efficiency and consistency take precedence.

Process And Die Characteristics: How Is "Separation" Achieved?

Though blanking, piercing, and punching differ in product and purpose, the physical process of material separation is the same: all utilize a die on a press to apply a high shear force to the sheet material, larger than its shear strength, in order to cause it to fracture and separate. However, to achieve different quality goals, the die design philosophies are very different.

The basic differences in die design:

The basic differences in die design are primarily in dimensional standards and subtle design:

1. Blanking Die:

Blanking die edge dimensions are the standard. Because the aim in blanking is to produce dimensionally precise parts, and the parts fall from the die hole, the nominal dimensions of the die edge clearly define the overall dimensions of the finished product. The punch dimensions are therefore smaller compared to the blanking clearance.

2. Punching Die:

The punch edge dimensions are used as a reference. Because punch-ing's aim is punch-ing an accurately sized hole, and the hole's size is determined by the punch that punches the material, the nominal sizes of the punch directly determine the internal dimensions of the hole, and die sizes are increased appropriately based on the clearance.

3. Piercing Die:

As a specialized punching die, the primary challenge is the safeguarding of the small punch. Because punches used in piercing (e.g., needle punches) are thin and numerous, they tend to deflect and break easily. Therefore, the die design must incorporate high-precision protective plates and guides to provide accurate guidance and protection to these thin punches throughout the process so that they do not break from lateral forces.

Gap selection:

Gap selection is a common technology among the three, yet the selection differs with the application. Blanking clearance (the space between the die and punch) is material type and thickness dependent, and its dimension has a direct effect on cross-sectional quality and die life.

Dissimilar objectives impose various sensitivities to gap variation: Blanking and precision punching require tight control of clearance. In order to sustain dimensional and cross-sectional dimensions; whereas certain perforation operations are focused on functionality and may accept a comparatively high level of clearance.

The three operations share the same separation principle but vary in mold design. Their comprehension is based on an understanding of the dimensional basis as well as the use of individual mold reinforcement and protection according to process details.

Quality And Precision Comparison: In What Ways Do The Outcomes Vary?

Although blanking, punching, and perforation are each a different process, their final results differ significantly in quality and precision. The differences directly influence product performance, appearance, and conditions of application.

1. Cross-Section Quality

All three processes produce typical punched cross-sections, i.e., glossy bands, fractures, and burrs, but with different quality requirements and difficulties in control.

Blanking and punching: The most exacting requirements for cross-section quality are demanded. Ideally, the cross-section should have a smooth, shiny band extending over at least one-third of the material thickness, with even breaks, and burr height strictly controlled. Quality is attained primarily by precise blanking clearance and sharp cutting edges.

Piercing: Cross-section quality is prioritized over functional performance. Due to the punch's smallness and high density, chip removal and cooling are problematic, and burrs are relatively more difficult to manage. Slightly larger burrs are accepted as long as they don't affect core functions (e.g., filtration and ventilation).

2. Dimensional Accuracy

Blanking: The final dimensions of the blanked part are regulated by die size and wear.

Punching and piercing: The punched or perforated hole size is subject to the punch size and wear.

The general influence factors of accuracy: Die wear (dimensional change and burr increase due to blade blunting), equipment precision (die centering assurance during punching), and sheet metal location precision. In punching, because of the relatively weak punch strength, dimensional stability can be influenced by minor offset or wear during long-time operation.

3. Speed and Efficiency

Blanking and punching: High-speed punch presses can be extremely efficient in production, with stroke rates in the hundreds or even thousands of strokes per minute, and are highly suitable for large-scale automatic production.

Piercing: Production rates are generally limited. To avoid the small and fragile punch from premature fatigue fracture due to high-frequency impact, punching is generally performed below the maximum speed. This is at the cost of some efficiency in exchange for die life and stability.

- Blanking and punching are precision-oriented processes, attaining high-quality cross-sections and precise dimensioning for product assembly and function.

- Piercing is a function-oriented process, with functional application of the hole array and mold longevity being emphasized, with some degree of quality maintained and potential trade-offs in precision and efficiency.

Material And Cost Considerations: How To Trade-Off And Select

In choosing among blanking, punching, or piercing, apart from technical feasibility, material and cost are significant commercial considerations for the final decision. Different process routes directly affect material consumption, production efficiency, and mold investment, and an overall trade-off is required.

1. Material Utilization

Blanking: Material consumption is one of the basic cost factors. Minimization of the area of scrap skeletons on the sheet by optimizing the layout (e.g., cross-laying or multi-row layout) is the most significant technique for unit cost saving.

Punching and piercing: Both these processes are performed on already existing blanks or semi-products. Their material efficiency depends primarily on the spacing of the holes themselves. In design, in addition to retaining the structural strength and purpose of the part, hole spacing should be minimized so that material waste is less.

2. Effect on Material Strength

The blanking operation produces cold work hardening of the material in the cut area, increasing hardness but reducing plasticity. This is risky for subsequent processing.

Blanking and Punching: In case other bending or flanging operations are required, the bend line should be kept as close as possible to the blanked edge to prevent cracking of the hardened area.

Piercing: Due to the closely spaced perforations, the hardening effect on the nearby material is more severe and localized and can lead to brittleness of the entire perforated area. This factor must be given complete consideration when designing parts requiring secondary forming.

3. Die Cost and Life

Blanking and standard punching dies: High initial investment but relatively low cost of dies. High-quality, wear-resistant steel (such as SKD11) punch and die dies can be durable and can produce hundreds of thousands to millions of pieces, so the die cost per piece is lower.

Piercing dies: The significant die cost considerations are maintenance and consumables. Small punches are consumable parts, easily worn out, bent, or broken by successive impact. Die changes therefore become more frequent, contributing significantly to maintenance cost and comprising a large portion of total production cost.

In selecting a process, a total cost trade-off must be made:

- Blanking strives for optimization of material layout for optimum material utilization;

- Punching requires a trade-off between hole design and material hardening;

- Piercing can offer special functions, the excessive cost of die maintenance must be factored into the total cost consideration or a high cost penalty will be paid.

How Do I Select The Proper Process For My Project?

In high-precision manufacturing projects, deciding on the most appropriate sheet metal fabrication method for your product is the first step towards ensuring performance and controlling costs. With a variety of processes to select from, including blanking, punching, and piercing, you can apply the following easy decision-making process to arrive at a way forward within minutes:

Step 1: Decide your desired end product

Need the "outline" or "blank" of the actual product.

Choose Blanking. (For instance: gears, gaskets, housing profiles)

Need to machine a "hole" or "internal feature" in an existing sheet metal or part. Proceed to step two.

Step 2: Determine which hole feature you need

1.Need one or more independent holes (for instance, mounting holes, locating holes, or vias).

Choose Punching.

2. Need a large, smooth regular "dense array" of holes (e.g., screens, radiator grilles, or decorative patterns).

Select Piercing.

For high-complexity projects, consult the experts:

The above process is sufficient for most simple decisions. If your project, on the other hand, involves high-strength materials, very tight tolerances, complex assembly operations, or high quantities in production, the optimum process is often the synergistic application of a number of technologies.

If you're still in doubt, contacting an expert manufacturer such as LS Precision to advise is the best way to ensure that your project is foolproof.

LS Precision Manufacturing Case Study: Integrated Blanking And Punching Processing For High-Precision Automotive Brake Pad Baffles

1. Customer Pain Point:

An automotive supplier needed to manufacture in volume a high-strength steel baffle for a brake system. Not only was the high-accuracy contour (blanking) of this automotive part critical, but the positional tolerances for the various mounting holes (punching) required for assembly were very tight (less than ±0.03mm).

2. LS Precision Solution:

The engineering team at LS Precision designed and manufactured a multi-station precision progressive die. Within this die, the strip is precisely fed by an automatic feeder. All operations—punching pilot holes, initial blanking, precision punching, final blanking, and separation—are performed at various stations in a single continuous stamping stroke.

3. Results:

This high-precision progressive die solution achieved a stable and high production rate of 60 parts per minute, far exceeding customer expectation. 100% of the product dimensions were within tight automotive safety specifications, and the mass production yield was as high as 99.8%. LS Precision Manufacturing not only solves customers' technical and quality problems, but also significantly reduces their overall procurement cost per part by extremely high production efficiency and material utilization, therefore increasing their market competitiveness.

FAQs

1. Which of the three operations is the most expensive?

Punching and blanking costs depend on mold complexity and material consumption, while piercing, as it entails a large number of holes, could contribute to the expenses of the number of presses and mold costs, requiring careful analysis.

2. What is the best machining accuracy achieved?

At LS Precision Manufacturing, our technicians utilize precision molds to achieve exceptionally high machining accuracy of ±0.01mm, meeting the stringent requirements of most precision parts. Contact LS Precision to process your parts.

3. Can these processes be applied to all metal materials?

Yes, they can be performed from soft metals like aluminum and copper to hard materials like stainless steel and carbon steel, but molds need to be specially created based on the material's properties.

4. Can these three processes be combined?

Yes. Their processes can be combined. This is the most effective solution for precision manufacturing. For example, a progressive die allows multiple operations, such as punching and blanking, to be accomplished sequentially in a single die, significantly improving efficiency and accuracy.

Summary

Although blanking, punching, and piercing are all separate stamping processes, they each have a different fundamental function, technical focus, and application scenario. Blanking deals with the formation of high-precision product outlines, punching deals with the formation of inner hole details, and piercing involves the formation of large and densely arranged holes for special purposes. In precision manufacturing, the right process has a direct influence on product quality, production efficiency, and the total cost of the project.

If you are unsure of the best process for your product, LS Precision has a team of process experts available to help. Contact LS experts today for a free process solution analysis and accurate quotation.

Upload your design drawings now and get an instant metal stamping quote (metal stamping price), let LS be your strong backing in pursuit of ultimate metal stamping precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com