Instant Quoting

Instant Quoting Rapid Prototyping

Rapid Prototyping High-Volume Production

High-Volume Production

Instant Quoting for Your Spring Manufacturing Needs

LS Manufacturing provides instant, accurate quotes for all your custom spring and wire form needs. Our automated quoting engine analyzes your design to deliver a competitive price and lead time in minutes, not days. From concept to production, we ensure precision and efficiency at every step.

Choose from a variety of materials including music wire, stainless steel, galvanized steel, copper alloys, and high-carbon steel for optimal performance, durability, and corrosion resistance.

We provide plating, powder coating, passivation, oven baking, and more, with lead times averaging 2-4 days for surface treatment, enhancing the spring's performance and lifespan.

Achieve tight tolerances for various spring types, including compression springs, torsion springs, flat springs, and wire forms, ensuring perfect fit and functionality in your application

ITAR Registered

ITAR Registered ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

ISO 9001:2015,ISO 13485:2016,AS9100D and lATF 16949:2016 Certified

Upload Your Design & Get an Instant Quote Now!

Custom Spring Manufacturing Services

LS Manufacturing provides professional custom spring manufacturing services, including compression springs, extension springs, torsion springs, and special-shaped springs. Utilizing advanced coiling technology and strict heat treatment processes, we ensure precise force-deflection characteristics and long service life for automotive, electronics, medical, and industrial applications.

Rapid Quoting & Solution Evaluation:Receive instant quotes and manufacturability analysis by submitting spring parameters (wire diameter, OD, coils, etc.)

Full-Scale Spring Production:Wire diameter range 0.1-10mm, supporting materials like stainless steel, music wire, and copper alloys

Expert Performance & Process Support:Offer stress analysis, fatigue testing, and surface treatment (plating, passivation) guidance for optimal performance

Competitive Pricing:Automated production and process optimization provide cost-effective solutions for small to medium volume orders

Spring Manufacturing Service

Spring Manufacturing Product Showcase

Explore our high-volume spring manufacturing capabilities, delivering precision components with guaranteed consistency. We specialize in meeting exact specifications for load, durability, and on-time delivery.

Spring Manufacturing Advantages & Features

Our spring manufacturing services combine precision, consistency, and durability to provide optimal solutions for your high-volume production needs. Here's why LS Manufacturing stands out as your go-to partner for custom springs and wire forms.

Consistent Performance and Precision

Utilizing advanced CNC spring coiling machines and wire forming technology, we ensure every spring produced exhibits exceptional performance consistency and precision. We focus on maintaining strict tolerances to guarantee accurate load capacity and reliable operation, with load tolerances as low as ±5 grams and dimensional tolerances reaching ±0.05mm.

Fast Turnaround Times

Our streamlined processes enable rapid spring production without compromising quality. From prototyping to mass production, our standard lead times can be as short as 2-5 days, helping you efficiently meet project deadlines.

Wide Range of Materials

We offer a variety of materials specifically tailored for spring manufacturing, including music wire, stainless steel, carbon steel, copper alloys, and more. With over 100 material options available, we can match the ideal material to your application's specific requirements.

Custom Spring Finishes

To enhance the durability and performance of your springs, we offer a range of surface treatments such as zinc plating, phosphating, shot peening, powder coating, and more. With over 15 different custom finishes available, you can significantly improve corrosion resistance, reduce friction, and extend the fatigue life of your springs.

Scalability from Prototypes to High-Volume Production

Our spring manufacturing services are designed to accommodate any order volume, from single prototypes to large-scale production. With the capability to produce anywhere from 1 to 1,000,000+ springs, we support your evolving project needs with flexibility and scalability, ensuring consistent quality at every volume.

Comprehensive Quality Assurance

We implement a strict quality assurance process that includes in-process inspections and final checks using precision measurement equipment like optical comparators and load testers. Our ISO 9001, ISO 13485, IATF 16949 and AS9100D Certification underscores our commitment to delivering springs that meet the highest standards of reliability and performance.

Spring Manufacturing Case Studies

Our custom springs and wire forms have been successfully implemented across diverse industries. Below are examples showcasing our ability to deliver high-performance, durable components engineered for high-volume production requirements:

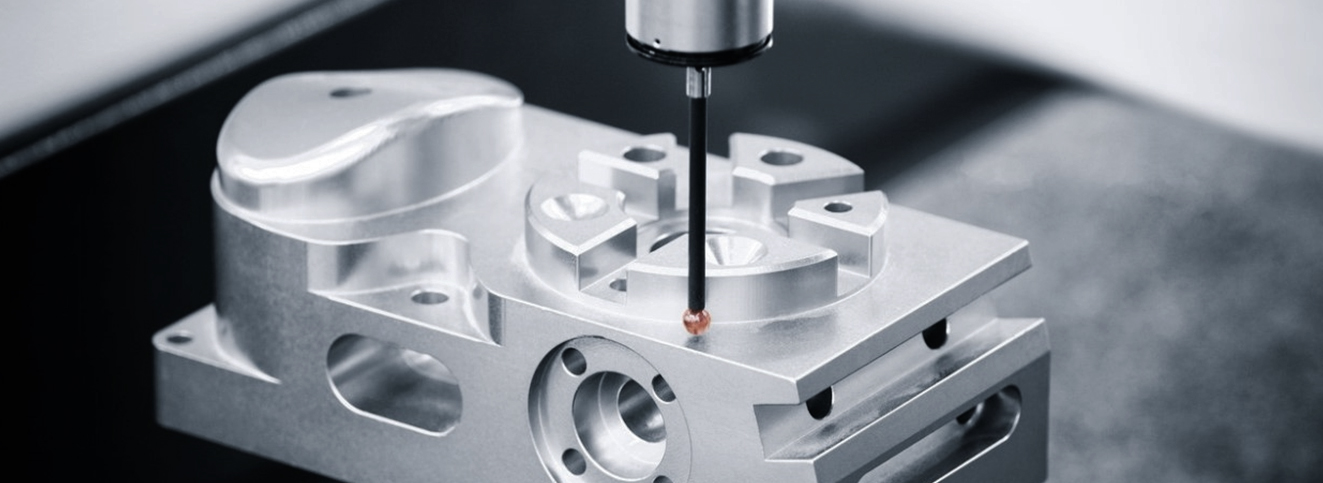

Spring Manufacturing Quality Control

At LS Manufacturing, quality is our top priority in spring production. We implement rigorous quality control throughout the entire manufacturing process to ensure every spring meets the highest standards of precision, durability, and performance. Our comprehensive quality assurance system utilizes advanced inspection methods to deliver consistent, reliable products for high-volume applications.

In-Process Inspections

Our quality control begins with in-process inspections, where each part is checked at various stages of production to ensure adherence to design specifications. This proactive approach helps identify and correct any issues early in the manufacturing process.

Final Inspections

Before any part leaves our facility, it undergoes a thorough final inspection to verify its quality and precision. We use advanced measurement tools and techniques to ensure that each part meets the required specifications and standards.

Precision Measurement Tools

Our quality labs feature spring testing machines, digital calipers, and surface analyzers to measure load rates, fatigue life, and material properties with exceptional accuracy.

ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification

Our commitment to quality is demonstrated by our ISO 9001,ISO 14001,IATF 16949 and AS9100D Certification. This international standard ensures that our quality management system is effective and continuously improving, providing our customers with consistent, high-quality products.

Continuous Improvement

We believe in continuous improvement and regularly review our processes and practices to identify areas for enhancement. By investing in the latest technologies and training for our staff, we strive to maintain our reputation for quality and innovation.

Need Assistance? We're Here for You.

If you have any questions or need assistance, our team is ready to provide support 24/7. Reach out to us through any of the methods below.

If you have any questions about spring design, materials, or manufacturing processes, our engineering team is ready to provide technical support. Contact us through the form below for prompt assistance.

What Our Clients Say About Us

A customer's words mean more than ours see what our satisfied customers have saidabout how we fulfilled their requirements.

Spring Manufacturing Latest News

Stay updated with the latest news and announcements from LS Manufacturing. Explore our latest articles below.