This design drawing is a "technical contract" in the eyes of the manufacturer- its lines and annotations directly define the cost, cycle and quality.

This article takes the precision aluminum frame as an example,dissecting the key details in the drawing (radii, hole types such as countersunk holes/through holes, groove depth), revealing how they significantly affect manufacturing costs, delivery time andfinished productstrength. Small design choices have huge consequences.

Designed for product designers and engineers, it helps you upgrade from "design thinking" to "manufacturing expert thinking". Understanding these "manufacturing languages" allows you to control budgets and quality at the source of design and avoid rework later.

This is the key to achieving "simplified supply chain:get a single price forgear machiningand housing". When your design accurately "speaks" the "language" of efficient execution by manufacturers, complex requirements can be integrated and optimized, and the supply chain response is more agile and transparent.Understanding the manufacturing language is the first key to controlling the cost and efficiency of your supply chain. Let's start the in-depth analysis.

Here’s What You’ll Learn:

- 60-second material decision rule:quickly lock in the gold standard ofaluminum/stainless steel/plastic, and balance cost and performance.

- Hidden cost codes of three major design features:how deep pocket processing, fillet radius, and hole type processes directly affect your quotation.

- 5-axis machining pitfall avoidance guide:When is 3-axis enough? When must you upgrade? Critical point analysis to save 30% of costs immediately.

- Dissecting the 5 major elements of professional quotations:from one-time programming fees to tiered discounts, understand the underlying logic of each cost.

- The finishing touch of surface treatment:analysis of actual cases ofsandblasting + anodizing, how 0.1mm thickness affects durability and aesthetics.

- The ultimate FAQ from the production line:conquer the minefields of "zero radius internal angle" and "blind hole thread tolerance" that even engineers are prone to step on.

Now, unlock the underlying logic of design is cost and become the core decision maker of supply chain cost control.

The Cornerstone Of The Material: Why Does It Look Like Aluminum?

When examining this precision-machined part, its appearance features provide us with important material clues. Visual analysis shows that the part surface has a typical metallic luster, and a close look at the machining marks (such as milling lines and drilling edges) shows that its characteristics are highly consistent with the machining performance ofaluminum alloys, especially 6061-T6 grades. The marks, reflective properties and texture left by this alloy after machining are reliable basis for experienced engineers or machinists to identify its material. Therefore, based on these significant visual features, we are highly confident that the part is made of 6061-T6 aluminum alloy.

So why choose aluminum instead of equally common stainless steel or engineering plastics? This stems from the matching of the core properties of different materials with application requirements:

Why choose aluminum? Comparison of stainless steel and engineering plastics:

| Features | Aluminum (e.g. 6061-T6) | Stainless steel | Engineering plastics (e.g. Delrin, PEEK) |

|---|---|---|---|

| Weight | Light (significant weight reduction) | Heavy | Lightest |

| Strength/rigidity | High strength-to-weight ratio | Highest strength/rigidity | Lower |

| Thermal conductivity | Good (good for heat dissipation) | Medium | Insulation |

| Processability | Excellent (easy to process, efficient, low cost) | Poor (difficult, high cost) | Good (but be careful of deformation/burrs) |

| Surface treatment | Flexible and easy (e.g. anodizing) | Optional (higher cost) | Limited |

| Corrosion resistance | Good (enhanced after anodizing) | Excellent | Depends on the material |

| Cost | Low combined cost of materials and processing | High cost of materials and processing | Variable material cost (PEEK is very high) |

6061-T6 aluminum is an ideal choice for this part because of itsexcellent lightness, strength, thermal conductivity, and especially excellent processing performance (high efficiency, low cost) and good overall cost-effectiveness.Although stainless steel is stronger and more corrosion-resistant, it is too difficult and expensive to process; although engineering plastics are light and insulating, they lack strength and rigidity. The visual gloss and marks are the embodiment of the easy processingcharacteristics of aluminum. The material selection fundamentally determines the manufacturing cost.

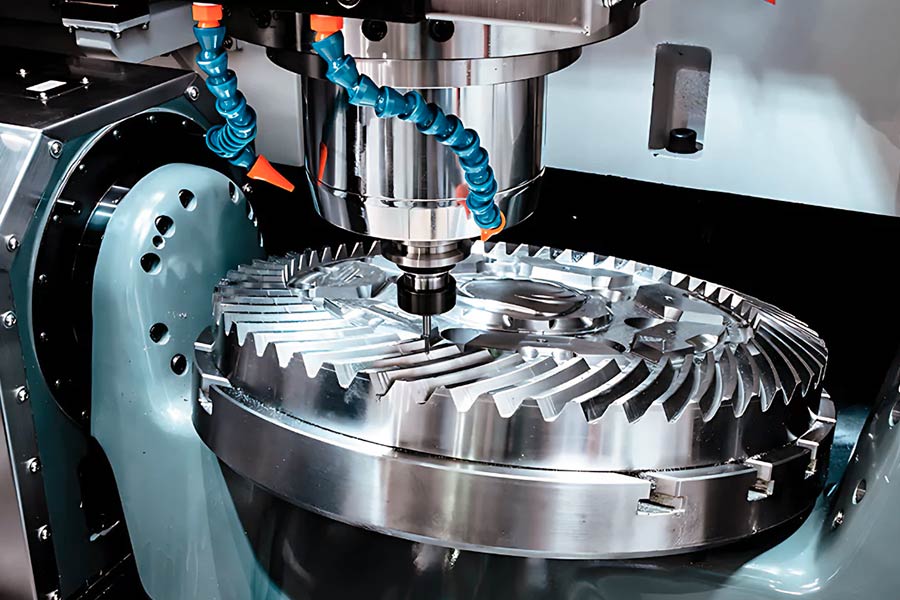

Core Technology: The Art Of 3-axis CNC Milling

1. Process applicability analysis

- Flat surface:Efficient processing can be achieved with aface millingcutter in one pass, and the X/Y/Z linear motion of the3-axis machine toolfully meets the needs.

- Vertical hole:Standarddrillormilling cuttercan be directly completed along the Z axis feed without angle adjustment.

- Rectangular groove:The end mill is achieved by layered cutting (Z-axis downcut) with X/Y axis contour pass, and the process is mature and stable.

2. Economic advantage

- Low equipment cost:The purchase and maintenance cost of 3-axisCNC machine toolsis much lower than that of 5-axis, and the operation threshold is low.

- Simplified programming and clamping:No complex multi-angle positioning is required, and most feature processing can be completed in one clamping, shortening the working time.

- High material utilization:Reduce waste by optimizing the tool path, suitable for mass production.

3. When do you need to upgrade to 5-axis machining?

- Complex surface:If the part contains non-orthogonal surfaces (such as turbine blades, organic shapes), 5-axis linkage is required to avoid tool interference and ensure accuracy.

- Lateral features:holes/grooves that are not perpendicular to the reference plane (such as inclined holes and sidewall bosses) require the workpiece to be rotated to adjust the processing angle.

- High-precision requirements:For hard-to-reach areas such as deep cavities and narrow gaps,5-axiscan optimize the tool posture to improve surface quality.

4. Process economy of this design

- Avoid high-cost features:strictly adopt orthogonal geometry (all holes are perpendicular, and the side walls of the grooves are parallel to the main axis) to avoid lateral processing requirements.

- Step-type structure replaces curved surfaces:Use multiple flat steps to achieve height changes (such as the bottom of the groove in the figure), which is more than 50% more efficient than curved surface processing.

- Cost comparison:If5-axis machiningis used instead, the cost per piece may increase by 2-3 times. This solution achieves high cost-effectiveness through design constraints.

This part is a typical design for 3-axis milling - exchanging geometric constraints for significant cost advantages, proving that simplifying the process path can become a core competitiveness.

The Devil Is In The Details: Cost Analysis Of Design Features

1. Deep pockets vs. shallow grooves

(1) Core issues: Material removal & tool stability.

(2) Cost drivers:

Processing time: Removing large amounts of material requires longermilling pathsand slower feed rates. Time is one of the biggest determinants of cost.

Tool overhang: Processing deep pockets requires longer tools. The longer the overhang:

The poorer the tool rigidity, the more prone it is to vibration, resulting in reduced surface quality and difficulty in ensuring dimensional tolerances.

Cutting parameters (speed, feed) must be significantly reduced to avoid tool breakage or excessive vibration, further slowing down the processing speed.

Tool wear increases, increasing tool costs and tool change time.

(3) DFM recommendations:

Minimize pocket depth: Design pockets as shallow as possible while meeting the functionality.

Consider alternatives: Can multiple shallower cavities replace a deep cavity? Can welded/assembled structures replace integral milling?

Stepped design: If depth is unavoidable, consider designing it in steps to allow for step-by-step machining with shorter tools.

2. Inner corner radius

(1) Core issue: Tool geometry limitations.

(2) Cost drivers:

“Zero radius” trap: The perfectly sharp inner corner (R=0) on the design drawing cannot be achieved by standard milling. Themilling cutteris cylindrical and will inevitably leave a fillet with a radius equal to the tool radius.

Expensive post-processing: If the function must be a sharp corner or a very small fillet (R < the minimum available tool radius), then:

Electrical discharge machining(EDM): Very time-consuming and expensive equipment, significantly increasing part cost and delivery time.

Manual corner cleaning: Inconsistent, inefficient, difficult to control quality, and increased labor costs.

(3) The cost of a small radius:

Even if the radius is greater than zero but very small (such as R0.1mm), an extremely fine tool must be used, resulting in:

- Extremely slow processing speed (small tools must have low feed).

- The tool is very easy to break, increasing costs and the risk of production interruption.

- More finishing paths are required.

(4) DFM recommendations:

Specify a reasonable and sufficiently large internal fillet radius: This is one of the golden standards for excellent DFM. The radius should be greater than or equal to 1.2 - 1.5 times the radius of the tool used for the expected machining depth in the area (leaving room for tool selection).

Uniform radius: Use the same fillet radius on the part as much as possible to reduce the number of tool changes.

Communicate with the processing party: Understand their commonly used tool library and design the radius to match their standard tools (e.g. R3mm, R5mm is better than R3.17mm).

3. Types of holes

(1) Core issues: Process complexity and number of tools required.

(2) Cost drivers:

①Through holes:

Simplest and most economical. Usually completed in one go with a drill (may require a center drill).

Lowest cost and fastest processing.

②Counterbores/Countersinks:

Additional processes: Need to drill first, then use a special countersink/countersink to process the countersink/taper.

Increase tool change time: Each tool change consumes machine tool running time (even automatic tool change takes several seconds to more than ten seconds, which can be considerable in batch production).

Increase tool cost and management: Additional special tools are required.

The cost is significantly higher than through holes (may increase time/cost by 50%-100% or more, depending on depth and quantity).

③ Tapped Holes:

Most processes: Usually require: drilling → (possibly chamfering) → tapping.

High-risk processes: The tap is prone to breakage during tapping (especially for small threads, deep threads, and hard materials). If it breaks inside the hole, it is very difficult to handle and may cause the workpiece to be scrapped.

Special equipment/tools: Taps are required (manual, machine, extrusion taps, etc.), and tapping fixtures or specific tapping cycles may be required.

Slow speed: The tapping speed is relatively low.

Highest cost: Significantly higher than through holes and countersunk holes, it is one of the most expensive common hole processing types (except for very large/deep threads). Deep threads, fine pitch threads, and blind holes are more expensive and riskier.

(3) DFM recommendations:

Prefer through holes.

Use countersunk holes/countersinks with caution to ensure that they are functionally necessary. Consider whether washers can be used instead of countersunk

holes.

Minimize the number of threaded holes and evaluate alternatives:

Can through holes + nuts/studs be used?

Can self-tapping screws be used (for specific materials and strength requirements)?

Can self-clinching nuts, wire thread inserts, etc. be used?

Optimize thread design:

Avoid blind holes with excessive depth (depth not exceeding 1.5-2 times the hole diameter).

Give priority to coarse threads (easier to process than fine threads).

Ensure the bottom hole size is correct.

Design necessary undercuts (bottom) or introduce chamfers (top).

What Are The Secrets To Getting Accurate Quotes?

1. How the instant quote platform works

Upload model: Submit 3D files in STEP/IGS format to define the geometry.

AI analysis: Automatically identify processing features (holes, surfaces, etc.) and evaluate complexity and manufacturability.

Input parameters: Select material, quantity, post-processing (such as anodizing).

Generate quote: The system integrates data, calculates costs and outputs a quote.

2. Interpretation of the quotation: In-depth analysis beyond the total price

A professionalCNC machiningquotation is not just a final total price figure. It should clearly break down the cost structure, let the user understand where the money is spent, and provide a basis for optimizing the design or order strategy. The following is a detailed interpretation of the key components and their impact on the final price:

Professional CNC machining quotation analysis table

| Quotation component | Detailed description | Impact on the final price | Cost optimization strategy |

|---|---|---|---|

| Setup cost | One-time fee for preparing to produce your specific parts. Includes: - CNC program writing (CAM programming) - Preparation and installation of special fixtures/tooling - Machine tool setup and debugging - First article inspection |

Significant impact on small batch/prototype prices: In single-piece or small-batch production, the setup cost allocated to each part will be very high and become the main part of the unit price. Amortized in mass production: As the quantity increases, the fixed setup cost is allocated to more parts, and the per-piece amortized cost drops sharply. |

Small batch: Accept a higher unit price. Batch: Increase the quantity to dilute the unit setup cost. |

| Material cost | The cost of the original blank (blank) required to manufacture a part. Depends on: - Material type (aluminum, steel, titanium, plastic, etc. have huge price differences) - Material grade - Size and volume of the blank required - Current market price of raw materials |

Basic cost: Is the starting point of part cost. Significant difference: The cost difference of different materials can be several times or even dozens of times (such as ordinary aluminum vs. titanium alloy). Impact of blank size: Needing larger blanks to process complex parts or meet clamping requirements will increase material cost and waste. |

Material selection: Choose the most cost-effective material while meeting performance requirements. Design: Optimize design to reduce material volume/waste (such as near net shape design). |

| Machining time | The time it takes a CNC machine to actually cut material and make a part. It is the main cost driver. It depends on: - Part geometry complexity: The more features, the more complex (deep cavities, narrow slots, small features, tight tolerances), the more curved surfaces, the longer and slower the machining path. - Machinability of the material: Hard and sticky materials require slower cutting speeds. - Required machining operations: 3-axis vs. multi-axis (4-axis/5-axis), whether multiple clamping is required. - Throughput: The machining time per piece multiplied by the quantity. |

Largest cost item: Typically 40%-60% or more of total cost. Highly sensitive: A small increase in complexity can result in a significant increase in processing time. Quantity linear effect: Processing time costs increase linearly with quantity (unit time cost * unit time * quantity). |

Design simplification: Reduce unnecessary complex features, increase the allowable internal corner radius, and avoid deep cavities and narrow grooves. Tolerance rationalization: Only mark strict tolerances at key locations. Consider design for manufacturability (DFM): Consider processing efficiency and difficulty in advance when designing. |

| Finishing cost | The cost of surface treatments performed after a part has been machined. Common options: - Anodizing (hard/decorative) - Sandblasting (matte or textured finish) - Powder coating - Plating - Passivation (stainless steel) - Polishing - Laser marking |

Optional but important: Parts that are not functional may not be needed, but are often critical for aesthetics, corrosion resistance, wear resistance, specific functions (conductivity, lubricity). Additional costs: Charges are charged per part or batch, which increases the cost per piece. Multiple factors affect: Cost depends on process type, coverage area (sometimes), color requirements, treatment standards, etc. |

Select by Need: Choose only the finishing necessary for function or appearance. Standardize: It may be cheaper to choose standard processes and colors commonly used by suppliers. |

| Volume Discounts | When the order quantity increases, the unit price offered by the supplier decreases. This is mainly due to: - Dilution of setup costs: Fixed setup costs are shared by more parts. - Improved production efficiency: Continuous production reduces non-cutting time such as tool change and debugging. - Material procurement advantages: Bulk purchase of raw materials may result in discounts. - Learning curve effect: Workers become more skilled in operation. |

Key levers for reducing costs: It has a huge impact on mass production projects and is one of the most effective ways to reduce unit costs. Non-linear relationship: The decline in unit price is usually most significant when the quantity is small, and as the quantity continues to increase, the decline gradually slows down. |

Planned quantity: According to actual demand and budget, try to increase the one-time production quantity to get discounts. Inquiry strategy: You can ask for quotations of different quantity levels (such as 1, 10, 50, 100, 500 pieces) for comparison |

3 Key Points to Reading Quotations

- Look at unit cost: more important than total price, especially when comparing different suppliers.

- Analyze cost structure: identify the main reasons for high prices (materials? complexity? small batches?).

- Verify parameter consistency: confirm that materials/quantity/post-processing match requirements.

Tip: Instant quotation is an efficient estimate, and complex parts require manual review; design simplification is the core of cost reduction.

Accurate quotation relies on complete model + parameter input; the key to cost reduction lies in optimizing design complexity and rationally planning batches.

Importance Of Surface Finishing

Surface treatment process comparison overview

| Processing type | Core function | Cost impact | Typical application scenarios |

|---|---|---|---|

| Sandblasting | Uniform matte texture, covering processing marks | Medium (equipment dependent) | Appearance parts, handheld device housings |

| Anodizing | Improve hardness/corrosion resistance, provide rich colors | Medium-high (complex process) | Consumer electronics, aerospace parts |

| Wire drawing | Directed texture, enhance metal texture | Medium-high (manual time-consuming) | Decorative panels, high-end home appliances |

| Polishing | High gloss mirror, improve visual grade | High (grading process) | Jewelry, luxury parts |

| Powder coating | Strong protection, thick coating with optional colors | Low-medium (batch advantage) | Outdoor structural parts, industrial equipment |

1. The fundamentality of materials and processes

Aluminum alloy is 30%-50% more expensive than ordinary steel, but it can achieve the comprehensive value of lightweight + corrosion resistance through anodizing.

TheCNC machining timeis directly related to the cost: deep and narrow cavities (>4 times the diameter) require longer tools, which increases the time by more than 40%.

2. Cost leverage of DFM principle

Reasonable fillet: ≥R0.5mm avoids customized tools (cost ↑200%);

Avoid deep pockets: depth ≤3 times the width can reduce the need for multi-axis processing;

Uniform wall thickness: differences >20% cause deformation risks, and post-processing costs surge.

3. Trade-off between surface treatment and tolerance

Sandblasting can coverCNC toolmarks (eliminating precision machining), but will reduce dimensional accuracy by ±0.1mm;

The cost of medical-grade mirror polishing (Ra≤0.2μm) is 5 times that of ordinary sandblasting, and the necessity needs to be strictly evaluated.

Your design decision is the most powerful cost controller - from material selection to 0.01mm tolerance setting, every detail is signed for the final quotation.

Summary

In a competitive market, efficiency and cost control are crucial. In-depth self-reflection during the design phase - questioning the necessity of each feature and evaluating the rationality of each tolerance - can not only optimize product performance, but also reshape supply chain efficiency. This lean design is the core key to unlocking the integrated quotation of gears and housings.

Choosing a single strategic partner to undertake comprehensive needs will give you:

- Process simplification: end the burden of managing multiple suppliers;

- Cost optimization: design improvements and integrated procurement double cost reduction;

- Quality consistency: unified standards ensure product reliability.

Before you submit a design for quotation next time, please review your model with the perspective of this article. Ask yourself: Is this feature necessary? Can this tolerance be relaxed? By asking these questions, you will not only get a better quotation, but also a more perfect final product.

Don't let a complex supply chain slow down your pace of innovation. Start with design optimization and a consolidated quotation to start your journey of simplification!

Contact our team now to submit your well-thought-out design!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com