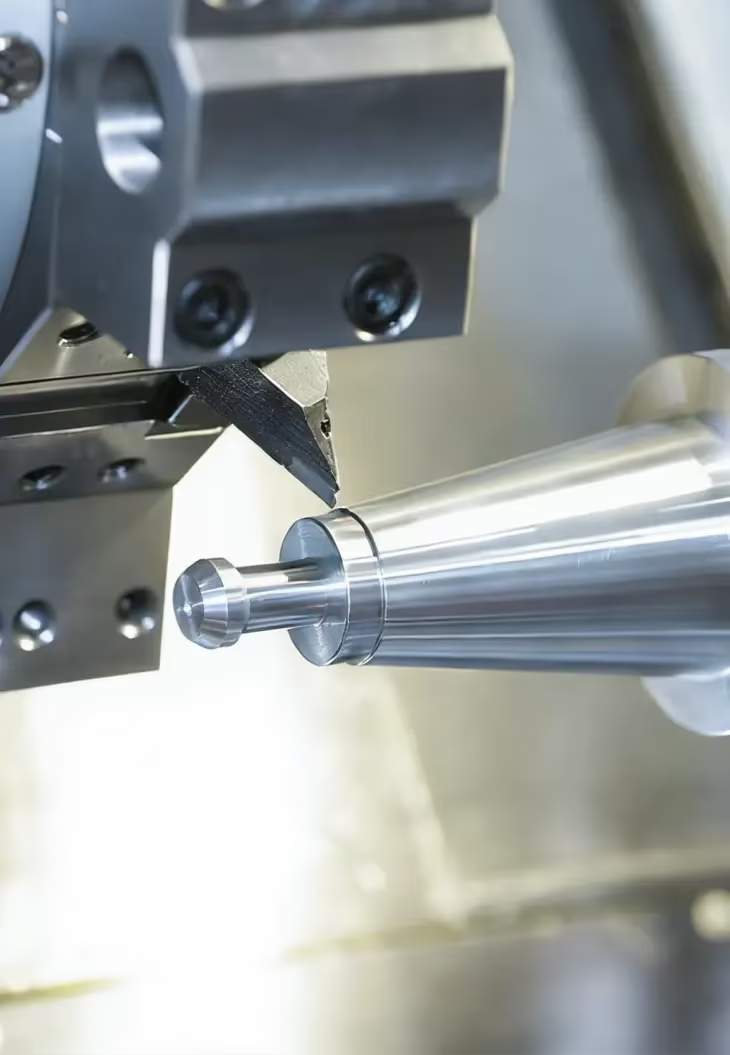

Precision machining addresses critical manufacturing challenges where component failure is not an option. LS Manufacturing delivers solutions for applications demanding uncompromising dimensional accuracy, material integrity, and performance reliability across high-stakes industries.

High-Performance Engine & Powertrain Solutions

Manufacturing of pistons, connecting rods, and transmission components with exacting tolerances to optimize power output, durability, and efficiency in demanding propulsion systems, where thermal stability and wear resistance determine operational success.

Advanced Electronic Component Fabrication

Production of connectors, shielding enclosures, and circuit substrates requiring micron-level precision to ensure signal integrity, EMI protection, and reliability in next-generation communications, computing, and consumer electronics applications.

Medical Device & Surgical Instrument Manufacturing

Creation of biocompatible implants and complex surgical tools with exceptional surface finishes and stringent cleanliness protocols, meeting rigorous medical standards where patient safety and procedural success depend on absolute precision.

Aerospace Structural & Flight Critical Components

Machining of high-strength, lightweight fasteners, brackets, and engine parts from advanced alloys, engineered to withstand extreme environmental stresses while maintaining absolute reliability in mission-critical aerospace applications.

Precision Mold, Die & Tooling Production

Development of intricate molds, dies, and production tooling with exceptional dimensional stability and wear resistance, essential for high-volume manufacturing of precision components across automotive, consumer, and industrial sectors.