When you step into the world of high-precision3D printing, the smooth surfaces and astonishing details immediately captivate you. But you'll soon be overwhelmed by a tangle of terms: SLA, LCD, and DLP. They all use photosensitive resins, but their working principles are vastly different. What exactly is "DLP resin," in particular? How does it differ from regular resins?

This guide will demystify DLP technology, explain what makes DLP resin unique, and help you understand why it's so popular in professional manufacturing.

To save you time, here is a quick overview of the core conclusions.

Quick Reference: Choose Your Tap at a Glance

|

Features |

DLP (Digital Light Processing) |

LCD (Liquid Crystal Display) |

SLA (Stereolithography) |

|

Light Source |

Industrial-grade UV projector |

UV-LED array + LCD mask screen |

Precision UV laser |

|

Working Principle |

Project the entire layer at once, just like playing a movie. Use LCD pixels as a "mask" to selectively transmit light. Use a laser dot to depict the layer outline point by point. |

||

|

Print Speed |

Very fast, especially suitable for printing small parts in full panels Faster, comparable to DLP Slower, speed depends on layer complexity |

||

|

Core Consumables |

Projector lamp (extremely long life) |

LCD screen (limited lifespan, approximately 2000 hours) |

Laser (longer life) |

|

Resolution |

Determined by projector pixels and projection area |

Determined by the pixel density of the LCD screen (4K, 8K) |

Determined by the laser spot size |

|

Key Benefits |

Fast speed, long equipment life, high reliability, extremely cost-effective, and low entry threshold |

Extremely high precision and excellent surface quality |

|

|

Resin Types |

Resins optimized for DLP projector wavelength and light intensity General purpose resins optimized for 405nm LEDs |

Resins optimized for laser wavelengths |

|

|

Core Equipment |

A digital light processor (DLP) chip, which is made up of millions of tiny mirrors. |

||

|

Workflow |

The light emitted by the UV light source shines onto the DLP chip, and the micromirrors on the chip accurately reflect the light of that layer of image to the bottom of the resin tank according to the digital model. |

||

|

Key Advantages |

Whether you are printing one part or a full plate of ten parts, as long as the height is the same, the printing time is exactly the same. This is because it cures by layer, not by point. |

||

In this guide, we'll delve deeper into DLP resins and go beyond simple definitions. After reading this, you'll have a better understanding of DLP resins, enabling you to make the best choice when selecting a product.

What is DLP 3D Printing Technology?

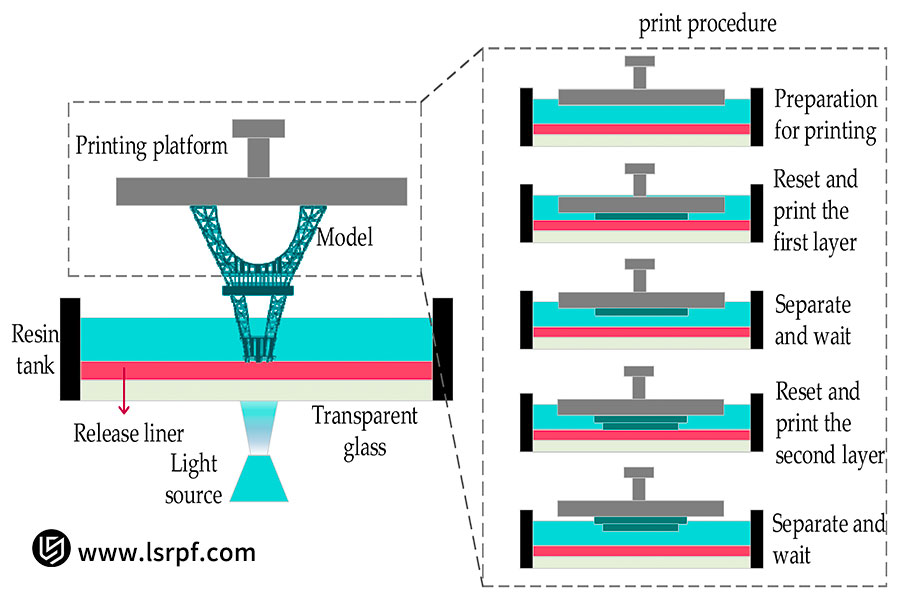

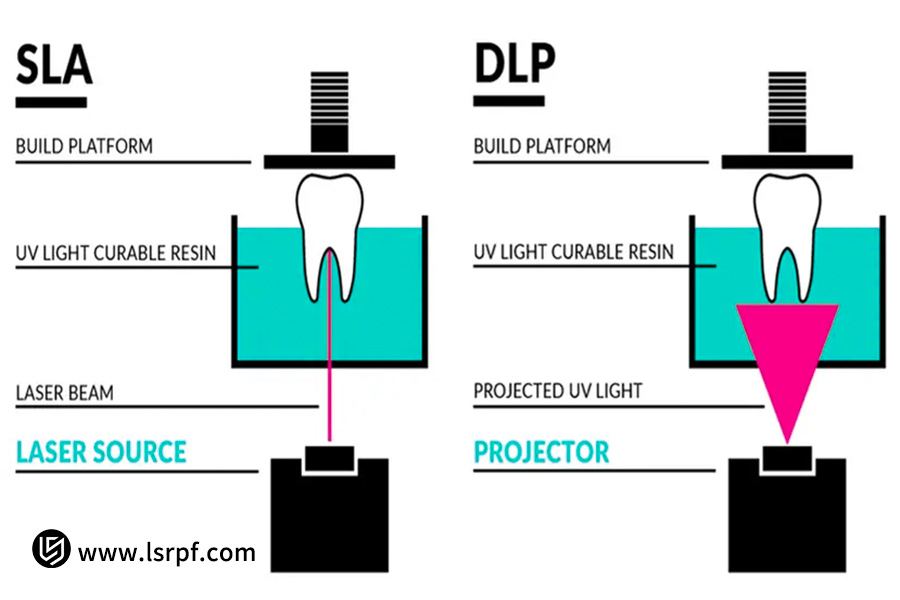

DLP (Digital Light Processing)3D printingis a resin-based additive manufacturing technology that uses a digital light projector to solidify liquid photopolymer resin layer by layer to build three-dimensional objects.

It is a resin 3D printing process that uses a light projector rather than a laser to solidify the liquid resin one layer at a time, resulting in faster printing speeds compared to some other resin printing methods.

DLP printers use a matrix of micromirrors arranged on a semiconductor chip to project light.

What Exactly is “DLP Resin”?

Now let's answer the core question: What exactly is "DLP resin"?

DLP resin is a type of photosensitive resin specifically designed for Digital Light Processing (DLP) 3D printing technology. It cures when exposed to light of a specific wavelength (usually UV light), creating a layer-by-layer curing reaction that forms three-dimensional objects.

So what are its advantages?

Optimization Point 1: Reaction Speed. The light intensity of a DLP projector is typically higher than that of an LCD backlight. Therefore, DLP resin requires a faster curing reaction to match the efficiency of DLP technology and prevent overcuring.

Optimization Point 2: Wavelength Matching. Different DLP printers may use different wavelengths of UV light. Dedicated DLP resins ensure that their photoinitiators are most sensitive to that specific wavelength, resulting in the most efficient and precise curing.

In short, using "DLP resin" ensures optimal performance from your DLP printer.

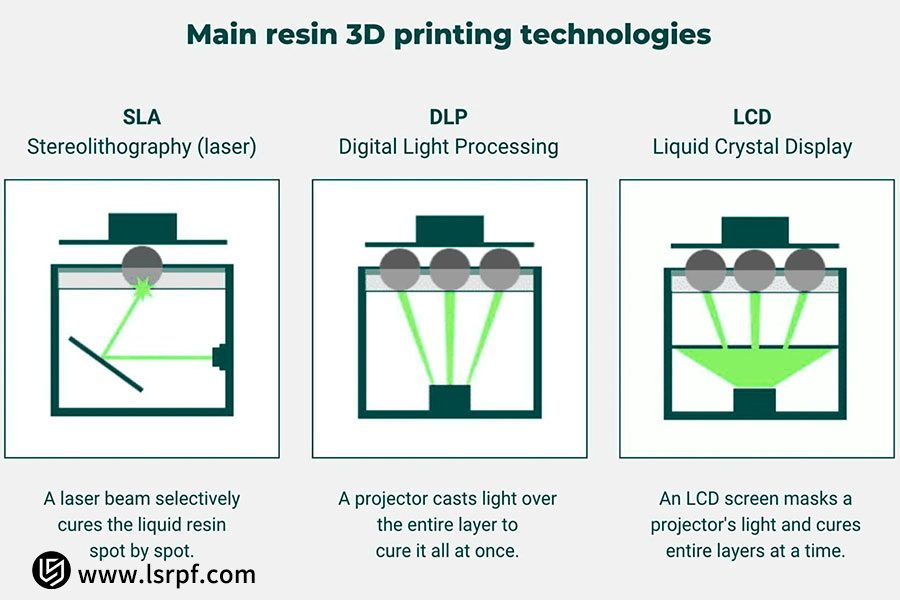

The Grand Showdown: DLP vs. LCD vs. SLA

There are three mainstream technologies exist forstereolithography: DLP, LCD and SLA. These technologies differ significantly from one another. So, what are their respective advantages? This is a key question for all stereolithography users. Below, we'll use a vivid analogy to better understand the characteristics of these three technologies.

DLP (Professional Race Car Driver): Extremely fast and particularly adept at mass production. While the initial investment in equipment is high, the projector is highly durable, resulting in lower long-term operating costs (especially maintenance).

LCD (Family Car): The ultimate value for money. It offers excellent print quality at a relatively low price. However, its core component—the LCD screen—is a consumable (resin printer LCD lifespan) and requires regular replacement, increasing long-term costs and downtime.

SLA(Artist): Pursuing extreme detail and surface smoothness. Like a patient sculptor, it meticulously carves with laser dots, resulting in the slowest production speed but often the most exquisite results.

So what exactly are DLP, LCD, and SLA? The following introduction will provide a deeper understanding and comparison among them. Hope it will help you.

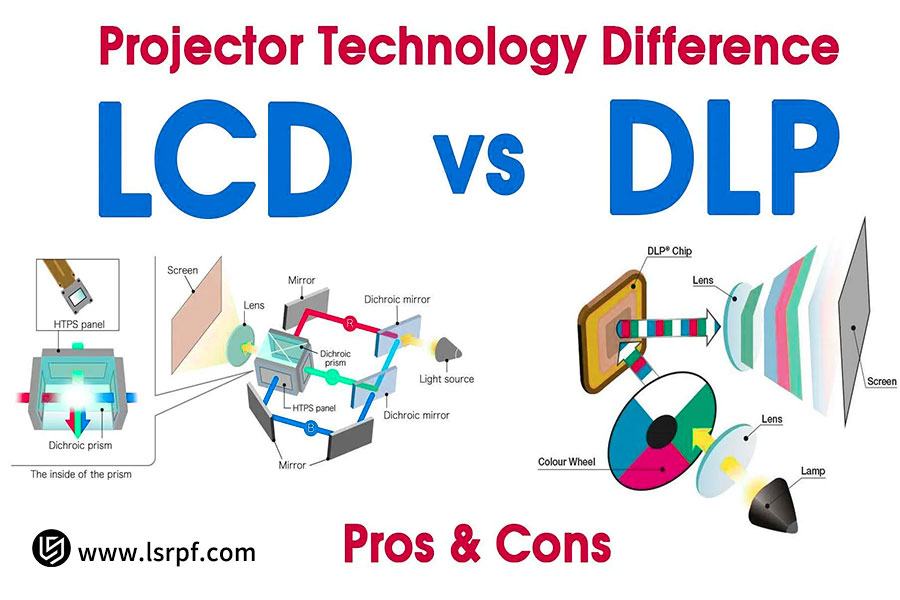

DLP, a digital light processing technology, shares many similarities with LCD. The main difference lies in the forming light source. DLP uses a digital projector to project the light for each layer. DLP digital projectors are technologically advanced and are monopolized by the American company Texas Instruments, resulting in high costs for domestic use. LCD, on the other hand, is used in 3D printers by replacing a standard LCD screen.

LCD technology, short for Selective Area Deposition (SLA), is currently the newest and most widely used photocuring technology. Its forming principle is that a UV lamp emits light, which is then "cut" out by an LCD screen to create each layer's shape. This light is then projected onto a release film, where it cures the entire layer in one go, layer by layer until the product is complete.

DLP, a digital light processing technology, shares many similarities with LCD. The main difference lies in the forming light source. DLP uses a digital projector to project the light for each layer. DLP digital projectors are technologically advanced and are monopolized by the American company Texas Instruments, resulting in high costs for domestic use. LCD, on the other hand, is used in 3D printers by replacing a standard LCD screen.

SLAis the oldest and most mature photocuring technology instereolithography. Thanks to the development of laser technology in the last century, 3D printing researchers were the first to consider using lasers for 3D printing. Different from other technologies, it uses laser generator and galvanometer to complete point light source scanning molding, which is line molding instead of surface molding, and the printing direction is upward, so it can print very large or large quantities of models.

Common Types of DLP Resins and Their Applications

Like other resins, DLP resins offer a vast family of materials suitable for a wide range of engineering needs. Below, we'll introduce common types of DLP resin and their applications in mutipletypes of 3D pritingand other fields.

Standard resins: These are used for visual prototyping and general-purpose models, available in a variety of colors.

Tough/Durable resins: These simulate the properties of engineering plastics like ABS or PC and are used for functional prototypes and snap-fit structures.

Flexible resins: These simulate rubber or TPU and are used for seals, gaskets, or parts that require flexibility.

High-Temperature resins: These can withstand high temperatures and are used for test cores in injection molds or fluid-conducting components.

Medical-Grade resins: These are certified for biocompatibility and are used inmedical applicationssuch as dental and surgical guides.

Why Choose DLP for Professional Manufacturing?

For businesses and professional users, choosing DLP isn't just for precision; it's also for efficiency and reliability.

High-volume production efficiency: DLP's speed advantage is greatly amplified when printing multiple small parts.

Long-term reliability: The lack of an LCD screen to frequently replace means less downtime for maintenance and more stable production output.

Consistent precision: The industrial-grade optical engine ensures consistent quality from the center of the build platform to the edge.

DLP technology is the leading choice for displays large and small. All digital displays are powered by DLP chips. It isaward-winning,long-lasting color accuracy,andindependent of light source. All DLP chips share the same construction as the award-winning DLP Cinema.

Case Study: From Slow Prototyping to Rapid Production

At LS, our professional team combines practical experience and practical application to provide optimal solutions andrapid prototyping. Below is a successful case study of how we used DLP technology to transform slow prototyping into rapid production:

Challenge: Amedical devicecompany needed to produce 50 precise housing prototypes for its new product for internal testing. The housings featured complex snap-fits and intricate textures.

Problem: Using their in-house LCD printer, they could only print two at a time, taking eight hours. After printing the 30th housing, the LCD screen developed a pixel failure, causing subsequent prints to fail and delaying the project.

LS Solution: The company uploaded their design files to our online 3D printing service platform. We immediately recommended DLP technology. Using our industrial-grade DLP printer, we filled the entire print bed with 12 housings, completing a batch in just six hours.

Result: The customer received all 50 flawless, consistent prototypes within two days, enabling smooth testing. Impressed by DLP's speed and reliability, they have chosen us as their preferred custom 3D printing partner.

Frequently Asked Questions (FAQ) about DLP Resin

1. Can DLP resins and LCD/SLAresins be mixed?

Not recommended. While they may cure, the results will be far from optimal. Using the wrong resin can result in incomplete curing, loss of detail, or overcuring, ultimately leading to print failure. While DLP and LCD/SLA photosensitive resins share similar primary components, and most modern printers utilize 405nm UV curing, mixing them is generally not recommended. This is for several reasons: First, resins from different brands may have different formulations, which can lead to uneven curing, decreased interlayer adhesion, and even resin denaturation. Second, some industrial-grade DLP printers use specialized wavelengths, such as 365nm, and incorrectly mixing 405nm resins can result in curing failure. However, if two resins are clearly labeled as compatible with the same wavelength (e.g., both are 405nm) and come from a trusted manufacturer, a cautious, small-scale mixing test may be acceptable—but beginners should still prioritize a single resin to ensureprint quality and machine stability. To be on the safe side, it's recommended to always adhere to the printer manufacturer's recommended resin type.

2. Does the pixelation of a DLP printer affect print quality?

Yes. However, it's important to note that the projection characteristics of DLP may cause slight "voxelization" (pixel gridding) at the edges. However, modern DLP printers can significantly smooth these artifacts through advanced anti-aliasing algorithms.

3. Which is better for beginners, DLP or LCD?

If you have a limited budget and want to quickly experience resin printing, LCD is an excellent starting point. If you're looking for long-term, stable production, faster speeds, and don't want to frequently replace consumables, DLP is a wiser investment. For beginners, LCD-based light-curing3D printers(such as those using MSLA technology) are generally a more user-friendly and practical choice. These printers are affordable, easy to use, and low-maintenance. While their LCD screens may need replacing after a year or two, they offer excellent value for money, making them a suitable entry point. They deliver exceptional print detail, and a wide selection of models are available, such as the Anycubic Photon Mono 4K or Elegoo Mars 3, both highly recommended entry-level options. In contrast, DLP printers, while offering slightly higher precision and longer light source life thanks to optical projection technology, are more expensive, complex, and require high calibration requirements. They are better suited for professional users seeking extreme detail or for mass production of small, precision parts. For those seeking an easy start and a limited budget, LCDs are a solid starting point. For those pursuing industrial-grade precision and willing to invest, DLPs offer a more advanced option.

What are the main advantages of DLP technology?

Speed and reliability. The high speed of curing an entire layer in one go, combined with the exceptionally long life of industrial-grade projectors, are DLP's core competitive advantages in the professional field.DLP3D printingtechnology demonstrates exceptional engineering-grade performance, embodying the "speed and fury" of digital manufacturing.

DLP's speed advantagelies in its revolutionary surface projection technology, which solidifies an entire cross-section instantly, like clicking a camera shutter. In dental applications, printing a full panel of 28 crowns took just 11 minutes, 3.5 times faster than traditional LCD technology. This speed remains constant even when printing clusters of finely textured jewelry. Even more impressively, the new generation of DLP equipment incorporates an intelligent light intensity regulation system, which reduces the exposure time per layer to 0.8 seconds while maintaining high accuracy. This allows the printing of a standard-sized hearing aid housing in just 6 minutes.

DLP's key strength lies in its reliability. Its core optical engine utilizes an aerospace-grade sealed design, and after 12 months of continuous operation in the harsh environment of an automotive manufacturing plant, its accuracy drift remained less than 25 microns. A unique dynamic optical calibration system compensates for focus shifts caused by temperature fluctuations in real time, ensuring 99.7% dimensional consistency for each batch of 2,000 electronic connectors. Tested data shows that the DLP system's mean time between failures exceeds 8,000 hours, more than four times that of industrial-grade LCD equipment.

This perfect combination of speed and reliability makes DLP the preferred choice for mass production environments. After adopting a DLP production line, an aviation parts supplier reduced its turbine bladeprototype productioncycle from 72 hours to 18 hours, while also reducing scrap rates from 5% to 0.3%. This exceptional combination of speed and stability is reshaping the production efficiency standards of modern manufacturing.

Call to Action (CTA):Stop worrying about choosing3D printing technology. Let the experts guide you. Upload your design files to our secure online platform. We'll analyze your design, recommend the best 3D printing solution, and provide you with an instant 3D printing price! Let our expertise accelerate your innovation.

Summary

DLP resin isn't magic; it's the fuel tailored for efficient, reliable, and professional-grade 3D printing. Working in conjunction with DLP projectors, it empowers engineers and designers to rapidly produce high-precision parts. When your project transcends mere hobbies and demands speed, reliability, and mass production, DLP technology and its specialized resin are the perfect choice.

In the face of these higher challenges, LS'sCNC turning serviceis your indispensable ultimate "tool". It represents industrial-grade precision, unparalleled repeatability and efficient productivity, allowing your design ideas to be perfectly, consistently and efficiently realized.Choosing LSis to inject industrial-grade precision power into your extraordinary craftsmanship.

Upload your design drawings now and get an instantCNC turning quote(cnc turning price), let LS be your strong backing in pursuit of ultimate woodworking precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only.LS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

LS Team

LS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseLS technologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com