In manufacturing and engineering, the question "Is cast iron better than steel?" is a very old and common question. The reply, however, is more an art of trade-offs rather than a "yes" or "no"; it's more of a complex situation. Cast iron and steel are both iron-carbon alloys with dissimilar performance profiles based on enormous differences in their chemical composition, production processes, and microstructure.

The key to choosing between cast iron and steel is not the overall superiority of the materials themselves, but rather correctly pairing your specific application, relative importance of performance, and budget. This article will provide a clear explanation of the fundamental characteristics of cast iron and steel, comparing their advantages and disadvantages.

Drawing from the immense experience and expertise of LS Manufacturing in material processing, the article will provide brief material selection guidelines that will help you make the most economical and reliable technical choices for each important component. To save you time, here’s a quick overview of the core conclusions.

Cast Iron vs. Steel Core Properties Quick Reference Table

| Feature Dimension | Cast Iron | Steel |

| Carbon Content | High (more than 2%) | Low (0.02% - 2%) |

| Manufacturing Process | Casting | Casting, forging, rolling |

| Main Advantages | Good wear resistance, good vibration damping, good casting fluidity, low cost | High strength, good toughness (impact resistance), good plasticity and weldability |

| Key Disadvantages | Brittleness, poor tensile strength, nearly impossible to forge or weld | Poor vibration damping, relatively high production cost |

| Typical Applications | Engine blocks, machine tool bases, brake discs, pipes | Constructional buildings, automotive frames, tools, cutting tools, mechanical shafts |

- Cast iron is a virtuoso in withstanding pressure and friction. Its inherent damping to vibration and affordability render it unbeatable in static structures that require stability and wear resistance.

- Steel is superior to resisting dynamic loads and impact. It cannot be beaten for strength and toughness, and that's why it's the material of choice for high-load, safety-critical applications.

The decision to use cast iron or steel is actually one of matching the product's operating conditions: do you desire vibration damping and cost as the highest priorities, or do you desire strength and toughness as highest priorities?

Why Trust This Guide? Practical Experience From LS Manufacturing Experts

The conclusions drawn here aren't book-based; they're the product of LS Manufacturing's shop experience on a daily basis in the sheet metal fabrication department. We do really know that the theoretical basis for material choice must be closely coupled with manufacturability.

For example, when we design a high-end server cabinet, we not just recommend mild steel of appropriate strength to ensure structural integrity, but we also use our Design for Manufacturability (DFM) expertise to best predict bend radii, weld locations, and tolerances on the drawings in advance to prevent potential deformation and stress concentration issues during manufacturing.

LS Manufacturing recently helped a customer effectively consolidate their equipment housing, which consisted of several dozens of parts that were welded together, into one single unit that was produced through precision stamping and laser welding. This innovative, beneficial sheet metal process enhancement added not only 30% product yield but also reduced overall costs through reducing assembly steps.

This is precisely the value that LS Manufacturing can provide you with: We take our broad experience in material properties and make it valuable, effective, and cost-competitive solutions to sheet metal fabrication.

Why Can't Material Selection Be Answered With A Simple "Which Is Better?"

In engineering, "Is cast iron or steel better?" is a classic fallacy. It is never black and white because the inherent differences between the two necessitate that they are designed to address different problems. The trap is knowing their inbuilt characteristics and to precisely match them to the particular working conditions.

1. Microstructure Determines Macroscopic Performance:

From the materials science perspective, the main difference between cast iron and steel lies in the carbon structure. In cast iron, the carbon is present mainly in free graphite structures (flakes or globules) that give it good vibration damping and abrasion properties but render it brittle.

On the other hand, the carbon in steel is primarily present as a solid solution structure with iron, such as pearlite, which is extremely strong, tough, and weldable. This radical structure difference alone results in the split of their uses right at the start.

2. Performance Trade-offs and the "Applicability Principle":

There is no such thing as a "one-size-fits-all" material. For example, in machine tool bases for heavy-duty use, where the absorption of vibration is necessary in order to ensure machining precision, the most suitable solution is cast iron with its multiple times higher shock-absorbing ability compared to steel.

However, for crane hooks subject to dynamic impact, steel's highest toughness is the unbeatable safety option. The wrong choice of material can prove disastrous. LS Manufacturing had once had a transmission part, intended to be used in conjunction with high-toughness steel, mistakenly fitted to regular cast iron. The component later fractured since it could not support the expected load, resulting in a costly shutdown of the entire production line.

A simple comparison table of performance is only a starting point. An informed decision requires the careful examination of the conditions of stress, operational conditions, production cost, and life requirements of the component.

When Is Cast Iron A Better Choice?

When the center requirements of your work require stability, vibration dampening, and the economics of complex molding, cast iron is often a wiser choice than steel. Its one-of-a-kind performance advantages are graphically reflected in the following examples, profoundly influencing the design decision between cast iron and steel.

1. Excellent Vibration Damping and Dimensional Stability:

Cast iron's natural graphite structure permits it to be a good vibration absorber of mechanical vibrations, and has a damping capability 5-10 times higher than steel. Precision machinery requires this. The guideways and bases of high-performance machine tools, for example, must be made of gray cast iron. It readily damps its internal and external vibrations so machining accuracy is not affected—a capability which no steel construction can surpass.

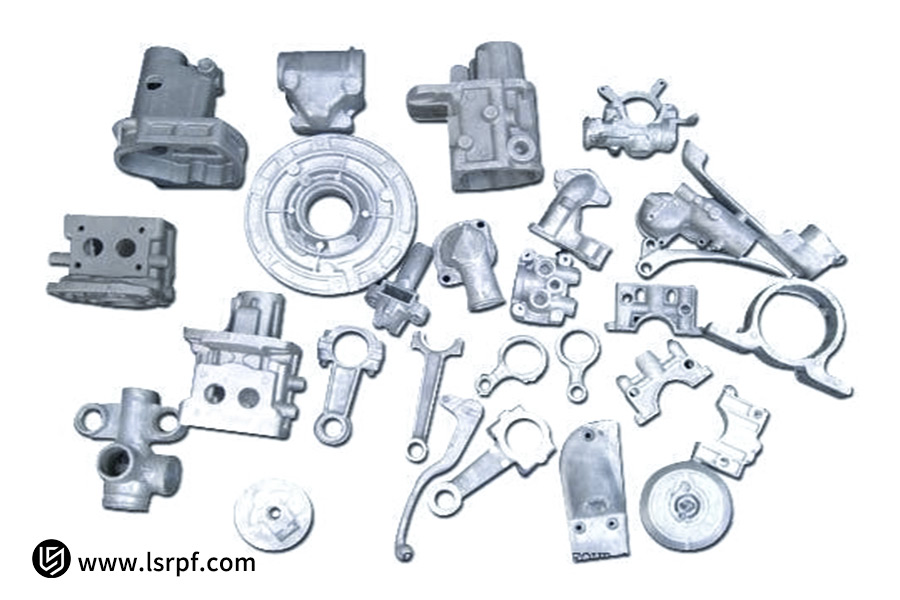

2. Excellent Complex Part Forming Capability and Cost-Effectiveness:

Cast iron's desirable melting point and good fluidity mean that it is easy to cast thin-walled parts with complex geometries and fine-grained cavities. In the case of complex structural parts such as engine blocks and hydraulic valve blocks, one-piece casting is far less expensive than machining or welding steel in pieces together. This maximizes the cost structure of cast iron and steel directly and, perhaps more importantly, with dramatic effect in high-volume production.

3. Inherent Wear Resistance and Self-Lubricating Properties:

Cast iron's graphite is a lubricant. When worn out, the graphite leaves a lubrication film on the surfaces of friction, which results in excellent wear resistance in oilless or low-oil conditions (e.g., piston rings and cylinder liners in engines). In parallel, cast iron, like steel, also has comparable compressive strength to steel, so it can support heavy static loads.

4. Performance Breakthroughs in Ductile Iron:

With the advent of ductile iron, the range of applications for cast iron has widened significantly. By spheroidizing the graphite, it achieves steel comparable strength and toughness while retaining the inbuilt vibration damping and casting advantages of cast iron.

Hence, it is widely used in higher tensile strength and fatigue-critical applications, such as heavy-duty truck axle housings and wind turbine hubs and bases, offering a perfect compromise between steel and cast iron in the performance and cost-effectiveness aspects.

If you're struggling to choose between steel and cast iron, contact LS Manufacturing for a free, custom professional analysis.

When Should Steel Be Prioritized?

Whenever design requires dynamic loads, high strength-to-weight ratio, and structural performance, steel demonstrates its invaluable value. Compared to cast iron, steel possesses decisive strengths in toughness, joinability, and better performance, and thus is the optimum material best for modern dynamic engineering structures. Following is a brief comparison of their mechanical properties:

| Performance Index | Cast Iron (Ductile Iron as an example) | Steel (Medium Carbon Steel as an example) |

| Tensile Strength | 400-600 MPa | 500-800 MPa (which can be increased with heat treatment) |

| Elongation | 10-15% | 15-25% (much higher toughness) |

| Impact Toughness | 15-30 J | 40-100+ J |

| Weldability | Poor, special processing only | Excellent |

| Heat Treatment Potential | Limited | Extensive (quenching, tempering, etc.) |

1. Excellent Combination of Strength and Toughness:

When comparing the cast iron and steel tensile strength and toughness, steel is ahead hands-down. Steel has a homogeneous crystal structure that is capable of absorbing severe impact, bending, and tensile loads without exception to brittle fracture. For safety-critical dynamic components such as crane hooks and heavy equipment drive shafts, steel is the safety first choice.

2. Unparalleled Weldability and Formability:

Between the weldability of steel and cast iron, the former is better. Steel may be welded with ease to form intricate large structures such as building frames and pressure vessels. Cast iron may only be welded through specialized processes and is susceptible to cracking, significantly limiting its applications in operations involving joining and alteration.

3. Extensive Heat Treatment and Performance Improvement:

Through heat treatment (e.g., tempering and quenching), steel can significantly increase its surface hardness, core toughness, or fatigue strength. Through the utilization of alloy steels (e.g., chromium-molybdenum steel), we can also "tune" its mechanical properties in a way that we can make highly wear-resistant molds or high-toughness critical components. Such tunability is not possible with cast iron.

When your application is under dynamic loads, impact hazards, requires highly complicated welded structures, or requires performance improvement through heat treatment, steel, due to its higher strength ratio to cast iron, high toughness, and unlimited scope for alloy steel application, is the automatic choice.

What Is The Truth About Material Brittleness?

The answer to the question, "Is cast iron more brittle than steel?" is more than a mere "yes." The definition of brittleness is the ability of a material to resist crack growth, and that is directly dependent on its microstructure.

1. Micromechanisms of Brittleness:

Gray cast iron brittleness is largely due to the flake graphite within it. The graphite flakes are akin to natural tips of microcrack in the material. They lead to severe stress concentrations under load and encourage propagation of cracks and catastrophic fracture. Steel's homogeneous microstructure does not contain such natural sites for defects to initiate from, and it dissipates energy by plastic deformation, which makes the material tougher.

2. Breakthrough in Toughness of Ductile Iron:

It is worthy to mention that not all cast irons are so brittle. The ductile iron, by transforming flake graphite into spherical shapes, highly reduces the effect of stress concentration. Its elongation can be increased from less than 1% for the case of gray cast iron to over 18%, and its impact strength is highly improved. Even in some applications, it can substitute forged steel, completely demonstrating the ability to control macroscopic properties by altering microstructures.

3. Operating Conditions Determine Brittleness:

Toughness of materials is not a fixed property; it is predominantly dependent on operating conditions. The major role is played by temperature: the majority of steels become brittle with a very sudden reduction in their impact strength at low temperatures, transforming from the ductile to the brittle state.

Therefore, in cold environments, structures need to incorporate good low-temperature toughness steels. For constantly pressed machine tool pedestals, the "brittleness" of cast iron under compressive loading is not a shortcoming but a virtue because of its high stiffness and damping of vibrations. Brittleness is a joint function of a combination of material type (i.e., ductile iron vs. gray cast iron), microstructure, and specific operating conditions.

Intelligent selection should be based upon an overall assessment of the component load type (impact or steady-state), operating temperature, and failure consequences, rather than a subjective qualitative term.

Machinability Comparison: Which Is More Suitable For Your Production Process?

In choosing between steel and cast iron machining, the material's machinability has a direct bearing on production efficiency, cost, and finished quality. As a practical-minded firm with extensive hands-on experience, LS Manufacturing will contrast the machining characteristics of these two materials from a production perspective to help you optimize your manufacturing process.

1. Advantages and Challenges of Cast Iron Machining:

Cast iron (especially gray cast iron) has very good machinability due to its graphite composition. Graphite also serves as a chip breaker and lubricant, which reduces cutting forces and enables the delivery of a smooth surface finish. In our example, higher cutting speeds and relatively long tool life are possible when turning cast iron parts like engine blocks. Surface hardening layers or pinholes in cast iron parts, meanwhile, induce erratic tool wear during cutting operations, calling for tight incoming material inspection and uniform cutting parameter control.

2. Precision and Control in Steel Machining:

Steel machining is a craft of the skilled hand. Its immobile chips encircle the tool and produce unwanted heat, which conflicts with accuracy. We succeed at this test in LS Manufacturing with certain tool geometries, precise coolant pressure, and intelligent cutting parameters. For example, when machining drive shafts of alloy steel, we employ staged cutting and high-pressure cooling to precisely regulate thermal deformation and preserve critical dimension tolerances and positional location precision.

3. Key Points for Process Optimization:

Effective production processes are based on targeted strategies. Diamond-coated tools are the secret to maximum tool life for cast iron, and for steel, it's chip control and cooling. Our engineers conduct cut tests in trials to determine the highest feed rate and speed for each operation and find an optimum between efficiency and quality. This cutting-edge approach enables us to provide our customers with cost-effective and long-lasting machining solutions.

With LS Manufacturing, we apply our extensive process database and broad field experience to ensure that any material can realize its highest value in your manufacturing process.

Cost Considerations: Beyond Material Price?

In making the determination that cast iron would be more expensive than steel, material unit price comparison is an unjustified determination. Best cost actually means a completely full-cost cost of producing cost accounting model that has fully considered the economics of the entire process from raw material to finished good.

1. Hidden Costs of Material Utilization:

The near-net-shape character of cast iron will lead to very high utilization of material and very low scrap in producing complex parts. Casting the same part from a steel billet and machining it will require massive material removal, resulting in massive scrap loss. Therefore, in a comparison of the cost of cast iron versus the cost of steel, one should employ net material cost rather than unit cost comparison.

2. Machinability Determines Manufacturing Costs:

Material machinability directly affects cost of manufacture. Cast iron is generally more machinable with less tool wear, whereas high-strength steel means lower cutting speeds, longer tool life, and higher energy usage. With one of our gearbox housing configurations, although the unit price of ductile iron was a bit higher, its superior machinability reduced total manufacturing costs 15% compared to a low-alloy steel alternative.

3. Lifecycle Costs and Quality Losses:

An effective cost analysis needs to include quality risks and life of service. The inherent casting characteristics of cast iron prevent potential weld fatigue failure in steel weldments and reduce the quality risks. Value engineering analysis reveals that for foundation components like machine tool beds, the better vibration damping characteristics of cast iron can improve machining precision and reduce product defects. These long-term benefits by far outweigh the difference in initial cost of material.

By systematically examining material usage, machine time, and loss of quality as full-process manufacturing cost drivers, and applying value engineering to enhance performance and cost, the most cost-efficient answer can be arrived at. This is the key to creating core value for LS Manufacturing.

Case Study: How LS Manufacturing Optimizes Material Selection For An Industrial Compressor Customer

One of the better-known manufacturers of industrial compressors was confronted with a massive dilemma: While its high-end product's all-steel frame provided reliable performance, its expensive cost of production would make it less saleable. Substituting it with ubiquitous cast iron, however, could result in insufficient strength at such vital points, which would compromise the equipment's durability. This is a classic example of the material optimization problems.

1. Customer Dilemma:

The first customer design was a main frame of welded low-alloy steel. While it met the strength requirements, it had three significant disadvantages: high material and cutting costs; welding distortion requiring lengthy finishing processes; and overall weight influenced the equipment's energy efficiency. The most critical thing to achieve with this project in breaking through was to achieve cost reduction without sacrificing core mechanical properties.

2. LS Manufacturing Solution:

The LS Manufacturing team, through systematic material optimization analysis, proposed the revolutionary solution:

- Finite element simulation determined stress distribution: Through precise simulation, 85% of the compressor casing was actually subject to vibration and pressure loads, while just 15% of the joints absorbed the majority of dynamic stresses.

- Ductile iron + partial steel sleeve composite structure: Most is cast in one pass in ductile iron, with prefabricated alloy steel sleeves only placed at key bearing seats and junctions to offer local reinforcement.

- Process Innovation Verification: A distinctive fixture is employed to ensure precision in casting, and a novel process of casting-inlaying was devised in order to obtain a perfect interface between the two materials.

3. Results and Value:

This trailblazing LS Manufacturing case produced outstanding results:

- 35% cost reduction, primarily through reduced material expenses, removal of weld processes, and improved processing efficiency;

- 22% weight reduction, improving the energy rating efficiency of the equipment;

- 40% reduction in vibration and noise, resulting in improved product quality.

The solution reliability was assured through 200,000 cycle pressure testing. This illustration demonstrates that excellent material selection is not always the choosing of two options; it is a thorough engineering analysis to get the right compromise between cost and performance. LS Manufacturing employs this rigorously disciplined problem-solving capability to continually create value above customer expectations.

FAQs

1. Can heat treatment improve the performance of cast iron parts?

Yes, but all of this can be accomplished within some scopes and limitations. Annealing effectively eliminates internal stresses of casting and prevents post-processing deformation of cast iron; normalizing uniformizes the matrix structure and optimizes overall mechanical properties. Quenching and tempering (tempering) significantly enhance the strength and hardness of ductile iron. But because cast iron is rich in carbon and silicon, its heat treatment window is narrower than steel. Heating and cooling rates must be finely regulated to avoid cracking or abnormal graphite diffusion, which again adds further to brittleness.

2. Which material is easier to repair with welding?

Steel is obviously preferable to weld repair. Its homogeneous structure and beneficial ductility enable it to be welded by standard welding material and practice and give uniformly good joint performance. Cast iron, on the other hand, is very low in weldability due to its high carbon content and low ductility. Severe thermal cycling through welding readily leads to the formation of a hard and brittle white cast iron microstructure in the heat-affected zone, which causes cracking.

3. Which material is more reliable for heavy-duty applications?

This will depend entirely on the character of the load. For hard-to-load, heavy-duty dynamic service subject to a high level of impact, fatigue, or complex alternating stresses (such as excavator booms and gear shafts), steel with good toughness and fatigue strength is more desirable. For fixed heavy-duty use with high static pressure, where stiffness and damping of vibrations matter most, such as large press frames and machine bed tools, cast iron is more reliable due to its improved compressive strength, damping ability, and stability.

4. Which is more cost-effective for small-batch production?

On small-series production conditions, steel is more cost flexible. Standard materials (e.g., plates and profiles) are readily available, and the steel can be easily formed by cutting, machining, and welding without any expensive tooling. Iron castings require special molds and wooden pattern pieces equaling high initial investment and long production time, thereby being usable only for large-series production to cover cost.

Summary

There is no one best option in the choice between steel and cast iron; what is needed is the solution that best fits your specific needs. Successful material selection is an in-depth analysis of five basic dimensions: mechanical performance, production process, cost profile, quality expectation, and supply chain stability.

LS Manufacturing, with its deep material science knowledge and technical experience, offers experienced material selection consulting. With systematic engineering analysis and years of direct experience, we help you secure the optimal balance between material cost and performance, realizing the highest product value.

For expert material selection advice especially for your project, contact our technical team today. Let us utilize our experience and expertise in selecting the best material solution for your product. Contact LS Manufacturing and upload your design drawings now and get an instant sheet metal fabrication quote ( sheet metal fabrication price), let LS Manufacturing be your strong backing in pursuit of ultimate sheet metal fabrication precision!

📞Tel: +86 185 6675 9667

📧Email: info@longshengmfg.com

🌐Website:https://lsrpf.com/

Disclaimer

The contents of this page are for informational purposes only. LS Manufacturing services There are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the LS Manufacturing network. It's the buyer's responsibility. Require parts quotation Identify specific requirements for these sections.Please contact us for more information.

LS Manufacturing Team

LS Manufacturing is an industry-leading company. Focus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precision CNC machining, Sheet metal manufacturing, 3D printing, Injection molding. Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. choose LS Manufacturing. This means selection efficiency, quality and professionalism.

To learn more, visit our website:www.lsrpf.com.